All-new 2019:

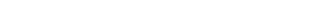

- All-in-one concept featuring front motor & mid motor build options included in the kit

- Includes both laydown and standup parts sets: gearboxes, motor upper brace, alu motor mounts, gear box idler gears, shock towers, rear roll center holders, gear covers and battery holders

- All-new shorter chassis for improved weight balance and improved traction

- All-new ultra-smooth ball diff increases traction & life time

- All-new multi-function rear upright helps to generate more traction & increase stability

- All-new longer rear arms for increased traction and consistency

- All-new RR suspension holder is compatible with both the new long arms and standard XB2 rear arms

- All-new longer rear driveshafts with 2.5mm pins for smoother operation

- All-new battery holder shifts electronics closer to the rear for better weight distribution in front motor configuration

- All-new 2-pads slipper for improved traction in low bite situations

- All-new Alpha 2 body for increased traction & stability

- All-new rear wing for increased traction

- Includes hard front steering block to improve handling

- Includes new rear wheels with deeper recess for wheel nuts

- Includes new composite chassis front guard from Hard material that increase stability of the car

- Includes new shorter composite front chassis side braces and soft graphite chassis guards

- Includes hard front suspension arms suitable for medium & high traction

- Includes hard front upper deck that makes the car more precise

- New greased ball-bearings for front steering blocks and rear uprights increase lifespan in dusty conditions.

- Revised shock absorber lower shims for more precise shock shaft movement

XB2 Concept.

The XB2 is distinctively XRAY – a premium, professional, high competition R/C car for the most demanding racers, developed with attention to the smallest details and backed by premium service & support…a luxury masterpiece.

Junior World Champion.

At the World’s most competitive off-road race – the World Championship, it was XRAY’s Daniel Kobbevik who brought the first Junior World Champion title to the XB2 platform. Tested and successfully run in the highest competition races now you can enjoy the winning platform.

Made in Europe.

USA Champion.

XRAY’s Ty Tessmann achieved the first ROAR National Championship for the XB2. Enjoy the same winning platform that is tested and proven at the highest levels of competition.

Precision.

The fit and finish of the XB2 needs to be experienced to truly appreciate the differences from the competition. Designed and manufactured using some of the world’s best CAD tools, machining and molding technology, and top-quality materials, XRAY sets the highest standards for ease of assembly, component tolerances and a premium build experience.

Racing Team.

Successful development of the XB2 – like all other XRAY platforms – would not have been possible without the involvement of the entire racing team working the entire year to test new ideas, prototypes, and improvements. The racing team travels to all major races around the world to provide XRAY drivers with first-class support & service so they can be assured that they always get 1st class treatment as part of the XRAY team.

All-in-One Concept.

New All-In-One concept offers great setup versatility to find the best configuration for any track condition. When grip is low, the mid motor position shifts weight to the rear tires for increased rear traction and stability. When track conditions improve and grip is up, the front motor position lowers CG and moves weight forward for increased steering and better corner speed.

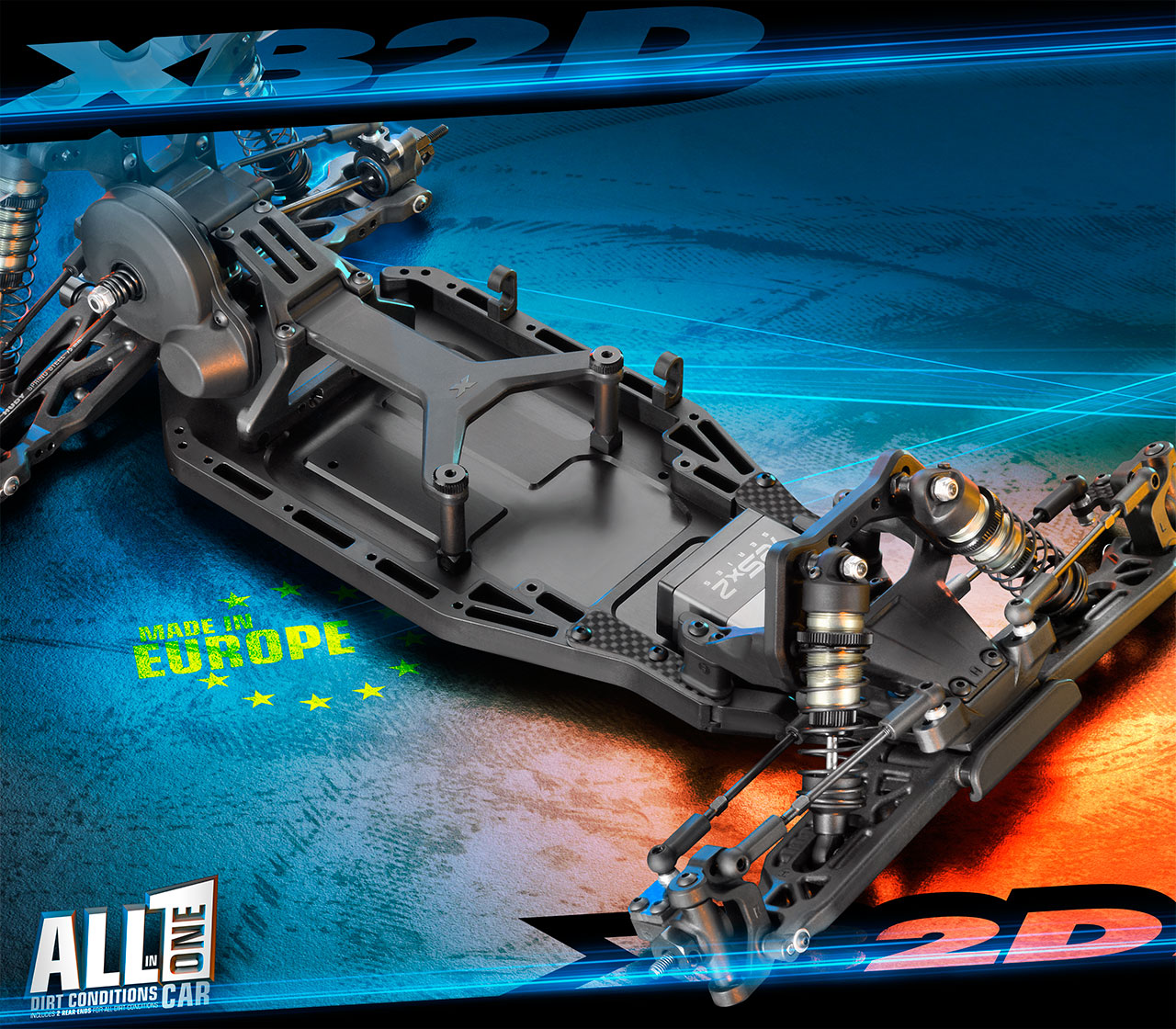

Gear Box.

The XB2D lets the user choose the perfect configuration for their needs. The stand-up transmission of the mid motor configuration for lower traction, and the laydown transmission for higher grip conditions.

Gear Box Gears.

Both idler gears are included to complete the transmission assemblies. A 36T graphite gear for the front motor build and a 25T graphite gear for the mid motor build. The 4 gear configuration is available only for the mid motor gear box.

Motor Plate.

The XB2D includes both motor plates for the front and mid motor gearbox configurations.

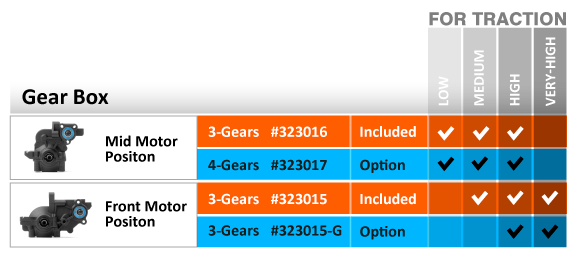

Shock Towers.

A graphite rear shock tower for front motor and composite tower for mid motor are included in each XB2D.

Both are specially design to have maximum performance for each gearbox.

Roll Center Holder.

Roll center holders for both front and mid motor position configurations are included.

Battery Strap.

Changing transmission configurations also allows moving the electronics to alter weight distribution. Both battery straps are included to keep the pack secured in all situations.

Spur Gear Covers.

Both gear covers are included for safety and to protect the transmission gears from debris.

Chassis.

The new XB2D chassis was shortened to increase grip on lower traction surfaces. The chassis is machined from 2.5mm Swiss 7075 T6 aluminum. The precision milling allows the chassis to create the desired flex and rigidity characteristics without sacrificing strength, while also reducing the vehicle weight. The chassis is then coated at XRAY’s own in-house robotic coating line.

Ball Differential.

The redesigned XB2 ball differential offers improved performance, durability, and easier maintenance. The externally-adjustable ball differential is machined from HUDY Spring Steel™ and is additionally hardened for extra durability and long lifespan. A high-quality carbide thrust bearing and carbide balls are included for ultra-smooth operation. Includes outdrive adapters designed for use with drive shafts with 2.5mm pin.

Slipper Clutch.

All new 2-pad slipper assembly offers smoother engagement for improved traction during acceleration. The stronger spring improves the consistency and ease of adjustment. An optional slipper eliminator is available to reduce rotating mass for improved throttle response in stock class racing when the slipper is not needed for traction assistance.

Multi-Adjustable Rear Suspension.

All-new rear suspension features the new adjustable rear upright design, longer CVD drive shafts, and longer rear camber link. The new system offers a huge range of roll center tuning adjustments for different track conditions.

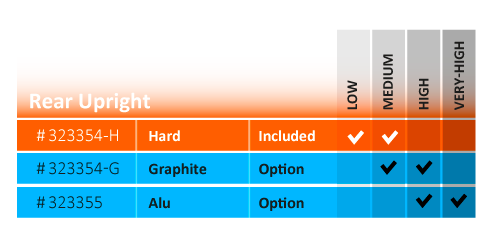

Rear Uprights.

All-new rear uprights feature multiple set-up options for upper & lower roll centers. The upper roll center is adjusted at the camber linkage via shims (up/down & in/out), while the lower roll center is adjustable via eccentric inserts for 9 different positions (up/down & in/out).

The multi-function uprights have the upper roll center position in the middle of axis of the connecting joint of the drive shaft to help generate more traction and increase stability.

There are three different uprights available: hard (included), graphite (optional), and aluminum (optional), each suitable for particular track conditions.

Drive Shafts.

To accommodate the new, fully-adjustable rear uprights and ball differential, the drive shaft length is increased to 75mm.

The XB2 driveshafts are manufactured from world-renowned HUDY Spring Steel™ and feature 2.5mm drive pins for maximum drivetrain efficiency. The drive shafts are some of the world‘s thinnest yet most durable drive shafts used in electric off-road cars. Treated with a proprietary hardening process, the drive shafts provide unbeatable lifespan and reliability.

Camber Link.

With the multiple roll center adjustment possibilities, the rear turnbuckle is longer to accommodate all the different camber link position alternatives.

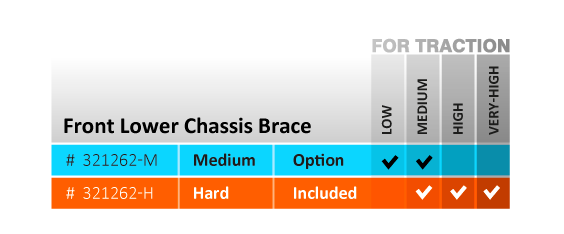

Chassis Brace.

The XB2D now includes the Hard front lower chassis brace for improved handling and consistency.

Side Guard Brace.

To improve front chassis flex, the front composite chassis braces were redesigned and shortened to allow for mounting all-new graphite side guard braces for better stability and performance.

Upper Deck.

As a part of the Multi-Flex™ system, the front upper deck is used to adjust chassis flex. There are two different upper decks available – medium (optional) and hard (included). The harder material makes the car more predictable and forgiving on the track.

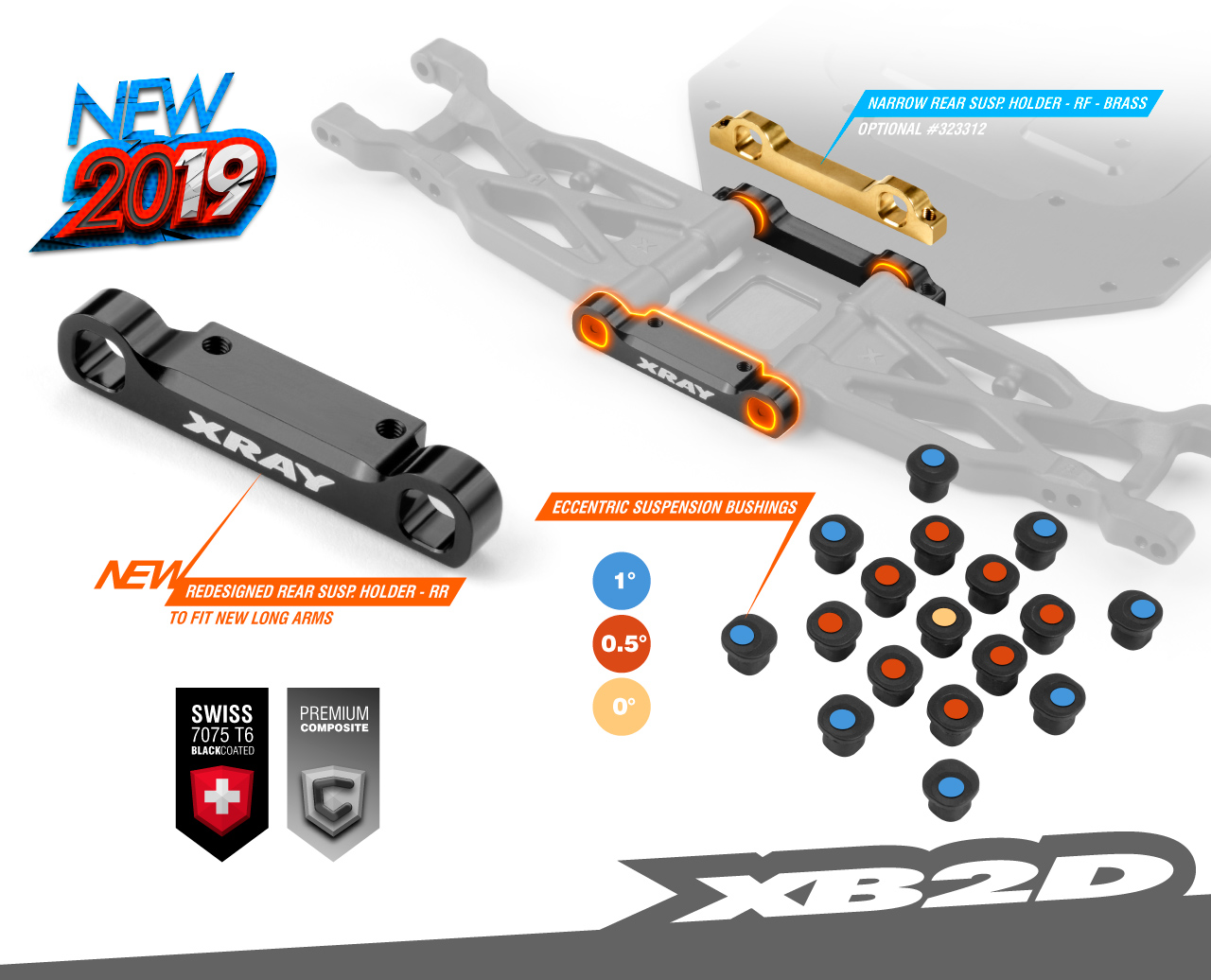

Integrated Suspension Settings.

The updated RR suspension holder fits both the new longer rear arms and standard arms for maximum tuning options.

The aluminum suspension holders feature Integrated Suspension Settings (I.S.S.™) which allows for quick & easy suspension geometry set-up.

Changing the position and shape of the included eccentric suspension bushings in the suspension holders, and adjusting the roll center shims and turnbuckle lengths, the XB2 suspension geometry is completely adjustable.

Suspension Arms.

The all-new longer, rear arms update the rear geometry for better consistency and improved handling.

There are two different rear suspension arms available: hard (included) and graphite (optional), each suitable for particular track conditions.

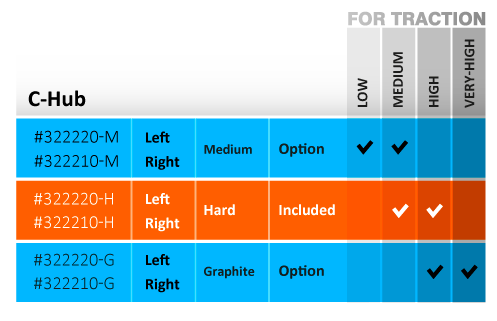

Caster Blocks.

The caster blocks are very lightweight, yet their construction makes them very stiff & rigid. The caster can be adjusted with values 0°, 2.5° or 5° by using included caster bushings.

There are three different caster blocks available – medium (option), hard (included) and graphite (option) – which are suitable for various track conditions.

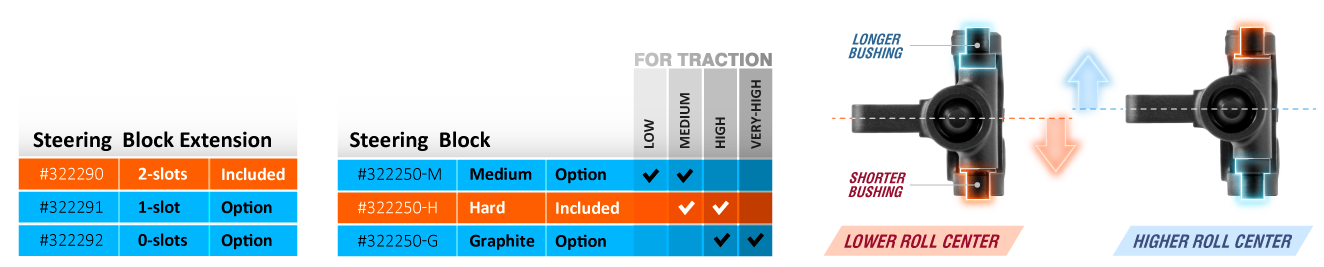

Steering Blocks.

The tiny yet tough steering blocks are comprised of composite steering blocks and graphite Ackermann extensions for variable Ackermann positions.

The composite blocks are molded from a special composite mixture for maximum strength.

There are three different steering blocks available – medium (option), hard (included) and graphite (option) – which are suitable for various track conditions.

Shocks.

To improve the precision of the shock shaft movement, the front composite shim was redesigned and updated with a more accurate mould design.

Well-built, reliable shock absorbers are extremely important for super-smooth suspension action on any type of track. The shocks on the XB2 have been specifically designed to be built easily, perform consistently, and last reliably. Careful attention was paid to the smallest details during the design process, as well as during long-term testing in various conditions.

Downstop is adjusted using composite shims under the pistons. Upstop travel is adjusted using composite shims under the shock collar.

Shock rods are machined from special steel material, precision hand-ground for maximum smooth operation, and additionally hardened for improved lifespan.

Wheel Hubs.

The XB2D comes equipped with offset hexes to perfectly match the width of the car with the new suspension arms and hubs.

Ultra-lightweight 12mm wheel hex drive hubs are CNC-machined from Swiss 7075 T6 black-coated aluminum. These ultra-true hex hubs have a clamping design which ensures ultra-solid mounting of the wheel on the hub.

To adjust track-width, optional offset wheel hex drive hubs are available.

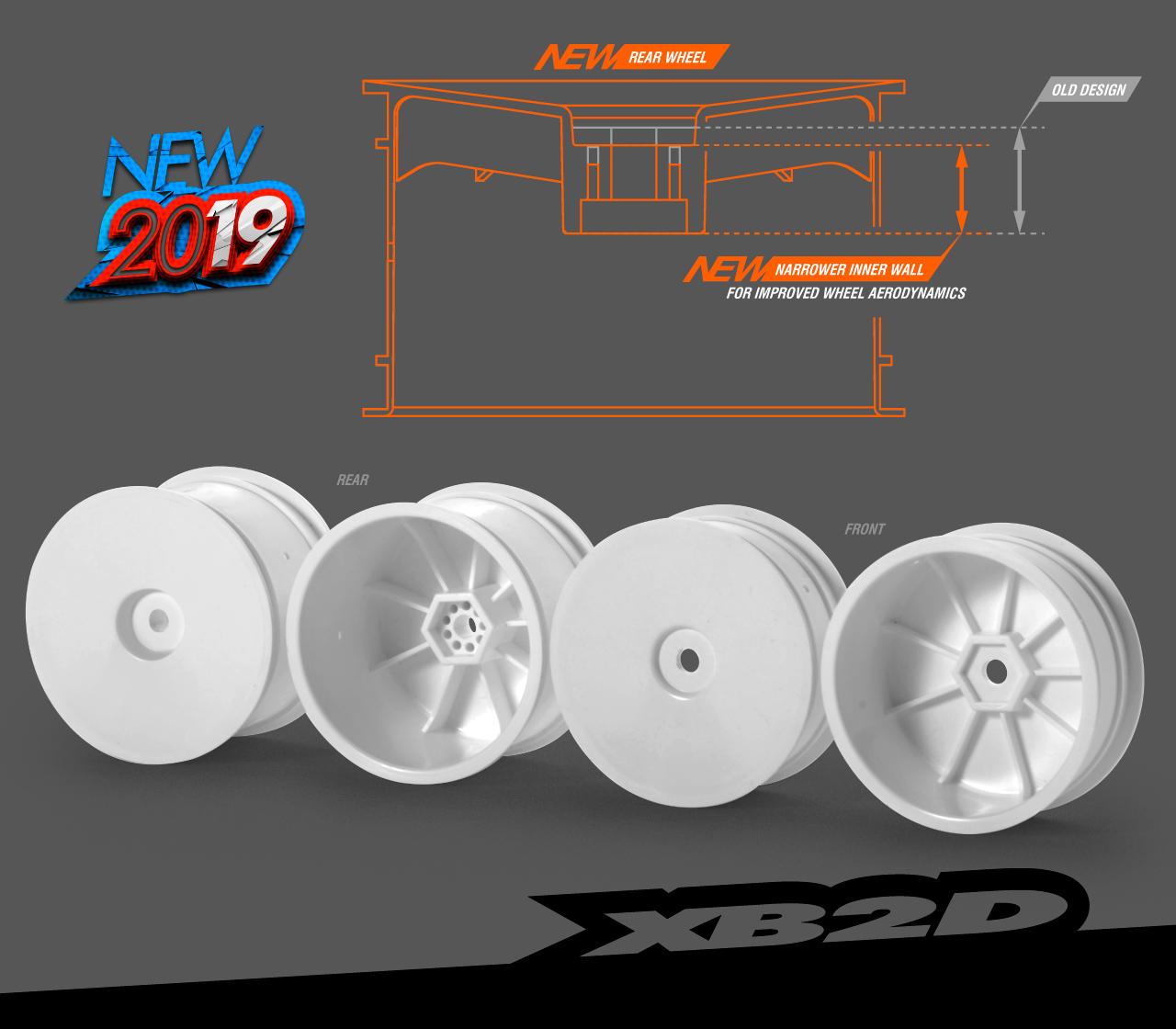

Wheels.

The included XB2 wheels feature a new, redesigned countersunk center area to allow the wheel nut to be positioned further into the wheel.

The wheels are perfect for high-competition racing. The wheels are made from a very flexible material, while still being ultra-durable to withstand impacts. The side of the wheel is aerodynamic for maximum performance. The wheels were designed to provide maximum traction.

Internal reinforcement ribs make the wheels as stable as possible and eliminate deformation. The wheels feature a 12mm internal hex.

Body.

The new high-performance Alpha 2 body was designed to increase downforce. This body generates 50% more grip then previous versions, which improves handling on low traction. The body is made from high-quality premium Lexan™ material.

The optional Beta 2 body is available for situations when less downforce is needed.

Rear Wing.

The stylish and effective rear wing was designed to have maximum rear grip on low grip tracks, and work perfectly with the XRAY XB2 body. Made from strong Lexan™ material, the wing is secured by the extended surfaces of the wing mounts and wing buttons to better support and extend the life of the wing.

Optional front Lexan™ wing (#323512) is used to generate front downforce and is mounted directly on the front.

Ball-bearings.

The XB2D features greased ball-bearings for front steering blocks & rear uprights to increase lifespan in dusty conditions. The remaining bearings are degreased and oiled with AeroShell® Fluid 12 for maximum smoothness and long life.

A full set of 22 high-speed ball-bearings are used throughout the drivetrain to ensure maximum efficiency.

Philosophy.

At the heart of XRAY's philosophy is a firm commitment to perfection when it comes to engineering, design, performance and support, all made possible by state-of-the-art in-house manufacturing. The XB2 is the epitome of perfection that is typical for XRAY.

Dipl. Eng. Juraj Hudy

XRAY Chief Designer

Commitment.

After 3 years of extensive development and testing in all track conditions (including carpet, astro turf, and dirt) we have released one of the best-performing 2WD 1/10 off-road car. Since that day we have remain committed to our goal to improving our products by continuous development and testing to ensure that you always get the best-performing XB2 straight out of the box.

Martin Bayer

XRAY XB2 Designer

Making Of.

The 3 years of development of the XB2 were full of blood, sweat, and tears, and certainly the most challenging yet rewarding years of my life. During those few years, my understanding of RC cars grew and expanded to a whole new level with all-new R&D knowledge and experiences that I am sure will help XRAY further develop our off-road platforms.

Read my exclusive story about Making of the XB2 to get a small glimpse of the challenges I went through to make this project a reality.

Martin Bayer

XRAY XB2 Designer - European Champion

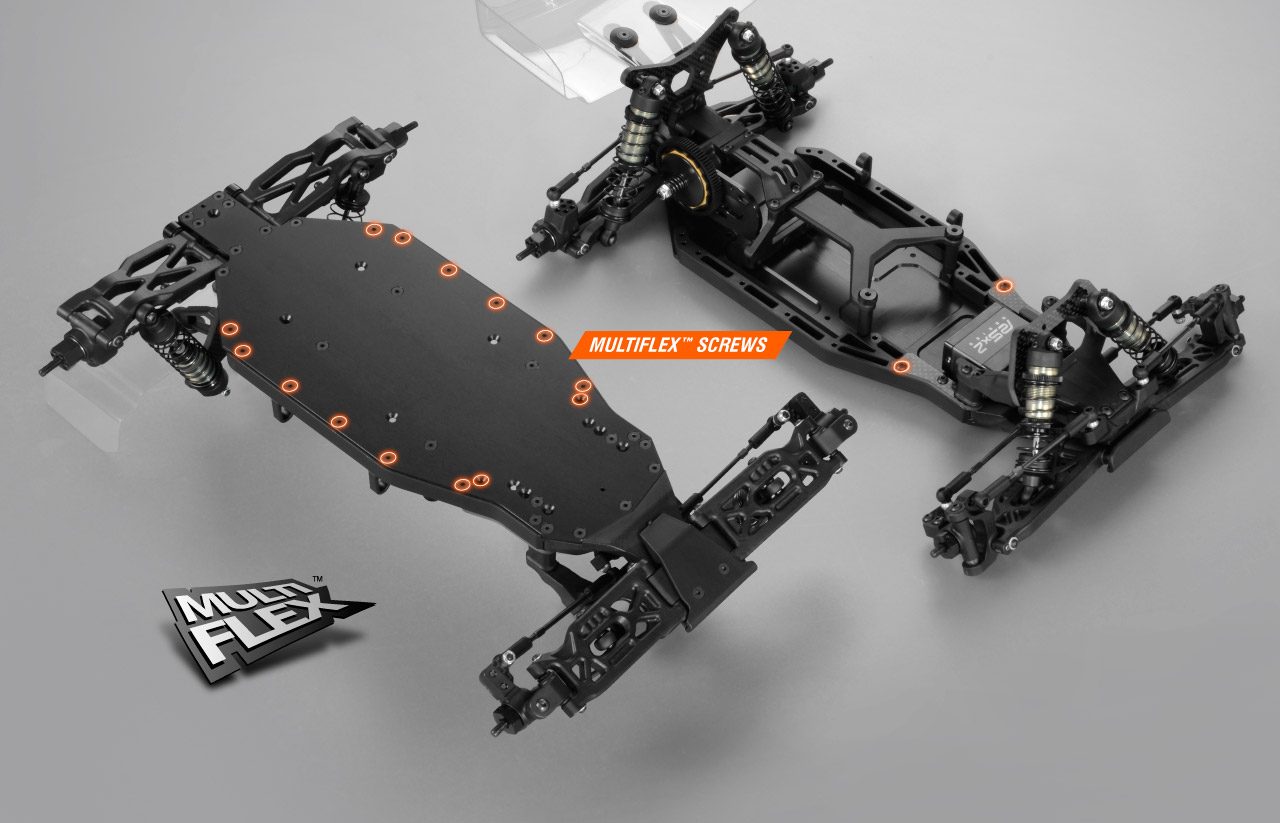

Chassis Multi-Flex™.

The milled grooves increase flex to generate more traction, and make the car more forgiving.

The invention of XRAY Multi-Flex Technology™ has resulted in some of the most significant milestones in RC model car development in the last decade. This innovation has not only resulted in awards and accolades, but has proven to be a distinct competitive advantage at tracks worldwide to help XRAY cars dominate races at local and national levels.

The XB2 incorporates Multi-Flex™ adjustment technology, which allows tuning the chassis flex for different track conditions.

Regardless if the track has low, medium, or super-high traction, you can adjust the chassis flex to suit track conditions to gain a distinctive advantage.

Multiple Servo Position.

To allow for more precise weight balance adjustment, the servo position is adjustable either more rearwards or frontwards; there are 3 positions to choose from.

When the servo is moved rearwards, there is more weight on the rear and less weight on the front. This results in less diving into a corner, while increasing rear traction. Recommended for low- and medium-traction conditions.

When the servo is moved more frontwards, there is more weight on the front and less weight at the rear. This increases the diving effect but reduces rear traction. Recommended for high- and very-high traction conditions.

Steering System.

The dual-arm steering system is very simple yet effective. The steering system is fully bearing-equipped with 8 high-speed ball-bearings for very precise steering. The Ackermann is easily adjusted by quickly & easily changing the steering link mounting positions on the steering plate.

Bump steer is easily adjusted for more aggression by inserting a shim between the steering block and steering linkage.

Ackermann is also easily adjusted by inserting a shim on the steering plate as well changing various graphite extension plates on the steering blocks.

Drivetrain.

The XB2 is a conventional gear-driven 2WD off-road car featuring:

• Rear ball differential (Dirt Edition) or gear differential (Carpet Edition)

with adjustable oil viscosity, featuring 53T gear and internal satellite gears

• 36T graphite composite idler gear

• 20T super-lightweight Swiss 7075 T6 hardcoated aluminum top shaft

• adjustable slipper clutch with 84T main spur gear

• rear CVD drive shafts

Gear Differential.

Carpet Edition only

Gear differential features diff outdrives designed for use with 2.5mm pin.

The strong diff outdrives are the result of a new hardening process that increases lifespan and reliability.

The XB2 rear gear differential is standard in the Carpet Edition, offering increased on-power steering that is beneficial on nearly all types of tracks but is especially great on carpet and astro turf.

The super-smooth gear diff includes a composite case and cover with internal satellite gears that are precision-molded from special XRAY-developed graphite composite material, ensuring long lifespan and super-smooth, efficient operation.

Spur Gear.

Precision-molded spur gears are made from XRAY's exclusive secret blend of composite material, allowing the gear to run true yet be robust enough to handle high-performance brushless motors. The spur gears are designed to have the lowest possible weight while staying strong and light. Each gear is stamped with the tooth number for easy identification.

The XB2 is equipped with an 81T spur gear which suits the majority of tracks. For additional tuning, optional 75T, 78T, 84T and 87T spur gears are available.

Suspension.

Correct suspension geometry is one of the most important features of any RC model car, while at the same time being one of the most difficult & challenging features for a designer.

Suspension is always a mixture of

• design and shape of individual suspension parts

• flex and hardness

• materials used

• mounting system

• geometry and position of mounting points of connecting parts

From the suspension arms, through the suspension blocks, to the light yet robust steering blocks, every suspension part has been carefully designed for the 2WD 1/10 off-road racing platform to provide responsive racing characteristics in all conditions.

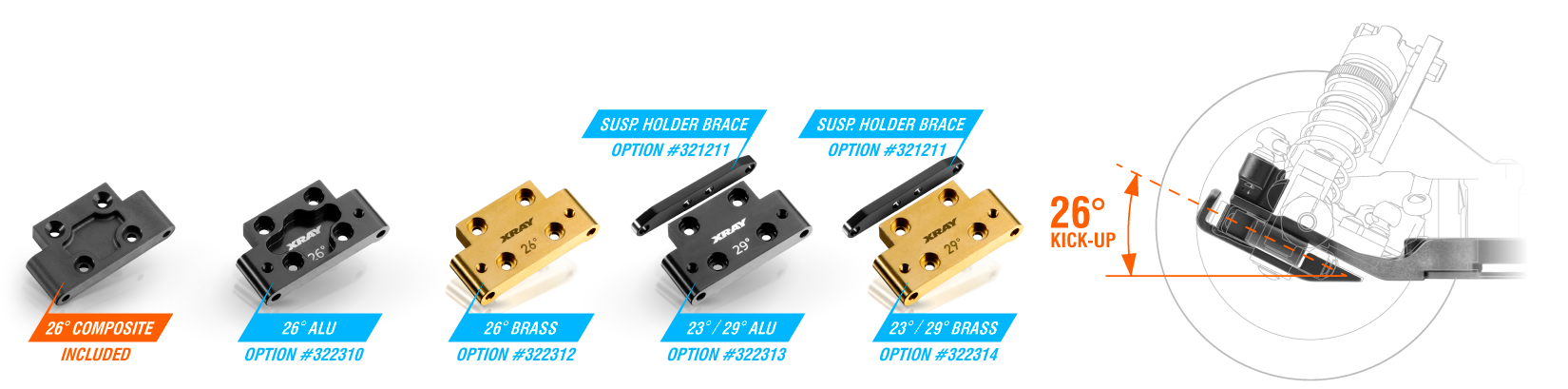

Arm Mount.

The lower composite arm mount is an important part of the chassis where the lower arms mount, and the block has an integrated 26° kick-up angle. Optional aluminum and brass arm mounts are available for further weight balance adjustment.

Turnbuckles.

For maximum reliability, all turnbuckles are manufactured from special HUDY Spring Steel™ material for turnbuckles which features a tougher core. These turnbuckles are used for front & rear upright linkages and steering system.

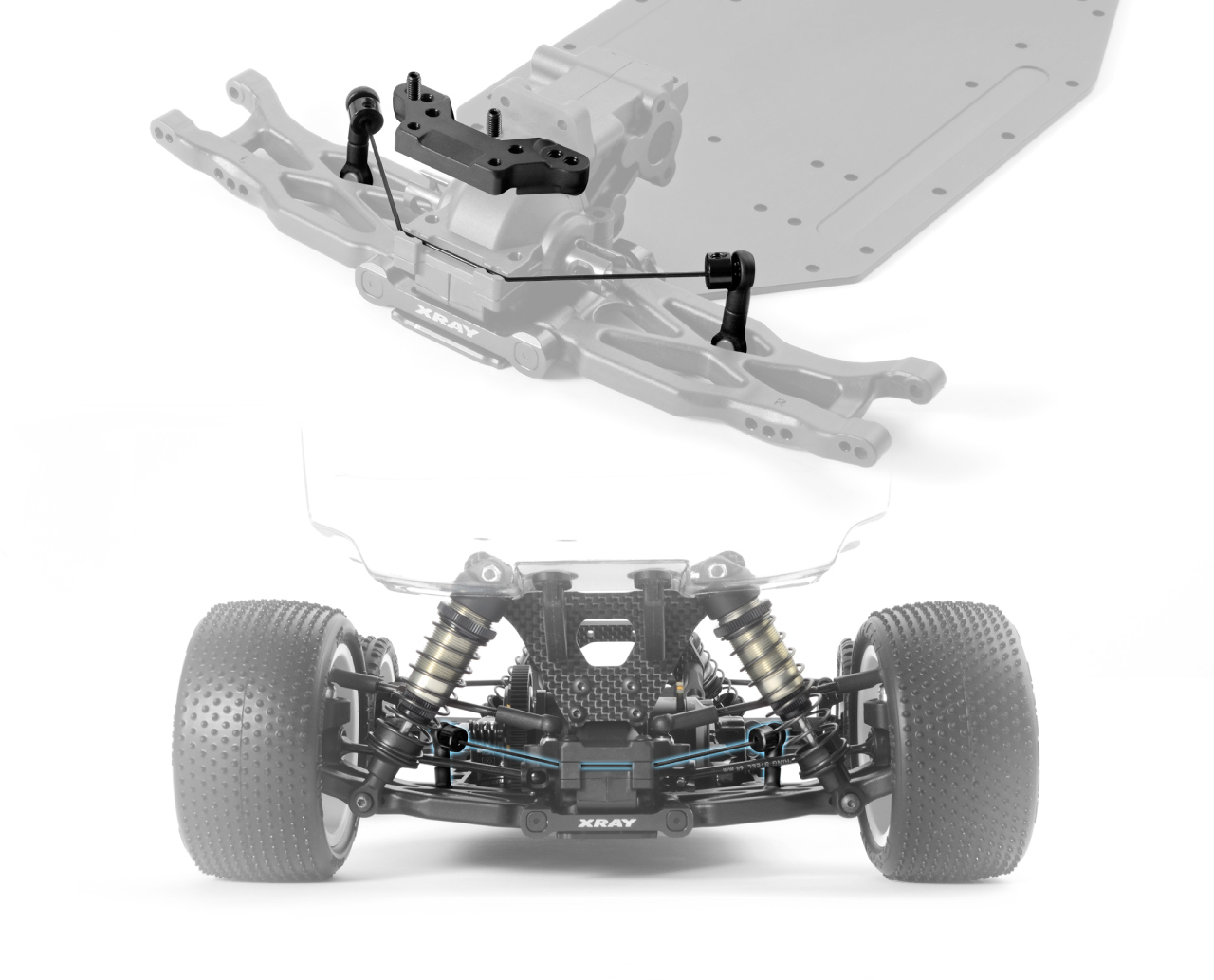

Anti-roll Bars.

In specific track conditions when the rear of the car must be stabilized, an optional rear anti-roll bar (#362400) can be easily installed. The anti-roll bar is mounted to the rear roll center holder and can be adjusted via the included linkages.

Anti-roll bar wires of different thicknesses are optionally available for fine-tuning; the wire thickness is laser-engraved for easy identification.

Shock Pistons.

Shock pistons are made from Delrin® and are molded using ultra-high precision moulds. All-new 2-hole pistons (1.6mm and 1.7mm holes) are now included in the set.

Shock Springs.

The XB2 comes equipped with softer springs for increased traction in dirt conditions.

The XB2 springs, like all other XRAY springs, are manually measured, selected, and matched into pairs to guarantee precisely equal length and damping characteristics.

Each spring is laser-engraved with stripes to clearly indicate the firmness.

Wheelbase & Weight Balance Adjustment.

Outer suspension pins holding the front caster block and rear uprights feature wheelbase shims for quick & easy wheelbase and weight balance adjustment. Using included shims in rear and in front, both front and rear blocks can be moved forward or rearward to adjust weight balance depending on track condition.

By moving the arms to the front, the balance & weight of the car are transferred more to the rear; this is recommended for medium- and high-traction conditions. By moving the arms to the rear, the balance & weight of the car are transferred more to the front.

Side Guards.

Side guards are an integral part of the XB2 Multi-Flex™ system. Moulded from medium-hardness composite material, the side guards make the chassis frame flex suitable for the majority of track conditions.

The tough composite side guards feature double-sided Velcro™ tape to seal the body perfectly to the chassis and seal against dirt.

There are two different chassis braces available – medium (included) and hard (optional) – which are suitable for particular track conditions.

The included side guards are moulded from medium-hardness composite and make the car faster in corners.

An optional hard-hardness composite moulded braces give the car increased stability on jumps.

Easy Diff Access.

The XB2 gear box is designed with all the finest details and craftsmanship incorporated. All parts fit perfectly together, and the super-easy access to the rear differential will be appreciated by every racer. The durable gear box houses the differential with all the rear transmission, and allows the mounting of the rear roll center holder, motor plate, and rear shock tower.

Carpet Edition and Dirt Edition each have unique gear boxes specifically designed for different track conditions.

Chassis Balance.

Chassis design focuses on balanced weight distribution and weight transfer. The chassis features pre-drilled holes for additional weights for optimum car balancing. Centerline holes are pre-drilled for easy balancing with the HUDY Chassis Balancing Tool #107880.

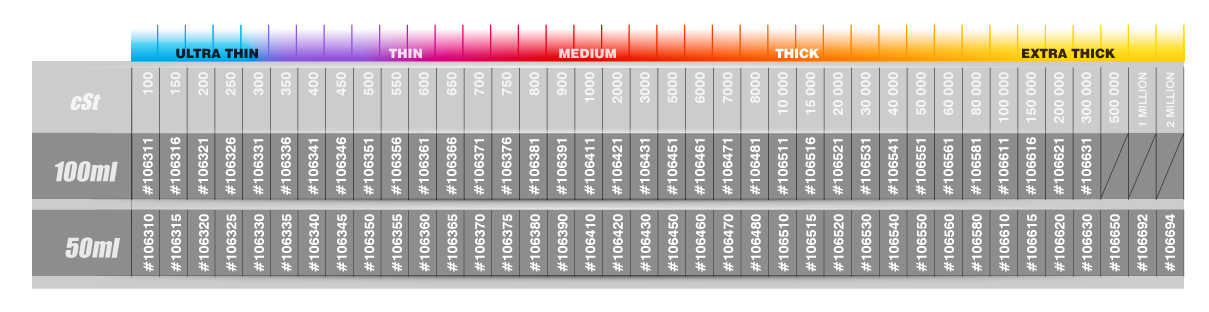

Silicone Oils.

HUDY Exclusive Silicone Oils are manufactured in Europe and each batch is laboratory tested and calibrated to ensure the highest possible consistency and quality from batch to batch. Based on the industry-standard cSt rating, the new line of oils will be easy to identify, adjust, and feel.

When following any set-up sheets by XRAY or XRAY team drivers, you can be sure that the oils you will get for your car are exactly same as those used by the factory racing team, thus ensuring very exacting set-ups and handling.

Graphite Grease.

The XB2 includes premium HUDY Graphite Grease which is a high-performance, advanced-technology semi-fluid lubricant which incorporates both extreme pressure additives and finely-dispersed graphite for load carrying. It is intended primarily for the lubrication of rotating parts and loaded gears. In addition to providing outstanding load carrying, it is formulated to have excellent adhesion and resistance to "fling-off" under extreme conditions. The grease reduces wear and increases parts life.

HUDY Graphite Grease #106210 .

Adjustment Possibilities.

The extensive range of adjustment possibilities includes: caster, camber, toe, kick-up, anti-squat, ride height, downstops, track-width, lower roll center, upper roll center, roll center position, bump steer, wheelbase, Ackermann, adjustable shocks, adjustable rear diff, adjustable slipper clutch, and adjustable XRAY Multi-Flex™.

Set-up Book.

The XB2 is one of the most adjustable electric 2WD off-road cars in the world. Whether you are a hardcore racing enthusiast or a club-level sportsman, you can very easily adjust the XB2 to suit your racing style, track type, and track conditions.

To fully understand the set-up possibilities, we recommend the legendary HUDY Set-up Book, loaded with over 40 pages of high-quality pictures and easy-to-understand RC car set-up explanations. Whether you are a novice driver or an experienced racer, you can easily learn many set-up tips & tricks and improve your set-up skills, ultimately translating into improved racing performance with your XB2. The HUDY Set-up Book is available for download exclusively at www.hudy.net

XRAY Instruction Manual.

XRAY Instruction Manuals have become the industry standard, being simply the best manuals you will ever get with an RC model car. Whether you are a first-time builder or an experienced racer, all instructions are straight-forward and easy to understand. The full-color instruction manual contains large 3D illustrations that show all assembly details in the clearest possible way.

XRAY VIP Customer Treatment.

Owning an XRAY model racing car is an experience on its own. Not only will you own the most premium luxury model racing car in the world, but you will also become a member of the prestigious family of XRAY owners with direct support and service from the XRAY factory. XRAY brings you the most up-to-date RC Web site on the Internet, with daily racing news and latest product developments. If you have any questions, problems or comments, you can ask the XRAY Support Team or any XRAY Factory Team Driver on the XRAY Support Forum. You can even upload your own set-up sheets or download from the thousands of different set-up sheets available from all around the world at the exclusive XRAY Virtual Set-up Sheet Database, the world’s largest set-up sheet database. And that is only the start of the VIP treatment you get by joining Team XRAY.