2018 All-new Features.

- All-new chassis with ultra-narrow design for improved steering characteristics, increased torsional stability, and new two-position option for pod link mounting for in-corner steering adjustment

- All-new redesigned & updated rear suspension

- All-new narrower pod plate

- All-new rear alu bulkheads feature a new clamp system for ultra-low CG and a new system for multiple motor mounting positions

- All-new ride height adjustment via shims and eccentric upper clamps

- All-new easier motor access

- All-new rear graphite rear brace significantly reduces tweak of the rear pod and lowers CG

- All-new narrower side tubes for improved handling and reduced weight

- All-new narrower rear link brace for shorter side tubes

- All-new lower pivot brace with nut groove for tweak-free movement

- All-new super lightweight and lowered pivot ball for lower, more stable roll center

- All-new harder front upper arms for easier handling & smoother steering

- All-new harder front upper arm mounts for easier handling

- All-new updated upper arm position adjustment shims

- All-new steering blocks with minimized play for improved steering response

- All-new updated upper ball joints with minimized play

- All-new center shock position adjustment allows for steering characteristic setting

- All-new extended shock absorber adaptor

- All-new graphite plate for antenna holder

- All-new longer servo mounts for mid-size servos

- All-new 1 hole shock pistons

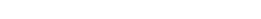

XRAY X10 Platform.

The X10 is a typical XRAY car – a premium, professional, high competition model racing car for the most demanding racers, developed and designed with attention to the smallest details.

The new X10 is a 1/10 GT pancar based on the XRAY’s European Championship-winning X12 pancar. Sharing many high-performance parts with its smaller cousin, the X10 has incorporated all the finest details to achieve a state of perfection.

XRAY focused its efforts on refining all of the already well thought out parts and assemblies to make the new X10 easy to drive, work on, and adjust. The new X10…the best-performing pancar to get you to the Winners Circle.

Martin Hudy

XRAY designer

XRAY Design.

Designed in virtual reality using the world's most sophisticated CAD tools, and manufactured using the world's best machining and molding technology, the X10 has attained a level of perfection that is second to none. All parts are purpose-designed and manufactured by XRAY, so all parts fit and work perfectly together.

Premium.

Legendary XRAY premium design, workmanship & material quality and unmatched attention to the finest details result in a state of perfection achieved by well thought-out refinements to create a car that is easy to drive, work on, and adjust.

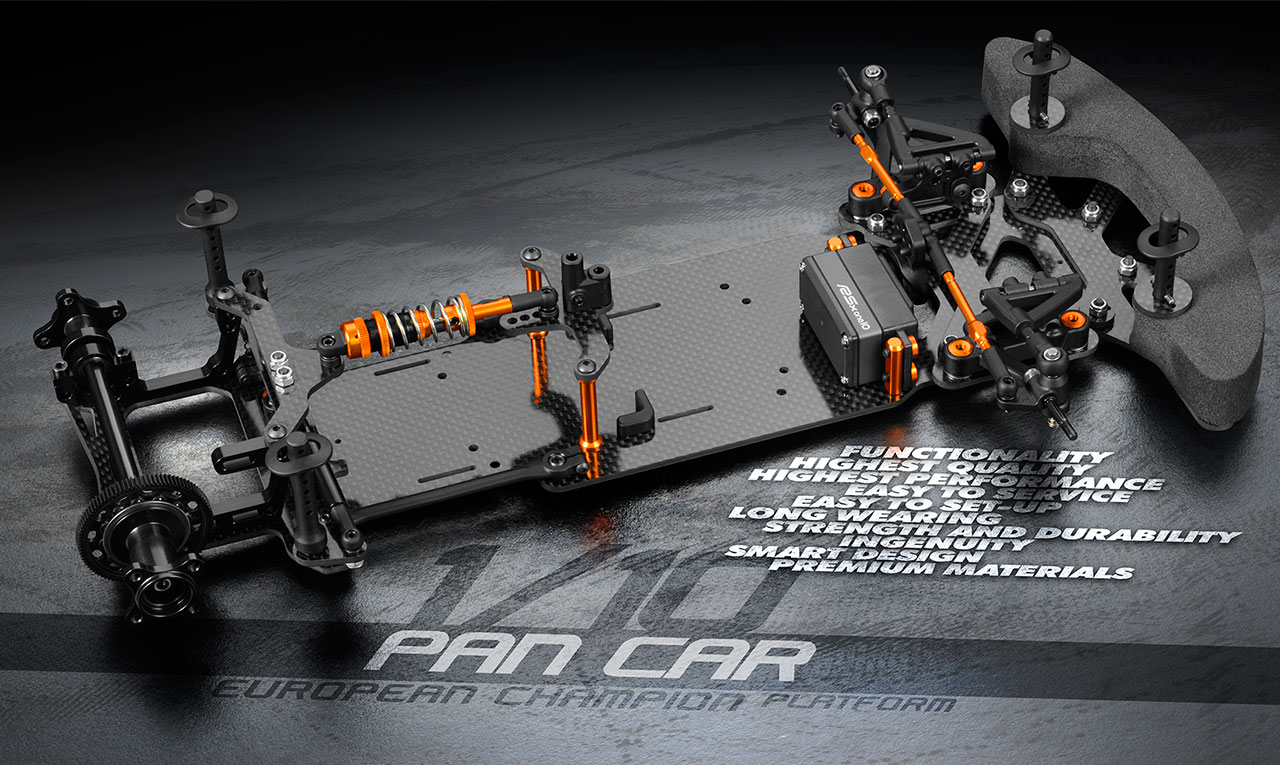

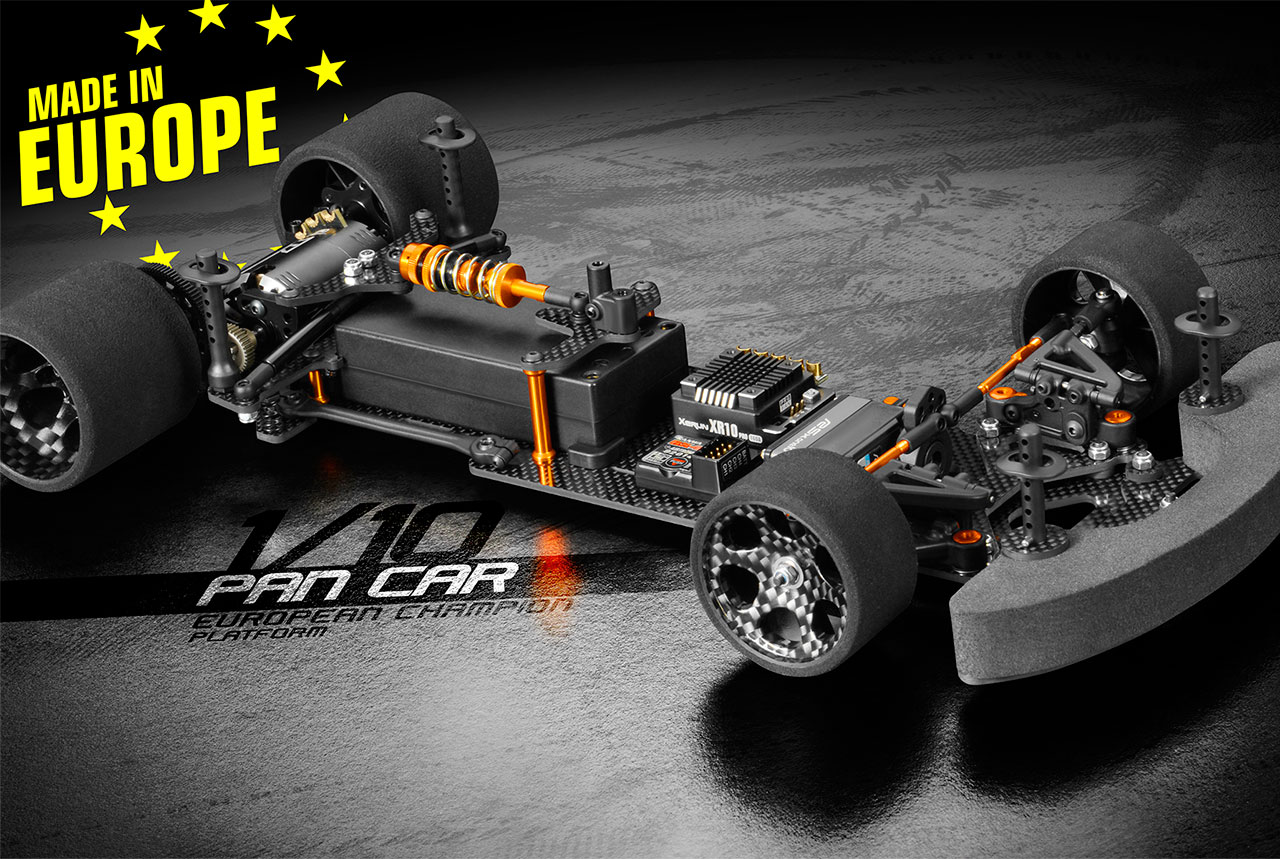

Made in Europe.

From unique HUDY Spring Steel™, through the world’s strongest Swiss 7075 T6 aluminum, along with XRAY’s own secret composite mixtures, to the premium high grade graphite materials… everything is exclusive and premium on the X10. Using premium European exclusive materials crafted by XRAY’s engineering artists using the state of the art German, Italian, and Swiss CNC machines, the X10 is a blend of only the world’s finest.

Chassis.

The new chassis includes a new two-position option for pod link mounting. The first outer position is standard, while the new inner position allows for angled mounting of the pod links to improve in-corner steering.

The new, ultra-narrow chassis is designed for short battery packs, giving improved steering response and better overall traction on all track surfaces. Torsional stability has been increased resulting in increased grip while eliminating tire scrubbing in high-speed corners. The car handles bumps much better, as well.

The CNC-machined chassis is custom-manufactured from stiffer 2.5mm high-grade graphite material with a specially-designed compound for carpet racing.

Rear Suspension.

Everything is new in the rear suspension, from the new rear pod plate, through the all-new alu bulkheads, and the new rear brace up to the rear link brace; everything was updated and redesigned for improved performance and durability.

The rear suspension features a conventional rear pod that is adjustable via pivot-ball links, providing extremely easy assembly and tuning while being very effective and giving the highest competitive performance.

Pod Plate.

The rear pod was redesigned to fit the new aluminum bulkheads and graphite brace.

The compact, ultra-lightweight rear pod is constructed from high-strength aluminum bulkheads, a rear graphite brace, and thin (but strong) high-grade graphite plates.

The smart pod design allows for super-easy motor access, accommodating all motors.

Bulkheads.

The all-new rear pod plate features a narrower design in rear, allowing the bulkheads to be moved closer together. The motor position has been offset more to the right for improved weight balance, especially when using heavier brushless motors.

The position of the rear left bulkhead was moved more than ~5mm to the right to improve weight balance, as well as to shorten the pod to make it lighter.

The rear suspension is mounted on a premium-quality graphite pod plate that works independently of the chassis. The updated design of the new pod plate works with the new aluminum rear bulkheads, as well as widening the rear pod links for more stability.

Motor Access.

The open-top design of the rear pod left-side bulkhead provides super-easy motor access. The rear pod accommodates all motors.

Rear Ride Height.

The all-new alu bulkheads allow for very quick & easy ride height adjustment. No more hassle to disassemble the car to change the rear ride height!

The included ride-height shims are inserted between the bulkhead and eccentric upper bulkhead clamp to alter the ride height. The eccentric clamps are designed to offer two different alternatives, thus extending the range of ride height adjustment. Smart & easy.

The new ride-height adjustment method allows ultra-fine adjustment by 0.25mm increments, compared to the previous 0.5mm increments using eccentric bushings.

Rear Brace.

The all-new rear graphite brace replaces the previous aluminum brace, significantly reducing tweak of the rear pod. To keep the lowest possible CG, the brace is positioned in the lowest possible position.

Machined from premium graphite, the brace is flexible yet rigid enough to withstand serious crashes.

Rear Link Brace.

The all-new rear link brace features a narrower design to accommodate the new shorter side tubes. The new, lighter brace moves the weight more towards the chassis centerline.

The graphite rear link brace holds the side tubes as well as the side springs and body posts, and works as a backstop for the battery pack.

Side Tubes.

The all-new narrower side tubes give reduced weight and offer improved car handling.

Lateral damping side tubes provide ultra-smooth side damping, making the car easier to drive and easier to work on. The outer aluminum tube and inner Delrin® tube give ultra-smooth operation.

Pivot Brace.

All-new tweak-free lower pivot brace was redesigned for easier mounting of the pod plate on the chassis. Thanks to the nut groove on the brace, nuts that connect chassis with the brace will find the position by themselves, removing the need to reset the position for free movement when mounting the pod plate.

The composite upper & lower pivot braces were redesigned to allow the pivot ball to be lowered by 0.5mm so as to lower the roll center of the car, resulting in more rear traction and improved rear stability.

The pivot ball is smaller and lighter, which is very important for a pan car. The pivot ball has an internal thread so a separate locking nut atop the pivot ball is not needed any more. This saves weight but also allows for greater side movement of the rear pod.

Front Suspension.

Strong & simple, yet refined front suspension made from strong, lightweight, self-developed composite material. Reactive caster settings available using 2.5°, 5.0° or 7.5° eccentric bushings. Tiny yet strong HUDY Spring Steel™ upper pivot balls ensure smooth, bind-free operation, while composite lower pivot balls allow the front suspension to operate smoothly.

Quick & easy adjustment of front caster, track-width, roll center, and ride height via included shims and clips.

Kingpins.

Super-smooth, hardened steel kingpins are the foundation of the front suspension.

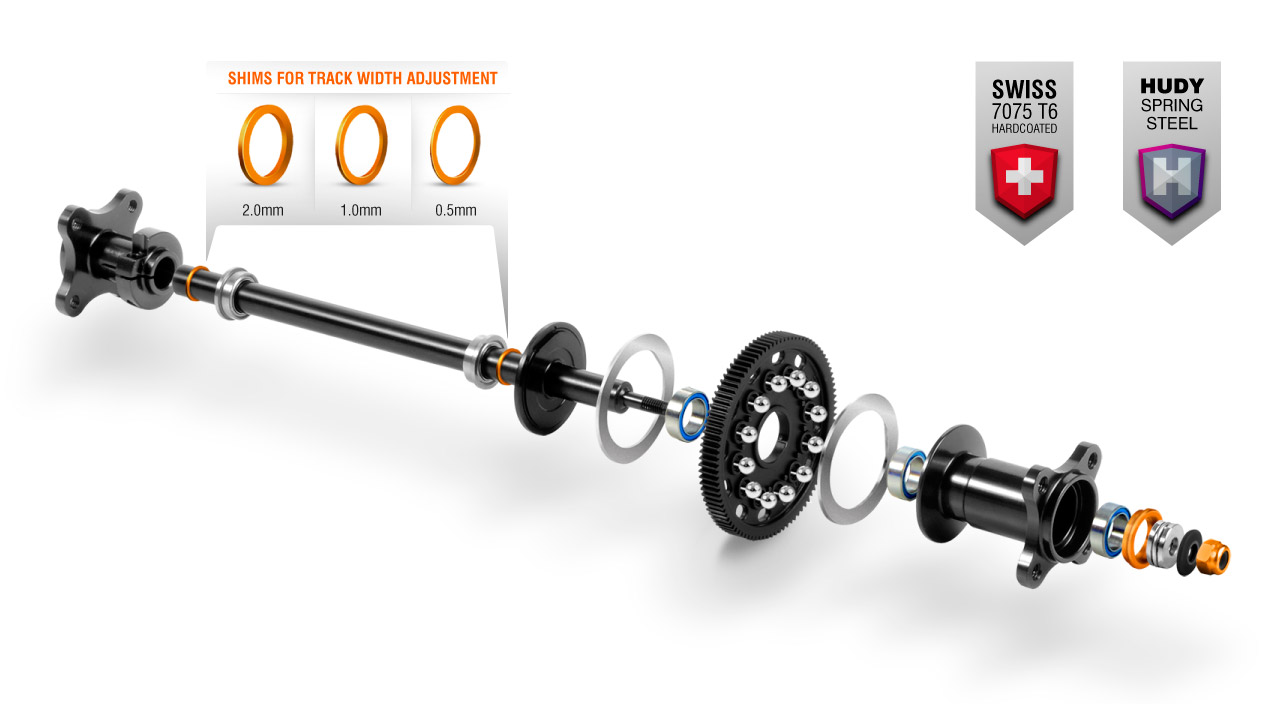

Wheel Axles.

Ultra-precise wheel axles CNC-machined from premium HUDY Spring Steel™ are additionally hardened and hand ground for precision fitment.

Adjustable Turnbuckles.

Front upper 3mm adjustable HUDY Spring Steel™ camber turnbuckles are lightweight yet very durable to withstand hard impacts, with precision threading to ensure fine camber adjustment. Steering linkages are made from adjustable 4mm turnbuckles manufactured from lightweight aluminum.

Steering Blocks.

Excess play in the steering block and front upper ball joints was removed to improve steering response.

New steering blocks are made from a harder material to make the car easier to drive and give smoother steering.

Front Upper Arms.

Both front upper arms and the front upper arm mounts are moulded from harder composite material to make the car easier to drive and give smoother steering.

The upper arm shims allow for moving the front upper arm mount together with the upper arm more out from the lower arm, thus generating less camber gain and making the car easier to drive. With more shims, less camber gain is generated, reducing initial steering and making the car less twitchy.

Camber Gain.

The upper arm shims allow for moving the front upper arm mount together with the upper arm more out from the lower arm, thus generating less camber gain and making the car easier to drive. With more shims, less camber gain is generated, reducing initial steering and giving less “twitchiness.”

Shock Position.

Unique & innovative center shock position adjustment allows use of various positions on the graphite antenna holder to adjust the shock position and length. By using a longer or shorter shock, the damping and steering characteristics can be changed.

Longer Shock:

• Shock built WITH adaptor (extension)

• Improved drivability over bumps, improved on-power traction

Shorter Shock:

• Shock built WITHOUT adaptor

• Improved steering response, quicker direction changes

Shock Absorber.

The fully-adjustable XRAY shock absorber features a hard-anodized aluminum shock body for superior durability. The fine-threaded shock body allows for quick & easy shock spring preload adjustment.

Tiny, thin shock membrane gives smooth dampening characteristics, and a super-soft silicone shock O-ring gives super-smooth operation while preventing oil leakage.

The ultra-finely finished shock shaft with precision-molded composite shock piston ensures optimum shock oil flow and smooth action.

A simple yet smart shock construction allows for quick & easy shock-length adjustment for rear pod downstop adjustment.

The number of holes in shock piston were changed from 2 to 1 for improved on-power steering.

Servo Mounts.

New, longer servo mounts fit standard servos, the most frequently-used servo in this class. The mid-size servo mounts are available as an option.

Pre-drilled chassis holes for the servo mounts on both left & right sides allow the placement of the servo on either side to maintain proper balance. Aluminum servo stands allow flat mounting of the servo onto the chassis for the lowest possible CG.

Weight Balance.

The layout of the electronics and position of individual sections of the car were designed with optimum weight distribution and balance in mind.

The steering servo is located in a lay-down position for lowest CG at the chassis center, and the layout of the chassis allows the batteries to be placed either frontwards or rearwards. Depending on battery configuration, the ESC and receiver can be placed in various positions for ideal weight transfer and balance.

Battery Placement.

Battery placement position on the chassis has a significant influence on weight balance adjustment. The chassis design allows the battery to be installed in either a forward or backward position, secured by composite battery holders.

Track-Width.

The lower suspension arms feature smart eccentric aluminum inserts which allow quick & easy changing and setting of track-width depending on track conditions. Optional aluminum 0.5mm and 1.0mm eccentrics are used to set wider or narrower track-width.

Ride Height.

The front suspension uses ride height adjustment shims which enable very quick, precise and hassle-free ride height adjustment for various track conditions. The set of 0.2, 0.4, and 0.6mm ride height adjustment shims are included for fine tuning.

Reactive Caster.

Reactive caster is easily adjustable by using easy-to-change eccentric bushings of 2.5°, 5.0° or 7.5° (included). Reactive caster is used to adjust the amount of caster change when the front end of the car is compressing (diving) or decompressing (rising).

Wheelbase.

The front chassis upper brace features 3 suspension mount positions which allow for fast and comfortable wheelbase adjustment.

Bump Steer.

Optional 3mm shims are available for the steering block to make the car easier to drive under high-traction conditions.

Ackermann.

The quick adjustable Ackermann positions can be adjusted by adding/removing shims between the servo and servo holders. The composite shims included in the kit come in three different sizes: 3x6x1, 3x6x2 and 3x6x3. Ackermann influences the steering of the car, and therefore it is important to make it an adjustable feature.

Servo Saver.

4-spring servo saver gives more precise steering, making the car easy to drive while handling more consistently.

The tiny yet robust servo saver protects the servo from impact damage. Easy Ackermann adjustment is made via shims mounted below steering block pivot balls.

Side Springs.

The side springs are straight instead of conical, which helps improve the side traction and handling of the car. The straight side springs have more consistent and smoother compression which results in smoother out-of corner exiting, and reduces the chance of traction rolling.

Rear Axle.

The ultra-strong lightweight steel axle is used to provide maximum reliability even in the serious crashes. The rear differential features high-grade precision carbide balls for spur gear, hardened and precision-ground D-steel shims, and premium carbide axial thrust bearing.

Spur Gear.

Precision-molded spur gears are made from XRAY's exclusive composite material, ensuring true running, super-quiet operation, and robustness for handling powerful motors. A range of optional spur gears for fine tuning is available.

Rear Hubs.

Aluminum rear hubs are machined from lightweight aircraft aluminum, specially lightened and black-coated for stylish looks. The rear left aluminum wheel hub features a center-balanced clamping mounting system, ensuring secure mounting while eliminating vibration and run-out.

Antenna Mount.

A tiny lightweight antenna mount secures the optional lightweight yet strong molded fiberglass rollover antenna #376310.

Body Posts.

Robust body posts with fully-adjustable body holders; optional super fine +1 or +2mm body backstops available optionally for even more super-fine body height adjustment.

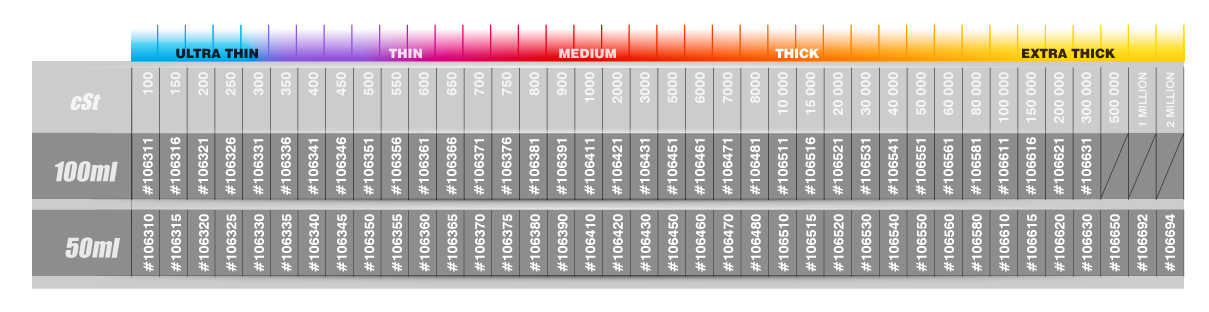

Silicone Oils.

HUDY Exclusive Silicone Oils are manufactured in Europe and each batch is laboratory tested and calibrated to ensure the highest possible consistency and quality from batch to batch. Based on the industry-standard cSt rating, the new line of oils will be easy to identify, adjust, and feel.

When following any set-up sheets by XRAY or XRAY team drivers, you can be sure that the oils you will get for your car are exactly same as those used by the factory racing team, thus ensuring very exacting set-ups and handling.

Ball-Bearings.

A full set of 10 high-speed, blue-sealed and steel ball-bearings are used throughout the drivetrain to ensure maximum efficiency. All of the bearings are degreased and oiled with Aero Shell® Fluid 12 for maximum smoothness and long life.

Premium Composite Parts.

All composite parts are manufactured by XRAY using premium self-developed composite mixtures which guarantee sufficient flex of the suspension parts, while being hard enough to withstand hard impacts.

Front lower arms are made from a harder material to make the car easier to drive and give smoother steering.

Fully Adjustable.

Fully adjustable front camber, caster, wheelbase and toe; front & rear track-width, front & rear ride height, front & rear springs, rear shock absorber, rear downstop, pod damping, battery position, pod weight balance, and chassis tweak.

Chassis Weight Balance.

Chassis and rear POD features pre-drilled centerline holes for optimum weight balance adjustment using HUDY Chassis Balancing Tool #107880.

XRAY Orange.

The majority of aluminum parts are orange anodized for a better, more distinctive XRAY design look. The combination of traditional XRAY orange & black coloring gives the car the perfect look.

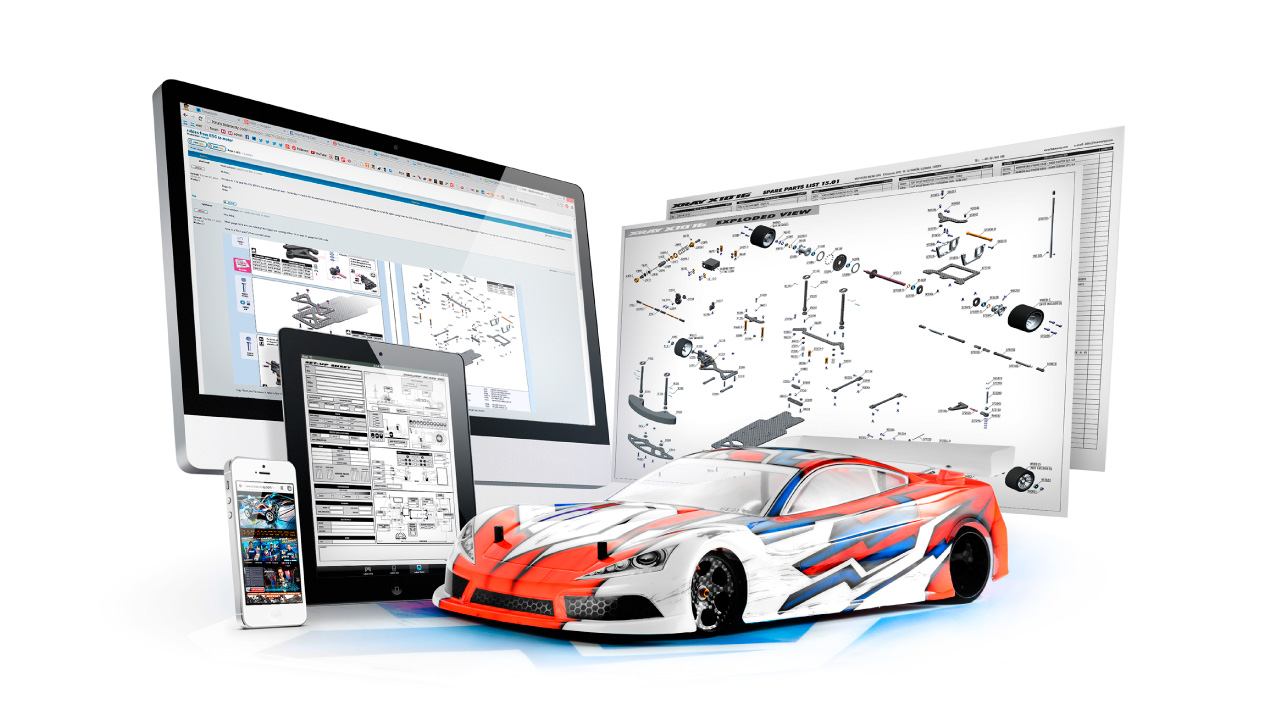

XRAY Instruction Manual.

XRAY Instruction Manuals have become the industry standard, and are simply the best manuals you will ever get with an RC model car. Whether you are a first-time builder or an experienced racer, all the instructions are straight-forward and easy to understand. The full-color instruction manual contains large 3D illustrations for easy comprehension.

XRAY VIP Customer Treatment.

Owning an XRAY model racing car is an experience on its own. Not only will you own the most premium luxury model racing car, but you will also become a member of the prestigious family of XRAY owners with superb support and service from the XRAY factory. The XRAY Web portal features up-to-date racing news and latest product developments. If you have any questions, problems or comments, you can ask the XRAY Support Team or any XRAY Factory Team Driver on the XRAY support forum. You can even upload your own set-up sheets or download from the largest RC set-up database at the exclusive XRAY Virtual Set-up Sheet Database. And that is only the start of the VIP treatment you get by joining Team XRAY.