2025 All-new Features

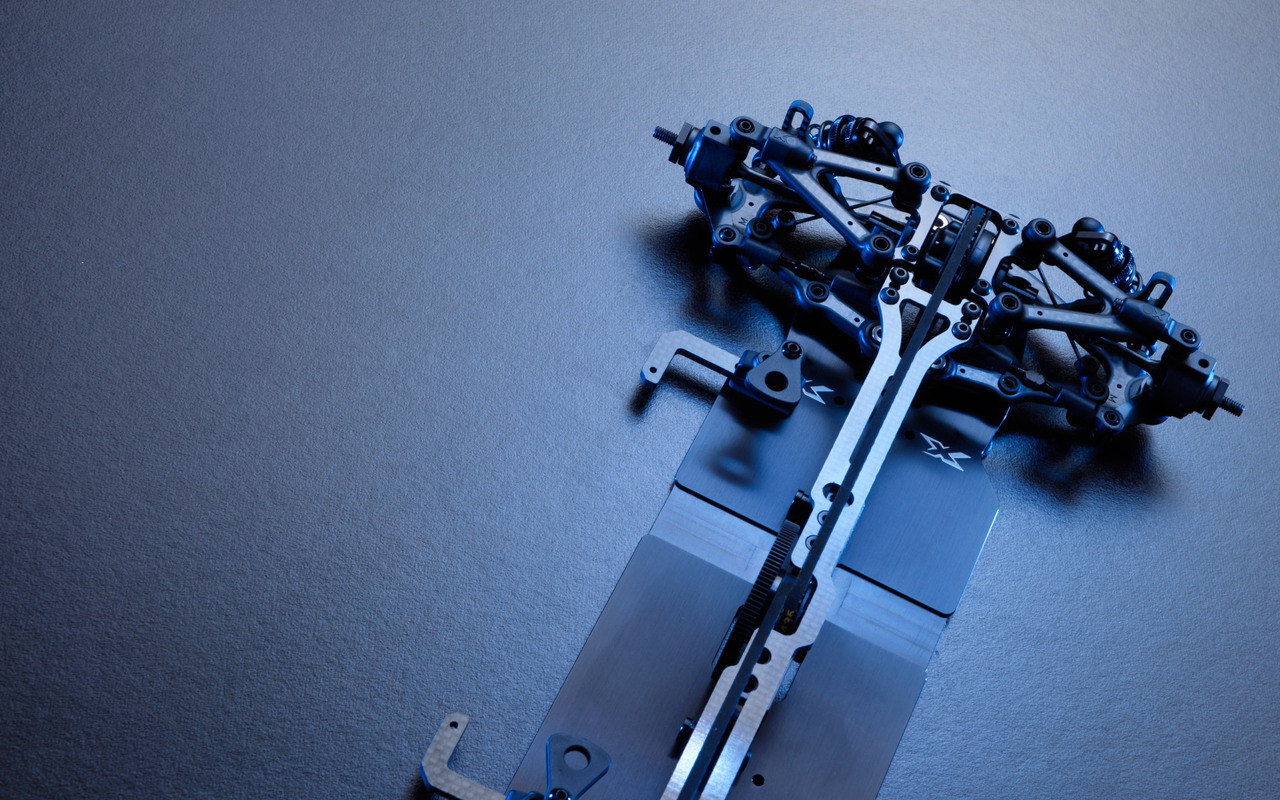

- All-new shorter shocks positioned 4mm lower than previous geometry improve cornering speed, mid-corner steering and stability, as well as reduced traction rolling in high traction conditions

- New shock holders relocate upper shock mount position to compliment shorter shock geometry

- All-new link style upper suspension arms included in the kit as an alternative to the traditional CFF upper arms for maximum adjustability & improved handling in certain conditions

- Aluminum one-piece low CG servo holder with 3 mounting configurations

- Low profile 3D printed rubber bumper included in kit for improved durability and airflow

- One-piece low profile upper front bumper for lower CG

- All-new flex limiting top deck shims for improved stability

- Wider wheel hubs included in the kit for the best all-around performance out of the box

Made in Europe.

Designed, developed, and fully manufactured in-house at the XRAY factory in Slovakia, Europe, using the most high-tech German and Swiss machines and premium European materials, crafted with XRAY's trademark attention to detail by our production specialists. The X4 is truly a masterpiece.

X4 Editions.

The X4 platform is tested for improvements across all track conditions to provide race-ready performance out of the box. Even with this goal, there are still differences in track conditions that can require different components for the best results.

Two versions of the X4’24 allow customers to choose their ideal starting point: the Graphite Edition and the Aluminum Edition, each tuned for different track conditions.

The Graphite edition is intended for asphalt tracks and lower traction carpet tracks.

The Aluminum edition is suitable for all carpet tracks, ranging from the low- to medium bite found on many EU carpet tracks to the high bite conditions found on US black carpet, and on very high traction asphalt tracks.

The X4 platform is tested for improvements across all track conditions to provide race-ready performance out of the box. Even with this goal, there are still differences in track conditions that can require different components for the best results.

Two versions of the X4’25 allow customers to choose their ideal starting point: the Graphite Edition and the Aluminum Edition, each tuned for different track conditions.

The Graphite edition is intended for asphalt tracks and lower traction carpet tracks.

The Aluminum edition is suitable for all carpet tracks, ranging from the low- to medium bite found on many EU carpet tracks to the high bite conditions found on US black carpet, and on very high traction asphalt tracks.

XLP vs XLP2.

All-new XLP2 shocks are 4mm lower compared to the previous XLP, improving cornering speed, mid-corner steering and stability, and minimizing traction rolls in high traction conditions.

XLP2 Shock Absorbers.

All the XLP2 shock parts are specifically designed for the smallest possible size to reduce the weight and keep the lowest possible CG.

Shock bodies are CNC-machined from premium Swiss 7075 T6 aluminum and hardened to ensure the maximum lifespan. The aluminum upper and lower nuts have a low-profile design, including sealing O-ring and upper composite ball joint. The shock shaft, shock adjustable nut, spring retainer and pivot balls are designed to achieve the lowest shock height possible.

The included shock pistons sets are 4-hole pistons with 1.1 and 1.2mm diameter holes. The pistons are molded using a special process and composites to ensure extreme roundness while maintaining maximum stiffness and durability.

All the XLP2 shock parts are specifically designed for the smallest possible size to reduce the weight and keep the lowest possible CG.

Shock bodies are CNC-machined from premium Swiss 7075 T6 aluminum and hardened to ensure the maximum lifespan. The aluminum upper and lower nuts have a low-profile design, including sealing O-ring and upper composite ball joint. The shock shaft, shock adjustable nut, spring retainer and pivot balls are designed to achieve the lowest shock height possible.

The included shock pistons sets are 4-hole pistons with 1.1 and 1.2mm diameter holes. The pistons are molded using a special process and composites to ensure extreme roundness while maintaining maximum stiffness and durability.

Shock Holders.

Made possible by the shorter XLP2 shocks, new shock holders relocate the upper shock mount position 4mm than previously possible. The new geometry improves cornering speed, mid-corner steering and stability, and reduces traction rolling in high traction conditions.

The versatile shock holders use shims for adjusting the shock position in precise shock angle increments. The rear shock holder offers an Active or Fixed dampening setting in addition to the shock angle. All shocks are located 3mm lower, improving CG, cornering speed and stability, while also making the car easier to drive and more resistant to traction rolling.

Simplified shock mounting uses a captured mounting stud secured to the shock holder with a special setscrew. It is not necessary to use thread lock as the setscrew will keep the stud secure even during shock install/removal.

Made possible by the shorter XLP2 shocks, new shock holders relocate the upper shock mount position 4mm than previously possible. The new geometry improves cornering speed, mid-corner steering and stability, and reduces traction rolling in high traction conditions.

The versatile shock holders use shims for adjusting the shock position in precise shock angle increments. The rear shock holder offers an Active or Fixed dampening setting in addition to the shock angle. All shocks are located 3mm lower, improving CG, cornering speed and stability, while also making the car easier to drive and more resistant to traction rolling.

Simplified shock mounting uses a captured mounting stud secured to the shock holder with a special setscrew. It is not necessary to use thread lock as the setscrew will keep the stud secure even during shock install/removal.

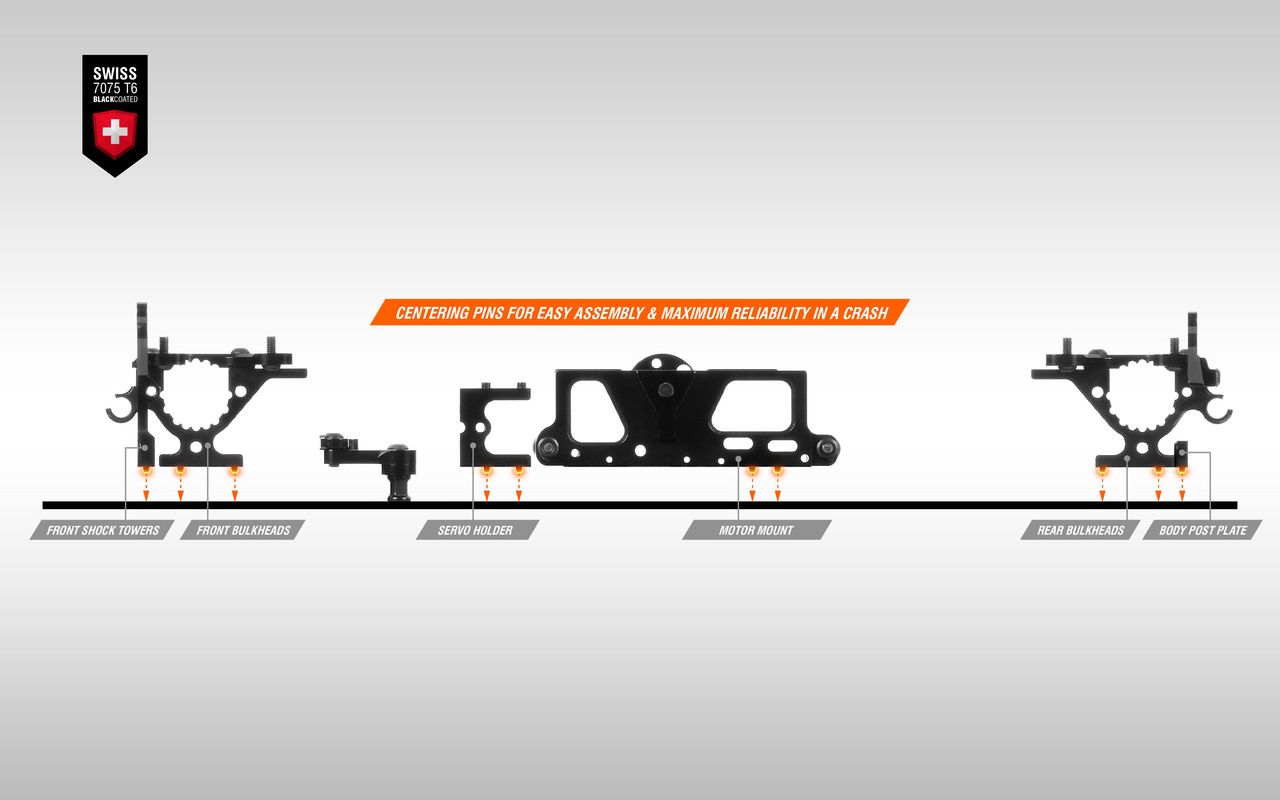

Servo Mount.

The new aluminum one-piece low CG servo holder can be mounted in 3 different configurations. The new mount uses fewer parts to lower CG and reduce weight.

There are three configurations for installing the servo mount to the chassis:

Front and Middle Screws – the most mechanical traction, best option for low- to medium traction tracks.

Middle and Rear Screws – reduced mechanical traction, best option for medium- to high traction tracks.

Front, Middle and Rear Screws – the stiffest setting, best option for any condition that requires maximum response.

The universal servo mount features centering pins for tweak-free assembly and maximum rigidity.

The new aluminum one-piece low CG servo holder can be mounted in 3 different configurations. The new mount uses fewer parts to lower CG and reduce weight.

There are three configurations for installing the servo mount to the chassis:

Front and Middle Screws – the most mechanical traction, best option for low- to medium traction tracks.

Middle and Rear Screws – reduced mechanical traction, best option for medium- to high traction tracks.

Front, Middle and Rear Screws – the stiffest setting, best option for any condition that requires maximum response.

The universal servo mount features centering pins for tweak-free assembly and maximum rigidity.

Servo Mount Alternatives.

Upper Link Arms.

The new adjustable link upper suspension arms provide expanded adjustability choices beyond those of the traditional CFF™ upper arms for maximum adjustability and improve handling in certain conditions. Including the CFF arms and the new link arms in the kit offers the driver the freedom of choice to expand the adjustment possibilities of their X4.

The upper link arms provide fully adjustable camber- and caster settings using 2 turnbuckles in each upper arm at all 4 corners.

The turnbuckles are connected using ball cups from durable composite materials.

The X4 Caster Gauges, #302390, are recommended for enhanced accuracy when building and adjusting the link arms.

The new adjustable link upper suspension arms provide expanded adjustability choices beyond those of the traditional CFF™ upper arms for maximum adjustability and improve handling in certain conditions. Including the CFF arms and the new link arms in the kit offers the driver the freedom of choice to expand the adjustment possibilities of their X4.

The upper link arms provide fully adjustable camber- and caster settings using 2 turnbuckles in each upper arm at all 4 corners.

The turnbuckles are connected using ball cups from durable composite materials.

The X4 Caster Gauges, #302390, are recommended for enhanced accuracy when building and adjusting the link arms.

Arms Comparison.

3D Printed Bumper.

Low-profile 3D printed rubber bumper is included in the kit for improved durability and airflow. The lightweight design contributes to a low CG and enhances the look of the car. The 3D printed rubber material has a longer life and much improved durability over a traditional foam front bumper.

Upper Bumper Brace.

The new one-piece low profile upper front bumper lowers CG and provides support to the chassis plate during a crash. Updated to match the new 3D printed rubber bumper, the new upper brace continues to provide protection during a crash and further improves the aesthetics of the car.

The composite front upper bumper brace protects against chassis damage in serious crashes by distributing the forces from a big impact to reduce the stresses on the chassis plate.

The new one-piece low profile upper front bumper lowers CG and provides support to the chassis plate during a crash. Updated to match the new 3D printed rubber bumper, the new upper brace continues to provide protection during a crash and further improves the aesthetics of the car.

The composite front upper bumper brace protects against chassis damage in serious crashes by distributing the forces from a big impact to reduce the stresses on the chassis plate.

Top Deck Shims.

All-new flex limiting top deck shims improve stability. The specially made steel shims can be fitted under the top deck flex screws for reduced flex. The shims provide an additional method to fine tune the car’s handling for different conditions. The shims can be used independently between the front and rear top decks.

Wheel Hubs.

Wider wheel hubs now included in the kit for the best all-around performance out of the box. The wider wheel hubs provide more forgiving handling with improved cornering speed & stability.

The included wheel hubs work with the SCS - Spring Clip System for simplified installation. The standard width hexes improve overall stability and allow for greater cornering speed with reduced aggressiveness.

Graphite composite front and rear hubs provide the proper suspension geometry for improved steering and traction. The hubs contain small size bearings and a drive axle that moves the driveshaft pivot point deep into the hub, in line with the hub’s rotational axis between the upper and lower arm. This alignment improves driveline efficiency and handling.

The ultra-narrow wheel hubs are lightened for reduced rotating mass.

The hubs allow full adjustability of the axle height to adapt the car to every condition.

The design of the hub is universal with the same part used at all four corners with corresponding extensions. The aluminum front steering plates and rear ARS plates are easily mounted depending on the hub’s location.

Wider wheel hubs now included in the kit for the best all-around performance out of the box. The wider wheel hubs provide more forgiving handling with improved cornering speed & stability.

The included wheel hubs work with the SCS - Spring Clip System for simplified installation. The standard width hexes improve overall stability and allow for greater cornering speed with reduced aggressiveness.

Graphite composite front and rear hubs provide the proper suspension geometry for improved steering and traction. The hubs contain small size bearings and a drive axle that moves the driveshaft pivot point deep into the hub, in line with the hub’s rotational axis between the upper and lower arm. This alignment improves driveline efficiency and handling.

The ultra-narrow wheel hubs are lightened for reduced rotating mass.

The hubs allow full adjustability of the axle height to adapt the car to every condition.

The design of the hub is universal with the same part used at all four corners with corresponding extensions. The aluminum front steering plates and rear ARS plates are easily mounted depending on the hub’s location.

Standard Features.

Some information shown below may include details from previous kits, and it may vary slightly from current kit specifications.

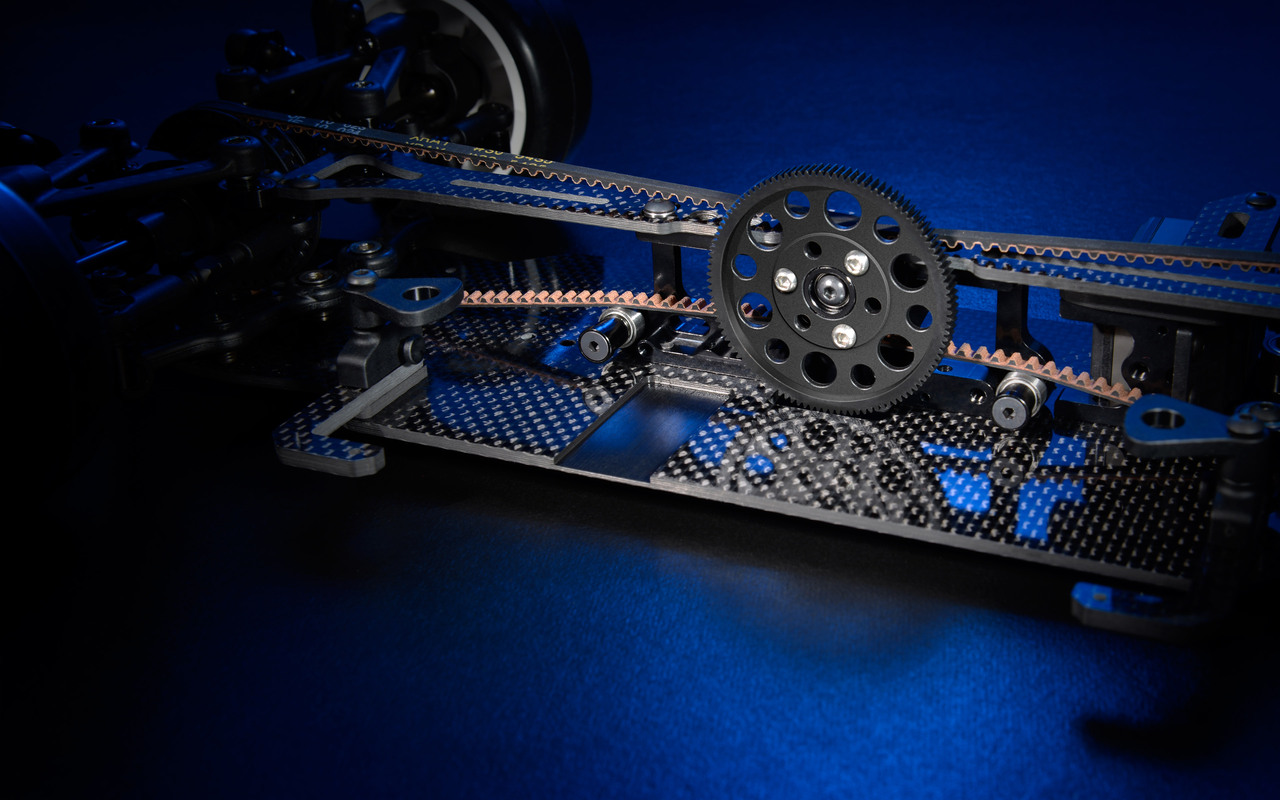

Chassis.

The chassis features a narrow design in the front center and rear center areas to eliminate chassis rub and improve cornering speed. The added material in the motor area extends overall chassis life. The chassis also features holes for the strong 3mm motor mount centering pins for improved durability and an extra forward motor mount screw position for black carpet.

The carbon adjustable battery holders are placed close to the chassis centerline so more material can be removed in the common chassis rub areas to improve cornering speed.

More material under the motor area improves the life of the chassis on the bumpy tracks while also improving chassis flex characteristics.

The motor mount features an extra front mounting point added for the high traction black carpet, improving the stability and consistency of the car in particular conditions.

The motor mount also features 3mm centering pins for exceptional durability in serious crashes.

The chassis features a narrow design in the front center and rear center areas to eliminate chassis rub and improve cornering speed. The added material in the motor area extends overall chassis life. The chassis also features holes for the strong 3mm motor mount centering pins for improved durability and an extra forward motor mount screw position for black carpet.

The carbon adjustable battery holders are placed close to the chassis centerline so more material can be removed in the common chassis rub areas to improve cornering speed.

More material under the motor area improves the life of the chassis on the bumpy tracks while also improving chassis flex characteristics.

The motor mount features an extra front mounting point added for the high traction black carpet, improving the stability and consistency of the car in particular conditions.

The motor mount also features 3mm centering pins for exceptional durability in serious crashes.

Chassis.

There are two chassis alternatives to choose from when selecting your X4’24:

The 2.2mm graphite chassis is CNC-machined from premium-grade material. This chassis is developed for all asphalt conditions. The narrow chassis is only 84mm wide with a variety of chassis flex adjustments that help to generate exceptional traction and give excellent steering characteristics.

The 2.0mm aluminum flex chassis is CNC-machined from premium Swiss 7075 T6 aluminum and then black coated. The narrow chassis is also 84mm wide and features special cut outs that provide the desired chassis flex characteristics. The bottom edge of the chassis is tapered to reduce contact between the chassis and the ground to improve cornering speed.

There are two chassis alternatives to choose from when selecting your X4:

The 2.2mm carbon chassis is CNC-machined from premium-grade material. This chassis is developed for all asphalt conditions. The narrow chassis is only 84mm wide with a variety of chassis flex adjustments that help to generate exceptional traction and give excellent steering characteristics.

The 2.0mm aluminum flex chassis is CNC-machined from premium Swiss 7075 T6 aluminum and then black coated. The narrow chassis is also 84mm wide and features special cut outs that provide the desired chassis flex characteristics. The bottom edge of the chassis is tapered to reduce contact between the chassis and the ground to improve cornering speed.

Top Deck.

2pcs split top decks are included in the kit to improve steering and traction in most conditions. The carbon version for asphalt tracks includes the open top deck in the front, the aluminum versions for carpet tracks feature the top deck with special wave shape connection in front that reinforces the flex of the front suspension without a completely rigid connection which improves stability and consistency.

The 2pcs top decks are reinforced around the motor mount screws area and the groove in the front top deck is thinner to add more material for improved durability.

The Multi-Flex™ top deck has a narrow shape for easier installation, improved handling characteristics and features several different flex options out of the box using top deck screws.

The machined ultra-precise top deck screws ensure the top deck is mounted completely tweak-free to improve the flex characteristics.

Made from 2.0mm carbon material, the shape of the top deck has been specifically designed to achieve maximum traction and great steering characteristics at the same time. Optional 1.6 top decks are available for low to medium traction carpet conditions.

2pcs split top decks are included in the kit to improve steering and traction in most conditions. The carbon version for asphalt tracks includes the open top deck in the front, the aluminum versions for carpet tracks feature the top deck with special wave shape connection in front that reinforces the flex of the front suspension without a completely rigid connection which improves stability and consistency.

The 2pcs top decks are reinforced around the motor mount screws area and the groove in the front top deck is thinner to add more material for improved durability.

The Multi-Flex™ top deck has a narrow shape for easier installation, improved handling characteristics and features several different flex options out of the box using top deck screws.

The machined ultra-precise top deck screws ensure the top deck is mounted completely tweak-free to improve the flex characteristics.

Made from 2.0mm carbon material, the shape of the top deck has been specifically designed to achieve maximum traction and great steering characteristics at the same time. Optional 1.6 top decks are available for low to medium traction carpet conditions.

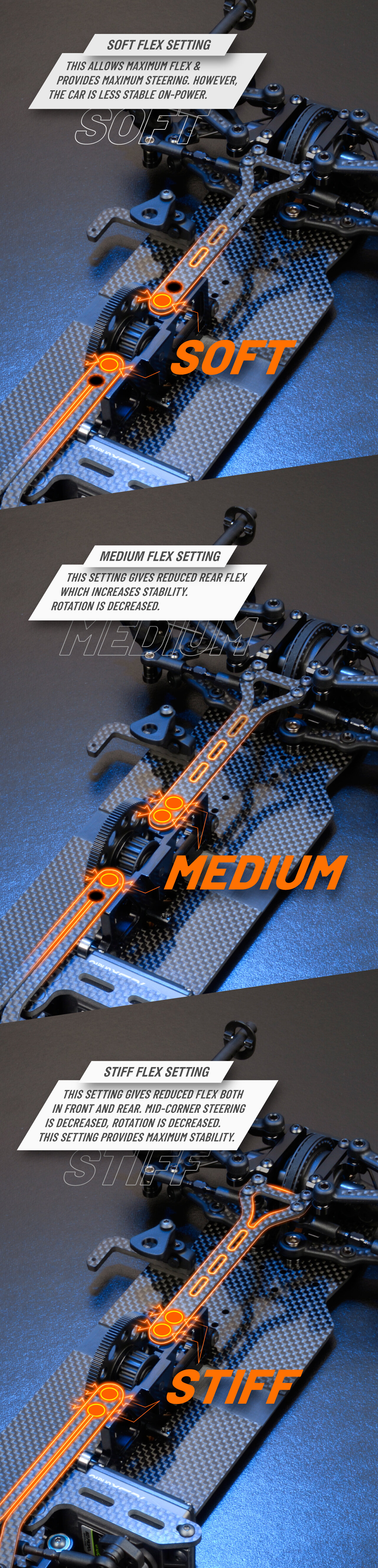

Top Deck Flex Settings.

The top deck flex settings allow quick and easy adjustment of chassis stiffness in 3 different alternatives.

Suspension.

The suspension components are designed with the proven inner shock position which feature an ultra-low CG. This configuration uses proven lower & upper arms, upper clamps & lower bulkheads, anti-roll bars, steering & ARS plates as well as shock holders.

Suspension Arms.

Upper & lower CFF™ suspension arms are the foundation for the inner shock mounting system with ultra-low under arm anti-roll bar mounts and efficient geometry. The suspension arms feature minimal flex and twist under dampening. With the shock mounted on the inside of the arm, the load is evenly distributed through the suspension arm, which maximizes the mechanical traction and responsiveness of the car.

The shock mounting location features an extremely low CG which improves cornering speed and stability. These features make the car easy to drive and resistant to traction rolling in high traction conditions. More centralized weight also improves tire wear and controls tire temperatures.

The CFF™ style of arms provide extremely responsive and sharp handling, generating great cornering speed & traction. The result is great drivability that is critical for improved lap times.

XRAY has specifically chosen different arm hardness to include in the carbon and aluminum versions of the X4 for the best possible out of the box performance on their intended surfaces.

X4 Carbon Edition include Medium suspension arms

X4 Aluminum Edition include Hard suspension arms

Upper & lower CFF™ suspension arms are the foundation for the inner shock mounting system with ultra-low under arm anti-roll bar mounts and efficient geometry. The suspension arms feature minimal flex and twist under dampening. With the shock mounted on the inside of the arm, the load is evenly distributed through the suspension arm, which maximizes the mechanical traction and responsiveness of the car.

The shock mounting location features an extremely low CG which improves cornering speed and stability. These features make the car easy to drive and resistant to traction rolling in high traction conditions. More centralized weight also improves tire wear and controls tire temperatures.

The CFF™ style of arms provide extremely responsive and sharp handling, generating great cornering speed & traction. The result is great drivability that is critical for improved lap times.

XRAY has specifically chosen different arm hardness to include in the carbon and aluminum versions of the X4 for the best possible out of the box performance on their intended surfaces.

X4 Carbon Edition include Medium suspension arms

X4 Aluminum Edition include Hard suspension arms

Inner Shock Mounting.

Inner shock mounting locations for optimized rolling characteristics & cornering consistency, as well as optimized flex and minimal twist under dampening. The front suspension has the shock position behind the drive shafts for a precise steering response and steering characteristics. The rear suspension has the shock position in front of the drive shafts for improved traction.

Rear Active Dampening Cornering Effect.

The rear shock holders offer Active or Fixed dampening setting alternatives. The Fixed setting is the traditional shock mounting method, while removing the M3x8 screw allow the Active holder bracket to pivot, softening the rear suspension dampening to improve off-power steering and increase rotation in high traction conditions.

Bulkheads.

The bulkheads integrate with the shock holders, as well as the ARS linkage mounting positions and rear body post holders. The anti-roll bars have a under arm mounting point for ultra-low CG. Both front & rear bulkheads include attachment points to secure the shock holder to the bulkhead to control flex characteristics.

The bulkheads use centering pins for easier positioning on the chassis and for increased rigidity and consistency.

The bulkheads feature two solid axle/diff height positions that were developed for different surfaces. The lower position is mainly designed for carpet, and the upper position is more common on asphalt. The anti-roll bar mounting position keeps the wire bar placed under the suspension arms for ultra-low CG.

Made from premium Swiss 7075 T6 aluminum, black anodized.

The bulkheads integrate with the shock holders, as well as the ARS linkage mounting positions and rear body post holders. The anti-roll bars have a under arm mounting point for ultra-low CG. Both front & rear bulkheads include attachment points to secure the shock holder to the bulkhead to control flex characteristics.

The bulkheads use centering pins for easier positioning on the chassis and for increased rigidity and consistency.

The bulkheads feature two solid axle/diff height positions that were developed for different surfaces. The lower position is mainly designed for carpet, and the upper position is more common on asphalt. The anti-roll bar mounting position keeps the wire bar placed under the suspension arms for ultra-low CG.

Made from premium Swiss 7075 T6 aluminum, black anodized.

Upper Clamps.

Heavy duty upper clamps feature exceptional durability in hard crashes and accommodate the inner shock mounting system.

The upper clamps use caster inserts for quick and easy set-up changes, and feature centering pins for precise installation and improved crash reliability.

The screws installed from the bottom of the caster inserts capture the inserts in the upper clamps to secure the inserts while servicing the car. The screws also serve as the upper arms pivot ball mounts, reducing the number of components in the assembly and reducing weight.

The upper clamps and caster inserts are made from premium Swiss 7075 T6 aluminum and black anodized.

Redesigned heavy duty upper clamps improve durability in hard crashes and accommodate the new inner shock mounting system.

The upper clamps use caster inserts for quick and easy set-up changes, and feature centering pins for precise installation and improved crash reliability.

The screws installed from the bottom of the caster inserts capture the inserts in the upper clamps to secure the inserts while servicing the car. The screws also serve as the upper arms pivot ball mounts, reducing the number of components in the assembly and reducing weight.

The upper clamps and caster inserts are made from premium Swiss 7075 T6 aluminum and black anodized.

Heavy duty upper clamps feature exceptional durability in hard crashes and accommodate the inner shock mounting system.

The upper clamps use caster inserts for quick and easy set-up changes, and feature centering pins for precise installation and improved crash reliability.

The screws installed from the bottom of the caster inserts capture the inserts in the upper clamps to secure the inserts while servicing the car. The screws also serve as the upper arms pivot ball mounts, reducing the number of components in the assembly and reducing weight.

The upper clamps and caster inserts are made from premium Swiss 7075 T6 aluminum and black anodized.

Motor Mount.

The motor mount features 3mm centering pins for maximum durability in serious crashes. The motor mount features an extra forward attachment point developed for US black carpet, improving the stability and consistency of the car in these high traction conditions.

A cutout provides additional clearance for speed controller wiring that improves the look and cleanliness of the electronics installation. The top deck mounting holes’ depth is reduced to allow top deck to have an improved flex effect.

The new motor mount features 3mm centering pins instead of 2mm, for improved durability in serious crashes. The motor mount features an extra front attachment point developed for US black carpet, improving the stability and consistency of the car in these high grip conditions.

A new cutout provides additional clearance for speed controller wiring that improves the look and cleanliness of the electronics installation.

The top deck mounting holes’ depth is reduced to allow top deck to have an improved flex effect.

The motor mount features 3mm centering pins for maximum durability in serious crashes. The motor mount features an extra forward attachment point developed for US black carpet, improving the stability and consistency of the car in these high traction conditions.

A cutout provides additional clearance for speed controller wiring that improves the look and cleanliness of the electronics installation. The top deck mounting holes’ depth is reduced to allow top deck to have an improved flex effect.

Motor Mount Flex Adjustment.

The motor mount is a vital part of the X4 Multi-Flex settings. The motor mount attaches to the chassis using various combinations of five possible screw locations. Two are placed in front of the layshaft axis and the other three screws are located to the rear. Up to four screws can be removed for chassis flex adjustment.

Steering & ARS Plates.

Updated front & rear steering plates work with the new arms and shock positions.

The new steering plates move the Ackermann position further out for more precise car control and make the X4’24 easier to drive.

The ARS plates move the toe link mounting position further forward for improved rotation in high traction conditions.

Anti-roll Bars.

The ultra-low CG anti-roll bars are attached from below the suspension arms with considerably reduced mounting hardware and material. The wobble-free anti-roll bar height is easily & comfortably adjusted via set screw from the top of the arm.

The ultra-low CG anti-roll bars are attached from below the suspension arms with considerably reduced mounting hardware and material. The wobble-free anti-roll bar height is easily & comfortably adjusted via set screw from top of the arm.

The included anti-roll bars were chosen specifically for the typical conditions found when using the graphite and aluminum versions of the X4’24 for the best possible performance out of the box.

X4’24 Graphite Edition includes 1.2mm front and rear anti-roll bars.

X4’24 Aluminum Edition includes 1.3mm front and 1.2mm rear anti-roll bars.

The anti-roll bar pivots in ball-bearings for maximum precision and free movement.

The complete range of different anti-roll bar thicknesses is designed to work with the ball-bearing roll bar mounting system.

Anti-roll bars have laser-engraved stripes (corresponding to bar thickness) for easy identification.

ECS BB Drive Shafts.

Our unique ECS system uses a redesigned drive shaft case with a C clip groove to secure the new aluminum pin retainer. Thanks to this system, no set screws are needed to capture the coupler pins, making the ECS assemblies easier and more convenient to assemble, and more reliable. The driveshaft service life is increased as the pins float freely in the joints, ensuring smoother rotation and improved cornering speed.

Rear Body Mounting System.

Extra thick 4mm carbon rear body post holder features maximum durability and stability from the minimal body post flex. The body post holder features 6 holes with 1.1mm spacing for the rear body posts plus a second bulkhead mounting position between the 1.1mm spacing for easier and more precise mounting of horizontal rear body posts. The higher position also accommodates the taller body post heights needed with common VTA bodies.

Body posts can be installed in a traditional vertical position or the popular horizontal orientation on the body post holder for a different feel on the track. The carbon fiber holder is machined from a strong 4mm thick material and is directly connected to the rear bulkheads.

Extra thick 4mm carbon rear body post holder features maximum durability and stability from the minimal body post flex. The body post holder features 6 holes with 1.1mm spacing for the rear body posts plus a second bulkhead mounting position between the 1.1mm spacing for easier and more precise mounting of horizontal rear body posts. The higher position also accommodates the taller body post heights needed with common VTA bodies.

Body posts can be installed in a traditional vertical position or the popular horizontal orientation on the body post holder for a different feel on the track. The carbon fiber holder is machined from a strong 4mm thick material and is directly connected to the rear bulkheads.

Battery Holders.

The X4 features a tweak-free, fully adjustable Quick Battery Mounting System. The Quick Battery Mounting System offers simple and secure battery installation without tape and without adverse effects on chassis flex.

The system controls the positioning of the pack in the chassis while at the same time reducing the battery pack’s impact on chassis flex, resulting in more consistent handling and stability.

Smart battery holders are specifically designed for LiPo batteries and are reinforced for harder impacts. The battery holders prevent the batteries from moving under racing conditions and crashes.

The X4 features a tweak-free, fully adjustable Quick Battery Mounting System. The Quick Battery Mounting System offers simple and secure battery installation without tape and without adverse effects on chassis flex.

The system controls the positioning of the pack in the chassis while at the same time reducing the battery pack’s impact on chassis flex, resulting in more consistent handling and stability.

Smart battery holders are specifically designed for LiPo batteries and are reinforced for harder impacts. The battery holders prevent the batteries from moving under racing conditions and crashes.

Designing the X4.

Watch video >

Designing the X4.

Watch video >

Making of the X4.

Watch video >

Making of the X4.

Watch video >

XRAY X4 - It's out there.

CFF™ Arms.

The unique CFF™ upper & lower suspension arms are an elegant engineering achievement that look great and perform even better on the track. Using XRAY’s own newly developed manufacturing process, a carbon fiber arm and composite arm are molded together using a fusion process to produce a single CFF™ suspension arm.

The benefits of the CFF™ arms are tremendous. The thickness of the inner carbon fiber plate determines the hardness and flex of the arm. The composite around the carbon helps control its flex and rebound, resulting in a very consistent feel from corner to corner.

Medium and hard versions are available to tune the X4 handling to different track conditions.

CFF™ Arms.

Unique CFF™ - Carbon Fiber Fusion upper & lower suspension arms for outstanding handling.

The unique CFF™ upper & lower suspension arms are an elegant engineering achievement that look great and perform even better on the track. Using XRAY’s own newly developed manufacturing process, a carbon fiber arm and composite arm are molded together using a fusion process to produce a single CFF™ suspension arm.

The benefits of the CFF™ arms are tremendous. The thickness of the inner carbon fiber plate determines the hardness and flex of the arm. The composite around the carbon helps control its flex and rebound, resulting in a very consistent feel from corner to corner.

Medium and hard versions are available to tune the X4 handling to different track conditions.

Suspension Mounting.

This direct mounting eliminates unwanted play between these extra components. Most importantly, the reliability and accuracy of the direct mounting ensure that settings remain consistent during a run even after a crash.

Suspension Mounting.

Thanks to the unique design of the CFF™ arms, all the suspension components are mounted directly on the arm without additional brackets, bushings or extensions. This direct mounting eliminates unwanted play between these extra components. Most importantly, the reliability and accuracy of the direct mounting ensure that settings remain consistent during a run even after a crash.

Suspension Mounting.

All suspension components mount directly to the CFF™ arms without additional parts, eliminating play between pieces to ensure accuracy and reliability.

Thanks to the unique design of the CFF™ arms, all the suspension components are mounted directly on the arm without additional brackets, bushings or extensions. This direct mounting eliminates unwanted play between these extra components. Most importantly, the reliability and accuracy of the direct mounting ensure that settings remain consistent during a run even after a crash.

Spring Clip System.

The all-new SCS – Spring Clip System allows for super easy, fast and simplified assembly of the ECS drive shaft with no set screws. Now it takes just one click to assembly or disassembly the drive shaft and you can forget about the hassle with the set screws and thread lock. Smart & easy.

Spring Clip System.

The all-new SCS – Spring Clip System allow for super easy, fast and simplified installation of the wheel hubs on the drive shafts. Now it takes just one click to install or remove the wheel hub and you can forget about the hassle with the outer C-clips. Smart & easy.

Spring Clip System.

The all-new SCS – Spring Clip System allow for super easy, fast and simplified installation of the wheel hubs on the drive shafts. Now it takes just one click to install or remove the wheel hub and you can forget about the hassle with the outer C-clips. Smart & easy.

Rear Hub Height Adjustment.

The kit includes two different pivot ball lengths of 5.5mm and 6.5mm for different rear hub height adjustments. The 6.5mm long pivot ball with 1mm extra thread length is suggested when using more than a 0.5mm hub height shim to improve the durability of the rear hub in serious crashes.

XLP Shock Springs.

All-new XLP series of springs are 3mm shorter to match the new shock length and provide the correct rates and ride height. They are available in a full range of rate choices including 2 new alternatives of the progressive springs C2.4-2.7 and C2.6-2.9.

The X4’23 stock shock springs offer versatile out of box performance for many conditions. The most popular C2.5-2.8 in front and C2.6 in rear are included in the kit.

All XRAY springs are manually measured, selected, and matched into pairs to guarantee precisely equal length and damping characteristics.

The included XLP series of springs are 3mm shorter than the ULP ones, to match the XLP shock length and provide the correct rates and ride height. They are available in a full range of rate choices including 3 alternatives of progressive springs C2.4-2.7, C2.5-2.8 and C2.6-2.9.

The X4’24 stock shock springs offer versatile out of box performance for many conditions. The most popular C2.5-2.8 in front and C2.6 in rear are included in the kit.

All XRAY springs are manually measured, selected, and matched into pairs to guarantee precisely equal length and damping characteristics.

Caster.

The most frequently used 2 dot caster inserts are included for the front, with the 3 dot inserts for the rear.

Aluminum inserts easily set the caster angle for quick and accurate tuning, and in the rear suspension, the inserts can be reversed for even more adjustment possibilities.

Gear Differential.

The gear differential includes steel diff outdrives for the BB drive shafts. The X4 gear diff produces the on-power steering that is needed on nearly all types of tracks, and is ideal for both carpet and asphalt tracks.

The gear diff includes a composite case and cover with the integrated pulley. The internal gears are precision molded from tough composite material and combined with aluminum drive shaft adapters to create a light and super-smooth differential.

Another key advantage of the gear diff is that it is virtually maintenance-free. When the diff is correctly built, there is no need for maintenance for a very long time… no need for frequent oil changes, and no leakage due to the superior sealing system.

The gear differential includes steel diff outdrives for the BB drive shafts. The X4 gear diff produces the on-power steering that is needed on nearly all types of tracks, and is ideal for both carpet and asphalt tracks.

The gear diff includes a composite case and cover with the integrated pulley. The internal gears are precision molded from tough composite material and combined with aluminum drive shaft adapters to create a light and super-smooth differential.

Another key advantage of the gear diff is that it is virtually maintenance-free. When the diff is correctly built, there is no need for maintenance for a very long time… no need for frequent oil changes, and no leakage due to the superior sealing system.

Solid Axle.

The solid axle features steel diff outdrives for BB drive shafts.

Solid axle pulley position has the front belt alignment to match the center layshaft for improved consistency and forward traction.

Battery Backstops.

The X4 motor mount has two integrated and adjustable battery backstops to precisely set the battery offset from the center of the car. The battery backstop system is designed for use with the increasingly common shorty batteries as well as standard packs.

The battery backstops prevent the batteries from moving in a crash and interfering with the spur gear on the center layshaft.

Battery Backstops.

Integrated battery backstops for standard and shorty packs set the battery position to adjust weight balance and prevent interference with the spur gear.

The X4 motor mount has two integrated and adjustable battery backstops to precisely set the battery offset from the center of the car. The battery backstop system is designed for use with the increasingly common shorty batteries as well as standard packs.

The battery backstops prevent the batteries from moving in a crash and interfering with the spur gear on the center layshaft.

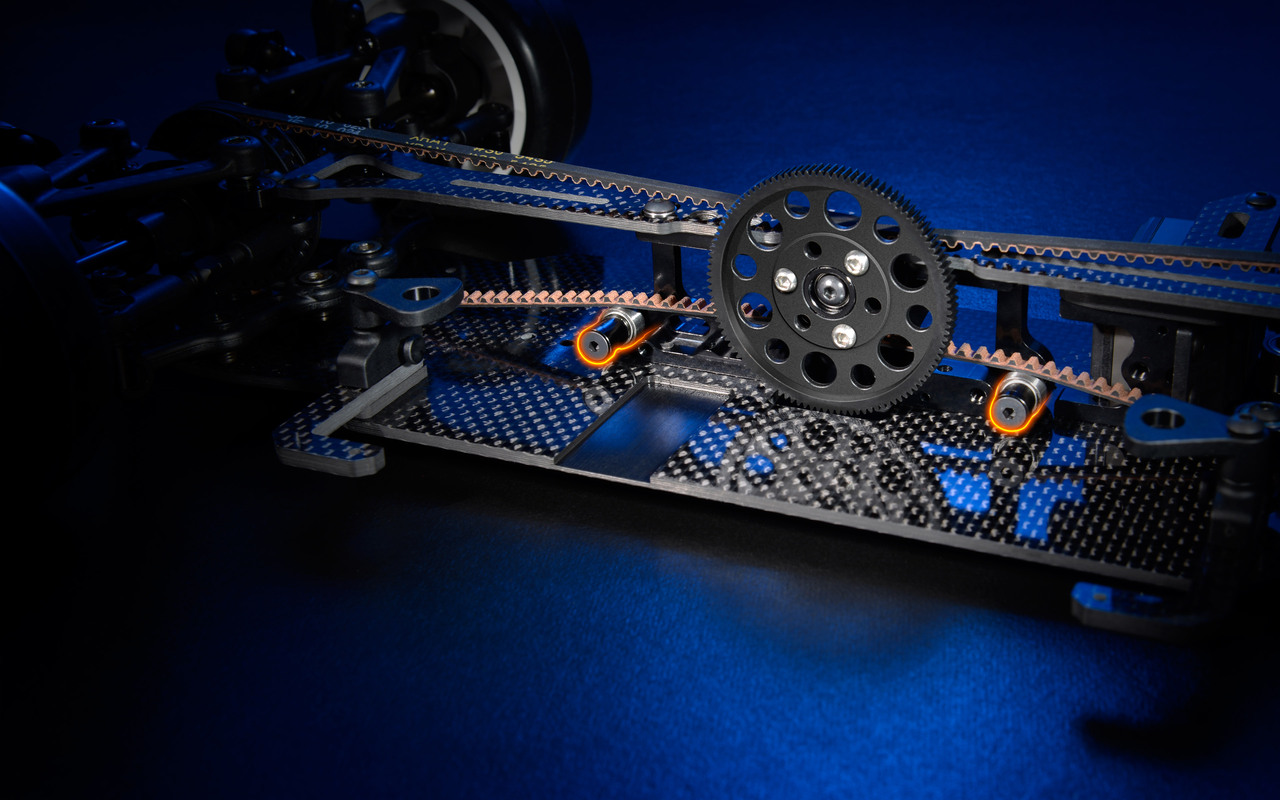

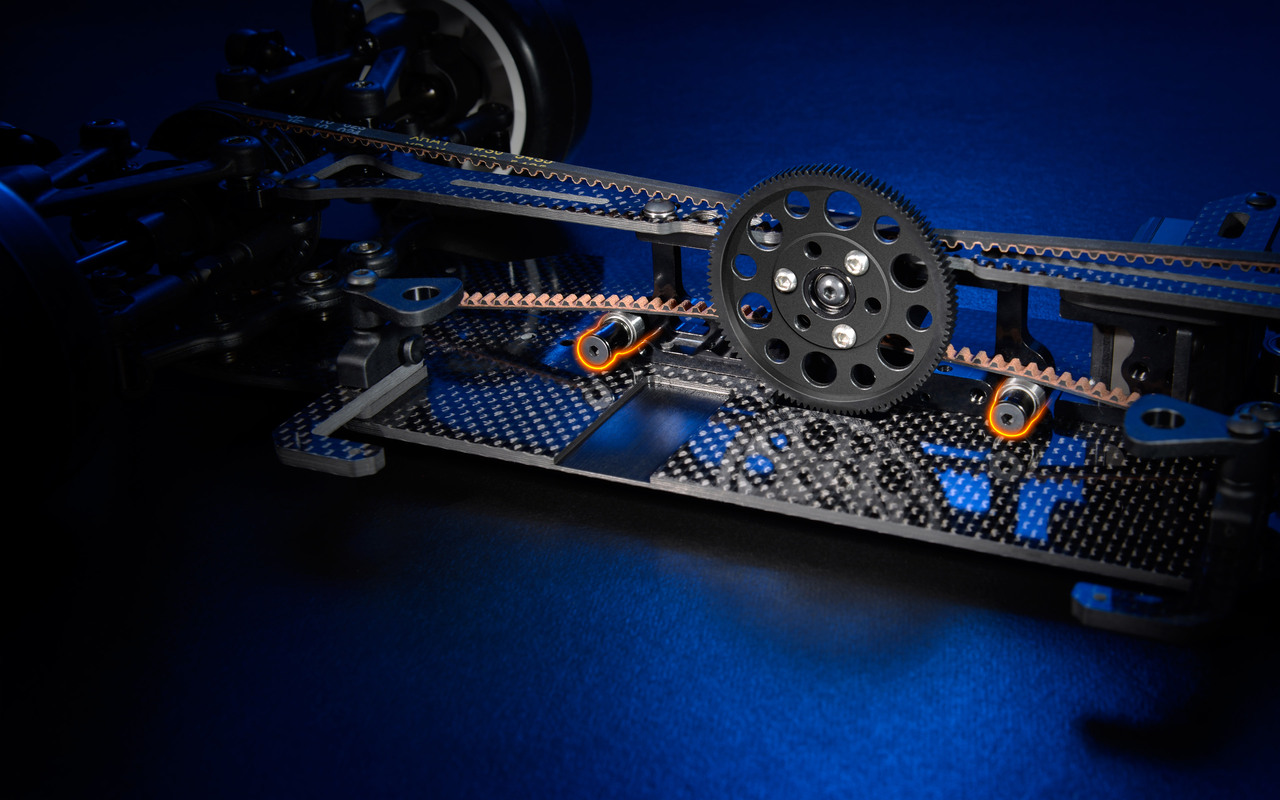

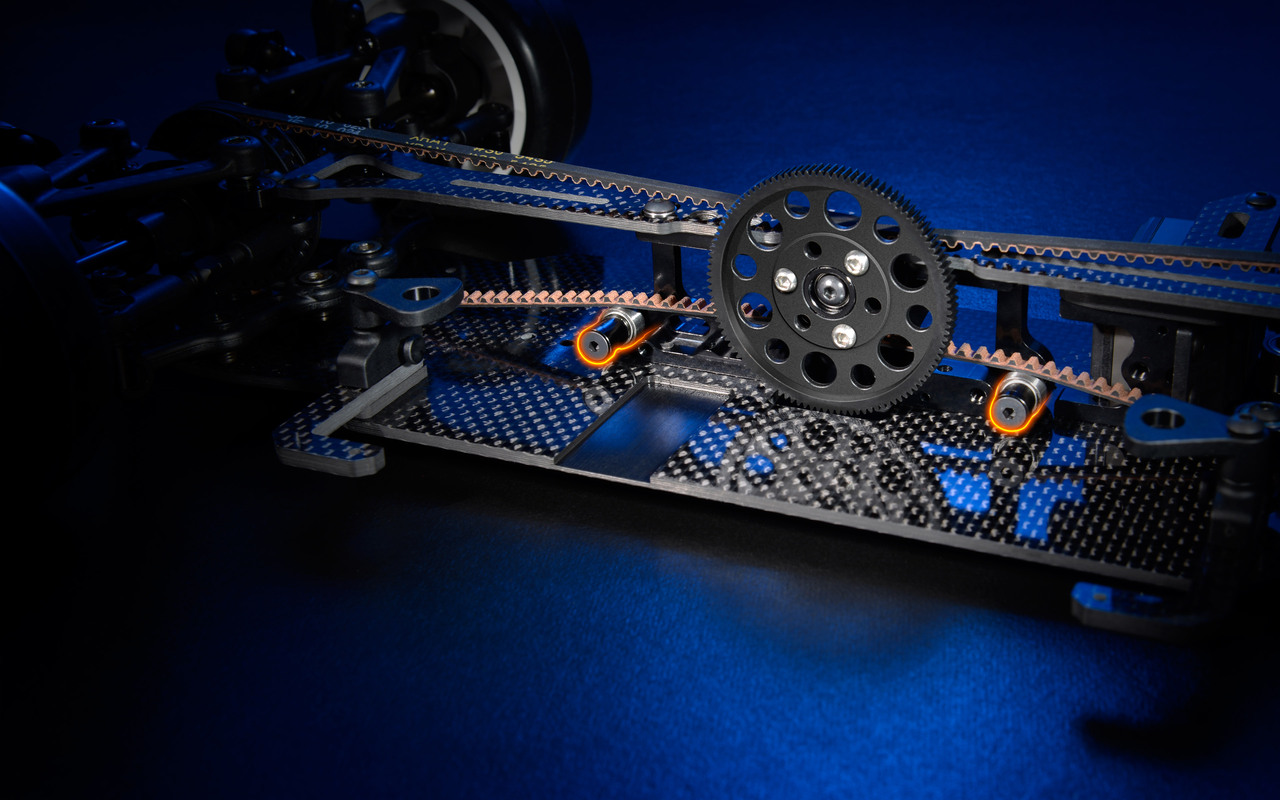

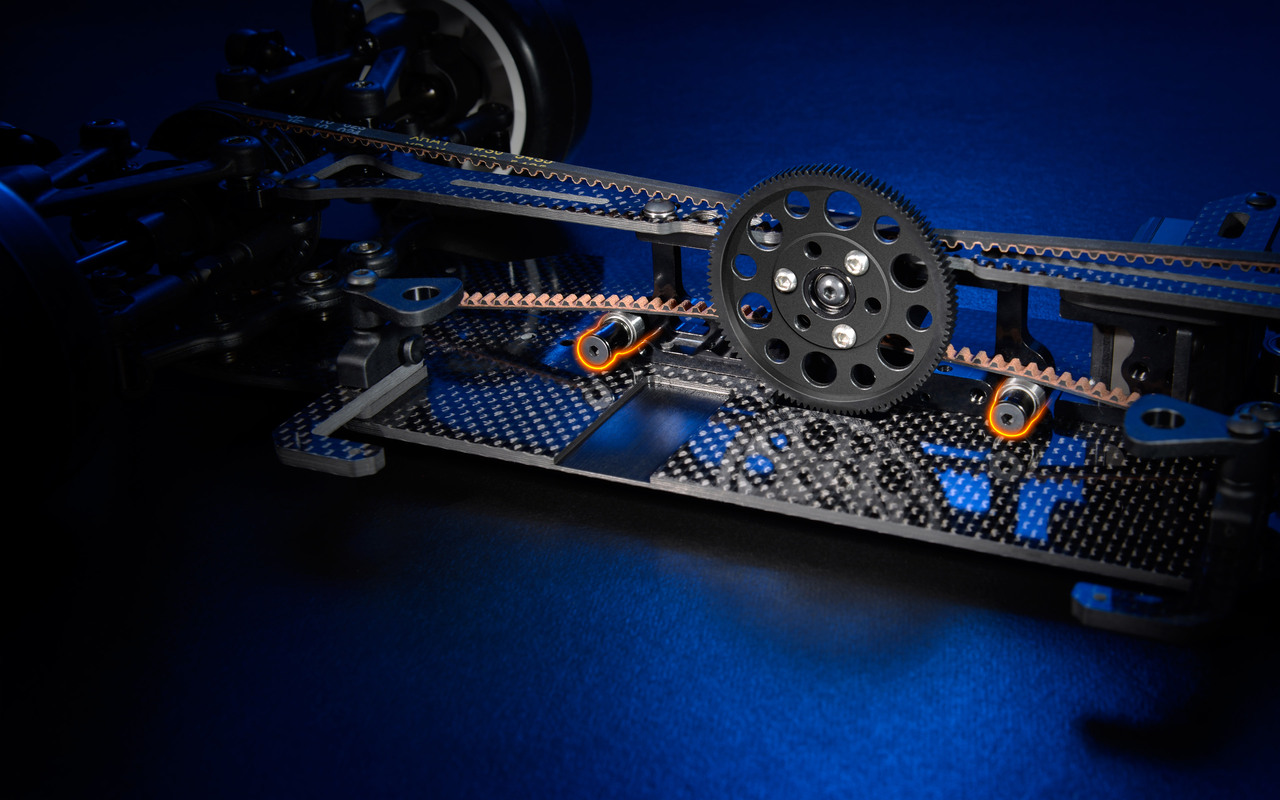

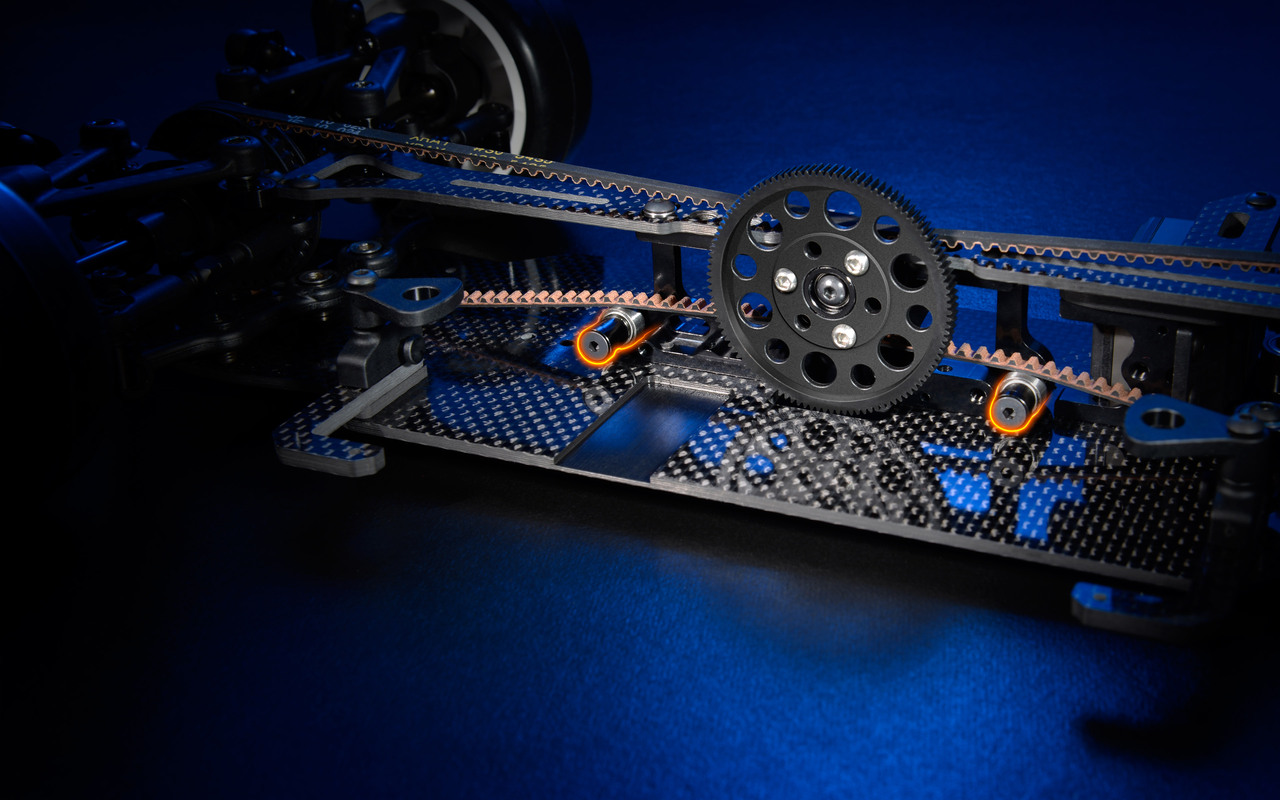

Belt Tensioners.

For maximum drive train efficiency there are two ball-bearing equipped belt tensioners integrated in the motor mount’s battery backstop components. The two tensioners are individually adjustable to control the tension of the front and rear belts independently.

Belt Tensioners.

Adjustable tensioners ensure proper belt adjustment for maximum drive train efficiency.

For maximum drive train efficiency there are two ball-bearing equipped belt tensioners integrated in the motor mount’s battery backstop components. The two tensioners are individually adjustable to control the tension of the front and rear belts independently.

Middle Layshaft.

The all-new aluminum layshaft is strategically CNC-machined to minimize rotating weight without compromising strength or integrity. The hollow layshaft is perfectly round with zero run out, reducing drivetrain vibration.

The lay shaft is machined from premium Swiss 7075 T6 aluminum and then black coated.

The composite belt pulleys key solidly to the layshaft, and the completed assembly is installed onto the motor mount’s steel layshaft axle.

Middle Layshaft.

The super-lightweight hollow aluminum layshaft eliminates drivetrain vibration.

The all-new aluminum layshaft is strategically CNC-machined to minimize rotating weight without compromising strength or integrity. The hollow layshaft is perfectly round with zero run out, reducing drivetrain vibration.

The lay shaft is machined from premium Swiss 7075 T6 aluminum and then black coated.

The composite belt pulleys key solidly to the layshaft, and the completed assembly is installed onto the motor mount’s steel layshaft axle.

Motor Mount -Brass Weights Nickel Couted

Motor Mount Brass Weight.

Smart design of the motor mount includes locations to install optional #309852 nickel coated brass weights specifically designed to fit around the driveline components and place the weight near the vehicle center.

Centering Pins.

All chassis mounted aluminum framework parts including the bulkheads, motor mount, servo holder, front shock towers and rear body post plates feature centering pins for easy assembly and maximum reliability in a crash.

Centering Pins.

All chassis mounted aluminum framework parts including the bulkheads, motor mount, servo holder, front shock towers and rear body post plates feature centering pins for easy assembly and maximum reliability in a crash.

Spur Gears & Pulleys.

Precision-molded spur gears are made from XRAY's exclusive composite material, ensuring true running, super-quiet operation, and robustness for handling powerful motors. A range of optional spur gears for fine tuning is available.

Spur Gears & Pulleys.

Precision-molded spur gears are made from XRAY's exclusive composite material, ensuring true running, super-quiet operation, and robustness for handling powerful motors. A range of optional spur gears for fine tuning is available.

Steering System.

The X4 steering system is designed for the best possible steering characteristics and cornering speed. The steering plate has optimized positions for the links and sits close to the chassis. The steering posts are short to reduce the flex in the steering system for more precise reactions to inputs. The steering system also features a shim on the bottom of the plate for easy adjustment of the steering lock angle. The aluminum steering arms are included as standard in each X4 kit.

The dual-arm steering system is supported by six ball-bearings and rotates on aluminum posts. Ackermann is easily adjusted by inserting shims between the steering plate and ball ends for the steering rods. The low position of the steering linkage gives the car improved handling going through the corners.

Steering System.

The steering system of the X4 has a responsive and precise feel from the low steering plate with efficient geometry, short posts, integrated adjustable steering lock and the included aluminum steering arms.

The X4 steering system is designed for the best possible steering characteristics and cornering speed. The steering plate has optimized positions for the links and sits close to the chassis. The steering posts are short to reduce the flex in the steering system for more precise reactions to inputs. The steering system also features a shim on the bottom of the plate for easy adjustment of the steering lock angle. The aluminum steering arms are included as standard in each X4 kit.

The dual-arm steering system is supported by six ball-bearings and rotates on aluminum posts. Ackermann is easily adjusted by inserting shims between the steering plate and ball ends for the steering rods. The low position of the steering linkage gives the car improved handling going through the corners.

T-Brace.

The X4 bulkheads have added centering pins for easier positioning on the chassis and for increased rigidity and consistency.

The new bulkheads offer an upper diff position that is higher than possible on previous models for improved handling in higher traction conditions resulting in better cornering speed and steering. The anti-roll bar mounting position keeps the wire bar placed under the drive shafts for a super low CG.

The bulkheads feature milled grooves for the ball bearing hubs so the bulkheads can sit 1mm closer to the chassis center line from each side.

The bulkheads are connected by a graphite brace in front and shock tower in rear for added stiffness.

Made from premium Swiss 7075 T6 aluminum, black anodized

T-Brace.

The optional T-brace mounts to the chassis just in front of the rear suspension and makes the car more stable, generates more rear traction, and allows for some chassis flex adjustments to alter steering characteristics by adding and removing screws from the brace.

Servo Saver.

The XRAY servo saver has become the industry-standard saver and remains unchanged and is included in each X4 kit.

Several linkage mounting positions are offered to make the steering linkage adjustment easier. The servo saver consists of 4 springs which makes the servo saver strong enough to provide the precise steering racers demand, while still being flexible enough to prevent servo damage in hard crashes. The servo saver has interchangeable bushings to fit most popular servos.

Servo Saver.

The popular XRAY servo saver that has become the industry-standard saver is included in the X4 kit for precise steering & sufficient flexibility to prevent servo damage in serious crashes.

The XRAY servo saver has become the industry-standard saver and remains unchanged and is included in each X4 kit.

Several linkage mounting positions are offered to make the steering linkage adjustment easier. The servo saver consists of 4 springs which makes the servo saver strong enough to provide the precise steering racers demand, while still being flexible enough to prevent servo damage in hard crashes. The servo saver has interchangeable bushings to fit most popular servos.

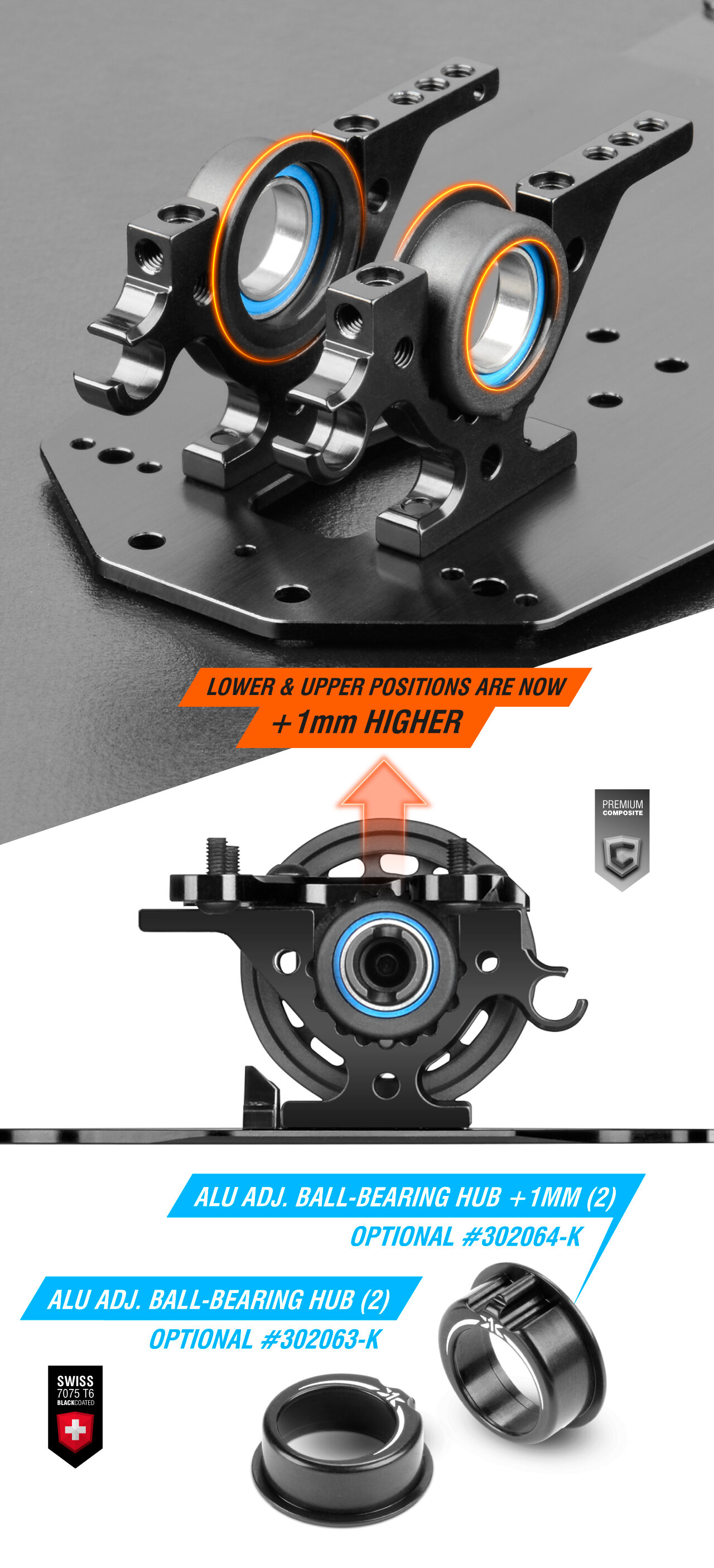

Bearing Holders.

Both front and rear bulkheads feature additional integrated belt-tension adjustment through the use of adjustable bearing eccentric holders. These holders are also reversible to move the differential height from the lower or upper position that is now +1mm higher than the T4 platform.

Special Hardware.

To ensure maximum performance, the X4's high-precision pivot balls are machined in-house and then black coated or nickel coated for a smooth and long lasting finish. To maintain proper balance through every run, the in-house machined top deck screws ensure tweak free handling from start to finish.

Special Hardware.

To ensure maximum performance, the X4's high-precision pivot balls are machined in-house and then black coated or nickel coated for a smooth and long lasting finish. To maintain proper balance through every run, the in-house machined top deck screws ensure tweak free handling from start to finish.

Drive Belts.

The 2-belt 4WD drivetrain concept provides maximum efficiency featuring 3mm narrow front and rear drive belts that have been specially ground for minimal thickness and maximum flexibility.

Drive Belts.

The 2-belt 4WD drivetrain concept provides maximum efficiency featuring 3mm narrow front and rear drive belts that have been specially ground for minimal thickness and maximum flexibility.

Ball-Bearings.

A full set of 25 high-speed, blue-sealed and steel ball-bearings are used throughout the drivetrain, steering and anti-roll bars to ensure maximum efficiency. All of the bearings are degreased and oiled with Aero Shell® Fluid 12 for maximum smoothness and long life. The bearings used in steering blocks and uprights have been specially selected to reduce unsprung weight and maximize drivetrain efficiency.

Ball-Bearings.

A full set of 25 high-speed, blue-sealed and steel ball-bearings are used throughout the drivetrain, steering and anti-roll bars to ensure maximum efficiency.

A full set of 25 high-speed, blue-sealed and steel ball-bearings are used throughout the drivetrain, steering and anti-roll bars to ensure maximum efficiency. All of the bearings are degreased and oiled with Aero Shell® Fluid 12 for maximum smoothness and long life. The bearings used in steering blocks and uprights have been specially selected to reduce unsprung weight and maximize drivetrain efficiency.

Silicone Oils.

HUDY Exclusive Silicone Oils are manufactured in Europe and each batch is laboratory tested and calibrated to ensure the highest possible consistency and quality from batch to batch. Based on the industry-standard cSt rating, the new line of oils will be easy to identify, adjust, and feel.

When following any set-up sheets by XRAY or XRAY team drivers, you can be sure that the oils you will get for your car are exactly same as those used by the factory racing team, thus ensuring very exacting set-ups and handling.

Silicone Oils.

HUDY Exclusive Silicone Oils are manufactured in Europe and each batch is laboratory tested and calibrated to ensure the highest possible consistency and quality from batch to batch. Based on the industry-standard cSt rating, the new line of oils will be easy to identify, adjust, and feel.

When following any set-up sheets by XRAY or XRAY team drivers, you can be sure that the oils you will get for your car are exactly same as those used by the factory racing team, thus ensuring very exacting set-ups and handling.

Chassis Balance.

The chassis features pre-drilled holes for additional weights for optimum car balancing and centerline holes for easy balancing with the HUDY Chassis Balancing Tool #107880.

Chassis Balance.

The chassis features pre-drilled holes for additional weights for optimum car balancing and centerline holes for easy balancing with the HUDY Chassis Balancing Tool #107880.

Adjustment Possibilities.

The extensive and impressive range of adjustment possibilities includes: ARS (Active Rear Suspension™), caster, camber, toe, anti-dive, anti-squat, ride height, downstops, track-width, lower roll center, upper roll center, roll center positions, steering roll center, wheelbase, Ackermann, steering lock, bumpsteer, belt-tension adjustment, adjustable shocks, adjustable in-line flex adjustment, adjustable front chassis flex, diff height and adjustable diff.

Adjustment Possibilities.

The extensive and impressive range of adjustment possibilities includes: ARS (Active Rear Suspension™), caster, camber, toe, anti-dive, anti-squat, ride height, downstops, track-width, lower roll center, upper roll center, roll center positions, steering roll center, wheelbase, Ackermann, steering lock, bumpsteer, belt-tension adjustment, adjustable shocks, adjustable in-line flex adjustment, adjustable front chassis flex, diff height and adjustable diff.

Tech Tip Videos.

To get the finest tips & tricks on how to build the X4 or to learn more about each of the set-up options, follow the series of XRAY X4 Tech Tip videos featuring Alexander Hagberg. The videos walk through each section of the building process with suggested assembly techniques, demonstrations, and detailed explanations of the various setup adjustments.

Tech Tip Videos.

To get the finest tips & tricks on how to build the X4 or to learn more about each of the set-up options, follow the series of XRAY X4 Tech Tip videos featuring Alexander Hagberg. The videos walk through each section of the building process with suggested assembly techniques, demonstrations, and detailed explanations of the various setup adjustments.

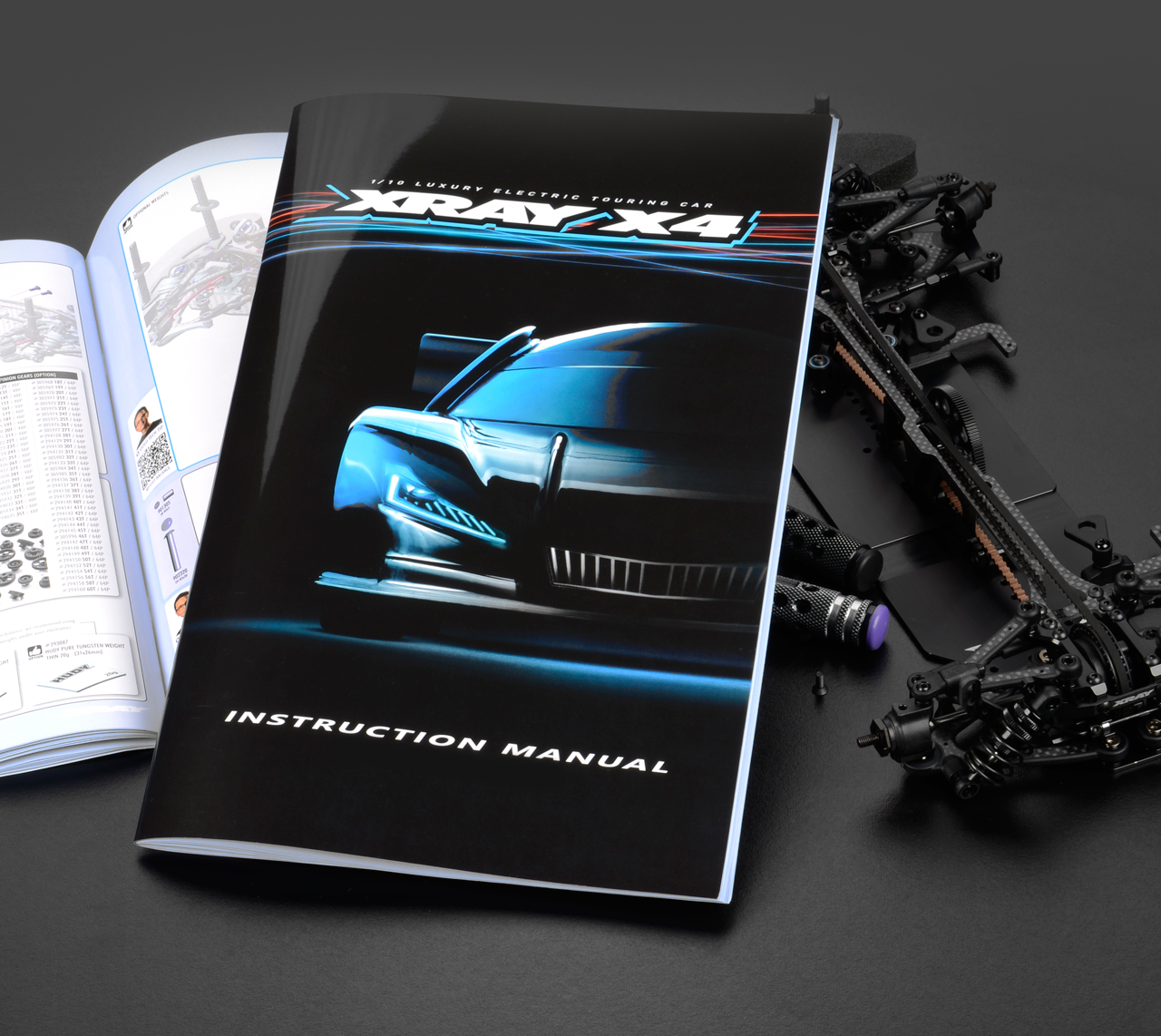

XRAY Instruction Manual.

XRAY instruction manuals have become the industry standard, being simply the best manuals you will ever get with an RC model car. Whether you are a first-time builder or an experienced racer, all the instructions are straight-forward and easy to understand. The full-color Instruction Manual contains large 3D illustrations that show all assembly details in the clearest possible way.

XRAY Instruction Manual.

XRAY instruction manuals have become the industry standard, being simply the best manuals you will ever get with an RC model car. Whether you are a first-time builder or an experienced racer, all the instructions are straight-forward and easy to understand. The full-color Instruction Manual contains large 3D illustrations that show all assembly details in the clearest possible way.

XRAY VIP Customer Treatment.

Not only will you own the most premium luxury model racing car in the world, but you will also become a member of the prestigious family of XRAY owners with direct support and service from the XRAY factory. XRAY brings you the most up-to-date RC Web site on the Internet, with daily racing news and latest product developments.

If you have any questions, problems or comments, you can ask the XRAY Support Team or any XRAY Factory Team Driver on the XRAY Tech Talk groups. You can even upload your own set-up sheets or download from the thousands of different set-up sheets available from all around the world at the exclusive XRAY Virtual Set-up Sheet Database, the world’s largest set-up sheet database. And that is only the start of the VIP treatment you get by joining Team XRAY.

XRAY VIP Customer Treatment.

Owning an XRAY model racing car is an experience on its own. Get the VIP customer treatment.

Not only will you own the most premium luxury model racing car in the world, but you will also become a member of the prestigious family of XRAY owners with direct support and service from the XRAY factory. XRAY brings you the most up-to-date RC Web site on the Internet, with daily racing news and latest product developments.

If you have any questions, problems or comments, you can ask the XRAY Support Team or any XRAY Factory Team Driver on the XRAY Tech Talk groups. You can even upload your own set-up sheets or download from the thousands of different set-up sheets available from all around the world at the exclusive XRAY Virtual Set-up Sheet Database, the world’s largest set-up sheet database. And that is only the start of the VIP treatment you get by joining Team XRAY.

Ready to win.