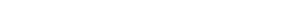

The GTX8 is an all-new 1/8 luxury nitro GT car based on the XRAY’s European Championship-winning XB8 off-road car. Sharing many high-performance parts the GTX8 incorporates all the finest details to achieve a state of perfection.

Concept.

The GTX8 is typically XRAY–premium, professional, high competition R/C car for the most demanding racers, developed with attention to the smallest details and backed by premium service & support…a luxury masterpiece.

Philosophy.

With XRAY's uncompromising design philosophy bringing everything together to make the best GT nitro car, the GTX8 has the unique XRAY character, born of precision craftsmanship, highest attention to detail, and using only the finest quality materials.

Heritage.

“I designed and hand-made my first off-road cars back in 1986, and they were dominating the races thanks to unbeatable reliability and best performance. Years later in 2004 we have started our first mass production XRAY XB8 platform based on our long-term experiences, knowledge, and R&D expertise gained over decades, taking over the heritage I brought with me.

Using the XB8 platform we have worked with the XRAY R&D team to create the finest and highest performing GT nitro car and I am happy that we continue to carry the legacy of my first off-road cars into this new platform in order to take you to the Winners Circle.”

Dipl. Eng. Juraj Hudy

XRAY Chief Designer

Design.

Designed in virtual reality using the world's most sophisticated CAD tools, and manufactured using the world's best machining and molding technology, the GTX8 has attained a level of perfection that is second to none. All parts are purpose-designed and manufactured by XRAY, so all parts fit and work perfectly together.

Commitment.

My commitment to perfection carries over into the GTX8 platform, as it has with all other XRAY platforms I am responsible for.

Owning an XRAY, you can be sure that we remain committed to our goal to improve our products by continuous development and testing to ensure that you always get the best-performing GTX8 straight out of the box.

Martin Hudy

XRAY GTX8 Designer

Experience.

Before I started racing off-road cars, I was actively professionally racing 1/5 scale on-road cars and I won 2x a European Championship. In my position as R&D Designer at XRAY, I was very happy to be involved again with an on-road project where I could bring my prior experience to the table.

I have thoroughly enjoyed my involvement in this new GT project, and I strongly believe this class will rapidly gain popularity due to its simplicity, easy handling, and great fun. I will continue to support the ongoing development of this new platform, and will be available to support all XRAY customers.

Martin Bayer

XRAY GTX8 Designer

The GTX8 project follows a typical development progress at XRAY: 3D models were first printed & tested, and after successful test results the production moulds were machined. To ensure perfect fitment of all parts, all pieces are individually tested during the development phase and then are tested on track to ensure maximum reliability and performance.

Made in Europe.

Designed, developed, and fully manufactured in-house at the XRAY factory in Slovakia, Europe, using the most high-tech German & Swiss machines and premium European materials, crafted with XRAY's legendary attention to detail by our artistic production specialists. The GTX8 is truly a masterpiece.

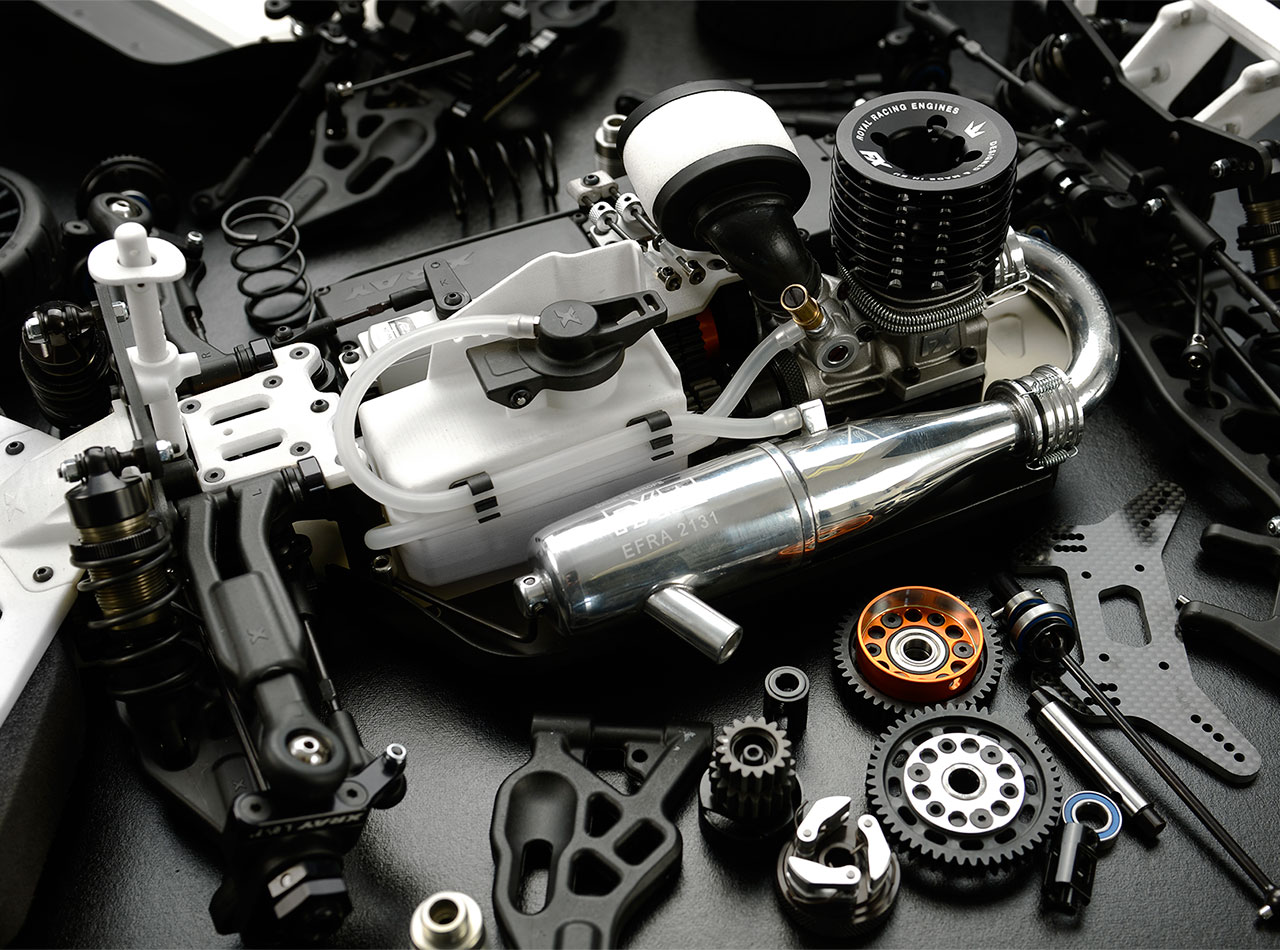

Chassis.

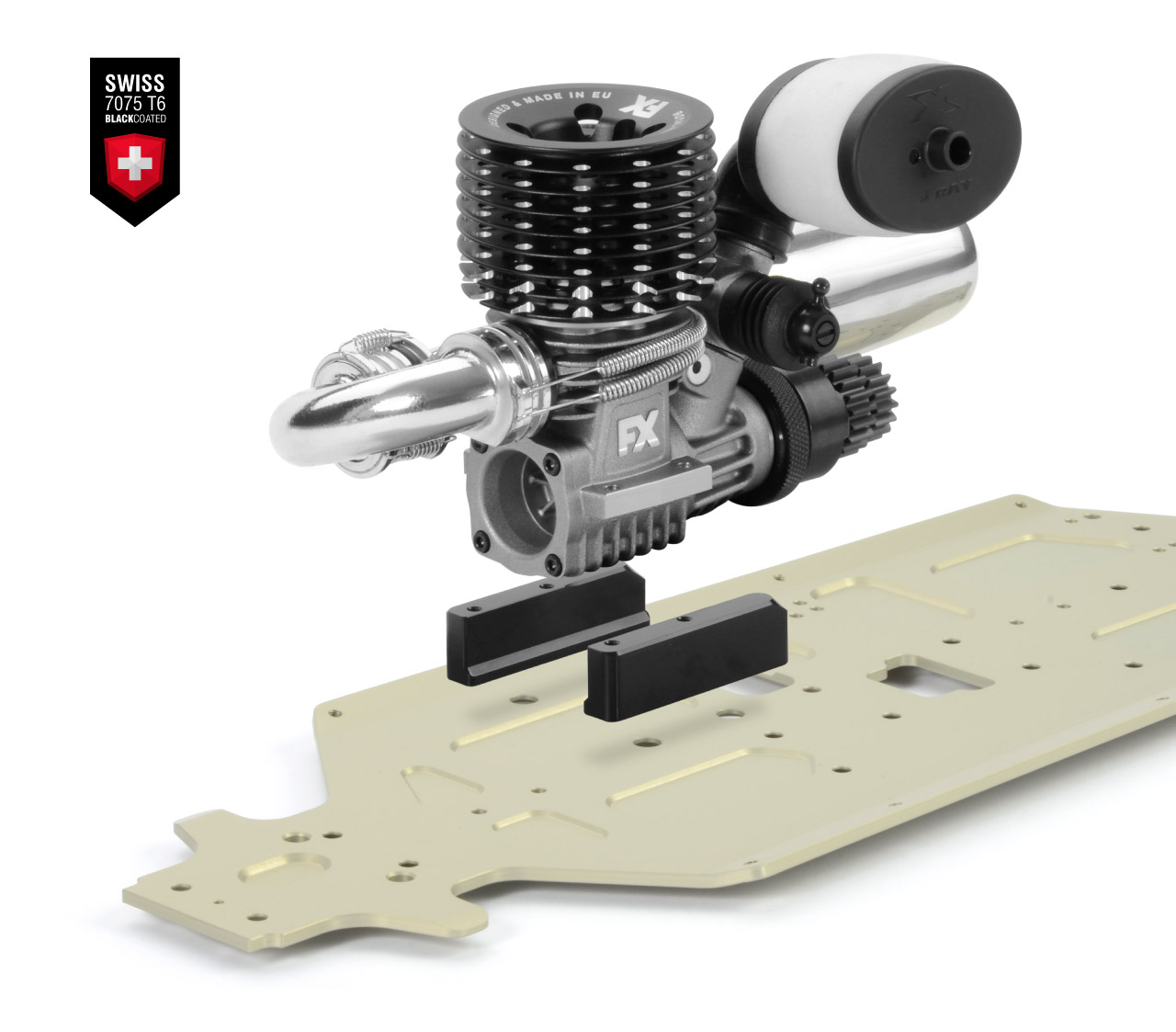

The chassis is CNC-machined from 3mm high-quality Swiss 7075 T6 aluminum, strategically machined in low-stress areas, and then anodized to make it as light as possible without affecting strength or rigidity.

Non-essential material below the engine, fuel tank, and differential was removed to allow for the lowest possible center of gravity and appropriate chassis flex.

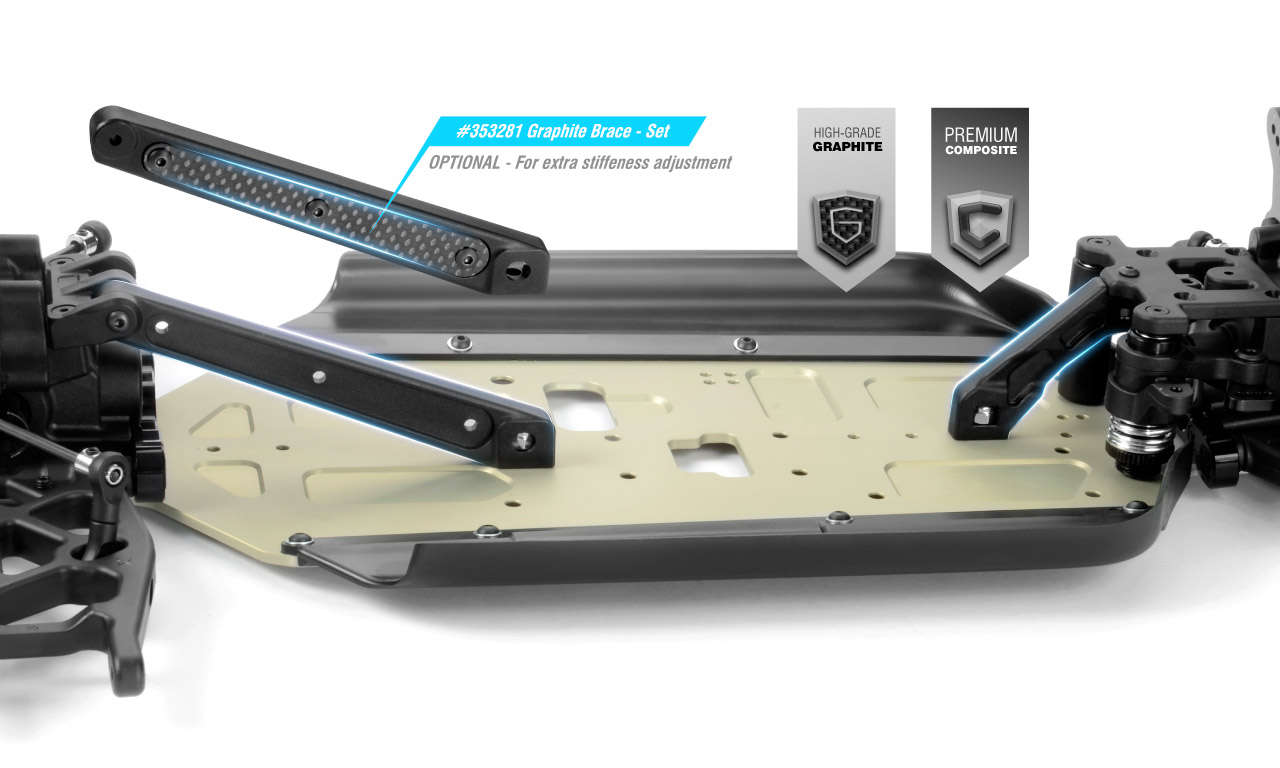

Chassis Braces.

Front and rear chassis braces have significant influence on chassis stiffness and flex, and as such have a great impact on handling under different grip conditions.

The longer rear brace is moulded from a medium-stiff composite mixture for proper flex & rigidity, and allows the mounting of optional graphite inserts to reinforce the brace to make it even stiffer (suitable for high-traction conditions).

Weight Balance Adjustment.

Weight balance on the GTX8 is easy to adjust for different track conditions. Weight can be moved to the front, middle, or rear by moving the suspension arms as required to get the best handling.

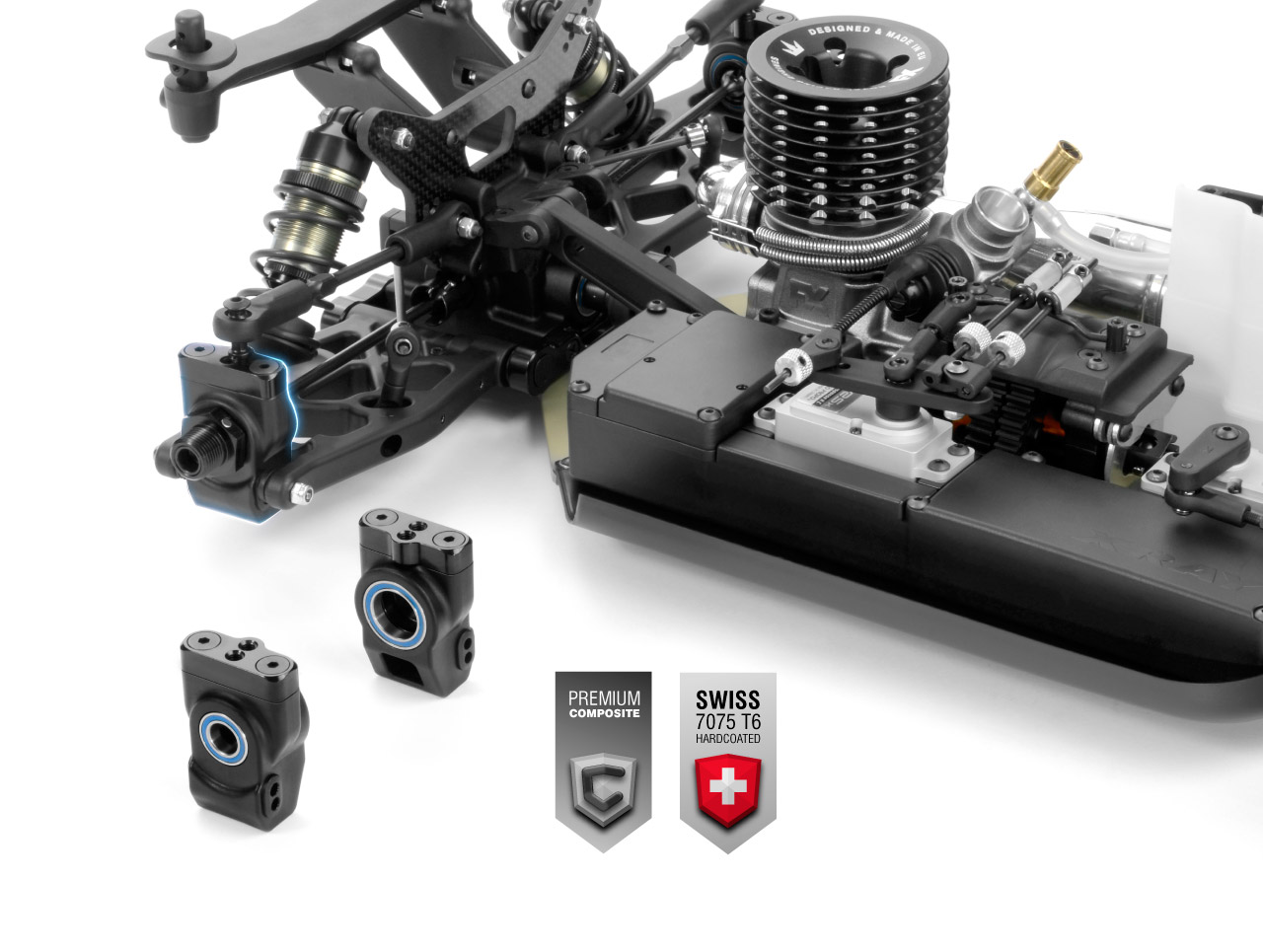

Bulkheads.

Diff bulkheads are an important chassis component, housing both the front and rear differentials and providing mounting points for the suspension mounts and shock towers.

The diff bulkheads have been designed for extreme durability, while providing easy access for tuning and maintenance.

Pivot Ball Suspension.

XRAY Pivot Ball Suspension XPBS™ is a uniquely innovative concept, and smart R&D design. The ultra-robust pivot ball suspension has integrated suspension geometry adjustment, with different kingpin plates being optionally available.

The complete integrated suspension geometry adjustment includes:

• Toe

• Wheelbase

• Anti-Squat

• Anti-Dive

• Caster

• Camber

• Track Width

• Bump Steer

• Upper Roll Center

• Lower Roll Center

• Kingpin angle

Suspension.

Correct suspension geometry is one of the most important features of any RC model car, while at the same time being one of the most difficult & challenging features to design properly.

Suspension is always a mixture of:

• Design & shape of individual suspension parts

• Flex & hardness

• Materials

• Mounting system

• Geometry & position of mounting points of connecting parts

From the suspension arms, through the suspension blocks, to the robust steering blocks, every suspension part has been carefully designed for the 1/8 racing platform to provide responsive racing characteristics in all conditions.

I.S.S.™ Suspension Holders.

The aluminum suspension holders feature Integrated Suspension Settings™ (I.S.S.) which allow for quick & easy suspension geometry setting.

Using eccentric suspension bushings inserted into aluminum suspension holders – as well as additional suspension shims – the GTX8 suspension geometry can be completely adjusted in mere seconds.

Suspension Arms.

GTX8 suspension arms are the result of long-term testing of different designs and layouts. Length, thickness, flexibility, geometry, and materials used… these are all part of the concepts and details that are thoroughly reviewed to create optimum suspension arms.

The suspension arm itself is rigid enough to provide a responsive feel, yet soft enough for extreme durability. The exclusive composite mixtures used for suspension arms are a perfect balance between reliability and performance.

Steering Blocks.

XPBS™ steering blocks are unique, innovative, smart... an authentic XRAY innovation.

The steering blocks feature the following integrated geometry adjustments:

• camber

• caster

• bump steer

• track-width

• kingpin angle

The steering block consists of a super-lightweight composite steering block and stiff Swiss 7075 T6 kingpin plate. The steering block is mounted via massive pivot balls into the upper & lower arms.

The upper pivot ball is mounted into an adjustable upper ball joint and via roll center shims to the kingpin plate; this assembly allows camber and upper roll center adjustment. Using shims of various thicknesses, the upper roll center can be adjusted quickly & easily.

The lower pivot ball is mounted into the steering block via an adjustable alu nut and composite bushing. By adjusting the pivot ball, both track-width and camber can be adjusted.

• A higher roll center (more shims) is recommended for grippy, high-traction tracks as well as for bumpy tracks.

• A lower roll center (fewer shims) is recommended for slippery and smooth tracks.

The included kingpin plate has two different mounting possibilities to choose either 0° or 7°.

Rear Uprights.

The ultra-tiny XPBS™ rear uprights are unique, innovative, and smart… an authentic XRAY innovation.

The rear upright consists of a super-lightweight composite upright block and stiff Swiss 7075 T6 mounting plate.

The upper roll center plate has a unique design that allows easy changing of roll center position. The roll center plate features 2 roll center positions; by reversing the orientation of the plate another 2 roll center positions are available. The roll center shifting is in range of 2.5mm. The roll center height of the upper camber link can be adjusted via shims of various thicknesses. The composite upright features 2 lower roll center positions.

The outer suspension pin – on which the rear upright sits – features 2 shims which allow for additional wheelbase adjustment.

The uprights feature integrated geometry adjustments including:

• camber

• upper roll center

• lower roll center

• wheelbase

Front Upper Suspension.

The front upper suspension is part of the innovative, unique XPBS™ suspension concept. Extra-strong and robust front upper arms are mounted to the front bulkhead assembly into the front shock tower and adjustable suspension holder. Using eccentric bushings, front inner upper roll center can be easily adjusted.

Caster is easily adjusted using caster clips which are inserted either in front or behind the front upper arms.

The ball link is inserted into the upper arm and the integrated adjustable turnbuckle can be accessed from outside for quick & easy camber link adjustment.

Turnbuckles.

To guarantee maximum reliability, all turnbuckles are manufactured from a special blend of HUDY Spring Steel™ which is specifically formulated for turnbuckles. The turnbuckles have a tougher core and are well suited for steering system and rear upright linkages.

Servo Saver.

The dual-arm steering system is simple yet effective, and features an integrated, easily adjustable servo saver and Swiss 7075 T6 aluminum steering plate.

Ackermann is easily adjusted by quickly & easily changing steering link mounting positions on the steering plate.

Bump steer is easily adjusted by shims between the steering plate and steering linkages.

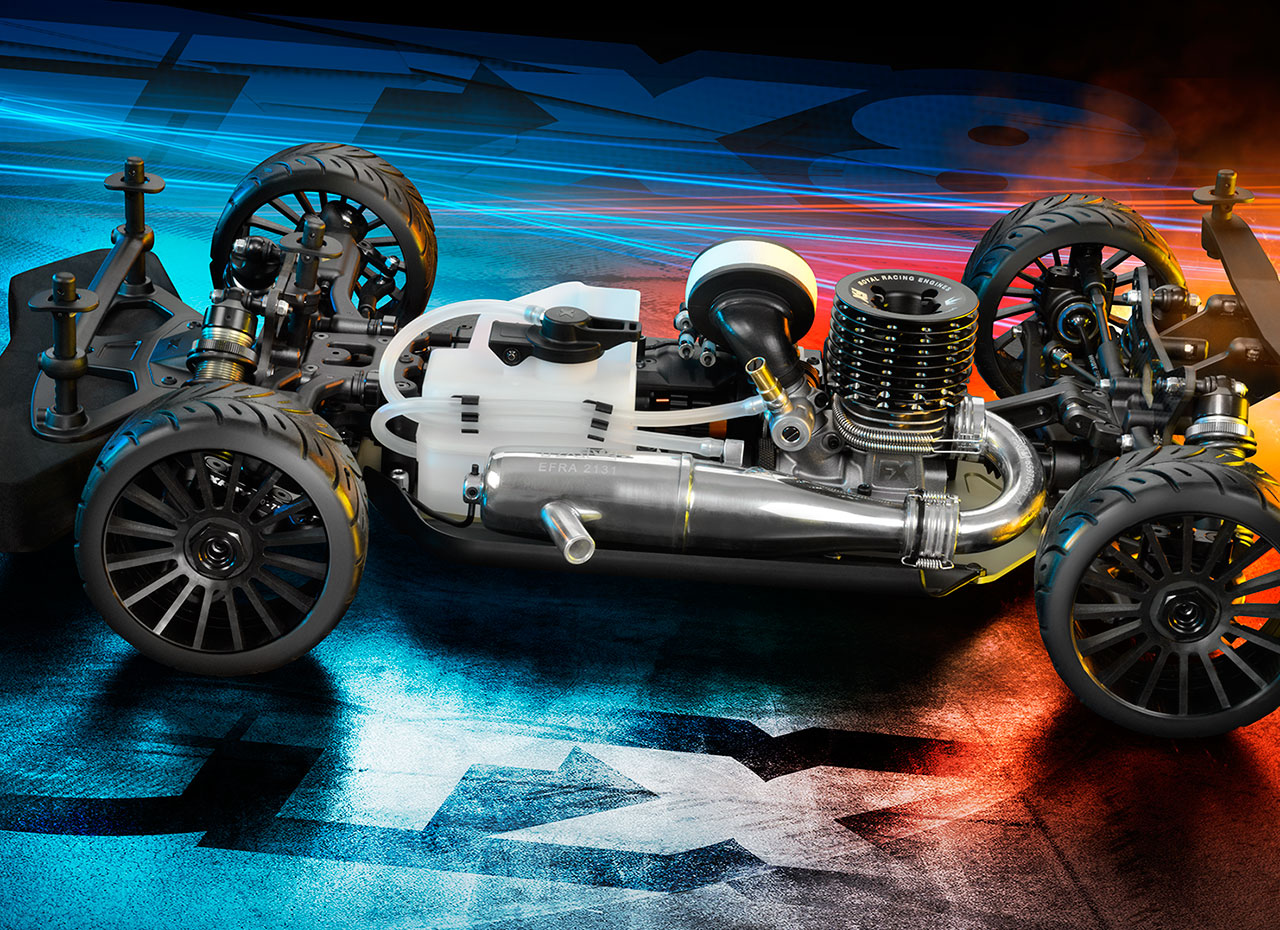

Drivetrain.

The GTX8 has a conventional shaft-drive 4WD drivetrain featuring:

• Front & rear gear differentials with adjustable oil viscosity,

46T crown gears, and 14T pinion gears

• Central 2-speed gearbox. (1st) 49T/16T, (2nd) 46T/19T

• Front, rear, and central CVD drive shafts

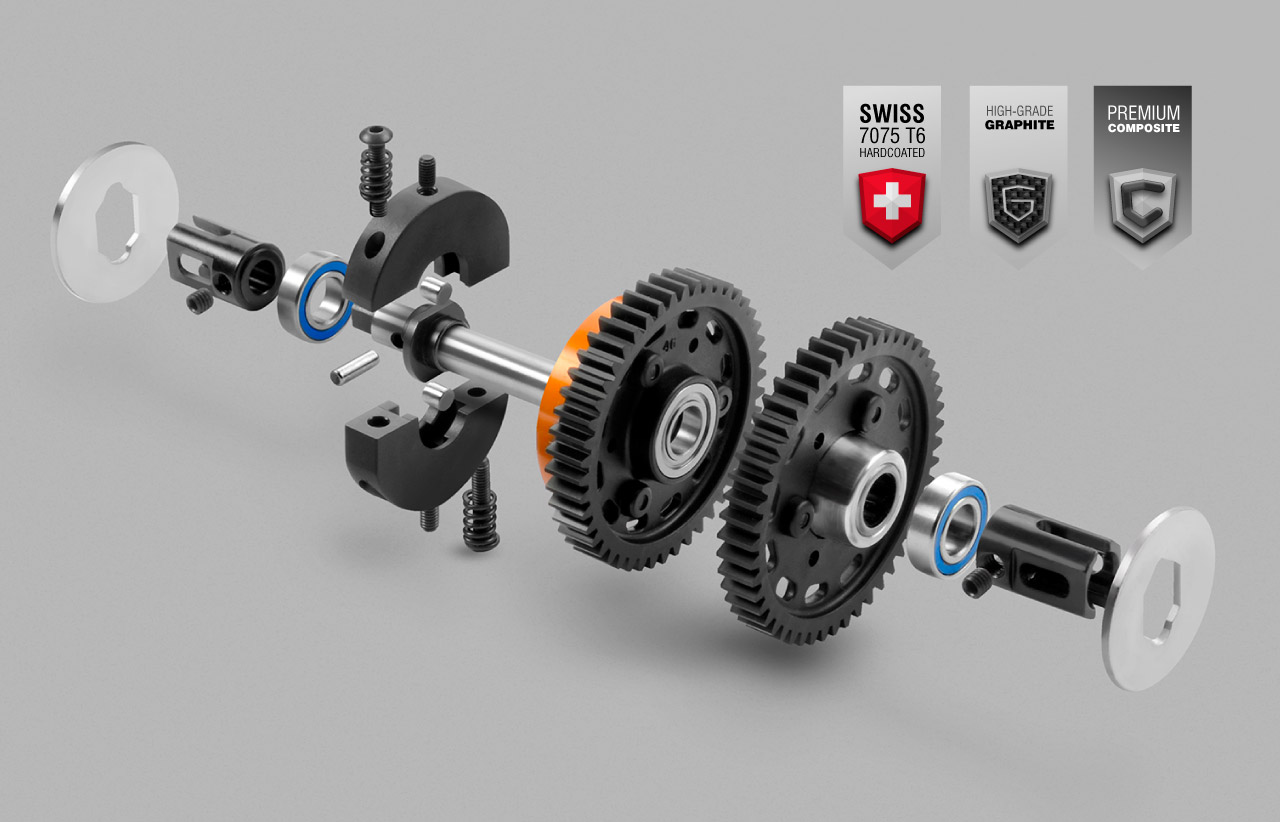

Gear Differential.

Rubber-sealed composite differential housings feature steel inserts that are manually precision ground after the molding process to guarantee a perfect fit with no vibration. Differential internal gears are made from pressed steel, which are then heat treated and machined for ultra‑high precision and smooth operation.

Diff Outdrives.

Super-lightweight diff outdrives are machined from HUDY Spring Steel™ with unnecessary material removed from the outer part of the outdrives to reduce rotating weight without affecting durability. The inner portions of the outdrives are additionally hand-ground for maximum precision and fitment into the diff case.

The outdrives are hardened using HUDY’s own special hardening process to provide extended lifespan and reliability.

Diff Gears.

Differential main gears are manufactured from HUDY Gear Steel on a precision manual gear machine. The material was specially formulated and developed for use in gears. All gears are hardened to provide the longest possible lifespan.

Drive Shafts.

GTX8 constant velocity drives (CVDs) are manufactured from world-renowned HUDY Spring Steel™. The drive shafts are some of the world‘s thinnest yet most durable drive shafts used in off-road RC cars.

The larger & stronger central outdrives feature protective rubber boots, thick 3mm pins, and protective locking rings.

All drive shafts and outdrives are hardened with a proprietary hardening process to provide unbeatable lifespan and reliability.

Alu Hex Hubs.

Ultra-lightweight 17mm wheel hex drive hubs are CNC-machined from Swiss 7075 T6 black-coated aluminum.

The alu hex hubs are specially machined to reduce rotating weight while guaranteeing wobble-free wheel mounting.

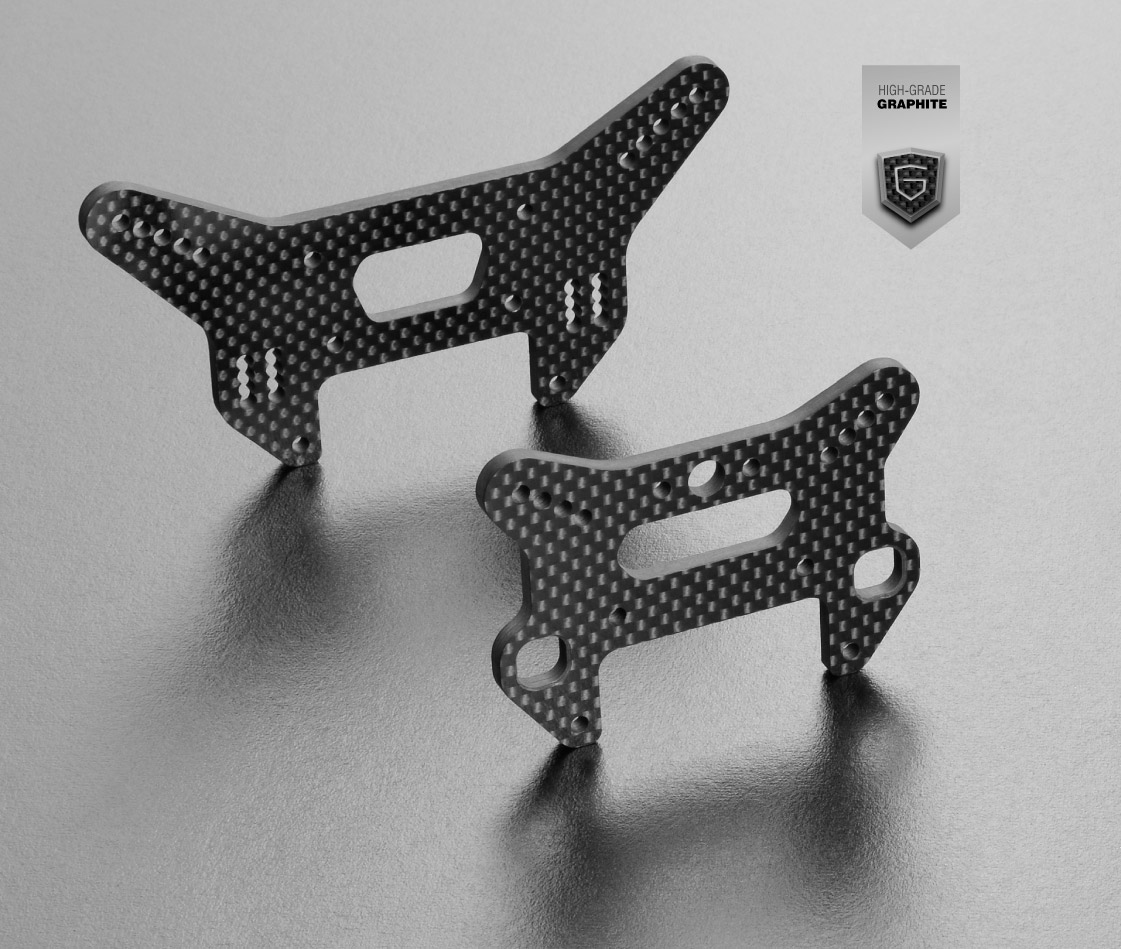

Shock Towers.

Shocks.

The GTX8 big-bore shocks have a special construction that offers superior reliability and performance.

The oversized big-bore shocks feature 18.5mm outer diameter shock bodies, externally threaded with an adjustable collar for quick & easy spring preload adjustment. The shock bodies are hardcoated in a titanium color and feature a 1-piece alu shock cap.

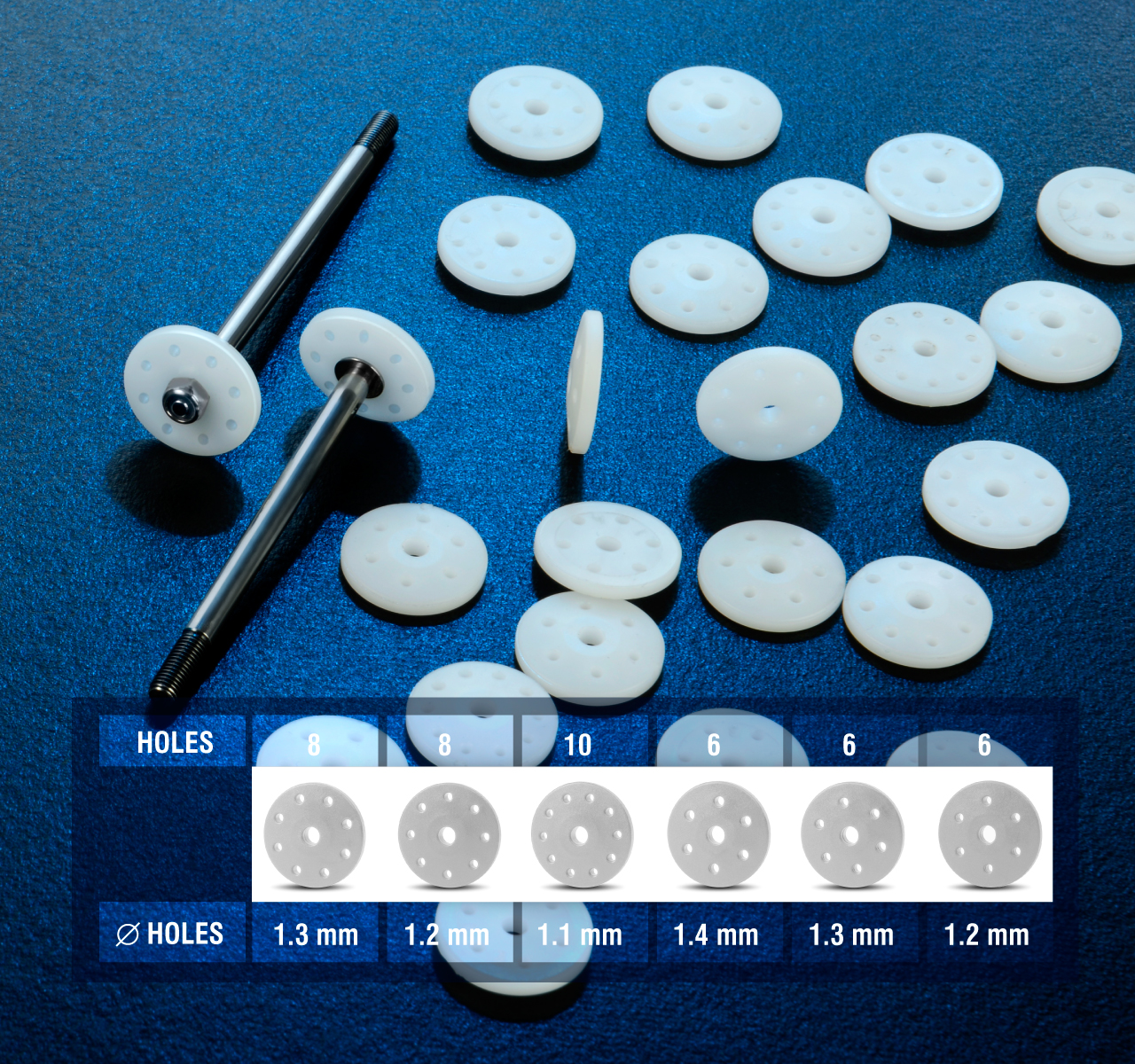

Ultra-precise shock pistons feature 6-, 8- and 10-hole options.

The large 16.0mm inner diameter of the shock bodies ensures proper & consistent shock oil flow through the perfectly-round pistons while they travel inside the smoothly-finished interior of the shock body. The result? More consistent damping characteristics.

Shock Springs.

GTX8 springs have been specifically designed to complement the big-bore shocks.

XRAY shock springs are manually measured, selected, and matched into pairs to guarantee precisely equal length and damping characteristics.

Shock Pistons.

Ultra-precise shock pistons feature 6-, 8- and 10-hole options. The big-bore pistons are molded from tough, well-proven Delrin® material to provide smooth action and durability. The precision molding production process ensures perfect piston roundness after production, so that the pistons move super-smoothly inside the shock bodies for identical perfect action in all four shocks.

Clutch.

The high-torque clutch provides smooth, continuous power transfer from the engine at high RPM. The clutch engages higher in the RPM range, resulting in more controllable power during acceleration.

The clutch features Swiss 7075 T6 aluminum flywheel and small, lightweight clutch shoes that are designed for engagement during the entire travel of the shoe. The extra-tough flywheel nut is machined from HUDY Spring Steel™.

The clutch is equipped with hard clutch springs; optional soft and medium springs are also available

2-speed Transmission.

The 2-speed transmission is mounted on a precision-manufactured, super-smooth layshaft made from tough HUDY shaft steel for 2-speed, which is additionally heat treated for extra strength and long life.

The 2-speed gear adapter is CNC-machined from Swiss 7075 T6 for precision fitment of the 1-way bearing, allowing super-precise and wobble-free installation of spur gears.

The high-quality 1-way bearing is hand-ground before installation for maximum running precision and strength. The 2-speed adapter is manufactured from hardened steel.

Engine Mounts.

High-grade, CNC-machined aluminum engine mounts are made of lightweight alloy, and they help to dissipate engine heat. The engine mounts are easily adjustable from the bottom of the chassis to obtain proper gear mesh.

Side Guards.

The strong side guards incorporate a large bottom radius to maximize flex performance. The side guards are moulded from a special composite mixture for increased flex to help generate more traction.

The tough composite side guards protect the car, muffler, and fuel tank from side impacts. The side guards perfectly fit the chassis and seal against dust.

Optional graphite side guard braces allow for very efficient and easy chassis flex adjustment to adjust the handling of the car to different track conditions. By adding the graphite braces, the entire chassis is reinforced, and the resulting stiffer flex will improve handling in high-traction conditions.

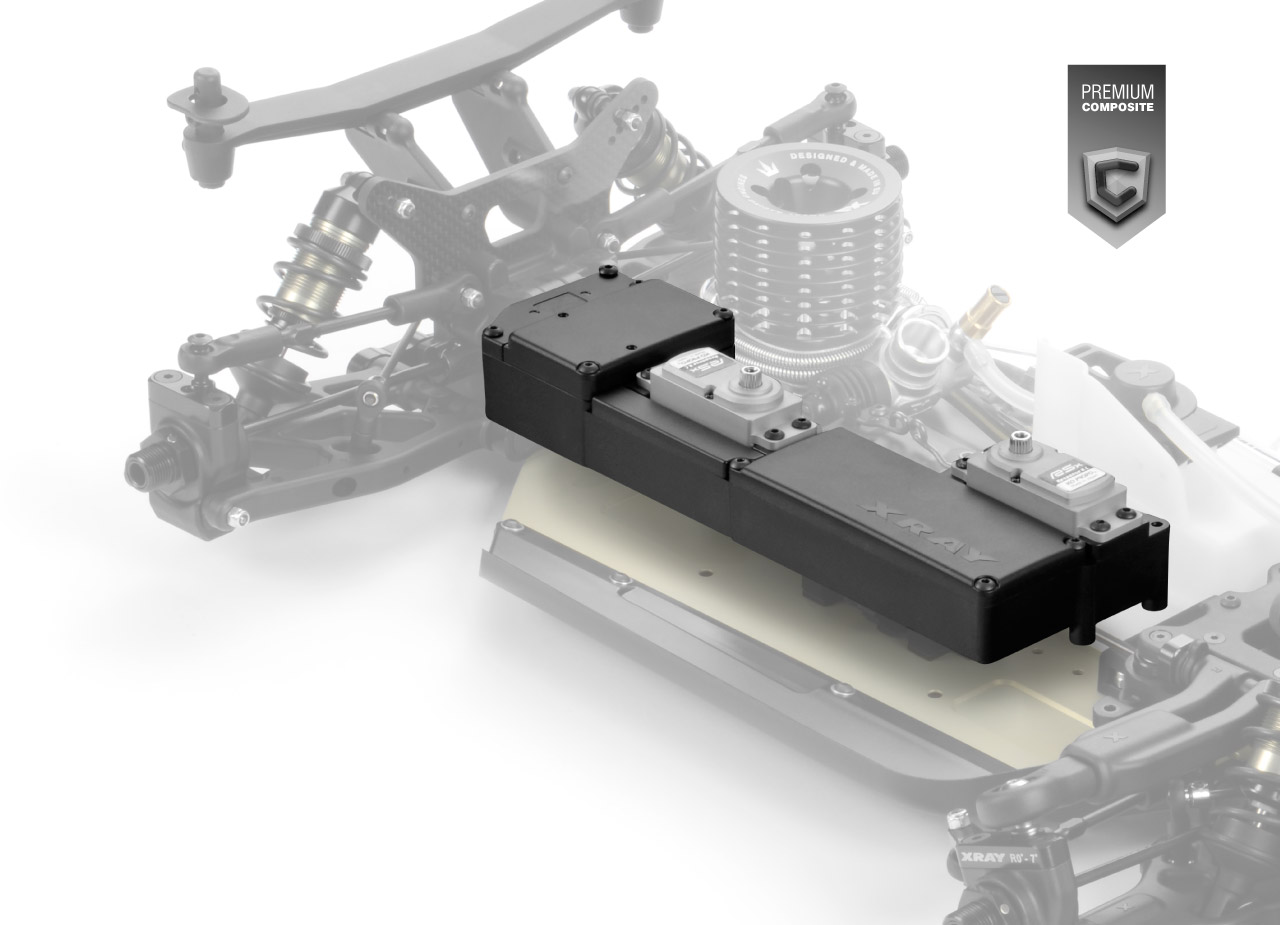

Radio Box.

The 1-piece electronics assembly is very compact and can be quickly & easily removed for servicing and cleaning. You need only to remove a few screws from the bottom of the chassis to remove the entire electronics assembly from the car.

The large molded radio box features a very clean design and layout that places the weight in key areas for proper balance. The batteries are placed along the centerline of the chassis in the front, and the lightweight receiver is placed on its side at the rear. The easy-to-access radio box is mounted on the side of the car and is secured by the fewest possible screws.

For racers not using a radio switch, a handy molded cover is included to help guarantee a leak-free radio box. The tight antenna tube holder ensures that the antenna tube stays attached even if the car flips over.

Brake System.

The GTX8 features a well-proven, high-performance braking system that is strong, precise, and dependable to make slowing and stopping consistent and reliable. Coupled with the car’s balanced load distribution, the extraordinary control imparted by the braking system gives you complete confidence as you pitch the car into corners.

XRAY focused on the smallest details when designing the brake system. The laser-cut, precision flat-ground steel brake disk allows for fade-free braking in conjunction with the special high-grip brake pads installed on laser-cut steel backing plates.

The brake disk is small, slim, and very lightweight. The precision hand-grinding allows true, wobble-free rotation. Brake inputs are transferred precisely to the brakes thanks to the rigid, high-precision machined brake cams. Brake disk and brake pad backing plates are specially heat-treated for maximum lifespan.

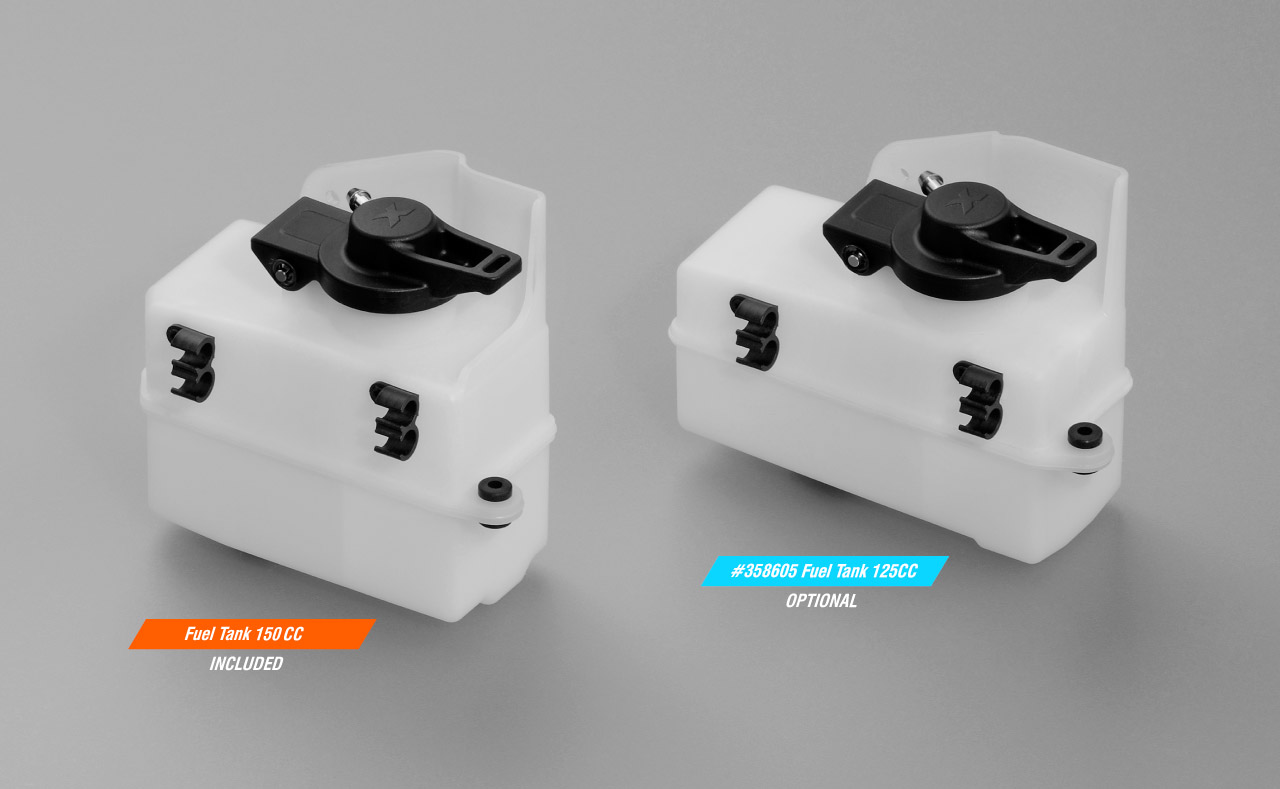

Fuel Tank.

The 150cc extra-large capacity fuel tank is super-strong and features an integrated floating stone filter to ensure that the fuel pickup will always be in the correct orientation, even if your car isn’t. This fuel pickup system will allow fuel to continue to flow to your engine, even while waiting for a marshal to right your inverted car.

Internal baffles ensure that fuel will always be in the area around the fuel line inlet.

The fuel tank cap features a very strong spring which ensures the cap will always close after refueling, and the specially-designed rubber seal perfectly seals the fuel tank to ensure that no fuel leakage will occur.

The fuel tank is molded from a special composite mixture that ensures very high reliability and rigidity. The molded-in splashguard protects the brakes from fuel spillage. The tank is mounted with rubber grommets to absorb vibration, and small composite holders secure thick 5.5mm silicone fuel tubing. Gluing of the tank pieces is performed by a special self-developed robotic system that ensures maximum accuracy and precision in pre-heating and gluing.

In order to comply with differing race regulations, the design of the car allows the installation of either the included 150cc fuel tank or optional 125cc fuel tank.

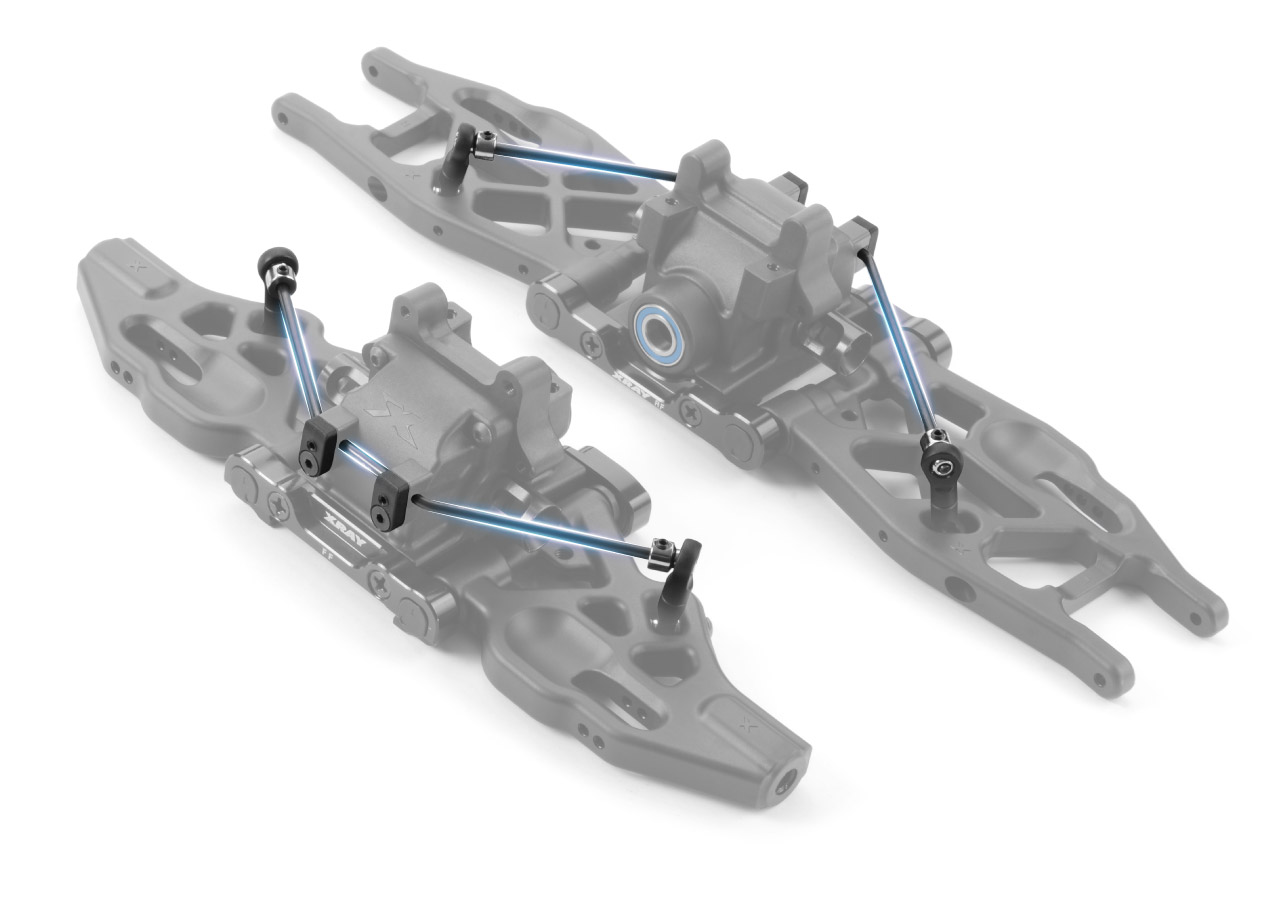

Anti-Roll Bars.

Anti-roll bars are manufactured from spring steel material. The front & rear roll bars are easily mounted to the diff cases, and can be adjusted using the connected linkages.

Anti-roll bar wires of different thickness are optionally available for fine-tuning.

Servo Brace.

A new connecting link was introduced between the throttle servo and the radio box to compensate for the softer, more flexible radio box as well as to eliminate throttle servo vibrations to the chassis. This will help to ensure more precise throttle and brake control.

Bumper.

The compact front foam bumper is made from high-resilience foam. The front upper bumper holder and lower composite bumper are molded from rigid composite to withstand hard crashes.

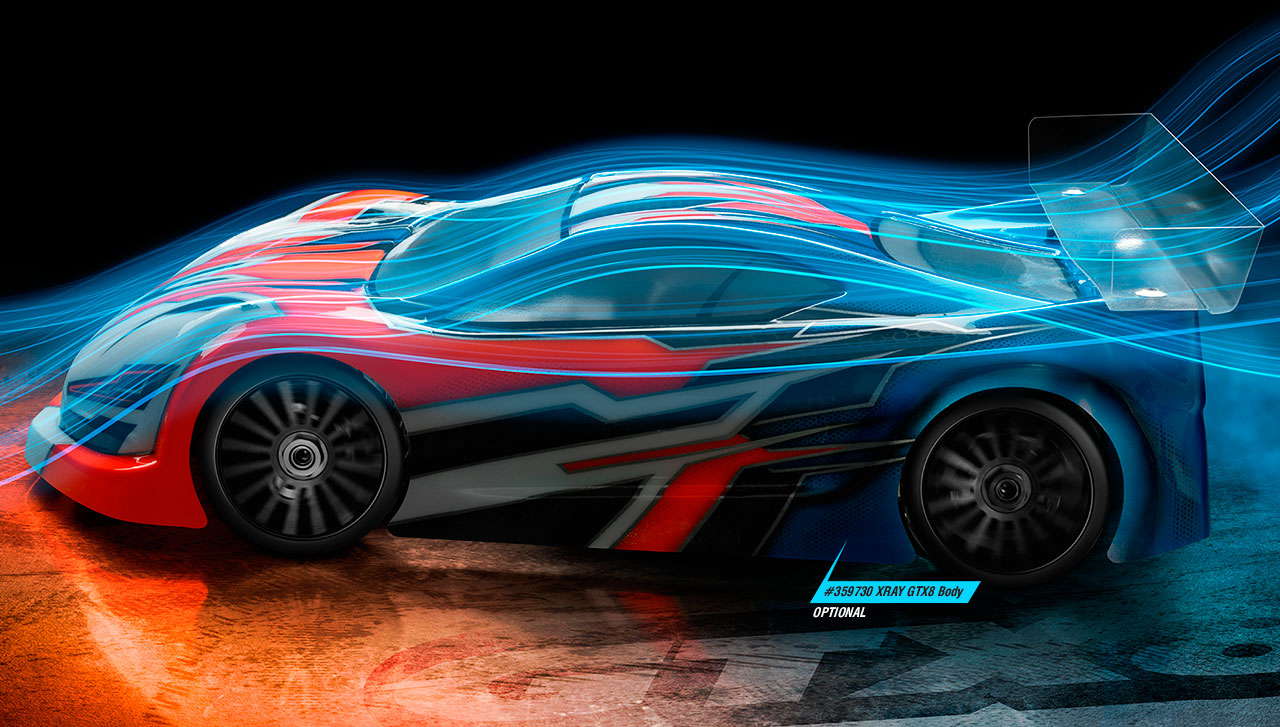

Body.

XRAY’s self-designed GTX8 body – made from high-quality Lexan™ material – features high-downforce areas: front windscreen for proper airflow, and side downforce areas for higher stability. The high-performance, low-profile aerodynamic body was designed by XRAY to perfectly fit the GTX8. The rear part of the body includes 3 wing struts for added durability; a high-strength wing is included.

The GTX8 body is available as an option only.

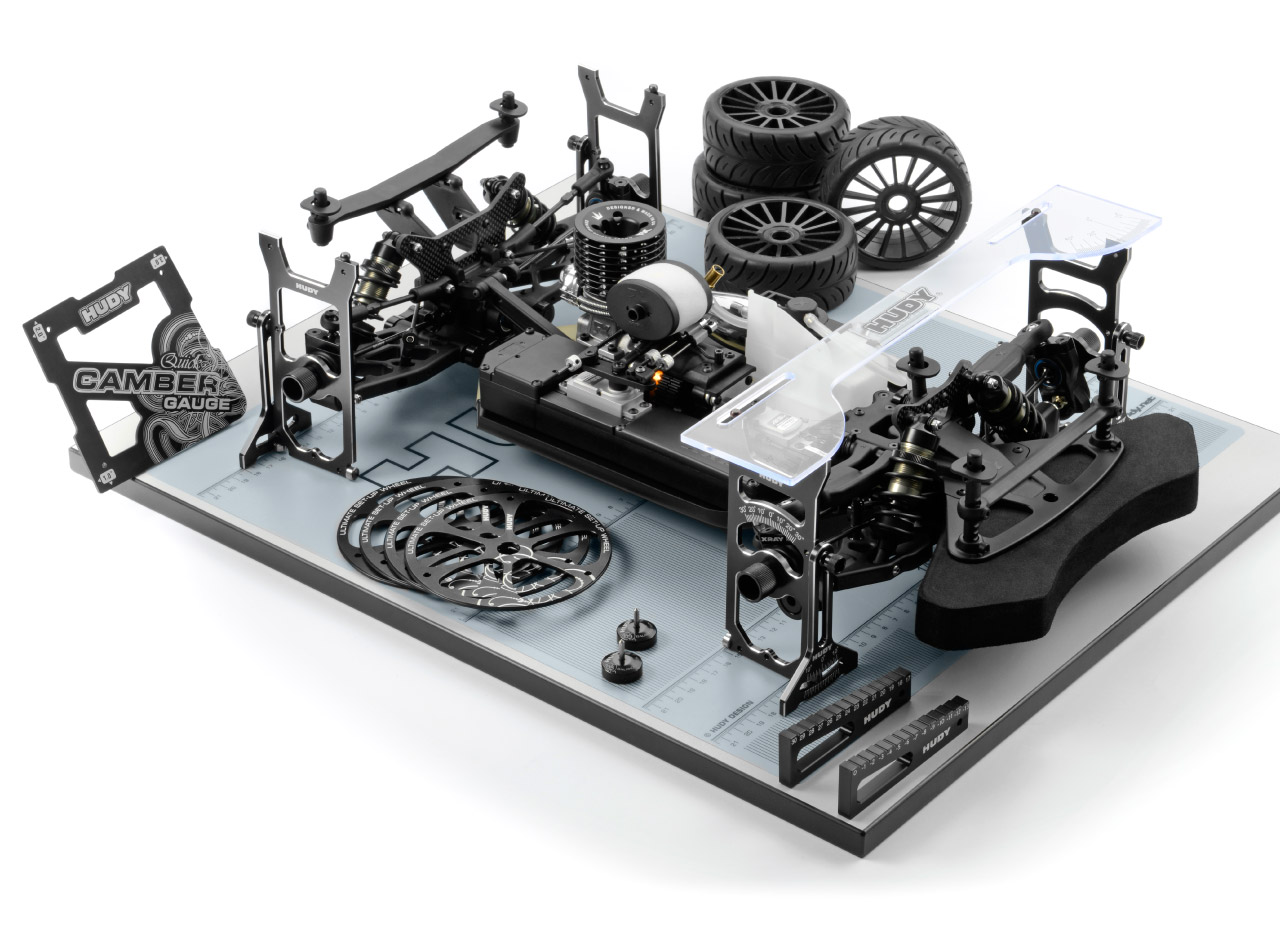

Adjustment Possibilities.

The GTX8 features fully-adjustable front & rear suspension geometry. For quick & easy adjustment, we recommend using set-up tools and accessories from HUDY, the world leader of RC tools.

The extensive and impressive range of adjustment possibilities includes:

• Caster

• Camber

• Toe

• Kick-up

• Anti-dive

• Anti-squat

• Ride height

• Downstops

• Track-width

• Lower roll center

• Upper roll center

• Roll center positions

• Bump steer

• Wheelbase

• Ackermann

• Adjustable shocks

• Adjustable front and rear diffs

• Adjustable XRAY Multi-Flex™

Instruction Manual.

XRAY Instruction Manuals have become the industry standard; they are simply the best manuals you will ever get with an RC model car. Whether you are a first-time builder or an experienced racer, all instructions are straight-forward and easy to understand. The full-color Instruction Manual contains large 3D illustrations that show all assembly details in the easiest and most comprehensive manner.

Chassis Balance.

The chassis design focuses on balanced weight distribution and weight transfer. Centerline holes are pre-drilled in the chassis plate for easy balancing with the HUDY Chassis Balancing Tool #107880.

Ball-Bearings.

The drivetrain ball-bearings now include grease instead of light oil to maximize the lifespan of the ball-bearings, especially in dusty conditions. A full set of 27 high-speed, blue-sealed ball-bearings are used throughout the drivetrain to ensure maximum efficiency.

Silicone Oils.

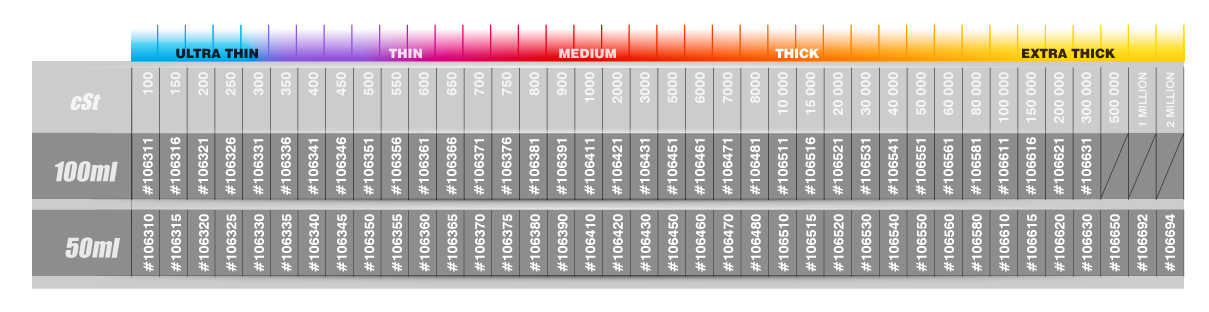

HUDY Exclusive Silicone Oils are manufactured in Europe and each batch is laboratory tested and calibrated to ensure the highest possible consistency and quality from batch to batch. Based on the industry-standard cSt rating, the new line of oils will be easy to identify, adjust, and feel.

When following any set-up sheets by XRAY or XRAY team drivers, you can be sure that the oils you will get for your car are exactly same as those used by the factory racing team, thus ensuring very exacting set-ups and handling.

Graphite Grease.

The GTX8 includes premium HUDY Graphite Grease - a high-performance, advanced-technology semi-fluid lubricant which incorporates both extreme pressure additives and finely-dispersed graphite for superior load carrying.

HUDY Graphite Grease is intended primarily for the lubrication of rotating parts and loaded gears. In addition to providing outstanding load carrying, it is formulated to have excellent adhesion and resistance from "flinging off" under extreme conditions. HUDY Graphite Grease reduces wear and increases parts life.

Click here for more information of the full HUDY Grease range

VIP Customer Treatment.

Owning an XRAY model racing car is an experience unto itself. Not only will you own the most premium luxury model racing car in the world, but you will also become a member of the prestigious family of XRAY owners with direct support and service from the XRAY factory. XRAY brings you the most up-to-date RC website on the Internet, with daily racing news, and the latest product developments. If you have any questions, problems or comments, you can ask the XRAY Support Team or any XRAY Factory Team Driver on the XRAY Support Forum. You can even upload your own set-up sheets or download from the thousands of different set-up sheets available from around the world at the exclusive XRAY Virtual Set-up Sheet Database. And that is only the start of the VIP treatment you get by joining Team XRAY.