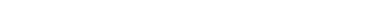

XB8 Platform.

Based on the ultra-successful XB8 platform, XRAY proudly presents the 2017-spec XB8 which incorporates the latest improvements and refinements gathered by the team, race-proven in the highest competition races around the world.

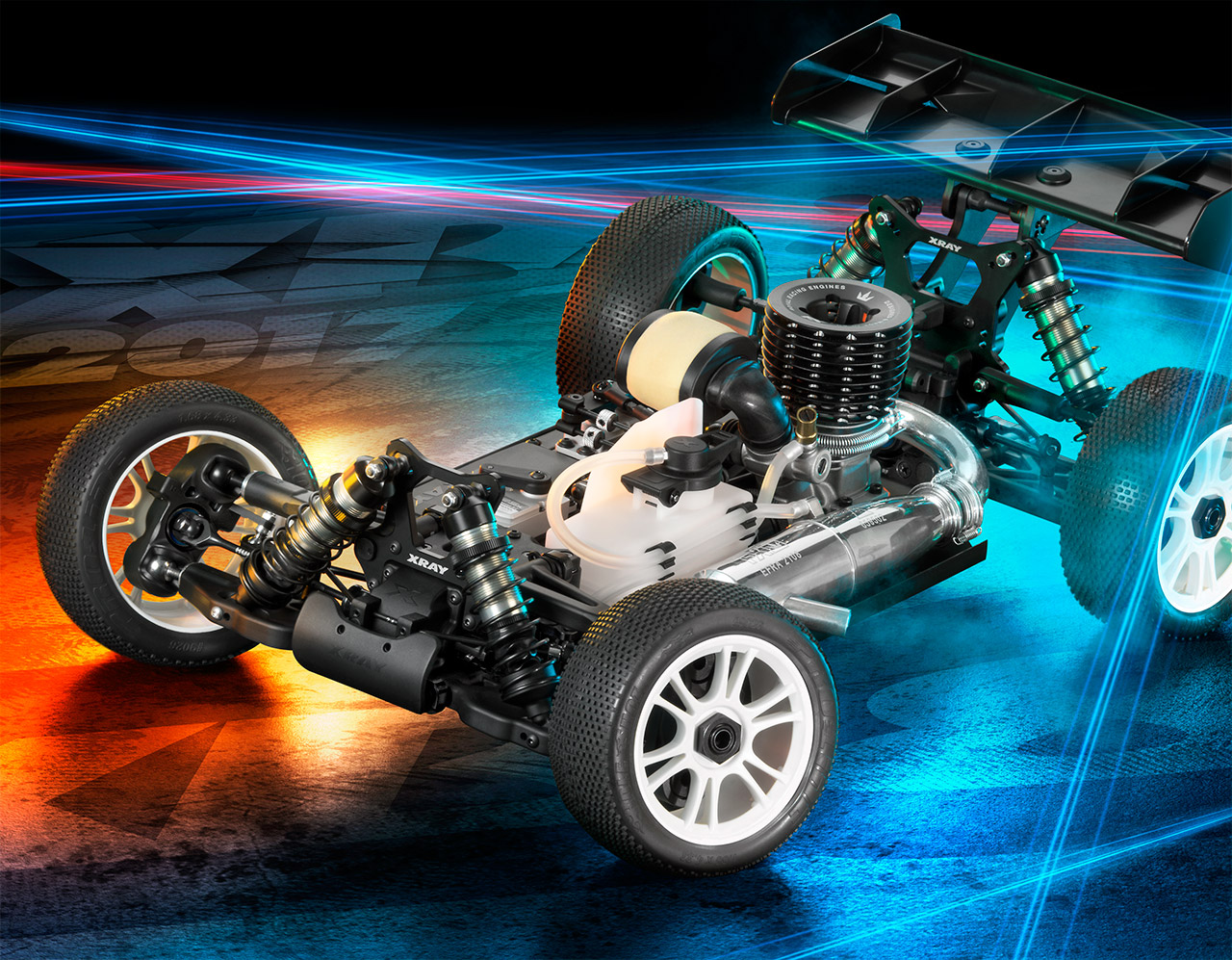

Development.

With my long-time experiences with 1/8 off-road racing, combined with the expertise I have gained from the R&D process at my previous projects at XRAY with XB2 and XB4 platforms, I have incorporated all the improvements & refinements to the XB8 platform to make it better, easier to work on, and more reliable.

Martin Bayer

XRAY XB8 Designer

Legend.

Team Development.

All the work and refinements on the XB8 were incorporated based on our own experiences, and also by vast majority based on feedback from drivers all around the world. New ideas and prototypes were long-term tested by the factory team worldwide to ensure the improvements would work well in all track conditions and tracks in Europe, America, and Asia.

Martin Bayer

XRAY XB8 Designer

High-Performance.

Making of.

Read my exclusive story about the making of the all-new XRAY XB8 here for an insider’s view of our daily work as RC car designers and what we have all done to make the new XB8 a reality.

Martin Bayer

XRAY XB8 Designer

Perfection.

Heritage.

“I designed and hand-made my first off-road cars back in 1986, and they were dominating the races thanks to unbeatable reliability and best performance. Years later in 2004 we have started our first mass production XRAY XB8 platform based on our long-term experiences, knowledge, and R&D expertise gained over decades, taking over the heritage I brought with me.

Since the release of the XB8 platform, we have continued our dedicated work to refine the platform annually to bring the latest improvements & innovations to make the XB8 stand out in crowd and take you to the Winners Circle.”

Dipl. Eng. Juraj Hudy

XRAY Chief Designer

XB8 Concept.

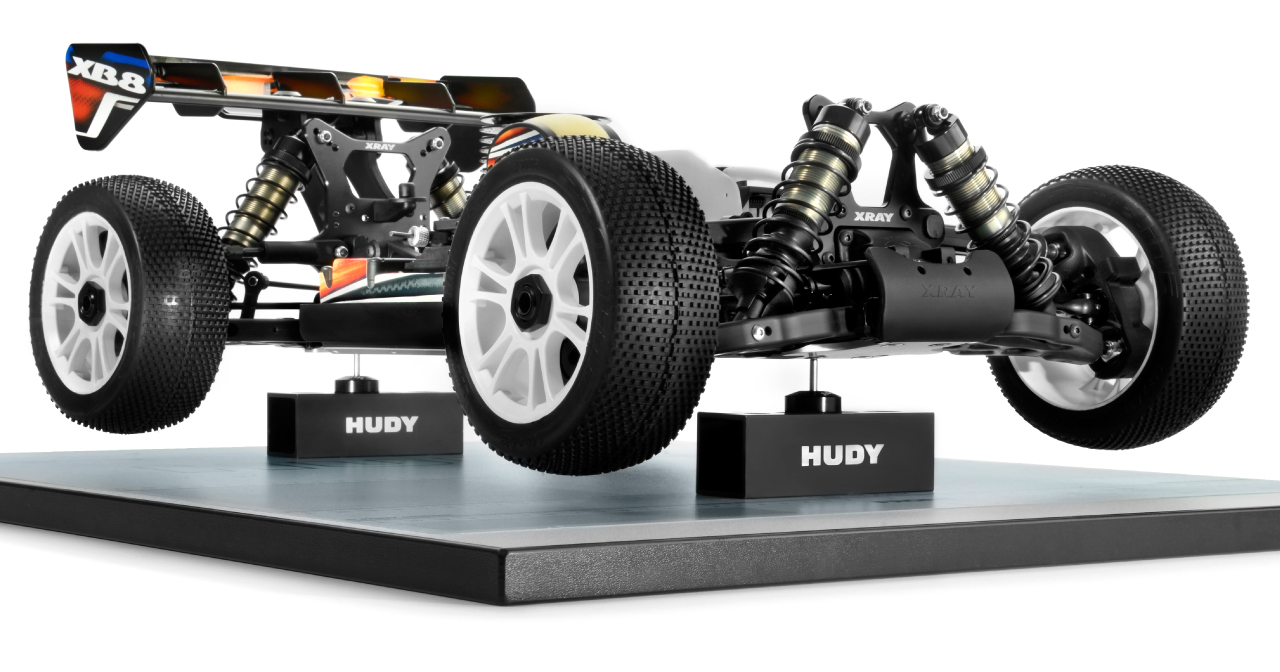

The XB8 is typical XRAY: premium, professional, high-competition for the most demanding racers, developed with attention to the smallest details, and backed by premium service & support… a luxury masterpiece.

World Champion Choice.

“With the most extreme conditions of 1/8th off-road racing I need to have complete trust in my equipment. With Team XRAY I know I get the complete attention to detail, constant product development and in-house R&D. With the soon-to-be-completed purpose built indoor test facility alongside the renowned world class manufacturing capability of XRAY meant my choice was simple. My future with Team XRAY and the XB8'17 is already here, I can't wait to get going and see you at the tracks. The XB8'17 is such a beautiful machine, I hope I bring it the results it deserves. Look out for my World Champions 'tech tips' and set-up advice throughout 2017 on the XRAY Facebook page and website.”

Ty Tessmann

World Champion

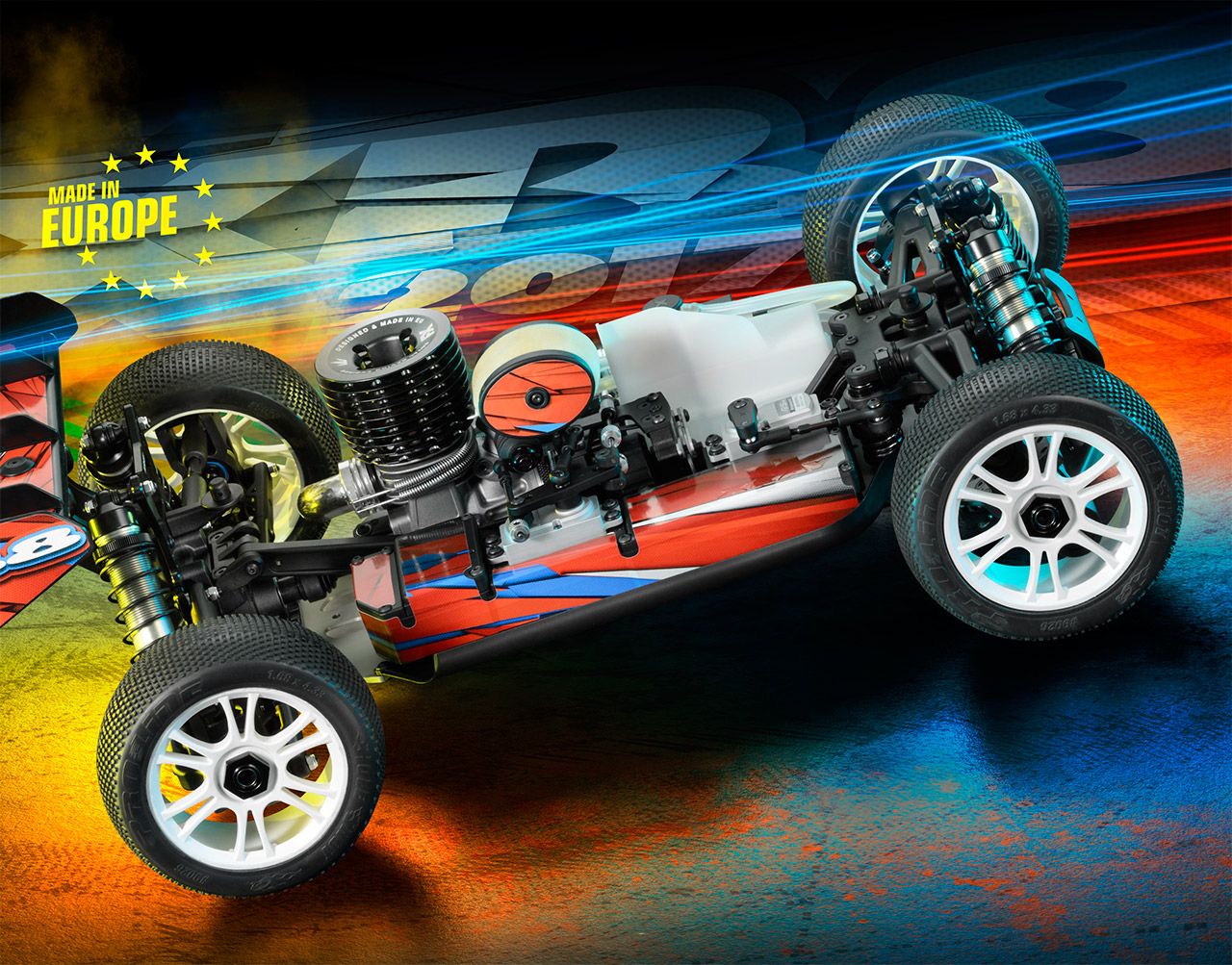

Made in Europe.

Designed, developed, and fully manufactured in-house at the XRAY factory in Slovakia, Europe, using the most high-tech German & Swiss machines and premium European materials, crafted with XRAY's legendary attention to detail by our artistic production specialists. The XB8 is truly a masterpiece.

All-new 2017.

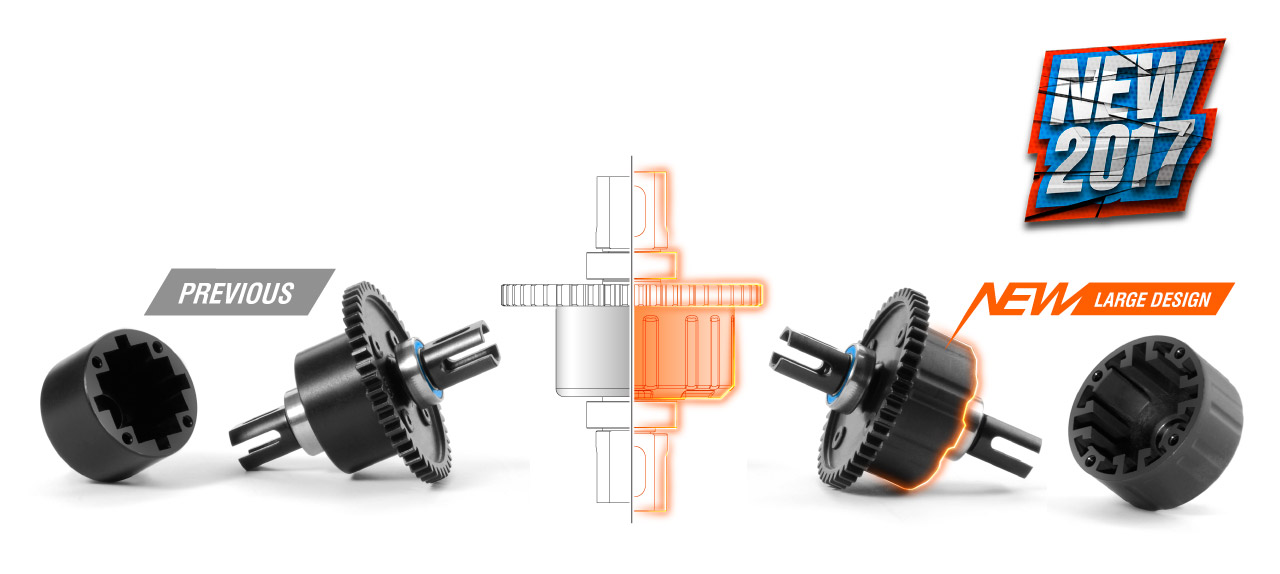

• Large volume front, central, and rear differentials for improved long run performance and reduced internal heat build up

• Stronger 2.5mm diff pins in all differential outdrives

• Longer front, central and rear internal cross diff pins

• Improved internal diff gears with re-profiled teeth for reduced friction and smooth operation

• All-new lightweight machined diff outdrives

• All-new profile 46T lightweight Hudy Steel central diff gear

• All-new larger rubber-sealed center differential housing

• New differential gaskets

• Front trailing steering blocks give increased forward traction and better handling

• Improved geometry steering block Ackermann plates

• New graphite material servo saver for increased reliability and smooth operation

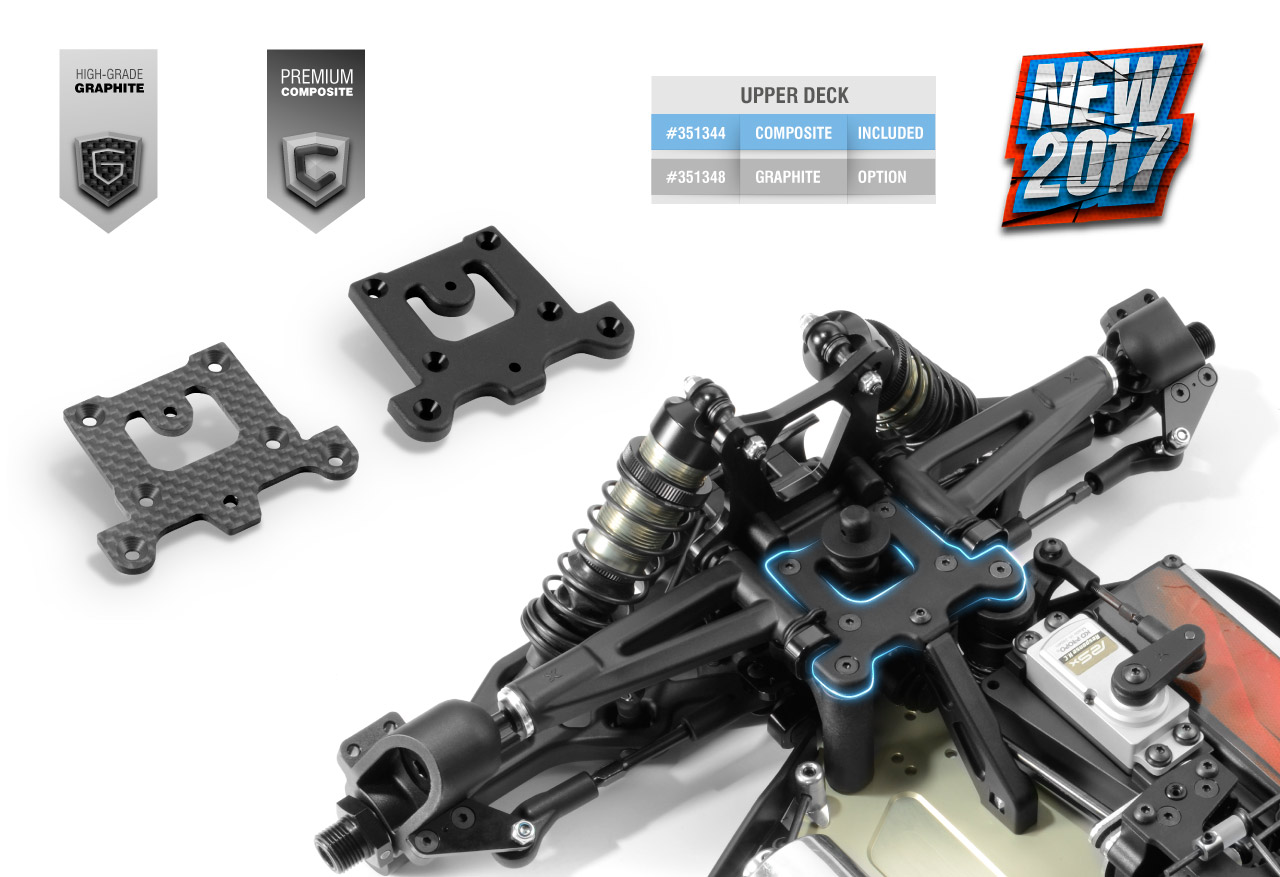

• Composite front upper top deck for added flex & increased steering

• Improved alu steering posts to accommodate new front upper plate

• Redesigned steering pivot balls to eliminate wheel locking

• Redesigned brake cam

• Narrow profile front suspension arms move the front wheels forward for improved take-off and landing on jumps

• Longer rear suspension arms for better handling, stability and increased traction

• Short alu rear suspension holders for new geometry

• Improved weight distribution and balance for increased traction

• All-new chassis flex adjustments using optional graphite stiffeners on the chassis guards

• Hard alu clutch shoes for smoother engagement

Gear Differential.

Internal Diff Gears.

Diff Outdrives.

Updated diff outdrives were created to accommodate the new stronger diff pins. The front longer diff outdrive adapters ensure that the drive shafts will not fall out in extreme crashes at full steering lock.

To reduce rotating weight, the super-lightweight diff outdrives are machined from HUDY Spring Steel™ which allows unnecessary material to be removed to further reduce weight without affecting durability. The inner portions of the outdrives are additionally hand-ground for maximum precision and fitment into the diff case.

All outdrives are hardened using HUDY’s own special hardening process for extended lifespan and reliability.

Central Diff Gear.

The central differential has an all-new extra-large design for increased reliability and performance. The new differential is over 5mm larger, with a larger oil capacity to reduce oil overheating in long runs, helping to keep differential performance as consistent as possible.

The central diff gears were updated to accommodate the new larger center diff housing.

Steering Blocks.

New trailing-axle steering blocks offer a significant handling improvement in all track conditions, making the car easier to drive and giving increased forward traction.

The steering blocks feature the following integrated geometry adjustments:

• camber

• caster

• bump steer

• track-width

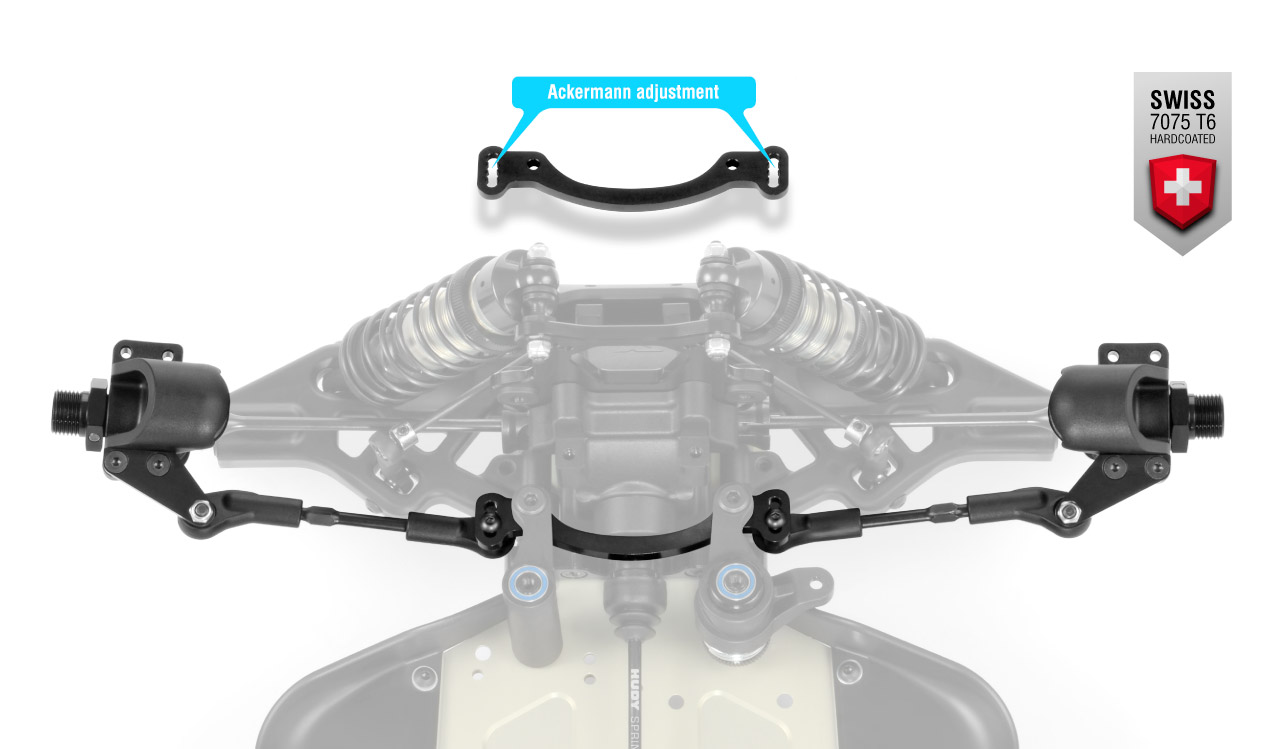

Steering Plates.

All-new steering plates change the front suspension geometry and thus change steering characteristics as well. The new updated geometry results into more linear and precise steering, making the XB8 more predictable and easier to drive.

Servo Saver.

To increase servo saver reliability, especially in dusty conditions, the all-new servo saver is moulded from new graphite material which is more resistant and efficient in dusty conditions.

The dual-arm steering system is simple yet effective, featuring an integrated easily-adjustable servo saver and Swiss 7075 T6 aluminum steering plate.

Ackermann is easily adjusted by quickly & easily changing steering link mounting positions on the steering plate.

Bump steer is easily adjusted by inserting shims between the steering plate and steering linkage.

Upper Deck.

The front upper deck is now made of molded composite material to improve flex which results in increased traction and improved steering characteristics.

Ball Studs.

New-design ball studs eliminate steering lock and allow greater steering radius.

Suspension Arms.

All-new longer rear arms make the car easier to drive in most track conditions. The new rear arms also give flex to help generate more traction and give better handling.

All-new, narrower front lower arms move the arms more frontwards, resulting in improved weight balance.

XB8 suspension arms are the result of long-term testing of different designs and layouts. Length, thickness, flexibility, geometry, and materials used… these are all part of the concepts and details that are thoroughly reviewed to create optimum suspension arms. The suspension arm itself is rigid enough to provide a responsive feel, yet soft enough for extreme durability. The exclusive composite mixtures used for suspension arms offer a perfect balance between reliability & performance.

I.S.S.™ Suspension Holders.

To accommodate the longer rear suspension arms, narrower aluminum suspension holders are used.

The aluminum suspension holders feature Integrated Suspension Settings™ (I.S.S.) which allows for quick & easy suspension geometry setting.

Using eccentric suspension bushings inserted into aluminum suspension holders – as well as additional suspension shims – the XB8 suspension geometry can be completely adjusted in mere seconds.

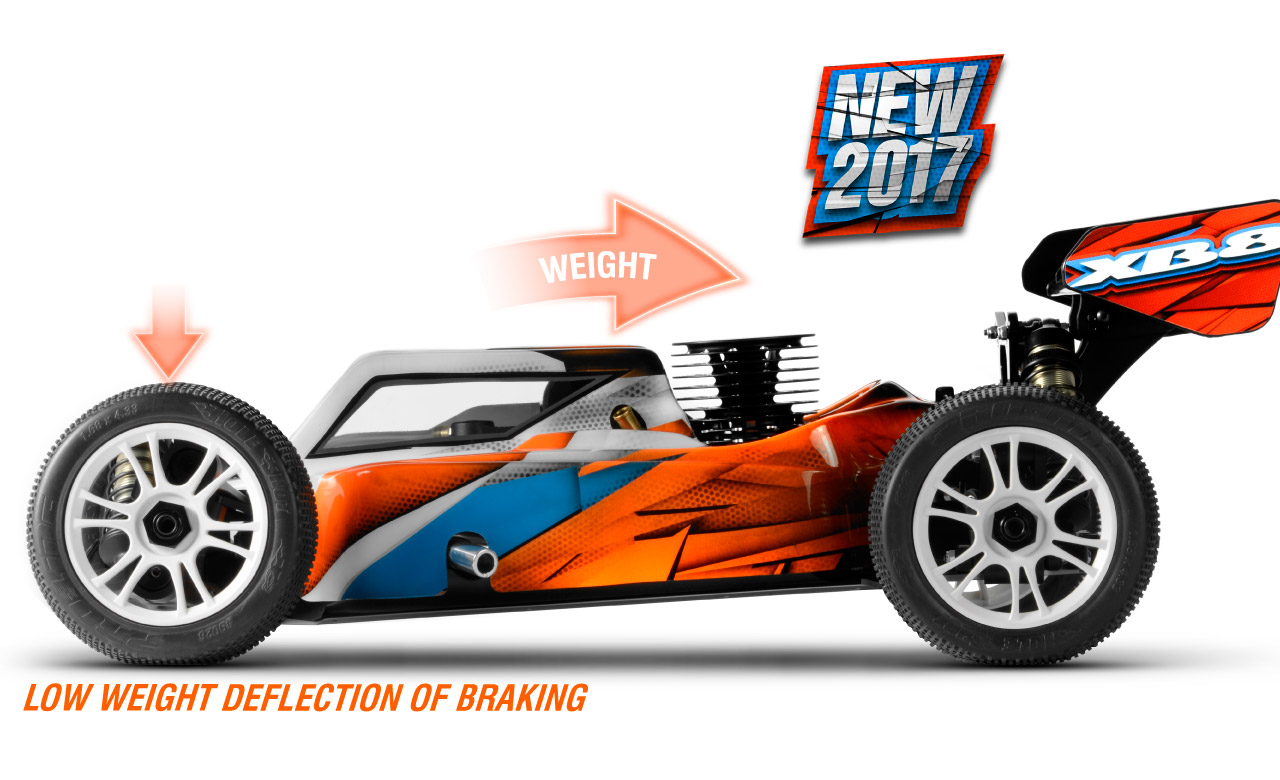

Weight Balance.

An all-new, improved weight balance was created by moving the front lower suspension arms more frontwards.

This new weight balance makes the car easier to drive, increases predictability, makes the car extremely resistant in rough parts of the tracks, and gives great handling in jumps and fast parts of the track.

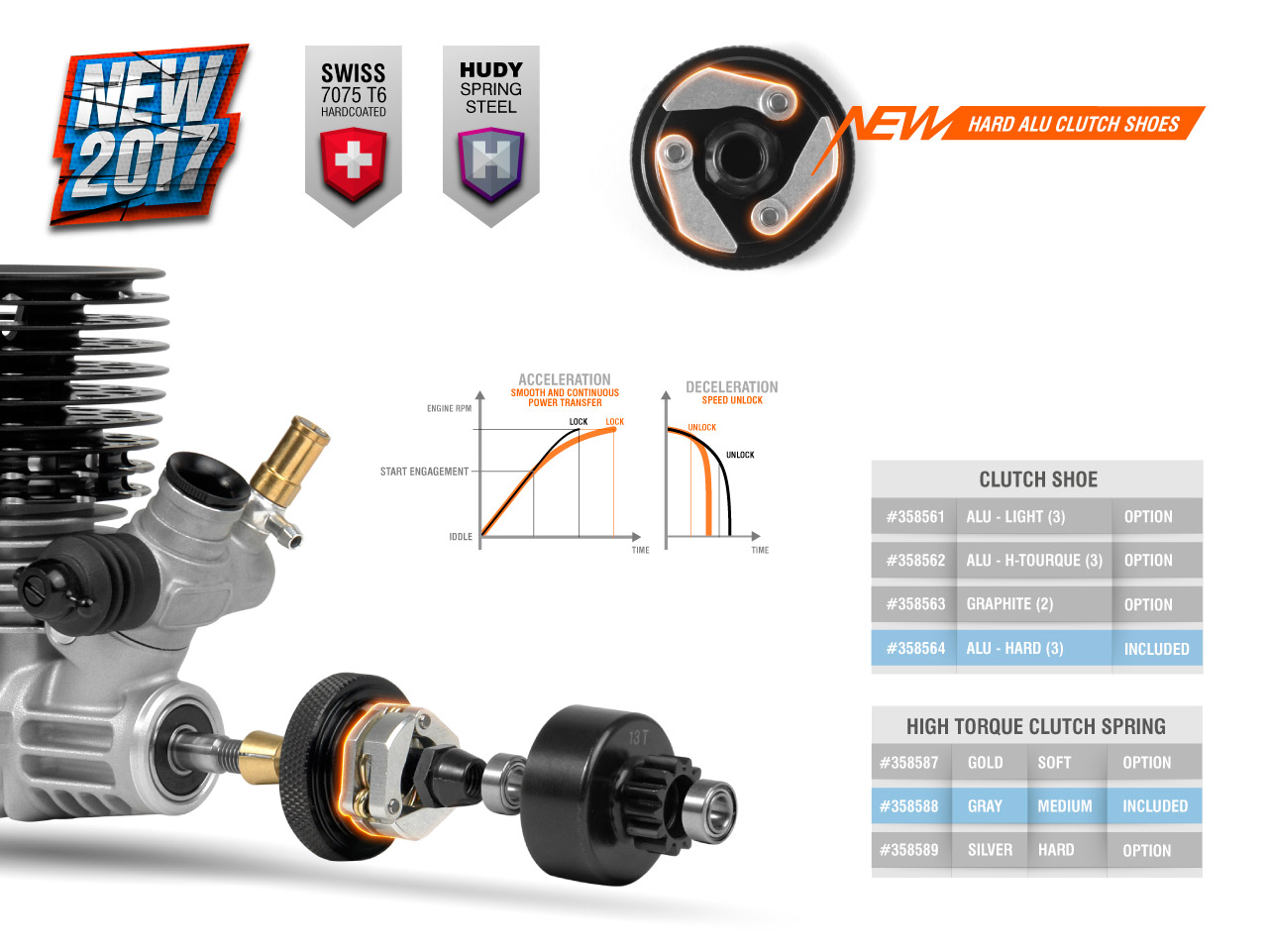

High-Torque Clutch.

The all-new hard alu clutch shoes allow for smoother engagement. The Swiss 7075 T6 clutch shoes are small, lightweight, and designed for engagement during the entire travel of the shoe. The shoes are less sensitive to wear and give improved lifespan.

The high-torque clutch provides smooth, continuous power transfer from the engine at high RPM. The clutch engages higher in the RPM range, resulting in more controllable power during acceleration, while still maintaining good handling and performance on jumps.

The Swiss 7075 T6 aluminum flywheel has a smaller diameter but heavier weight. The smaller diameter allows the flywheel to be more protected after landing large jumps, so there is a reduced chance of accidental engine stoppages.

The extra-tough flywheel nut is machined from Hudy Spring Steel™.

The clutch is equipped with soft clutch springs; optional medium and hard springs are also available.

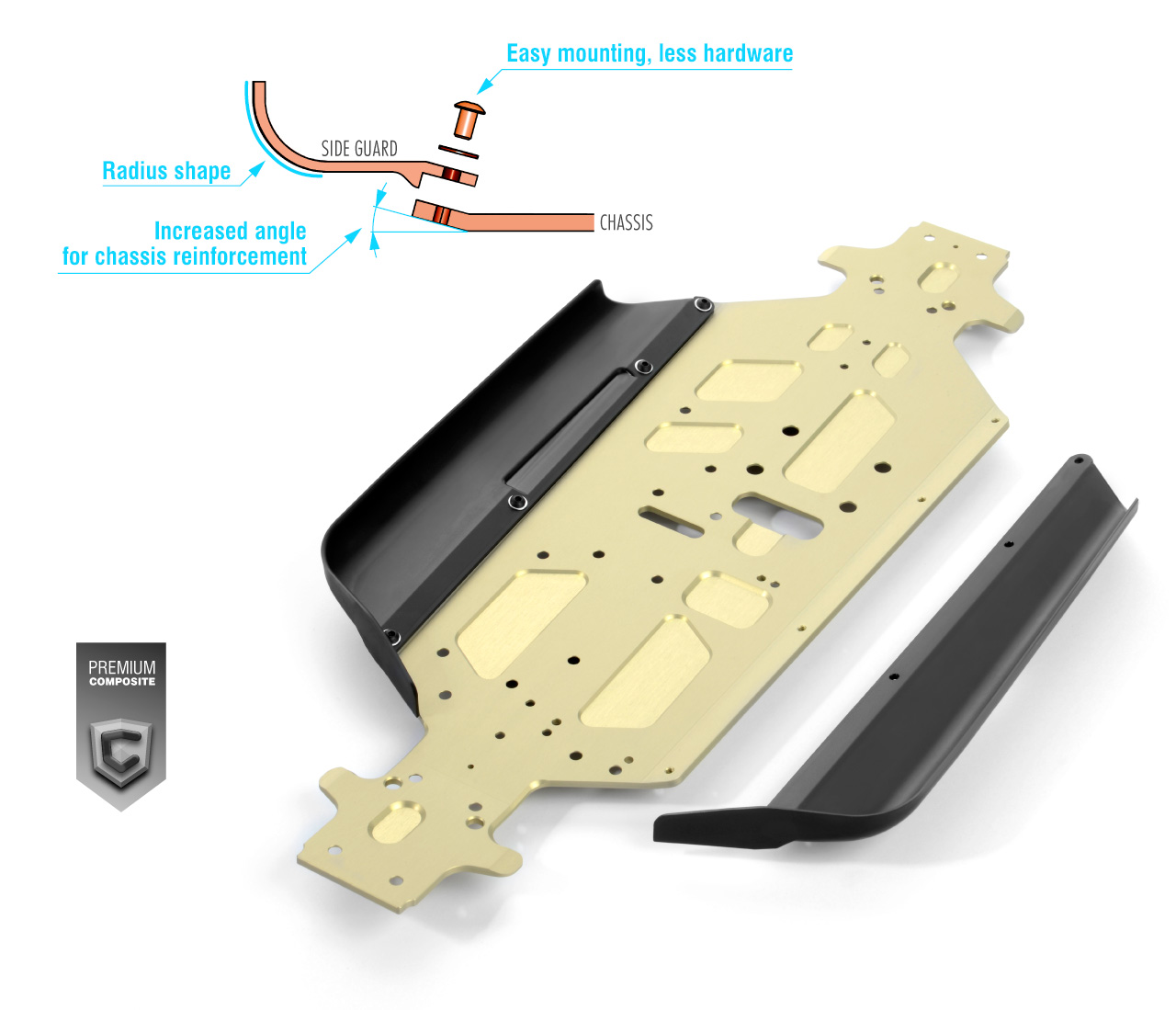

Side Guard Braces.

All-new optional side guard braces allow for very efficient and easy chassis flex adjustment to adjust the handling of the car to different track conditions. By adding the graphite braces, the entire chassis is reinforced and stiffer flex will improve handling in high-traction conditions.

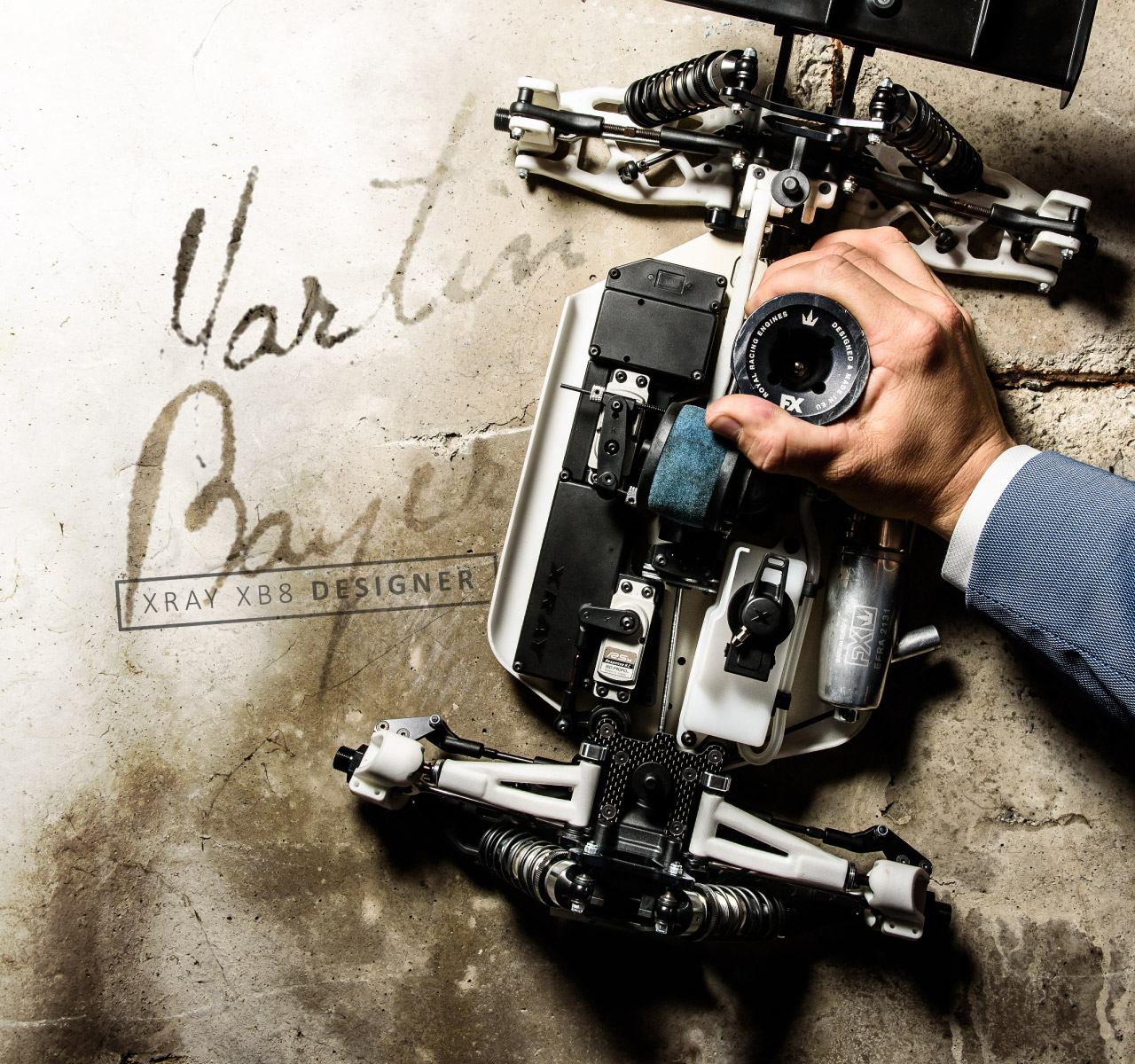

Chassis.

The XB8 chassis is CNC-machined from 3mm high-quality Swiss 7075 T6 aluminum, strategically machined in low-stress areas, and then anodized to make it as light as possible without affecting strength or rigidity. Non-essential material below the engine, fuel tank, and differential was removed to allow for the lowest possible center of gravity and appropriate chassis flex.

The rear of the chassis is wider to increase stability, and the front is narrower to improve steering. The short chassis has weight balance frontwards (including engine, radio box, fuel tank, and center diff).

Side Guards.

All-new side guards incorporate a larger bottom radius to make the car more stable on rough tracks. The radius of the side guards increases the car’s longitudinal flex. The side guards are moulded from all-new composite mixture for increased flex that helps generate more traction.

The tough composite side guards protect the car, muffler, and fuel tank from side impacts. The side guards perfectly fit the chassis and seal against dirt.

Chassis Braces.

Front and rear chassis braces have a significant influence on chassis stiffness and flex, and as such have great impact on handling under different grip conditions.

The rear brace has a direct mounting to the rear bulkhead instead to the rear shock tower. The mounting to the bulkhead eliminates transfer of vibrations and energy from the suspension via shock towers. This helps to improve landings and generates more off-power traction.

The rear brace is moulded from a medium-stiff composite mixture for better flex & rigidity, and allows the mounting of optional graphite inserts to reinforce the chassis brace to make it even stiffer (suitable for high-traction conditions).

Suspension Concept.

Suspension geometry is one of the most important features of any RC model car, yet at the same time is also one of the most difficult and challenging features for a designer to create and perfect.

Suspension is always a mixture of the following:

• Design & shape of individual suspension parts

• Flex & hardness

• Material characteristics

• Mounting method

• Ability to retain freedom of movement

• Geometry & position of connecting point mounting points

From arms & suspension blocks to light-yet-robust steering blocks, every suspension part has been specially designed for 1/8 off-road racing to provide responsive handling and performance characteristics under all racing conditions.

Over the years, XRAY has successfully gained and applied extensive knowledge of suspension geometry & stiffness, all of which has been carefully considered while designing suspension parts. The ultra-lightweight suspension parts are molded from special composite materials that make the parts very light, yet very durable to withstand the rigors of high-performance racing.

Front Upper Arms.

Moulded from a softer composite mixture, the front upper arm has increased flex in all directions to generate more traction. This also improves handling on rough or destroyed tracks.

Caster is easily adjusted using caster clips that are inserted either in front or behind the front upper arms.

Rear Uprights.

The 1-piece rear upright features geometry that allows it to generate more traction and better absorb bumps. The smart design allows the same upright to be used on both left & right sides.

The upright allows adjustment of the upper roll center by 3 different positions, and lower roll center by 2 different positions. The lower suspension pin on which the rear upright sits features 2 shims for wheelbase adjustment.

The rear uprights feature integrated geometry adjustments including:

• camber

• upper roll center

• lower roll center

• wheelbase

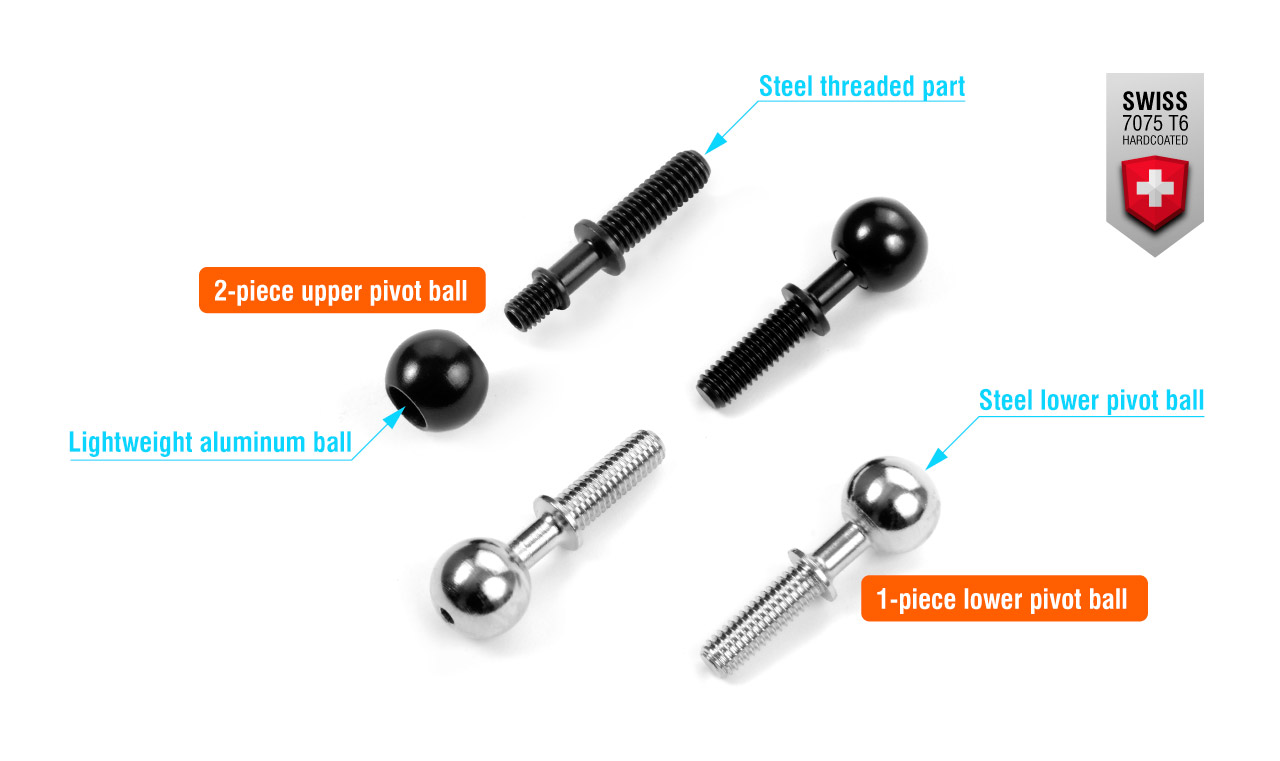

Pivot Balls.

To reduce weight and lower the CG, all-new front upper pivot balls are combined with steel threaded part for maximum strength. The aluminum ball is machined from premium Swiss 7075 T6 and additionally hardcoated for extended lifespan.

Ackermann.

Ackermann is easily adjusted on the machined Swiss 7075 T6 steering plate to ensure highest reliability and strength.

Bulkheads.

Diff bulkheads are an important chassis component, housing both the front and rear differentials and providing mounting points for the suspension mounts and shock towers.

The super-strong front & rear bulkheads withstand rigorous impacts and other abuse during racing conditions. The bulkheads have minimized ball-bearing play, resulting in increased gear teeth lifespan and minimized gear stripping.

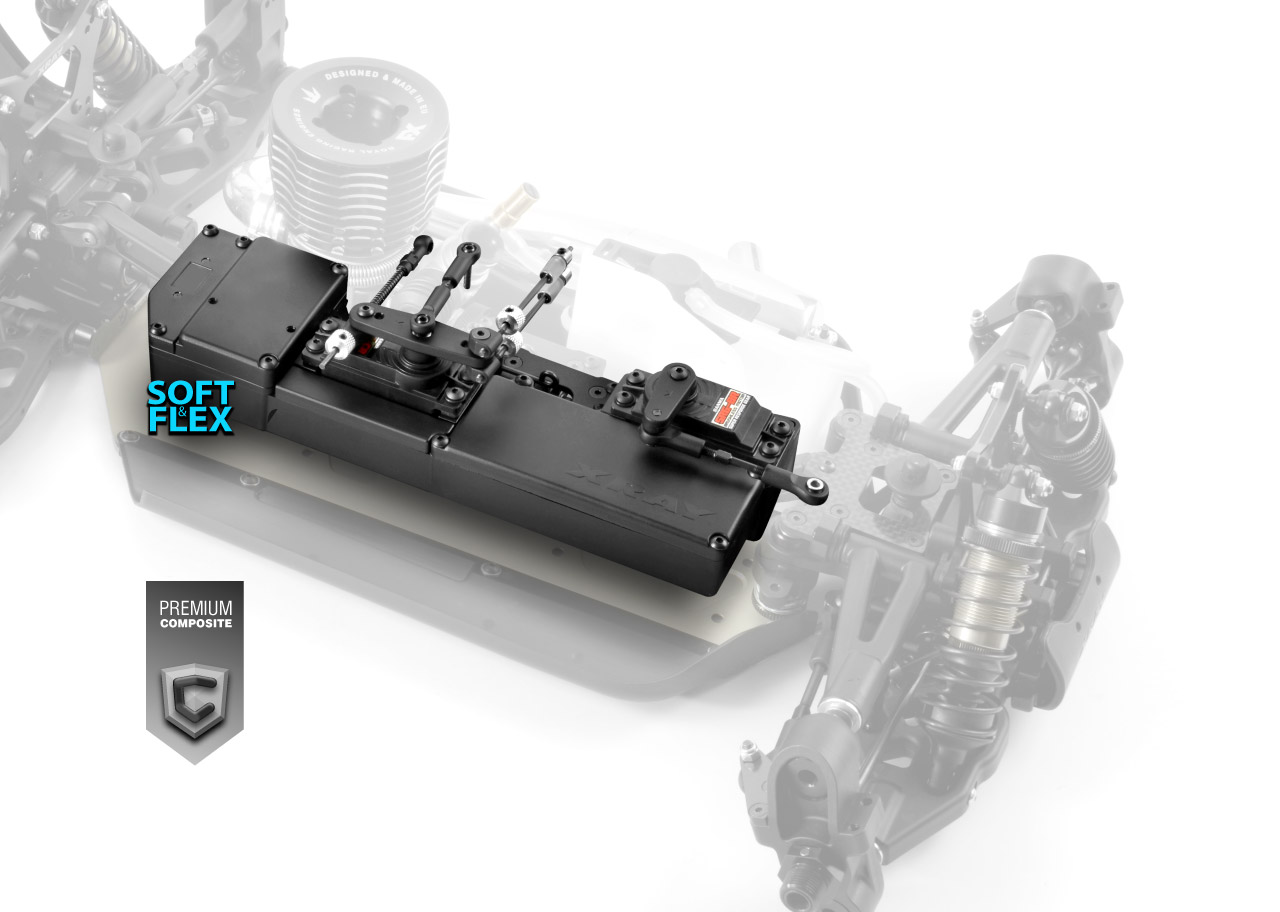

Radio Box.

To improve chassis flex & handling characteristics –especially in low- to medium-traction conditions – the radio box is moulded from a softer composite mixture which makes it more flexible.

The 1-piece electronics assembly is very compact and can be quickly & easily removed for servicing and cleaning. You need only remove a few screws from the bottom of the chassis to remove the entire electronics assembly from the car.

The large, molded radio box features a very clean design and layout that places the weight in key areas for proper balance. The batteries are placed along the front centerline of the chassis, and the lightweight receiver is placed on its side at the rear. The easy-access radio box is mounted on the side of the car and is secured by the fewest possible screws.

Servo Brace.

A connecting brace between the throttle servo and the radio box compensates for the softer, more flexible radio box, as well as eliminating throttle servo vibrations to the chassis. This ensures more precise throttle and brake control.

Drivetrain.

The XB8 is a conventional shaft-driven 4WD off-road car featuring:

• Front & rear gear differentials with adjustable oil viscosity, featuring 46T crown gears and 14T pinion gears

• Central differential with adjustable oil viscosity, featuring 46T spur gear with standard 13T engine clutchbell

• Front & rear universal drive shafts, and central CVD drive shafts

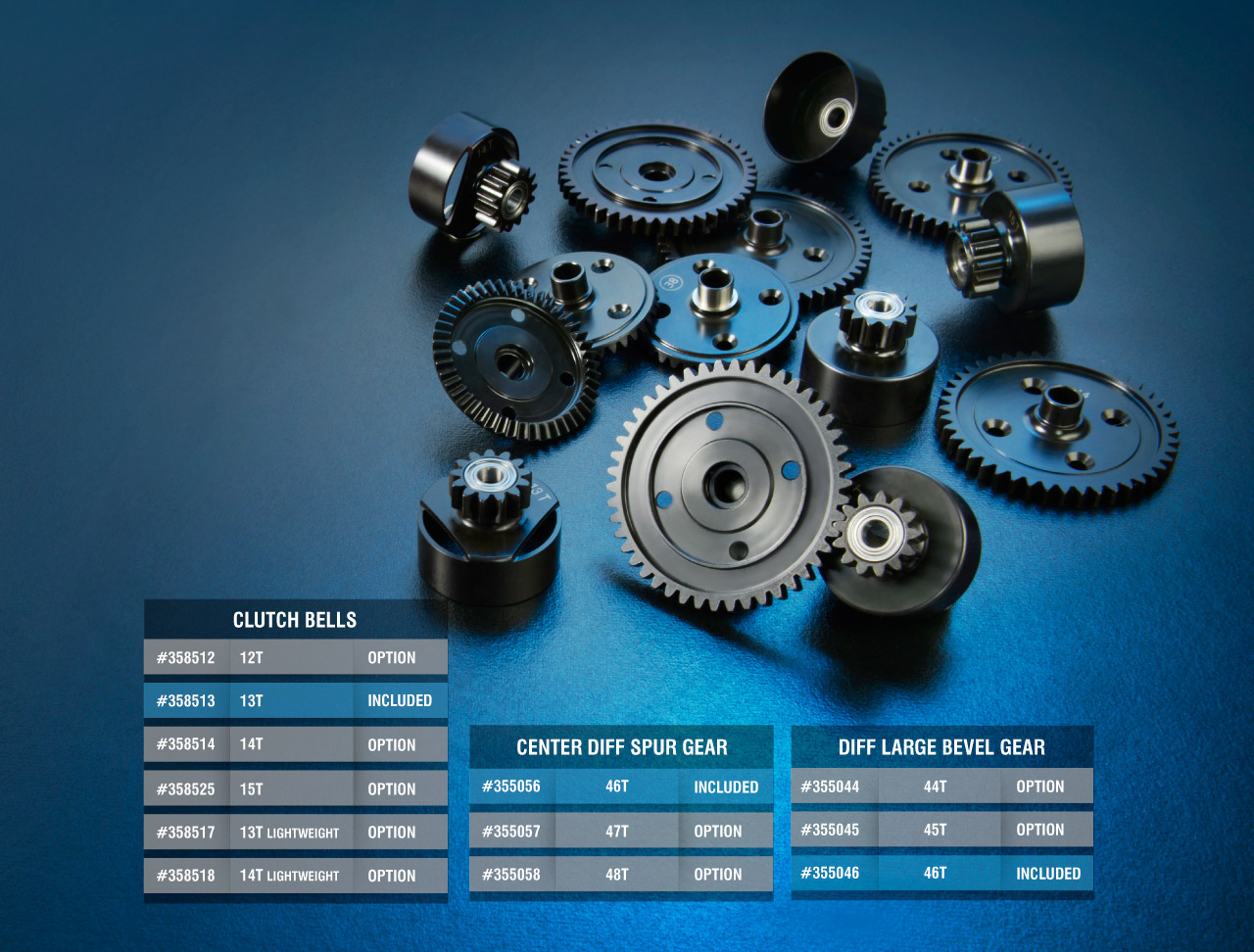

Diff Gears & Drivetrain Ratio.

Differential main gears are manufactured from HUDY Gear Steel on a precision manual gear machine. This material was specially formulated and developed for use in gears. All gears are hardened to provide the longest possible lifespan.

A wide range of different gears — spur gear, clutchbell, crown gear — is available for perfect set-up and tailoring to particular racing conditions.

• Clutchbells are available in sizes of 12T, 13T, 14T, and 15T.

• Spur gears are available in a range of 46T, 47T, and 48T.

Drive Shafts.

The universal drive shafts used on the XB8 generate more traction and have less resistance in the front when maximum steering angle is applied.

All drive shafts are manufactured from world-renowned HUDY Spring Steel™, resulting in some of the world‘s thinnest yet most durable drive shafts used in off-road cars. All drive shafts and outdrives are hardened with a proprietary hardening process to provide unsurpassed lifespan & reliability.

The central larger & stronger outdrives feature protective rubber boots, thick 3mm pins, and protective locking rings.

Turnbuckles.

To guarantee maximum reliability, all turnbuckles are manufactured from a special blend of HUDY Spring Steel™ which is specifically formulated for turnbuckles. The turnbuckles have a tougher core, making them very well suited for the steering system and rear upright linkages.

Alu Hex Hubs.

Ultra-lightweight 17mm wheel hex drive hubs are CNC-machined from Swiss 7075 T6 black-coated aluminum.

The alu hex hubs are specially machined to reduce rotating weight while guaranteeing wobble-free wheel mounting.

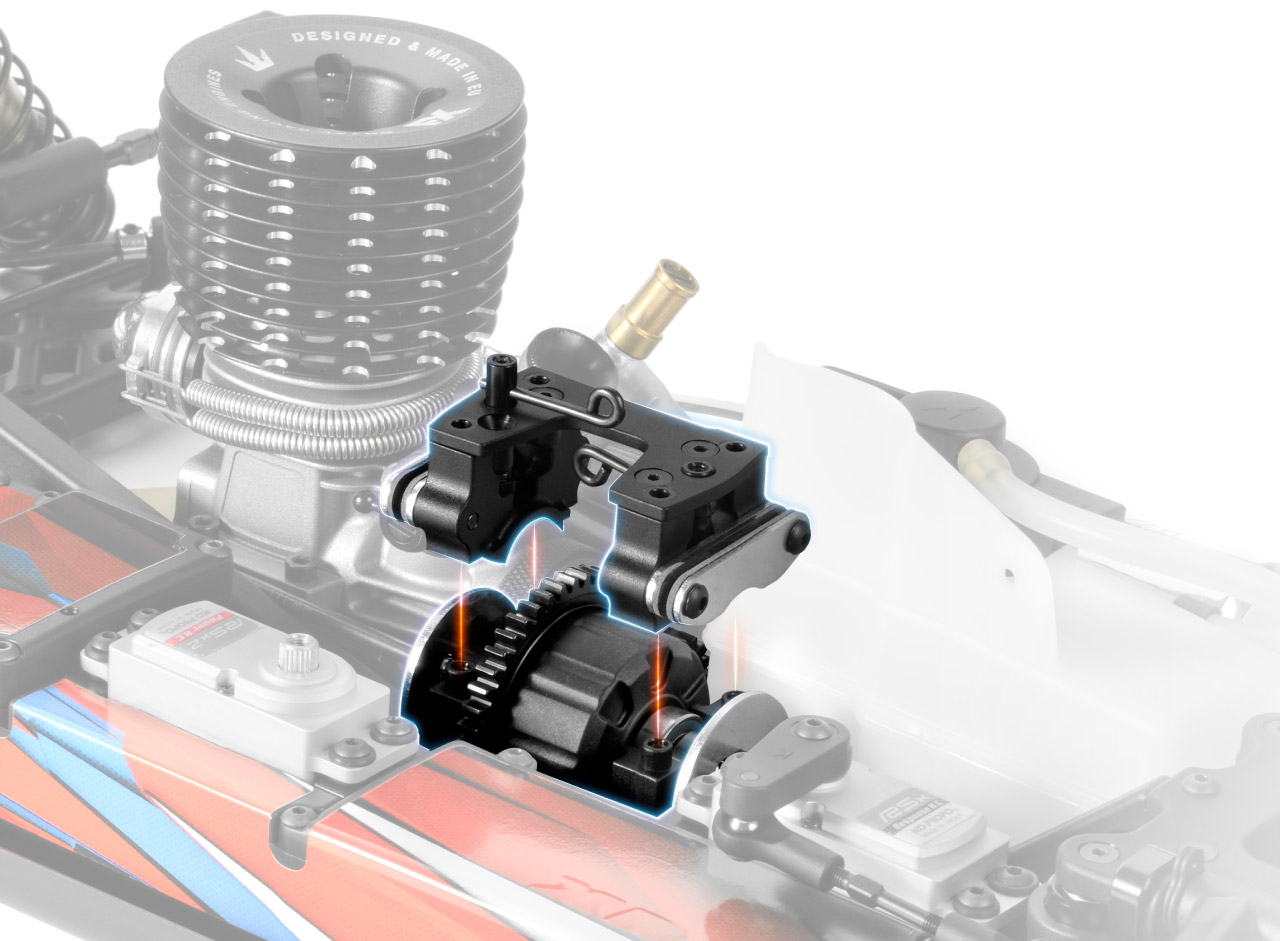

Center Differential Access.

Access to the center differential is super easy by releasing the upper deck with only 4 screws. The low center diff housing is sized to accommodate optional spur gears, and the stands are lowered to keep the weight as low as possible and to allow smaller central diff gears to be used. The center diff housing stands hold the effective and race-proven brake system.

Brake System.

The XB8 features a well-proven, high-performance braking system that is strong, precise, and dependable to make slowing and stopping almost effortless. Coupled with the car’s balanced load distribution, the extraordinary control imparted by the braking system gives you complete confidence as you pitch the car into corners.

XRAY focused on the smallest details when designing the brake system. The laser-cut, precision flat-ground steel brake disk allows for fade-free braking in conjunction with the special high-grip brake pads installed on the laser-cut brake plates. The brake disk is small, slim, and very light. The precision hand-grinding allows true, wobble-free rotation. Brake inputs are transferred precisely to the brakes thanks to the rigid, high-precision machined brake cams. Both brake disk and brake pads are specially heat-treated for maximum lifespan.

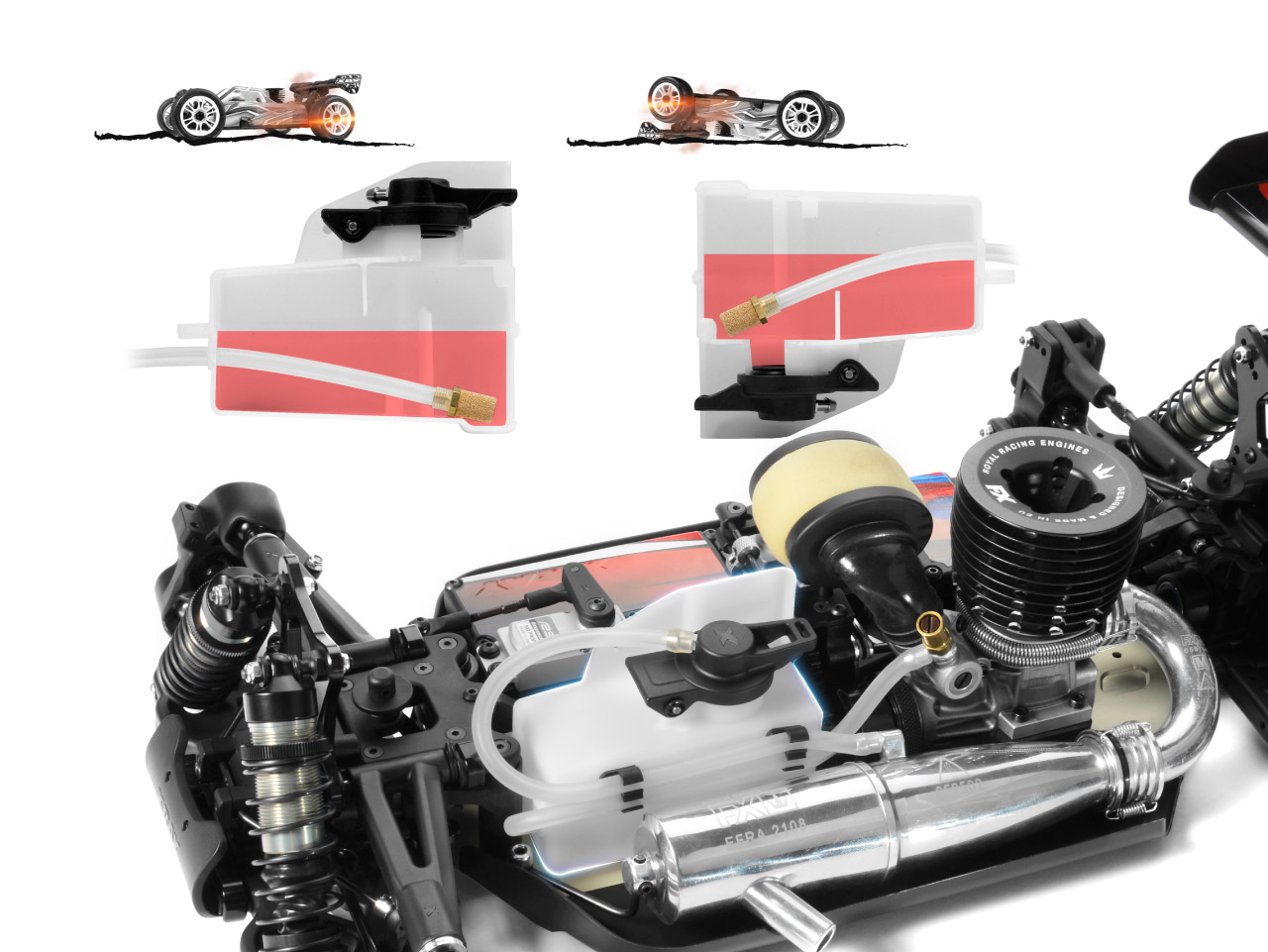

Fuel Tank.

The extra-strong fuel tank features an integrated floating stone filter that ensures that the fuel pickup will always be in the correct orientation, even if your car isn’t. This fuel pickup system will allow fuel to continue to flow to your engine, even while waiting for a marshal to reach your inverted car and put it back on its wheels.

Internal baffles were added inside the fuel tank to ensure that the fuel will always be in the area around the fuel line intake so even in large jumps the fuel will be constantly supplied to the engine.

The fuel tank cap features a very strong spring which ensures the cap will always close after refueling, and the specially-designed rubber seal perfectly seals the fuel tank and ensures no fuel will leak outside.

The fuel tank is molded from a special composite mixture that ensures very high reliability and rigidity. The molded-in splashguard protects the brakes from fuel spillage. The tank is mounted with rubber grommets to absorb vibration, and small composite holders secure thick 5.5mm silicone fuel tubing. Gluing of the tank pieces is performed by a special self-developed robotic system that ensures maximum accuracy and precision in pre-heating and gluing.

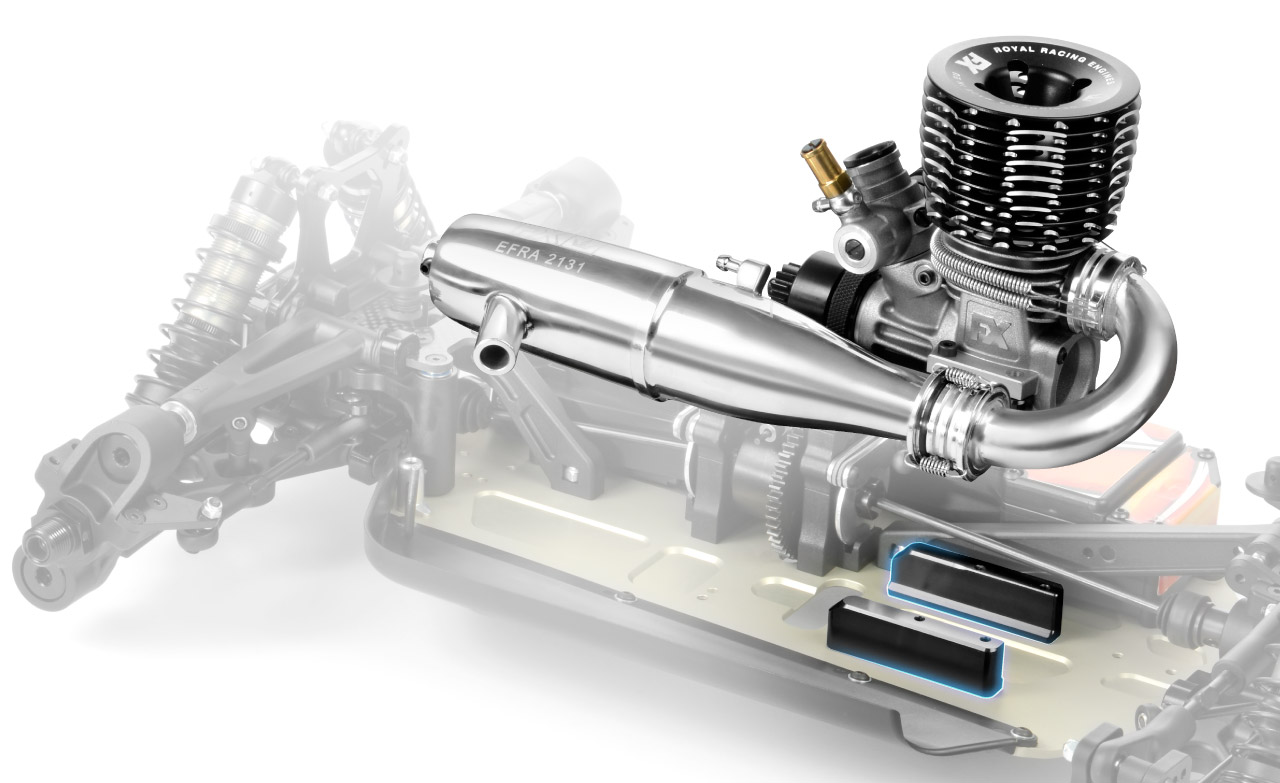

Engine Mounts.

The engine mounts extend up to the engine front bearing for improved chassis reinforcement in the longitudinal direction, and in jumps this will minimize chassis bending between the clutchbell and spur gear.

The CNC-machined aluminum engine mounts are made from superior-grade, lightweight alloy which helps to dissipate engine heat. The engine mounts are easily adjustable to obtain proper gear mesh.

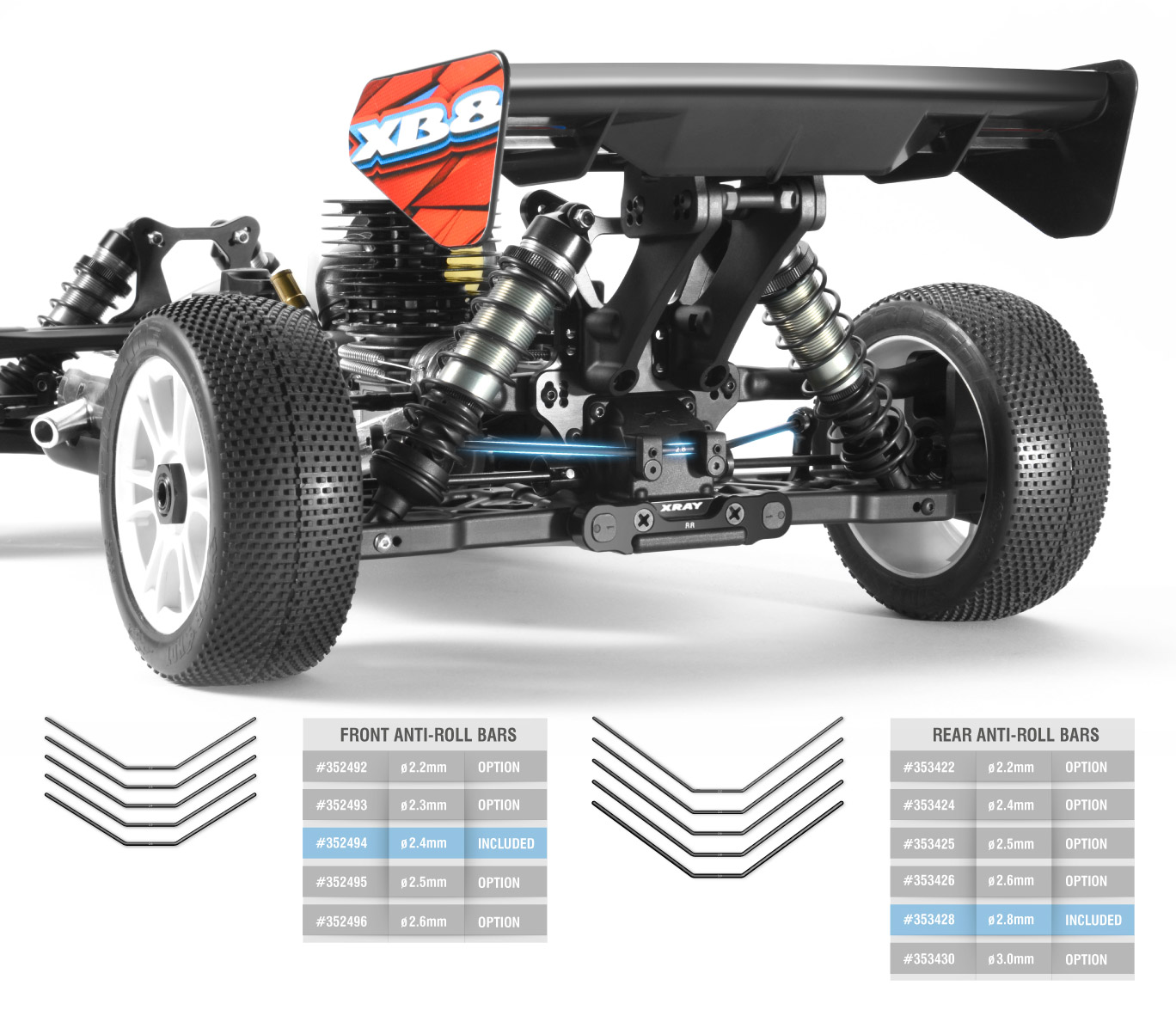

Anti-Roll Bars.

Anti-roll bars used to stabilize the car are manufactured from spring steel material. The front & rear roll bars are easily mounted to the diff cases, and can be adjusted through adjustable linkages.

Anti-roll bar wires of different thickness are optionally available for fine-tuning your set-up.

Shock Towers.

Aluminum towers are CNC-machined from premium Swiss 7075 T6 and then additionally black coated. The stiffer alu shock towers give better performance at high-traction tracks.

Optional graphite shock towers offer more flex to generate more traction, and are recommended for low-traction tracks.

Shocks.

Oversized big-bore shocks feature 16.2mm I.D. shock bodies which are externally threaded for use with an adjustable collar for quick & easy spring preload adjustment. The shock bodies are hardcoated in a titanium color, and feature a 1-piece alu shock cap.

The specially-formulated rubber material of the shock membrane ensures equal damping characteristics from the beginning of the race to the end, even after extreme use.

The lower shock assembly ensures very free movement of the shock rod inside the shock body, while at the same time minimizing oil leakage and keeping dirt out. Two shock O-rings – manufactured from a superior silicone compound to allow ultra-free movement of the shock rod while still maintaining a tight seal – are installed in the lower part of the shock body and are secured with composite shims. The entire lower shock assembly is secured with the lower aluminum shock cap which makes assembly/disassembly very quick & easy.

Thick, robust shock shafts will handle all abusive racing conditions and big jumps. The 3.5mm thick shock shafts are precisely machined from special high-tensile steel, and afterwards are ground to a super-smooth finish to ensure smooth movement.

Shock Springs.

XB8 shock springs offer a mix of progressive & linear characteristics. XB8 springs are slightly progressive, but under more compression change characteristics to become more linear. This gives excellent feeling & feedback of the car in all different track conditions.

These XRAY shock springs, like all other XRAY springs, are manually measured, selected and matched into pairs to guarantee precisely equal length and damping characteristics.

There are two types of springs offered optionally:

• Linear: Spring rate is constant during the entire spring compression. Springs with different spring rates are available as optional tuning parts.

• Progressive: Spring rate is not linear, but rather the spring rate get progressively heavier the more the spring is compressed. As the car initially enters the corner, the spring works like a softer spring to provide maximum traction. As the chassis begins to roll in the middle of the corner, the spring rate progressively increases until it works like a stiffer spring which allows the car to maintain maximum cornering speed.

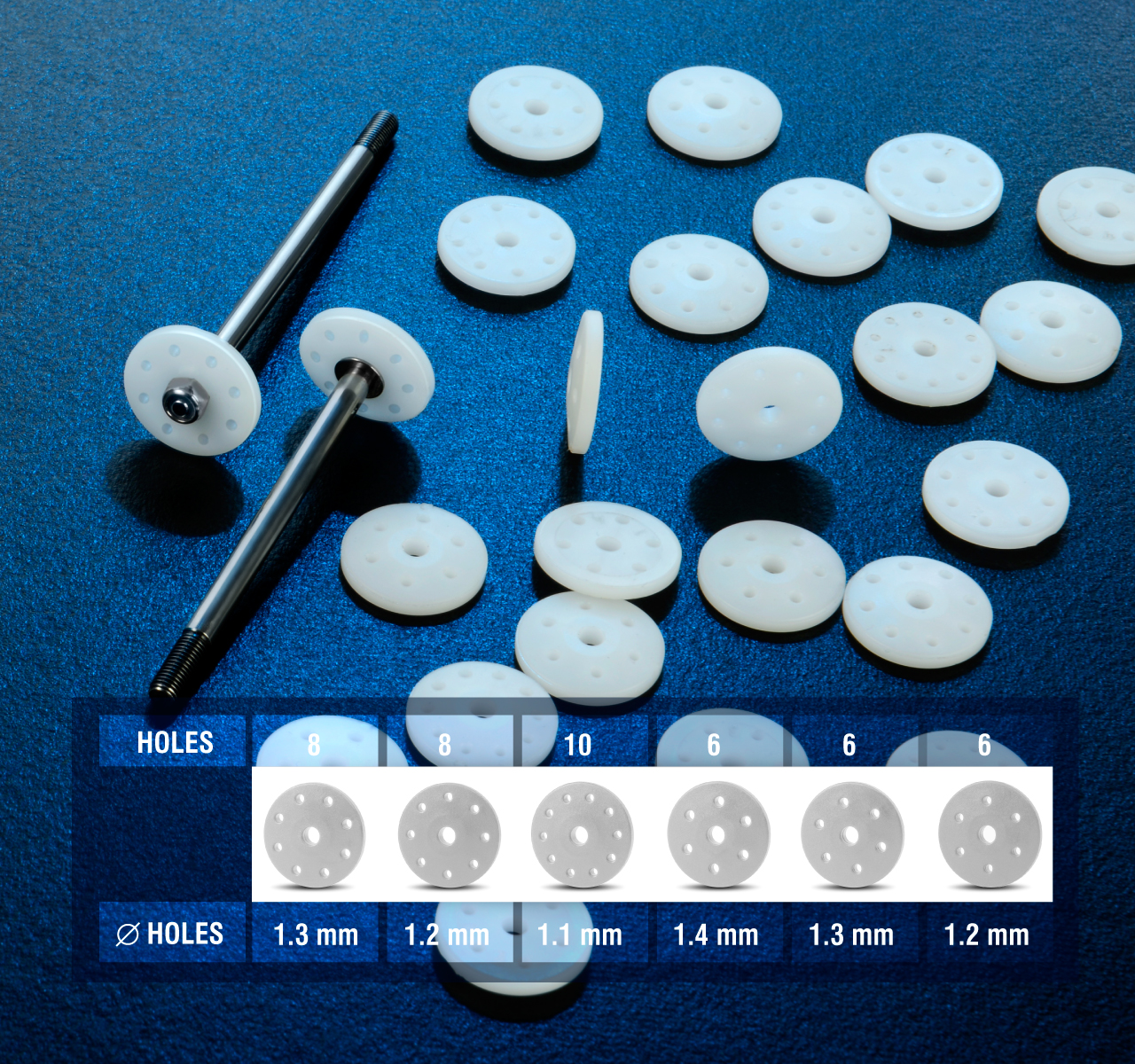

Shock Pistons.

Ultra-precise shock pistons feature 6-, 8- and 10-hole options. The big-bore pistons are molded from tough, well-proven Delrin® material to provide smooth action and durability. The precision molding production process ensures perfect piston roundness after production, so that the pistons move super-smoothly inside the shock bodies for identical perfect action in all four shocks.

Silicone Oils.

HUDY Exclusive Silicone Oils are manufactured in Europe and each batch is laboratory tested and calibrated to ensure the highest possible consistency and quality from batch to batch. Based on the industry-standard cSt rating, the new line of oils will be easy to identify, adjust, and feel.

When following any set-up sheets by XRAY or XRAY team drivers, you can be sure that the oils you will get for your car are exactly same as those used by the factory racing team, thus ensuring very exacting set-ups and handling.

Graphite Grease.

The XB8 includes premium HUDY Graphite Grease - a high-performance, advanced-technology semi-fluid lubricant which incorporates both extreme pressure additives and finely-dispersed graphite for load carrying. HUDY Graphite Grease is intended primarily for the lubrication of rotating parts and loaded gears. In addition to providing outstanding load carrying, it is formulated to have excellent adhesion and resistance from "flinging off" under extreme conditions. HUDY Graphite Grease reduces wear and increases parts life.

Click here for more information of the full HUDY Grease range

Air Filter.

To minimize the dust getting into the air filter, the air filter cover mounting positions were modified and improved.

The smooth-flowing, efficient air filter is made from two parts. Air filter oil is included as standard. The universal rubber elbow allows fitment to most standard 1/8 buggy engines.

Ball-Bearings.

The drivetrain ball-bearings now include grease instead of light oil to maximize the lifespan of the ball-bearings, especially in dusty conditions. A full set of 24 high-speed, blue-sealed ball-bearings are used throughout the drivetrain to ensure maximum efficiency.

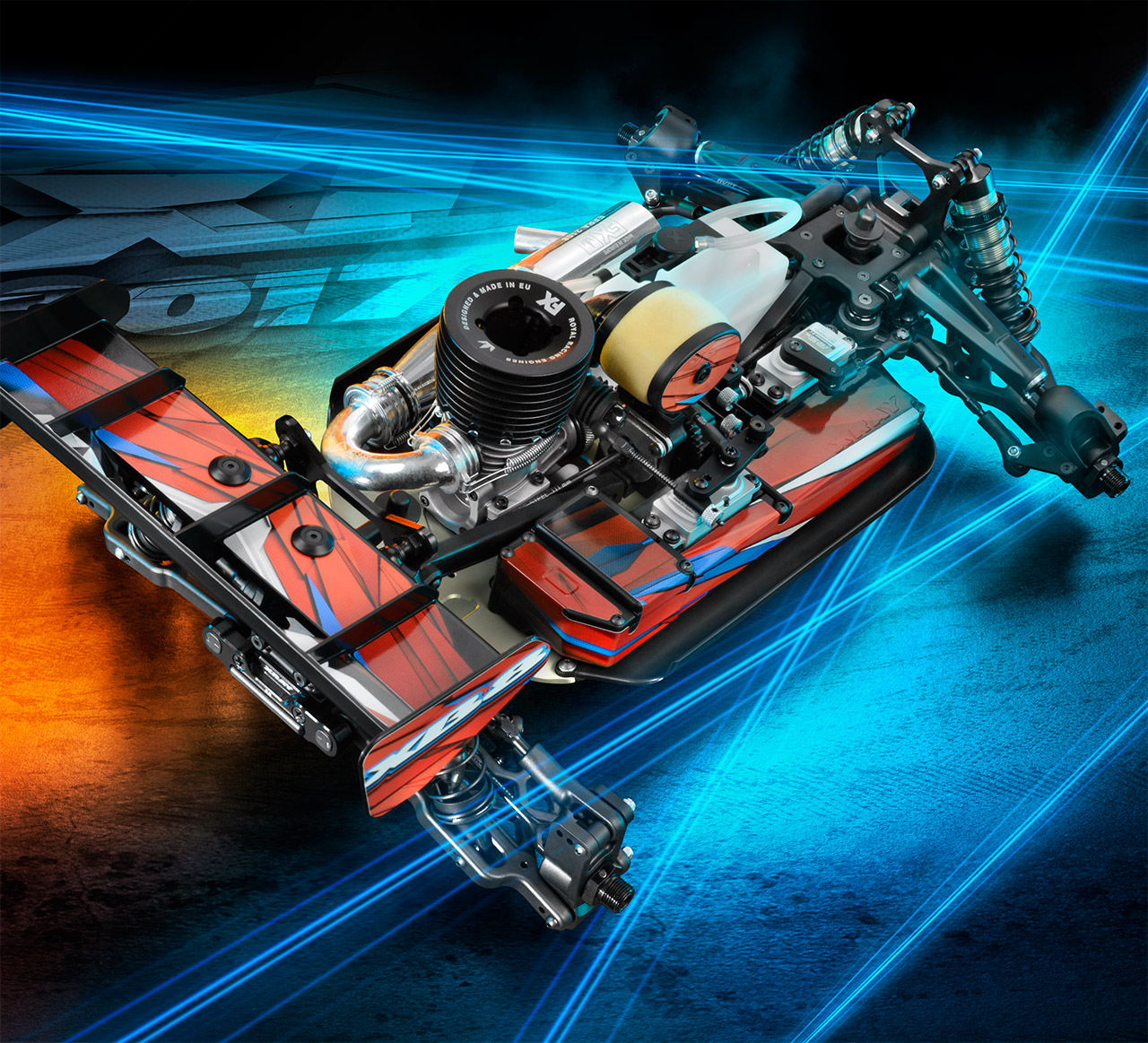

Body.

The all-new XB8 body was completely redesigned & improved in all aspects. Improved aerodynamics, increased downforce, increased side stability, improved landing of the car, and significantly increased rear downforce make the XB8’16 racing body unbeatable in performance design. Produced from high-quality, premium Lexan™ material.

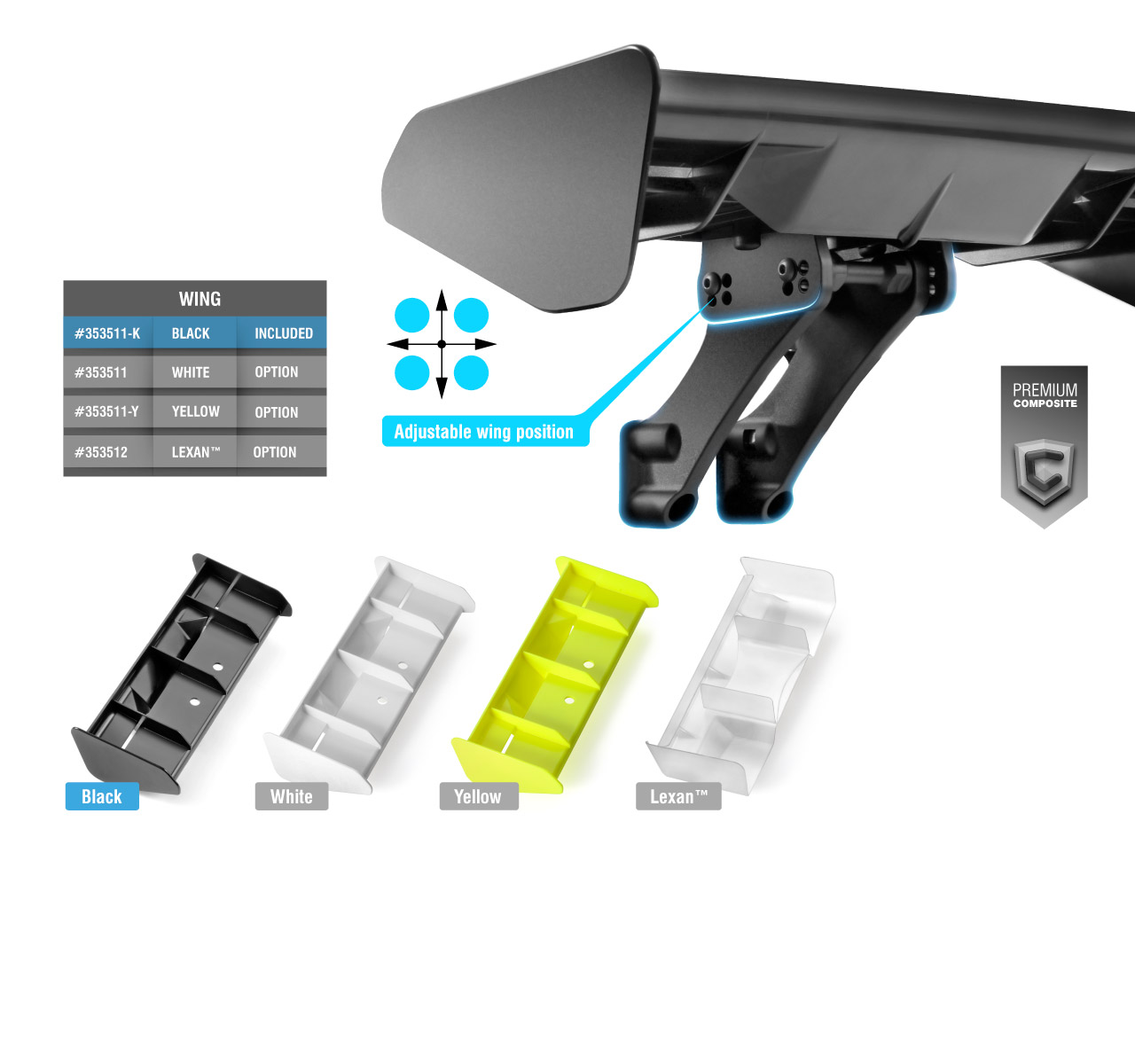

Wing.

The stylish and effective rear wing was designed to provide the appropriate amount of downforce and generate required stability for the car. Made from a strong special composite mixture, the wing was designed to survive severe abusive and extreme crashes while keeping its shape.

Rear wing holders are made from a special composite mixture to withstand abuse and crashes, and feature several different wing mounting positions.

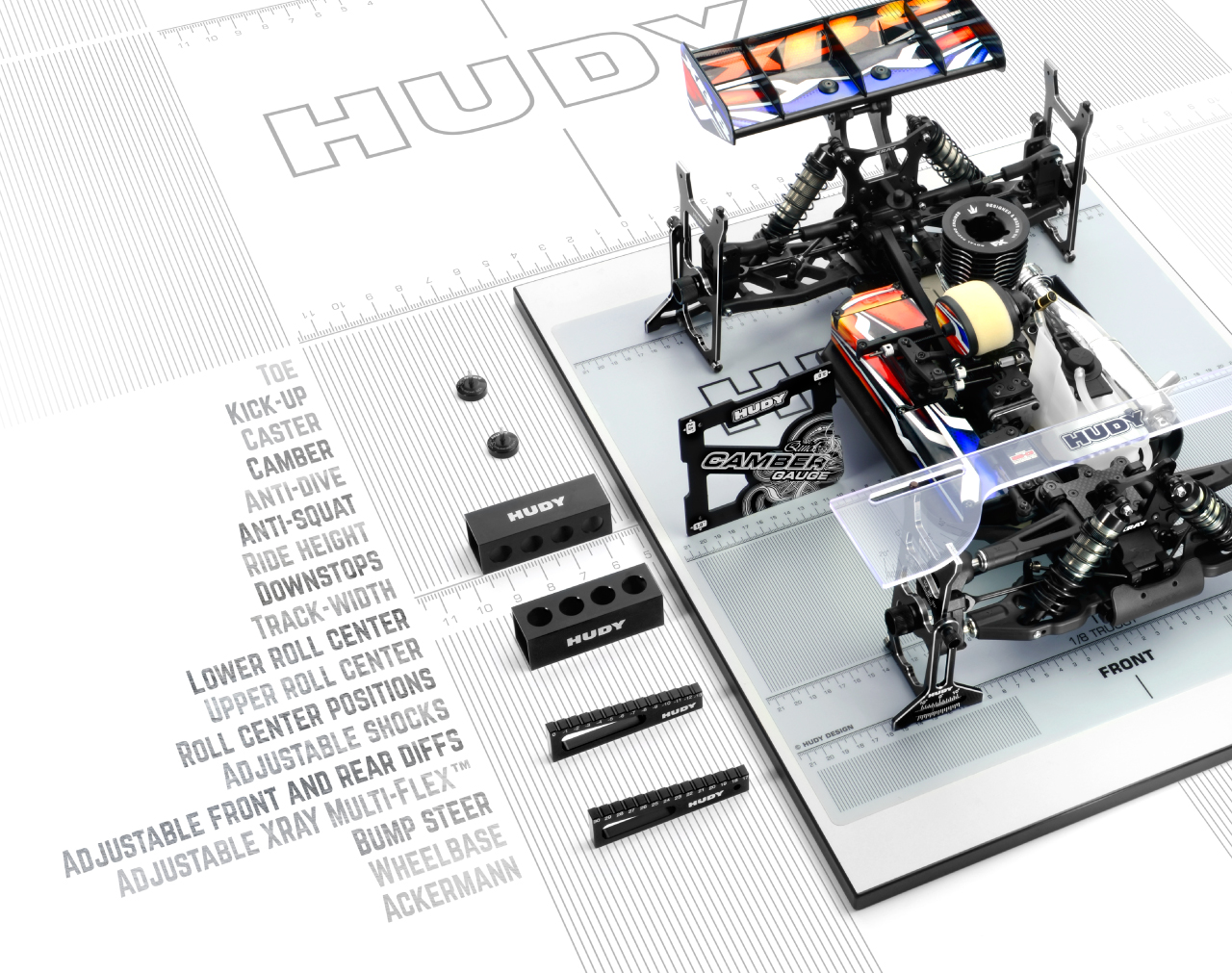

Adjustment Possibilities.

The XB8 features fully-adjustable front and rear suspension geometry. For quick & easy adjustment, we recommend using set-up tools and accessories from HUDY, the world leader of RC tools.

Chassis Balance.

The chassis design focuses on balanced weight distribution and weight transfer. Centerline holes are pre-drilled for easy balancing with the HUDY Chassis Balancing Tool #107880.

HUDY Set-Up Book.

The XB8 is one of the most adjustable off-road cars in the world. Whether you are a hardcore racing enthusiast or a club-level sportsman, you can very easily adjust the XB8 to suit your driving style, track type, and track conditions.

To fully comprehend the set-up possibilities of the XB8, we highly recommend the HUDY Set-up Book which is loaded with over 50 pages of high-quality pictures and easy-to-understand RC car set-up explanations. The HUDY Set-up book will teach you many set-up tips & tricks to help improve your set-up skills, ultimately translating into improved racing performance with your XB8. The HUDY Set-up Book is available for download exclusively at www.hudy.net

Instruction Manual.

XRAY Instruction Manuals have become the industry standard, and are simply the best manuals you will ever get with an RC model car. Whether you are a first-time builder or an experienced racer, all instructions are straight-forward and easy to understand. The full-color Instruction Manual contains large 3D illustrations that show all assembly details in the easiest and most comprehensive manner.

VIP Customer Treatment.

Owning an XRAY model racing car is an experience unto itself. Not only will you own the most premium luxury model racing car in the world, but you will also become a member of the prestigious family of XRAY owners with direct support and service from the XRAY factory. XRAY brings you the most up-to-date RC website on the Internet, with daily racing news, and the latest product developments.

If you have any questions, problems or comments, you can ask the XRAY Support Team or any XRAY Factory Team Driver on the XRAY Support Forum. You can even upload your own set-up sheets or download from the thousands of different set-up sheets available from around the world at the exclusive XRAY Virtual Set-up Sheet Database. And that is only the start of the VIP treatment you get by joining Team XRAY.