2018 All-new Features:

- Recent EOS Champion, European Champion, USA Champion and World Champion platform

- Redesigned chassis accommodates new lower motor mount to decrease the CG

- Lower motor mounts decrease the weight position of motor and central slipper clutch/diff, improving cornering speed and stability

- Redesigned lower composite central bulkhead fits the new lower alu motor mount

- Redesigned side guard allows motor to be positioned lower

- Improved shock absorber lower shims give more precise shock shaft movement

- Improved construction and production details on both front & rear differential crown gears results in quieter operation and increased reliability

World Champions.

Bruno Coelho made a stunning debut at the last World Championship with his XRAY XB4, setting the TQ and winning the World Championship title!

XRAY XB4 – World Championship winning 1/10 off-road 4WD car to bring you to the Winners’ Circle.

Made in Europe.

USA Champion.

At one of the world’s most competitive off-road races – the USA National Championship – it was XRAY’s Ty Tessmann who brought the first USA National Champion title for the XB4 platform using prototypes of new 2018 parts. Tested and successfully run in the highest competition races, you can now enjoy the very same car that Ty has been using… the Champion’s car.

Concept.

European Champions.

With ongoing development of the XB4 platform, Team XRAY continues to win at the highest competition levels including the European Championship. In 2017, Bruno Coelho won another European Championship for Team XRAY team with the XB4 platform.

Legend.

EOS Champions.

XRAY XB4 and Bruno Coelho are back-to-back EOS Champions. After winning the 2015-2016 season, Team XRAY with Bruno Coelho again wins the 2016-2017 season.

Chassis.

The new XB4 chassis was redesigned with the main focus to lower the CG to improve cornering speed and stability. The new chassis accommodates the new lower motor mount.

CNC-machined from high-quality Swiss 2mm 7075 T6 aluminum, the chassis is strategically machined in low-stress areas to make it as light as possible without affecting strength or rigidity; additionally black-coated for increased lifespan.

Weight distribution, chassis width & length, and proper flex have key influences on the handling of the car. All of these features were incorporated into the design of the chassis.

Motor Bulkhead.

The all-new lower motor bulkhead decreases the weight position of motor and central slipper clutch/diff, improving cornering speed and stability.

Machined from the premium Swiss 7075 T6, the motor bulkhead is strong and lightweight.

Central Bulkhead.

With the lower CG design focus on the new XB4, the central bulkhead was lowered as well.

The graphite central upper deck holds ball-bearings in the motor mount and bulkhead assembly, while the upper deck allows easy access for slipper clutch adjustment.

Side Guards.

The side guards were redesigned to allow the motor to be positioned as low as possible on the chassis to improve cornering speed and stability.

Tough composite side guards perfectly fit the chassis to seal against dirt and protect from side impacts.

Molded from a hard composite material, the side guards are an important part of the chassis flex adjustment for the majority of track conditions. For very-low-traction tracks, optional medium stiffness side guards are available.

Shocks.

To improve the precision of the shock shaft movement, the front composite shim was redesigned and updated with a more accurate mould design.

Well-built, reliable shock absorbers are extremely important for super-smooth suspension action on any type of track. The shocks on the XB2 have been specifically designed to be built easily, perform consistently, and last reliably. Careful attention was paid to the smallest details during the design process, as well as during long-term testing in various conditions.

The shocks are membrane-free, yet they still allow for easy, consistent building and rebound setting using the bleed-screw shock cap design.

Downstop is adjusted using composite shims under the pistons. Upstop travel is adjusted using composite shims under the shock collar.

The aluminum body, lower nut, and bleeder shock caps are all machined from premium Swiss 7075 T6 aluminum.

Shock rods are machined from special steel material, precision hand-ground for maximum smooth operation, and additionally hardened for improved lifespan.

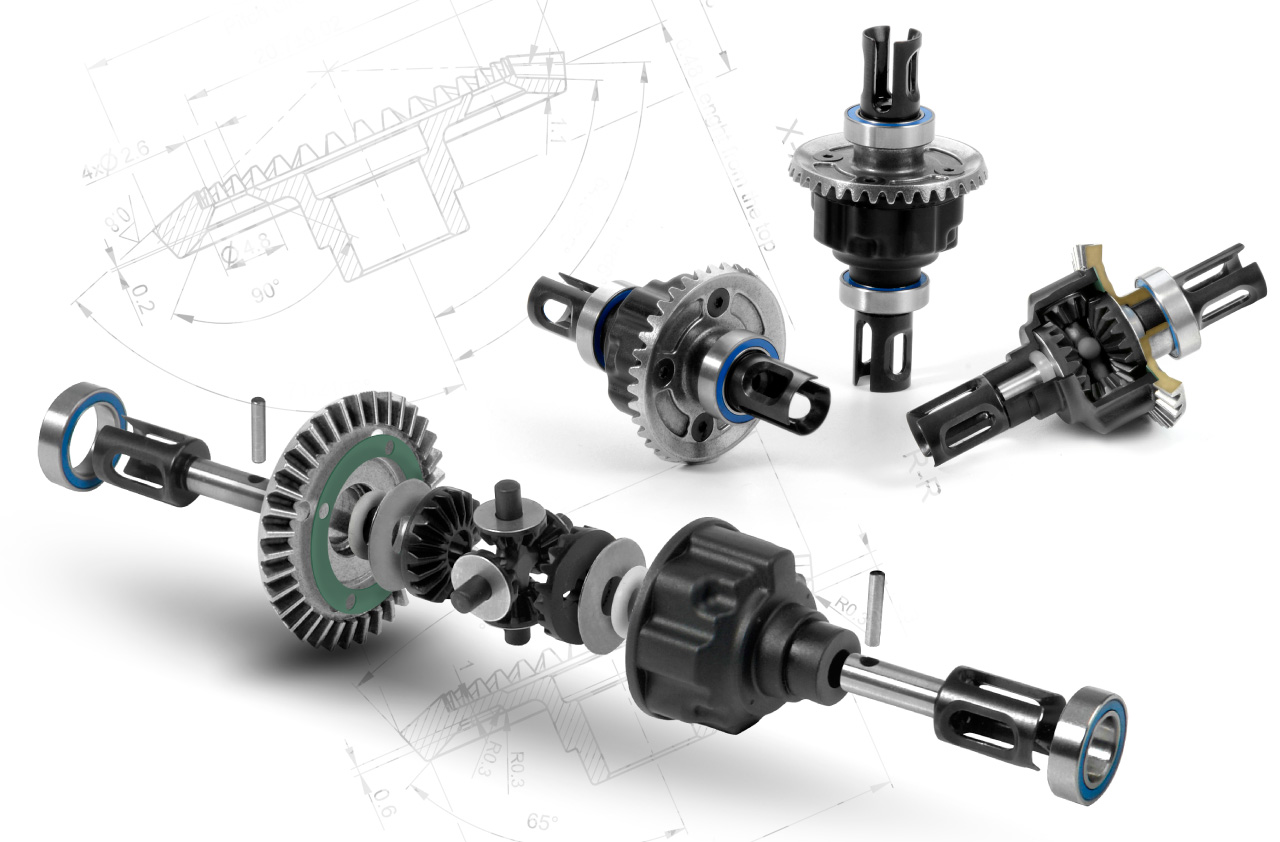

Diff Gears.

To improve the reliability of the differential and ensure quieter operation, both front and rear differential crown gears construction and production details were improved.

Both front & rear diff crown gears and pinion gears are made from steel which has been additionally hardened to ensure increased lifespan and reliability.

For clay and low-traction tracks, optional graphite diff crown gears can be used for increased traction.

Philosophy.

At the heart of XRAY's philosophy is a firm commitment to perfection in engineering, design, performance and support… all made possible by state-of-the-art in-house manufacturing. The XB4 is the epitome of perfection that is typical for XRAY.

Dipl. Eng. Juraj Hudy

XRAY Chief Designer

Winning Heritage.

Commitment.

“Being part of the R&D team, I know how much time, energy, and effort is put into developing all of our cars. Chasing perfection is a never-ending process, and as such we strive to bring you an improved & better-handling XB4. You will be amazed by the handling & reliability improvements of the new XB4’18, which will help bring you to the Winners’ Circle.”

Martin Bayer

XRAY Factory Team driver

European Champion

High Performance.

Development.

Perfection.

Racing Team.

Multi-Flex™.

The XB4 incorporates the legendary and innovative Multi-Flex™ adjustment technology, which allows tuning of chassis flex for different track conditions.

Regardless if the track has low, medium, or super-high traction, you can adjust the chassis flex to suit track conditions to gain a competitive advantage.

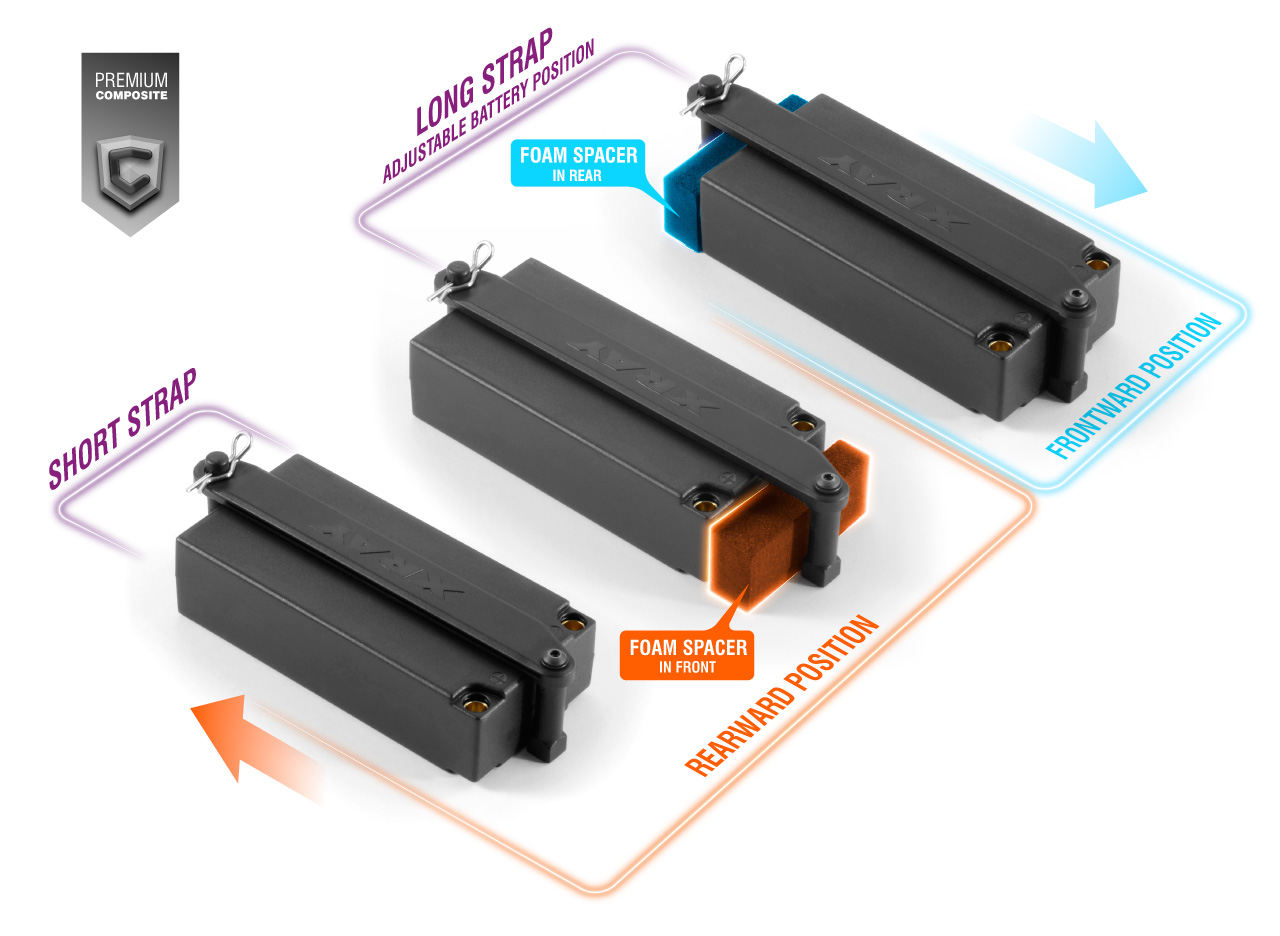

Chassis Weight Balance.

The XB4 chassis design allows for easy weight balance adjustment. You can move the motor frontwards or rearwards, and you can do this independently of the short battery pack that can be moved frontwards or rearwards as well.

Chassis Brace.

The graphite chassis brace – machined from high-grade graphite material – is installed in the lower part of the composite brace connected directly to the chassis. The brace reinforces the rear of the car and generates more stability while increasing traction.

The chassis brace is a vital part of the Multi-Flex™ setting.

When using the graphite chassis brace, the composite rear lower brace must be removed.

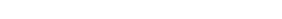

Electronics Plate.

A very handy, compact electronics plate allows for mounting the speed controller for quick & easy removal and assembly, and was redesigned to fit the new chassis and side guards.

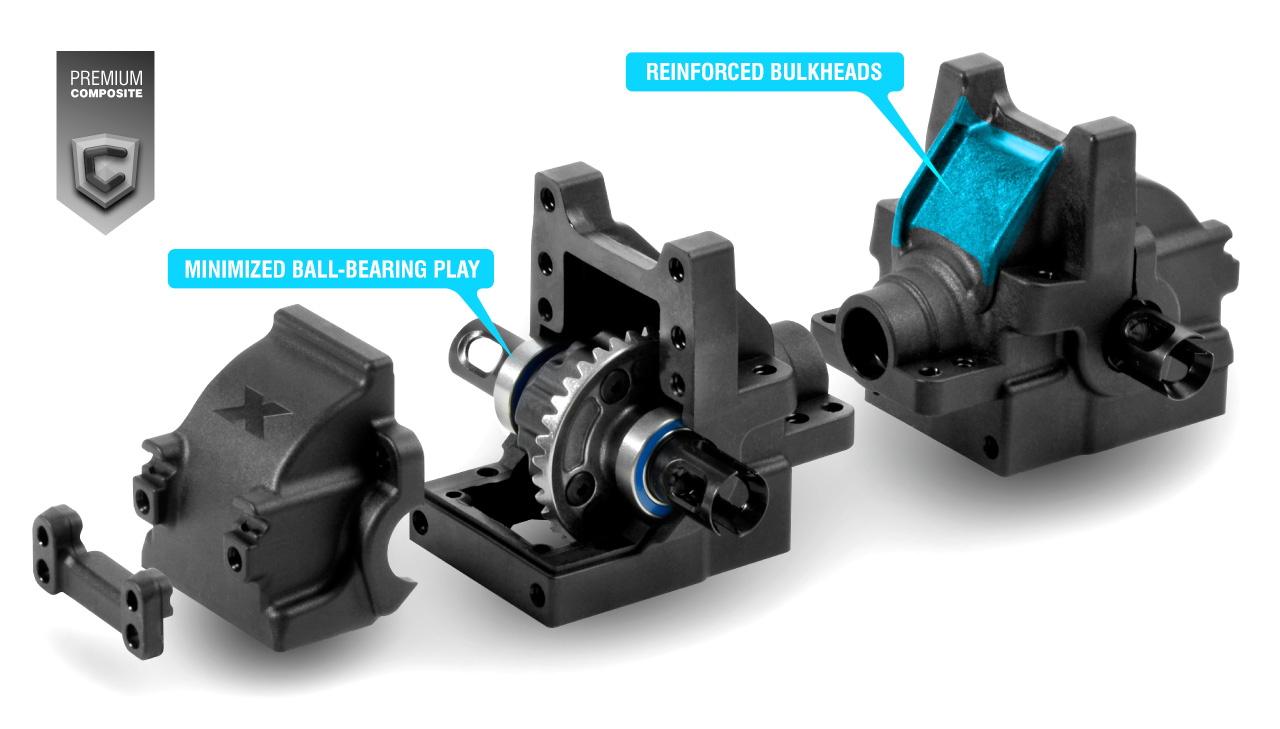

Bulkhead.

The super-strong front & rear bulkheads withstand rigorous impacts and abusive racing conditions. The bulkheads have minimized ball-bearing play, resulting in increased gear teeth lifespan and minimized gear stripping.

XRAY’s attention to the finest details, R&D and engineering are obvious in the design of the diff bulkheads. These unique bulkheads allow super-fast & easy diff exchange and servicing by dismounting only 4 screws from the front of the bulkhead and bottom of the chassis. This super-fast diff access is available at both front & rear.

Upper Decks.

There are no long top decks on the XB4, but instead the XB4 features separate front, central, and rear upper decks which are independent from chassis flex adjustment and work only as part of the front, central, and rear diff assemblies.

All upper decks are machined from high-grade graphite.

Servo Mount.

The independent servo mount allows the steering servo to be mounted to the chassis without touching it, ensuring the elimination of unwanted chassis tweak and improvement of overall traction.

Drivetrain.

The XB4 is a conventional shaft-driven 4WD off-road car featuring:

• front & rear gear differential with adjustable oil viscosity,

featuring steel 35T crown gear and steel 14T pinion gear

• central slip adjustable clutch with 81T main spur gear

• front, central, and rear CVD drive shafts

The internal ratio of the drive train is 1:2.5

Drive Shafts.

XB4 constant velocity drives (CVDs) are manufactured from world-renowned HUDY Spring Steel™.

The drive shafts are some of the world‘s thinnest yet most durable drive shafts used in electric off-road cars.

Hardened with a proprietary hardening process, the drive shafts provide unbeatable lifespan and reliability.

The CVD assembly also features a composite safety collar to keep the mounting pin solidly in place.

Central Drive Shafts.

With the weight balance adjustment feature – depending on motor position – the center diff block moves as well and appropriate-length central drive shafts must be selected & installed.

Gear Differential.

The XB4 gear diff ensures increased on-power steering which is needed on nearly all types of tracks, and is ideal for both carpet and clay tracks.

The super-smooth gear diff includes a composite case and cover with integrated crown gear. The internal gears are precision-molded from tough XRAY developed and mixed composite material ensuring high life time and super-smooth and efficient operation.

The maintenance-free diff design is a feature that will benefit racers of all levels. When the diff is correctly built, there is no need for maintenance for a very long time… no need for frequent oil changes, and no leakage due to our superior sealing system.

Ball Differential.

The optional ball differential was designed and is suggested for low traction track conditions. Externally adjustable ball differential is machined from HUDY Spring Steel™ and additionally hardened for extra durability and long lifetime. High-quality carbide thrustbearing is included for smooth operation and the carbide balls ensure ultra-smooth running. The ball differential comes factory pre-assembled.

Central Differential.

A central differential is recommended for use on clay and low-traction tracks to increase traction.

The super-smooth gear diff includes a composite case and cover with exchangeable spur gear. The gear diff set includes 81T spur gear and a 84T spur gear is available as an option.

The maintenance-free diff design will benefit racers of all levels. When the diff is correctly built, there is no need for maintenance for a very long time… no need for frequent oil changes, and no leakage due to our superior sealing system.

Diff Outdrives.

To reduce rotating weight, the super-lightweight diff outdrives are machined from HUDY Spring Steel™ material which allows additional material to be removed on the outer part of the outdrives, further reducing the weight without effecting durability. The inner part of the outdrives is additionally hand-ground for perfect fitment into the diff case.

The outdrives are hardened using XRAY’s own special hardening process to provide extended lifespan and reliability.

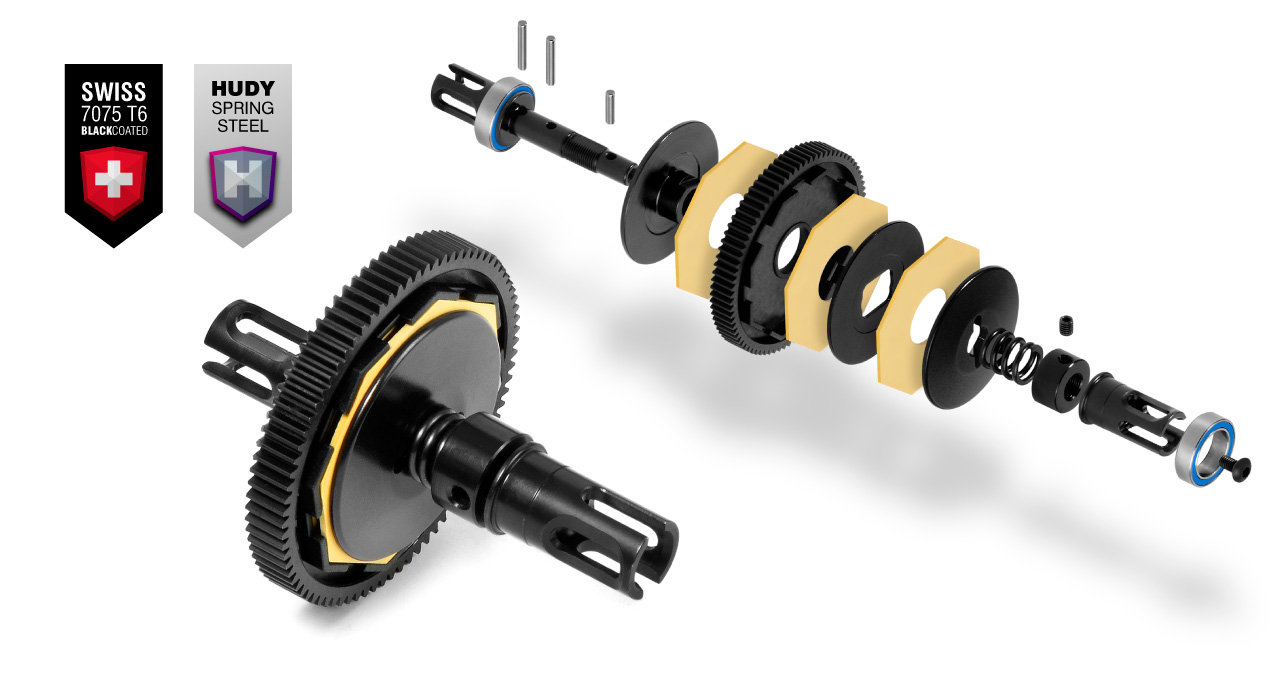

Slipper Clutch.

Power from the motor is transferred to the drivetrain via an adjustable, central slipper clutch for quick & easy tuning. The 3-pad slipper clutch ensures smoother clutch operation and more efficient braking, and clutch adjustment is easier, more consistent, and ultra-fine.

The lightweight slipper clutch plates have a machined relief which decreases the friction surface to assist with clutch slip adjustment. With this design, pressure is on the circumference of the clutch pads for increased efficiency.

The slipper clutch pads are made from ultra-efficient SLS material with very high slip efficiency, thus allowing very precise slip adjustment.

The clutch outdrives are super lightweight, manufactured from HUDY Spring Steel™ and additionally hardened for extra lifespan & reliability. The slipper plates are machined from premium Swiss 7075 T6 and additionally hardened, then given a black final surface treatment.

Spur Gear.

Precision-molded spur gears are made from XRAY's exclusive secret blend of composite material, allowing the gear to run true yet be robust enough to handle high-performance brushless motors. The spur gears are designed to have the lowest possible weight while staying strong and light. Each gear is stamped with the tooth number for easy identification.

The XB4 is equipped with an 81T spur gear which suits the majority of tracks. For additional tuning, optional 75T, 78T, 84T and 87T spur gears are available.

Motor Mount.

The motor is connected to an eccentric mounting plate, with the assembly then inserted into an integrated motor holder/drivetrain support. The design allows quick & easy motor rotation to adjust gear mesh, and yet clamp securely using only a single screw.

To ensure the motor will not loosen in a serious crash or due to insufficient tightening, the motor plate has a bayonet mounting system which prevents it from being dislodged from the motor holder. By rotating the motor mount plate to the opposite direction, the motor can be quickly removed from the motor holder.

Removing the motor or adjusting the gear mesh is easy and fast, with changes possible in only a few seconds.

Motor Mount Assembly.

Suspension.

The correct suspension geometry is one of the most important features of any RC model car, while at the same time being one of the most difficult and challenging features for a designer.

The suspension is always a mixture of:

• design and shape of individual suspension parts

• flex and hardness

• materials used

• mounting system

• geometry and position of mounting points of connecting parts

From the suspension arms, through the suspension blocks, to the light yet robust steering blocks, every suspension part has been specially designed for the 1/10 off-road racing platform to provide responsive racing characteristics in all conditions.

I.S.S.™ Suspension Holders.

The aluminum suspension holders feature Integrated Suspension Settings (I.S.S.™) which allows for super-fast & easy suspension geometry setting. This XRAY concept was first introduced in the very first XB8 and now has been carried over to the 1/10 scale XB4.

Using eccentric suspension bushings – which are inserted into aluminum suspension blocks – as well as additional shims, the XB4 suspension geometry can be completely adjusted including:

• caster

• camber

• front & rear toe-in

• front & rear roll-center

• front kick-up

• rear anti-squat

• wheelbase

• track-width

Wheelbase Adjustment.

Suspension arms allow for quick & easy wheelbase adjustment. Using included 2mm shims, both front and rear suspension arms can be moved either forward or rearward to adjust weight balance depending on track conditions.

By moving the arms to the front, the balance and weight of the car are transferred more to the rear; this is recommended for medium- and high-traction conditions.

By moving the arms to the rear, the balance and weight of the car are transferred more to the front.

Suspension Arms.

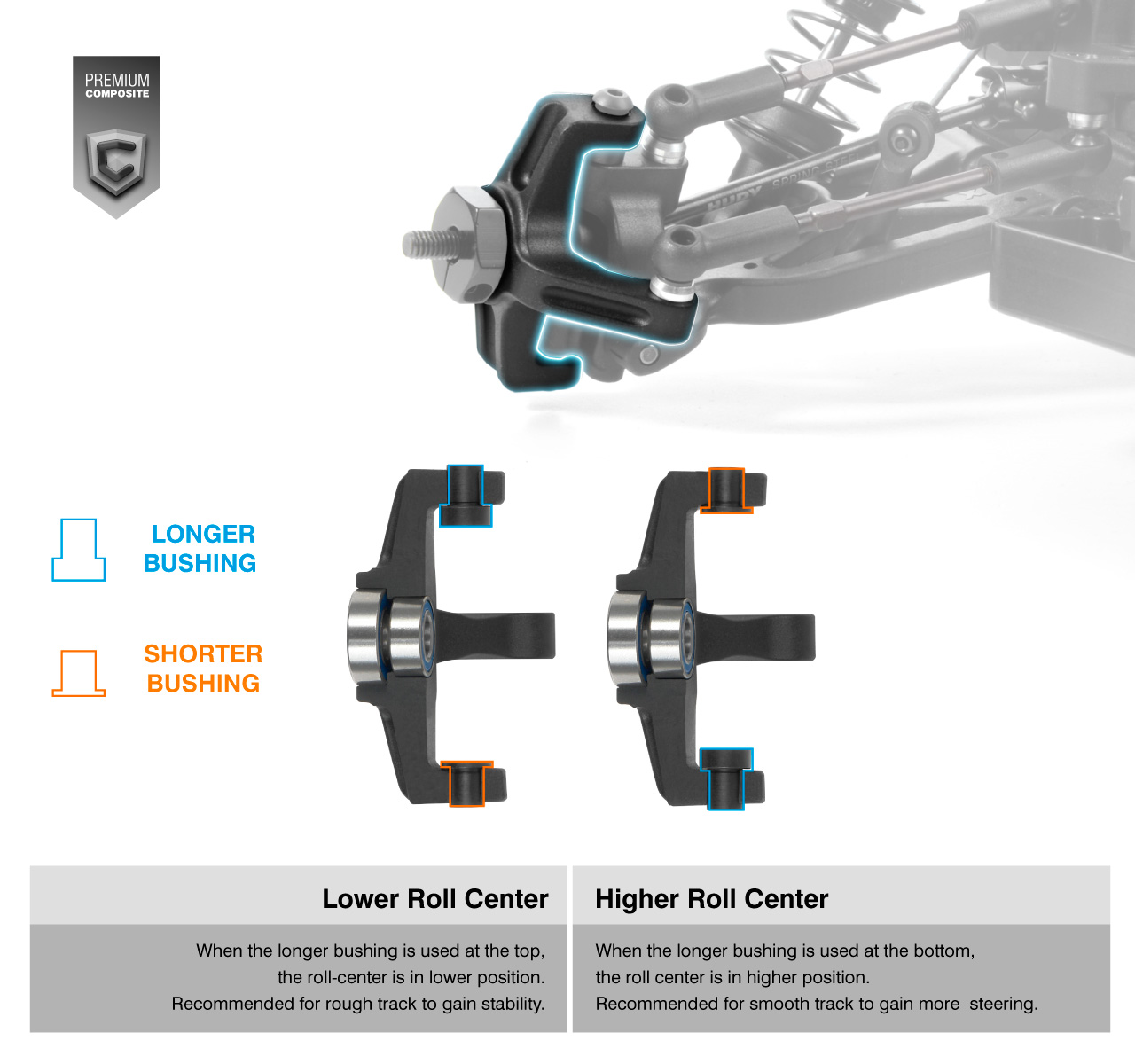

Steering Blocks.

The tiny yet tough steering blocks are molded from a special composite mixture for maximum strength.

Composite steering block inserts allow for very quick & easy lower roll center adjustment. With additional shims and extra inserts, fine tuning the roll center is easily achieved.

For maximum drivetrain reliability, larger 5x12 ball-bearings are used in the outer position with increased dynamic load. On the inner position, the smaller 5x10 ball-bearings are used for minimized unsprung weight.

Caster Blocks.

The 1-piece caster blocks are very lightweight, yet the construction makes them very stiff and rigid. The non-adjustable caster angle is preset to 9°. Roll center position can be quickly & easily adjusted by inserting different thickness of shims atop the caster block (between the block and the vertical ball stud).

The front of the chassis is pre-angled with an integrated 8° caster angle, however the position of the adjustable eccentric bushings in the I.S.S.™ suspension holders influences the caster as well. (For example, if the eccentric bushings have the roll center in middle position, the caster angle is 9° which when added to the 9° caster block gives a total of 18° caster. The total adjustability range for caster is 16-20°.)

Optional caster blocks with 6° and 12° built-in caster angles are available for further suspension geometry adjustment.

There are four different caster blocks available: medium (optional), hard (included), graphite (optional) and aluminum (optional), each suitable for particular track conditions.

The new hard caster blocks increase stability in high-traction conditions, and help to increase cornering speed.

Rear Uprights.

The super-compact rear uprights feature 3 different upper roll center positions. The rear uprights have 0° toe to ensure stability and to prevent suspension geometry changes in hard crashes.

For maximum drivetrain reliability, larger 5x12 ball-bearings are used in the outer positions for increased dynamic load. Smaller 5x10 ball-bearings are used in the inner positions to minimize unsprung weight.

The outer suspension pin on which the rear upright sits uses adjustment shims to alter the wheelbase.

There are four different uprights available: medium (optional), hard (included), graphite (optional), and aluminum (optional), each suitable for particular track conditions.

Steering System.

The dual arm steering system is very simple yet effective and features an integrated easily adjustable servo saver. Ackermann is easily adjusted by quickly & easily changing the steering link mounting positions on the steering plate.

Bump steer is easily adjusted for more aggression by inserting a shim between the steering block and steering linkage.

Turnbuckles.

Shock Towers.

The front shock tower has a new design with different shock mounting positions featuring an extra additional shock mounting position for extra-fine tuning.

Both front & rear shock towers are machined from premium-grade graphite and are lightweight & strong, with multiple shock positions and roll center adjustment positions. The front shock tower is 3.5mm thick; the rear is 3.0mm thick and holds the wing mount.

Shock Pistons.

Shock pistons are made from Delrin® and are molded using ultra-high precision molds. All-new 2-hole pistons (1.6mm and 1.7mm holes) are now included in the set.

Shock Springs.

The all-new shock springs are shorter to allow more fine ride height adjustment especially on carpet tracks. The XB4 springs have been specifically designed to complement the big-bore shocks.

There are two types of springs in offer:

• Linear – The spring rate is constant during the entire spring compression. Springs with different linear spring rates are available as optional tuning parts.

• Progressive - The main advantage & benefit of progressive springs is that as the car initially enters the corner the springs work like softer springs to provide maximum traction. As the chassis begins to roll in the middle of the corner, the spring rate progressively increases until it works like a stiffer spring which allows the car to maintain maximum cornering speed.

XB4 springs, like all other XRAY springs, are manually measured, selected, and matched into pairs to guarantee precisely equal length and damping characteristics.

Each spring is laser-engraved with stripes to indicate the firmness; the more strips, the harder the spring.

Variable Shock Mounting.

Silicone Oils.

HUDY Exclusive Silicone Oils are manufactured in Europe and each batch is laboratory tested and calibrated to ensure the highest possible consistency and quality from batch to batch. Based on the industry-standard cSt rating, the new line of oils will be easy to identify, adjust, and feel.

When following any set-up sheets by XRAY or XRAY team drivers, you can be sure that the oils you will get for your car are exactly same as those used by the factory racing team, thus ensuring very exacting set-ups and handling.

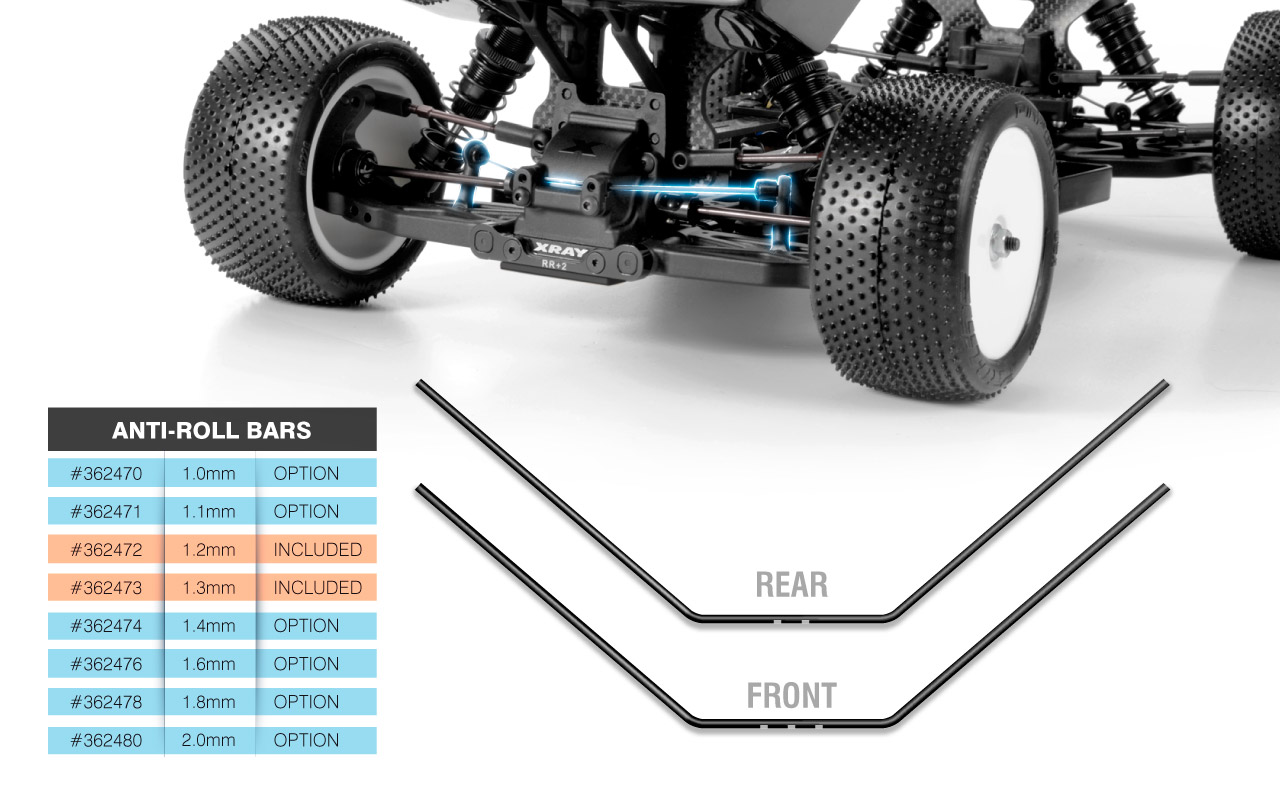

Anti-roll Bars.

Anti-roll bars are manufactured from special spring steel material and are included to stabilize the front & rear ends of the car. The roll bars are easily mounted to the diff cases and can be adjusted with the linkages.

Both front & rear anti-roll bars are interchangeable since they have same design and shape. The thickness of each anti-roll bar is laser-engraved for easy identification. Anti-roll bar wires of different thickness are optionally available for fine-tuning.

Wheel Hubs.

Ultra-lightweight 12mm wheel hex drive hubs are CNC-machined from Swiss 7075 T6 black-coated aluminum. These ultra-true hex hubs have a clamping design which ensures ultra- solid mounting of the wheel on the hub.

The rear alu hex hubs are specially machined to reduce rotating weight while guaranteeing wobble-free wheel mounting.

To adjust track-width, optional offset wheel hex drive hubs are available.

Ball-bearings.

Battery Strap.

Body Posts.

Body.

The XB4 body features high-downforce areas - front window and top-roof flow channels – for proper airflow, and side downforce areas and top central rib for better stability.

The high-performance, low-profile aerodynamic body was designed by XRAY to perfectly fit the XB4 and work in most track conditions. The body is made from high-quality premium Lexan™ material.

For very-high-traction track conditions, an optional ultra-lightweight body is available that will reduce the roll of the car and improve rotation in corners.

Body Seal.

To improve protection against dust, Velcro® double-sided tape is included to ensure a perfect seal of the body to the side guards, to reduce the noise level of the running car.

Rear Wing.

Stylish and effective rear wing was designed to work perfectly with the XRAY XB4 body. Made from strong Lexan™ material, the wing is supported on the wing mounts by extra flat shims to better support and extend the life of the wing.

Optional thicker 1.5mm (#363511) and 2.0mm (#363512) rear wings are highly reliable with less chance of breakage, while at the same time influencing the performance of the car as well. The thicker wing gives higher traction and stability, but gives reduced steering.

Wheels.

The wheels included with the XB4 are perfect for high-competition racing, being made from a very flexible material while still being ultra-durable to withstand repeated impacts. The side of the wheel is aerodynamically designed for maximum performance.

Internal reinforcement ribs give superior stability and eliminate deformation. The wheels feature a 12mm internal hex.

Chassis Balance.

The chassis design focuses on balanced weight distribution and weight transfer. The chassis features pre-drilled holes for additional weights for optimum car balancing. Centerline holes are pre-drilled for easy balancing with the HUDY Chassis Balancing Tool #107880.

Adjustment Possibilities.

Graphite Grease.

The XB4 includes premium HUDY Graphite Grease which is a high-performance, advanced-technology semi-fluid lubricant which incorporates both extreme pressure additives and finely-dispersed graphite for load carrying. It is intended primarily for the lubrication of rotating parts and loaded gears. In addition to providing outstanding load carrying, it is formulated to have excellent adhesion and resistance to "fling-off" under extreme conditions. The grease reduces wear and increases parts life.

Set-up Book.

The XB4 is one of the most adjustable electric off-road car in the world. Whether you are a hardcore racing fanatic or a club-level sportsman, you can very easily adjust the XB4 to suit your racing style, race track type, and all track conditions. To fully understand the set-up possibilities we recommend the legendary HUDY Set-up Book, loaded with over 40 pages of high-quality pictures and easy-to-understand RC car set-up explanations. Whether you are a novice driver or experienced racer, you can easily learn many set-up tips & tricks and improve your set-up skills, ultimately translating into improved racing performance with your XB4. The HUDY Set-up Book is available for download exclusively at www.hudy.net

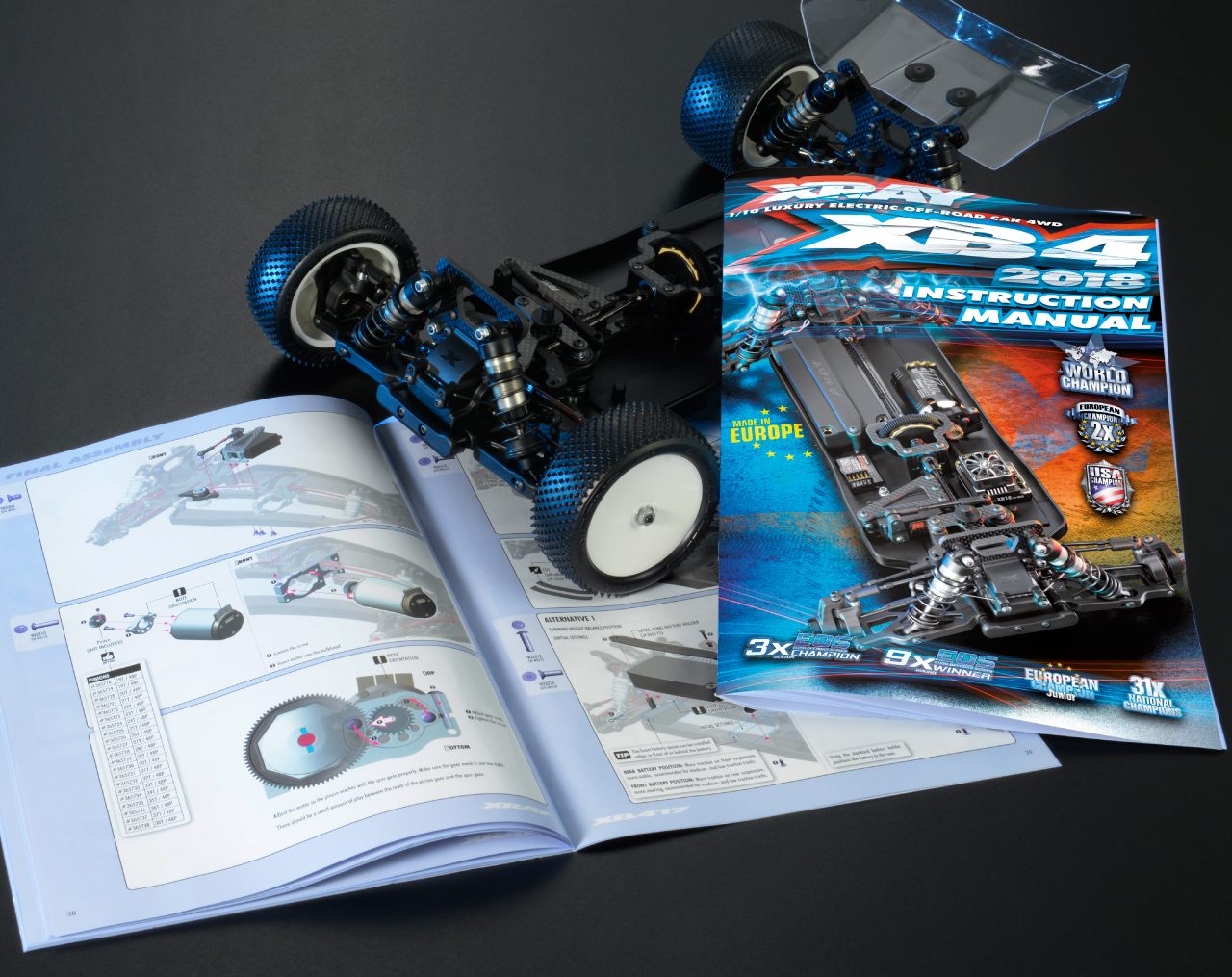

XRAY Instruction Manual.

XRAY VIP Customer Treatment.

Owning an XRAY model racing car is an experience on its own. Not only will you own the most premium luxury model racing car in the world, but you will also become a member of the prestigious family of XRAY owners with direct support and service from the XRAY factory. XRAY brings you the most up-to-date RC Web site on the Internet, with daily racing news and latest product developments. If you have any questions, problems or comments, you can ask the XRAY Support Team or any XRAY Factory Team Driver on the XRAY Support Forum. You can even upload your own set-up sheets or download from the thousands of different set-up sheets available from all around the world at the exclusive XRAY Virtual Set-up Sheet Database, the world’s largest set-up sheet database. And that is only the start of the VIP treatment you get by joining Team XRAY.