2023 All-new Features.

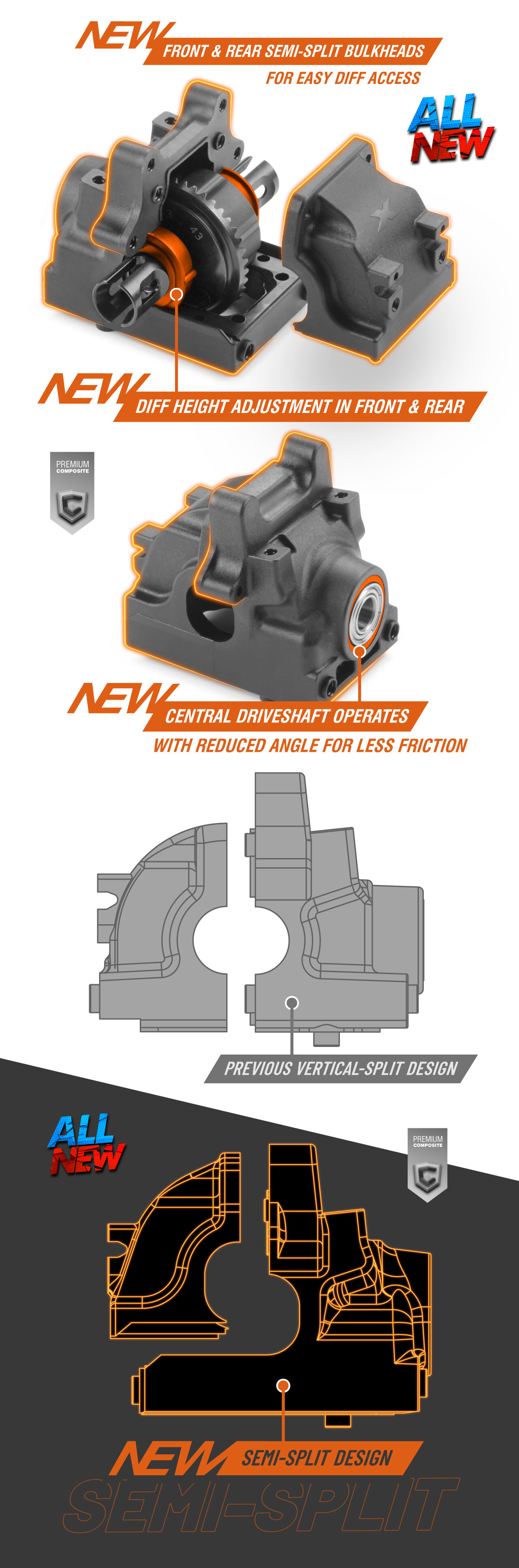

- All-new front & rear semi-split bulkhead with quick differential access without disassembling suspension

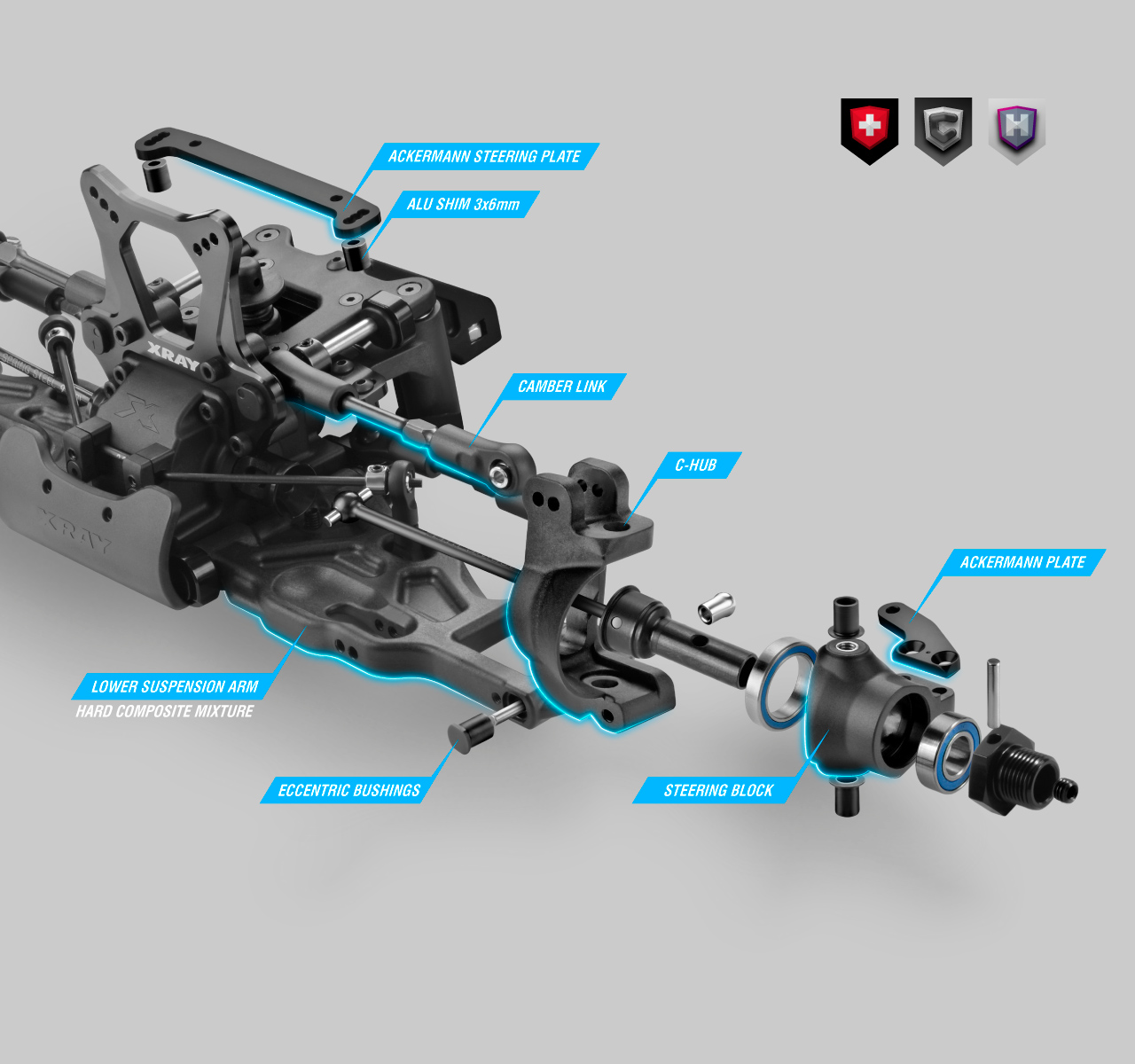

- New front & rear diff height adjustment through eccentric bushings

- Improved central drivetrain angle and height adjustment

- Redesigned chassis for semi-split bulkheads increases traction via improved rear chassis flex

- Adjustable center assembly with adjustable motor position to adjust weight balance

- Redesigned Ackermann plate to accommodate the new semi-split bulkhead

- Redesigned composite graphite servo saver to accommodate the new semi-split bulkhead

- Redesigned front aluminum & rear graphite shock towers

- Reinforced M3/M4 steel shock screws for increased reliability

- Updated alu steering plate and servo saver

- Front & rear lower suspension holders with new mounting positions

- Front upper suspension holder matches the new servo saver

- Redesigned wing holder fits the new semi-split rear bulkhead

- Wickerbill rear wing allows quick downforce adjustments and pre-marked airflow holes to reduce downforce

- Front upper arms with new mounting locations for optional wings for improved downforce

- New lower front bumper reduces weight and matches the new semi-split bulkhead

- Improved lower shock absorber ball joints for more secure fitment of the lower spring retainer

- New 46/13 internal gear ratio

European Champions.

The XRAY XB8E platform displayed its incredible performance advantage by winning the European Championships in the hands of Jean-Pierrick Sartel.

Team Development.

All the work and refinements on the XB8 were incorporated based on our own experiences and also from the vast majority of feedback from drivers all around the world. New ideas and prototypes were long-term tested by the factory team worldwide to ensure the improvements would work well in all track conditions and tracks in Europe, America, and Asia.

Martin Bayer

XRAY XB8 Designer

Heritage.

“I designed and hand-made my first off-road cars back in 1986, and they were dominating the races thanks to unbeatable reliability and best performance. Years later in 2004 we have started our first mass production XRAY XB8 platform based on our long-term experiences, knowledge, and R&D expertise gained over decades, taking over the heritage I brought with me"

Dipl. Eng. Juraj Hudy

XRAY Chief Designer

Perfection.

Designed in virtual reality using the world's most sophisticated CAD tools, and manufactured using the world's best machining and molding machinery, the XB8 achieves a level of perfection in all details that is second to none.

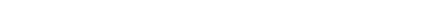

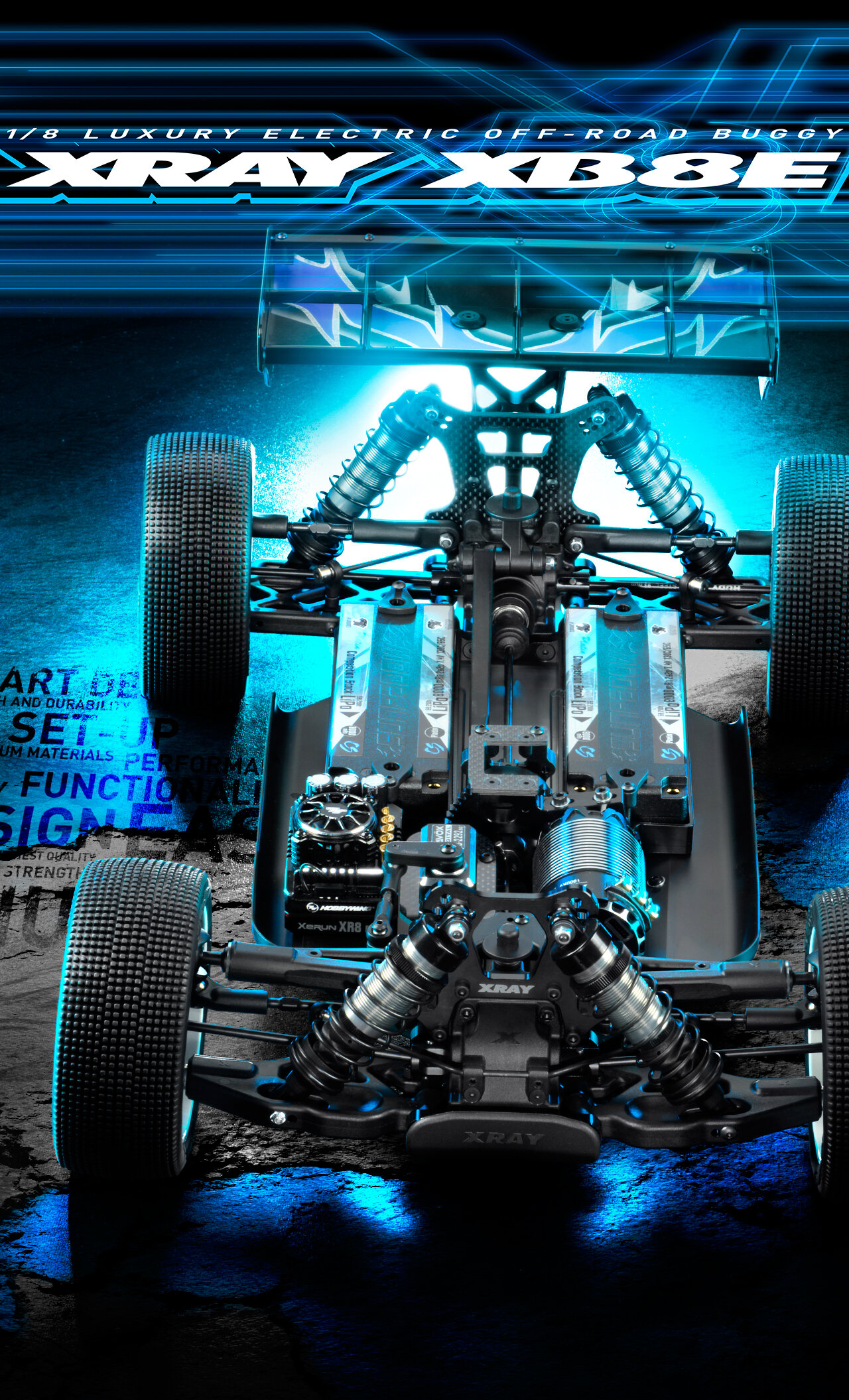

XB8E Platform.

Based on the ultra-successful XB8 platform, XRAY proudly presents the new XB8 which incorporates the latest improvements and refinements gathered by the team, race-proven in the highest competition races around the world.

- Functionality

- Highest quality

- Highest performance

- Easy to service

- Easy to set up

- Strength and durability

- Ingenuity

- Smart design

- Premium materials

Legend.

XRAY has been a driving force in the 1/8 off-road car racing scene since the release of the first XB8. Continuous development and evolution of the XRAY product line has led to ever-increasing performance. The craftsmanship, durability, and performance of XRAY kits have become legendary. Be part of the family, live the heritage.

Made in Europe.

Designed, developed, and fully manufactured in-house at the XRAY factory in Slovakia, Europe, using the most high-tech German & Swiss machines and premium European materials, crafted with XRAY's legendary attention to detail by our artistic production specialists. The XB8 is truly a masterpiece.

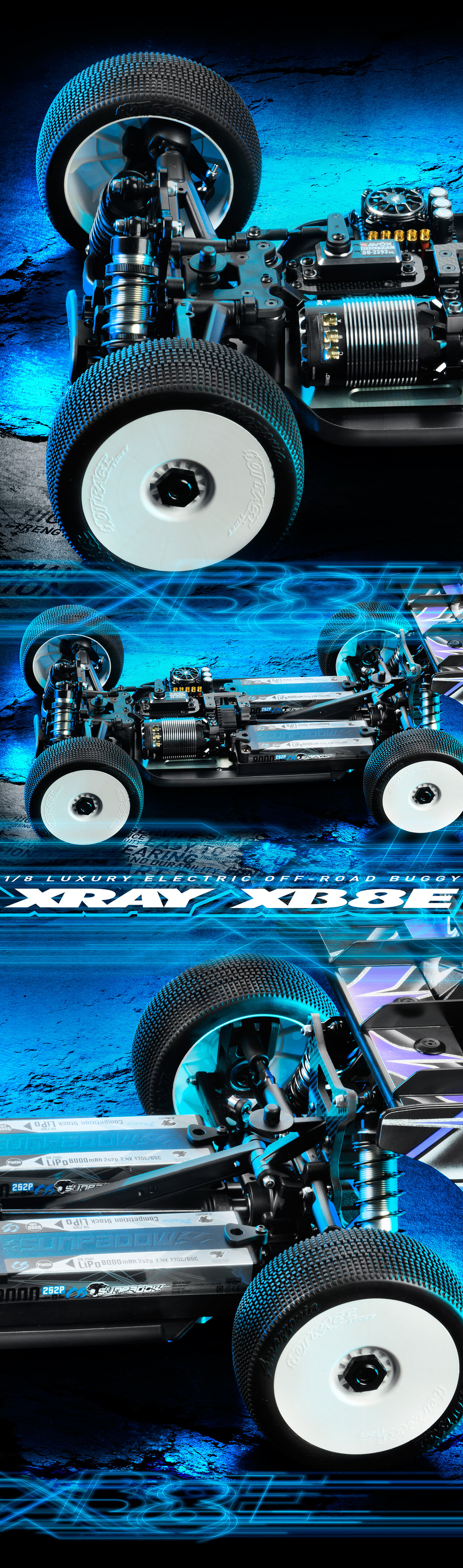

Diff Bulkheads.

All-new front & rear bulkheads feature a semi-split design for easy diff access while adding the valuable new diff height adjustment. The bulkhead design also uses a bushing for the gearbox input to alter the alignment and height of the bevel drive gear with the diff height. In addition to matching the new diff height adjustments, this input bushing also allows the front central driveshaft to operate with a reduced angle for less friction and wear on the CV joint components and improved driveline efficiency.

The XT8 bulkheads allow fast and easy differential access for setup changes or servicing by removing only 4 screws from the upper gear box cover while the lower section remains mounted to the chassis with the lower arms and suspension holders installed. This super-fast diff access is featured on both front and rear gearboxes.

All-new front & rear bulkheads feature a semi-split design for easy diff access while adding the valuable new diff height adjustment. The bulkhead design also uses a bushing for the gearbox input to alter the alignment and height of the bevel drive gear with the diff height. In addition to matching the new diff height adjustments, this input bushing also allows the front central driveshaft to operate with a reduced angle for less friction and wear on the CV joint components and improved driveline efficiency.

The XB8 bulkheads allow fast and easy differential access for setup changes or servicing by removing only 4 screws from the upper gear box cover while the lower section remains mounted to the chassis with the lower arms and suspension holders installed. This super-fast diff access is featured on both front and rear gearboxes.

All-new front & rear bulkheads feature a semi-split design for easy diff access while adding the valuable new diff height adjustment. The bulkhead design also uses a bushing for the gearbox input to alter the alignment and height of the bevel drive gear with the diff height. In addition to matching the new diff height adjustments, this input bushing also allows the front central driveshaft to operate with a reduced angle for less friction and wear on the CV joint components and improved driveline efficiency.

The XT8E bulkheads allow fast and easy differential access for setup changes or servicing by removing only 4 screws from the upper gear box cover while the lower section remains mounted to the chassis with the lower arms and suspension holders installed. This super-fast diff access is featured on both front and rear gearboxes.

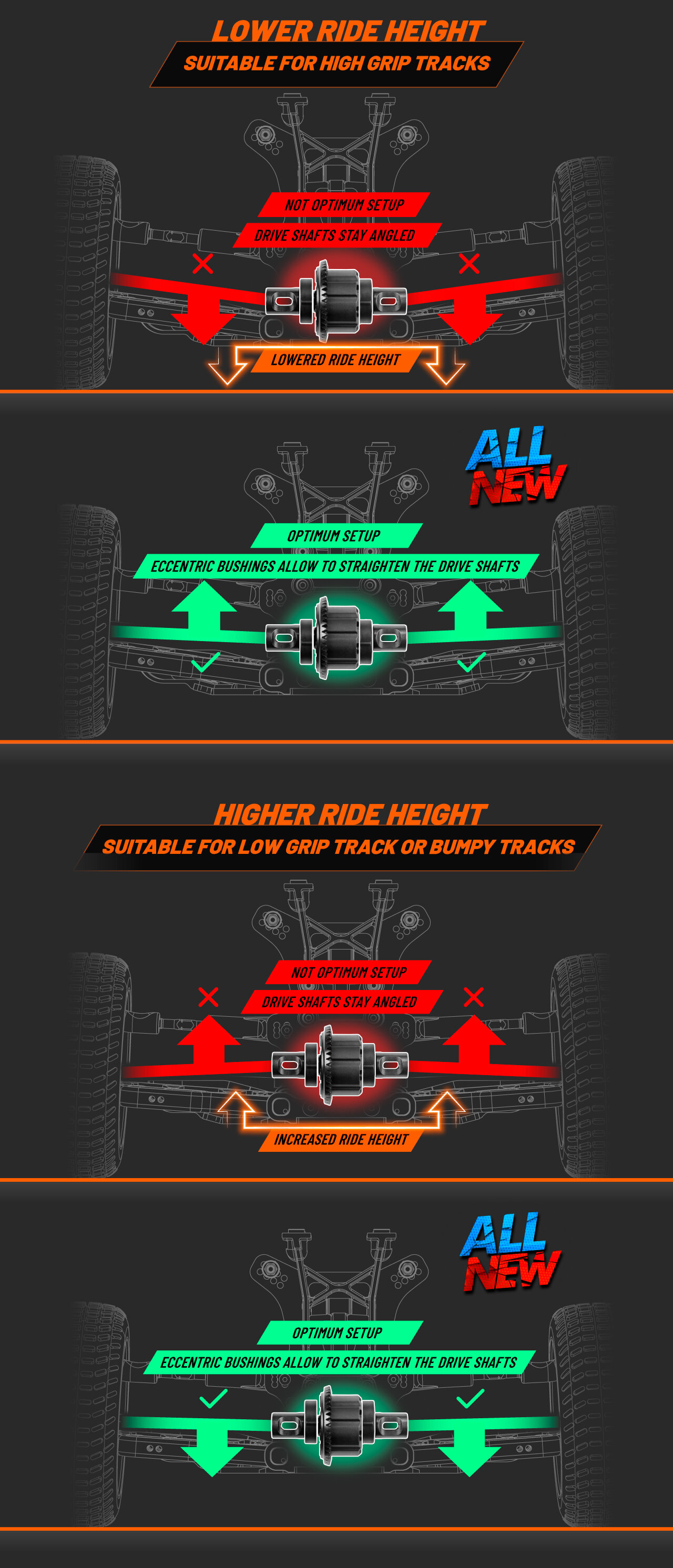

Diff Height Adjustment.

The new diff height adjustment of the semi-split bulkheads uses eccentric bushings to set the diff position. The diff height has 3 different settings. The diff height adjustment is a vital tuning option that allows quick set-up adaption for all different track conditions.

The ideal position will vary depending on the track conditions and ride height.

Redesigned Bulkhead V2.

Reinforced front and rear bulkheads were updated for added strength to ensure higher reliability and to improve the seal between the main bulkhead and cover plate. The revised bearing inserts also feature improved dust resistance and prevent debris from entering the bulkhead assemblies while offering the valuable differential height adjustment.

All-new front & rear bulkheads feature a semi-split design for easy diff access while adding the valuable new diff height adjustment. The bulkhead design also uses a bushing for the gearbox input to alter the alignment and height of the bevel drive gear with the diff height. In addition to matching the new diff height adjustments, this input bushing also allows the front central driveshaft to operate with a reduced angle for less friction and wear on the CV joint components and improved driveline efficiency.

The XB8 bulkheads allow fast and easy differential access for setup changes or servicing by removing only 4 screws from the upper gear box cover while the lower section remains mounted to the chassis with the lower arms and suspension holders installed. This super-fast diff access is featured on both front and rear gearboxes.

Diff Height Adjustment.

Central Drive Train.

The new design of the semi-split bulkhead allows to adjust the angle of the CV joint depending on the track conditions, traction of the track and ride height used.

At the high traction tracks a lower ride height is used and thus the diff placed in upper position to keep the drive shafts straighten and corresponding CV joint also in upper position.

At the low traction tracks an increased ride height is used and thus the diff placed in lower position to keep the drive shafts straighten and corresponding CV joint also in lower position.

The new design of the semi-split bulkhead allows to adjust the angle of the CV joint depending on the track conditions, traction of the track and ride height used.

At the high traction tracks a lower ride height is used and thus the diff placed in upper position to keep the drive shafts straighten and corresponding CV joint also in upper position.

At the low traction tracks an increased ride height is used and thus the diff placed in lower position to keep the drive shafts straighten and corresponding CV joint also in lower position.

Matched Gears.

The new differential crown gear and bevel drive gear feature specially designed profiles of the 46T and 13T gears for a perfectly matched engagement for smoother operation, less drag and significantly longer lifespan.

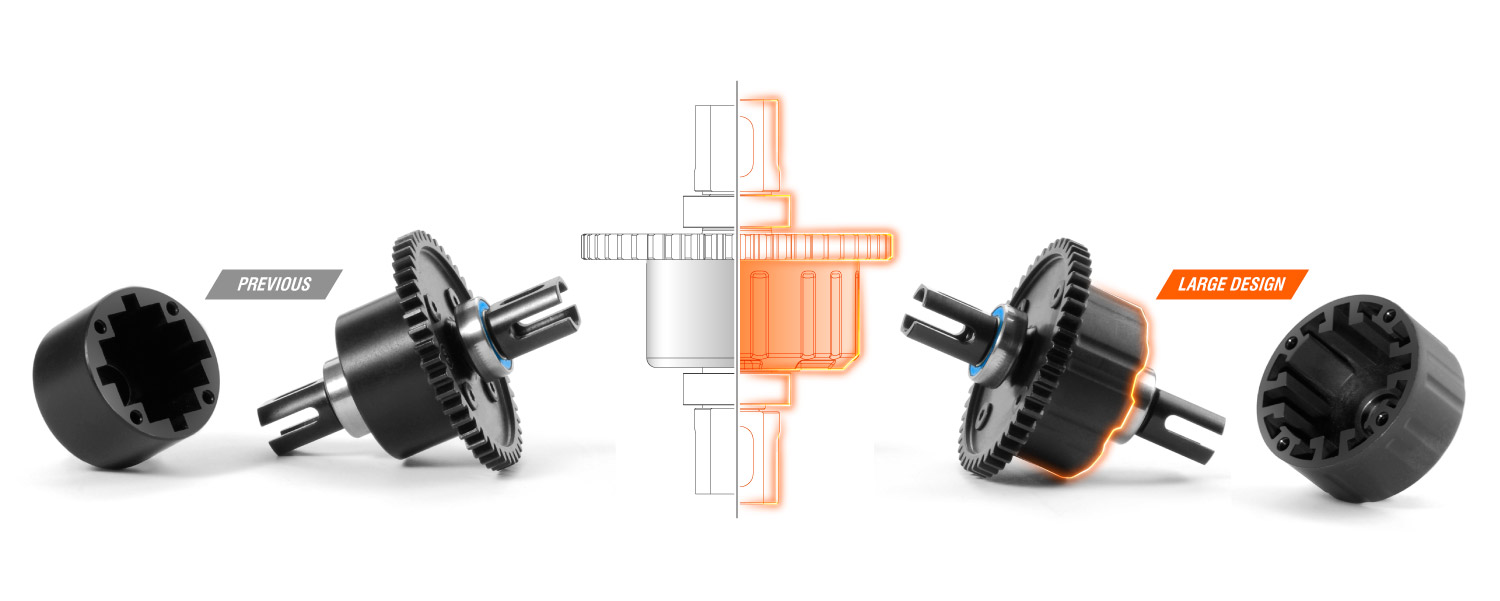

Gear Differential.

The high-volume differentials improve vehicle control and consistency over long runs and enhance reliability. The differentials feature larger capacity cases and larger internal gears with more teeth for improved differential moment. The larger oil volume and the shape of the gear teeth reduce overheating for improved consistency. The stronger diff pin design also improves reliability.

Easy Diff Access.

The semi-split bulkhead design and compact front bumper allows direct access to the differential while the entire suspension assembly remains mounted on the car.

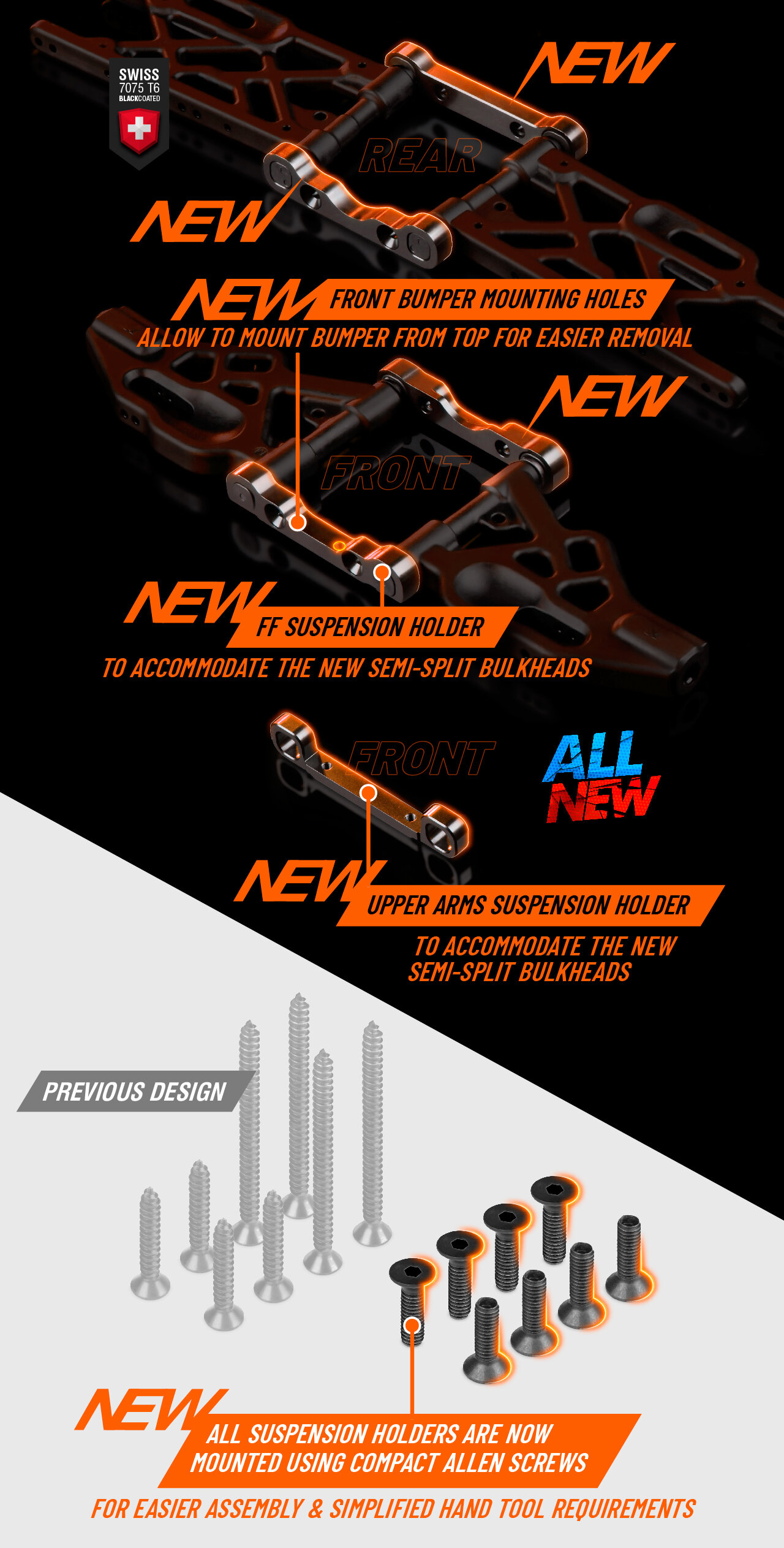

Chassis.

The chassis is updated to accommodate the all-new semi-split bulkheads and suspension holders, and features new milled pockets in the rear section for increased chassis flex.

The chassis is an important component that contributes to the XB8’s handling characteristics. The chassis dimensions and flex characteristics are selected for the best blend of stability, traction and steering. The chassis is machined for extra clearance under the bulkheads to accommodate the new diff height adjustment feature.

The chassis fits both SOFT and HARD composite radio boxes without chassis modification.

The chassis is CNC-machined from 3mm high-quality Swiss 7075 T6 aluminum; strategically machined in low-stress areas and then anodized to make it as light as possible without affecting strength or rigidity.

The chassis is updated to accommodate the all-new semi-split bulkheads and suspension holders, and features new milled pockets in the rear section for increased chassis flex.

The chassis is an important component that contributes to the XB8’s handling characteristics. The chassis dimensions and flex characteristics are selected for the best blend of stability, traction and steering. The chassis is machined for extra clearance under the bulkheads to accommodate the new diff height adjustment feature.

The chassis fits both SOFT and HARD composite radio boxes without chassis modification.

The chassis is CNC-machined from 3mm high-quality Swiss 7075 T6 aluminum; strategically machined in low-stress areas and then anodized to make it as light as possible without affecting strength or rigidity.

Chassis Layout.

Heavy duty lower bulkheads provide improved durability while maintaining ultra-low weight. The bulkheads have added material in the most critical area for improved strength; even stronger than the optional HD bulkheads from the X4’22.

The bulkheads use centering pins for easier positioning on the chassis and for increased rigidity and consistency.

The bulkheads feature two solid axle/diff height positions that were developed for different surfaces. The lower position is mainly designed for carpet, and the upper position is more common on asphalt. The anti-roll bar mounting position keeps the wire bar placed under the drive shafts for a super low CG.

The bulkheads have milled grooves for the ball bearing hubs so the bulkheads can sit 1mm closer to the chassis center line from each side.

The bulkheads are connected by a graphite brace in front and shock tower in rear for added stiffness.

Made from premium Swiss 7075 T6 aluminum, black anodized.

Shock Towers.

All-new front & rear shock towers are redesigned for the semi-split Bulkheads with the front shock tower also updated for the reinforced M4 shock screws that provide increased reliability.

The front shock tower is CNC-machined from 4mm Swiss 7075 T6 aluminum for strength and durability.

Rear shock tower from graphite material improves traction in all different track conditions. CNC-machined from extra-thick 4mm premium-grade graphite.

Front & rear shock towers featuring an additional row of shock absorber positions for super fine adjustments.

The lower row creates less chassis roll for higher corner speed while the upper row increase the roll to help increase traction.

All-new front & rear shock towers are redesigned for the semi-split Bulkheads with the front shock tower also updated for the reinforced M4 shock screws that provide increased reliability.

The front shock tower is CNC-machined from 4mm Swiss 7075 T6 aluminum for strength and durability.

Rear shock tower from graphite material improves traction in all different track conditions. CNC-machined from extra-thick 4mm premium-grade graphite.

Front & rear shock towers featuring an additional row of shock absorber positions for super fine adjustments.

The lower row creates less chassis roll for higher corner speed while the upper row increase the roll to help increase traction.

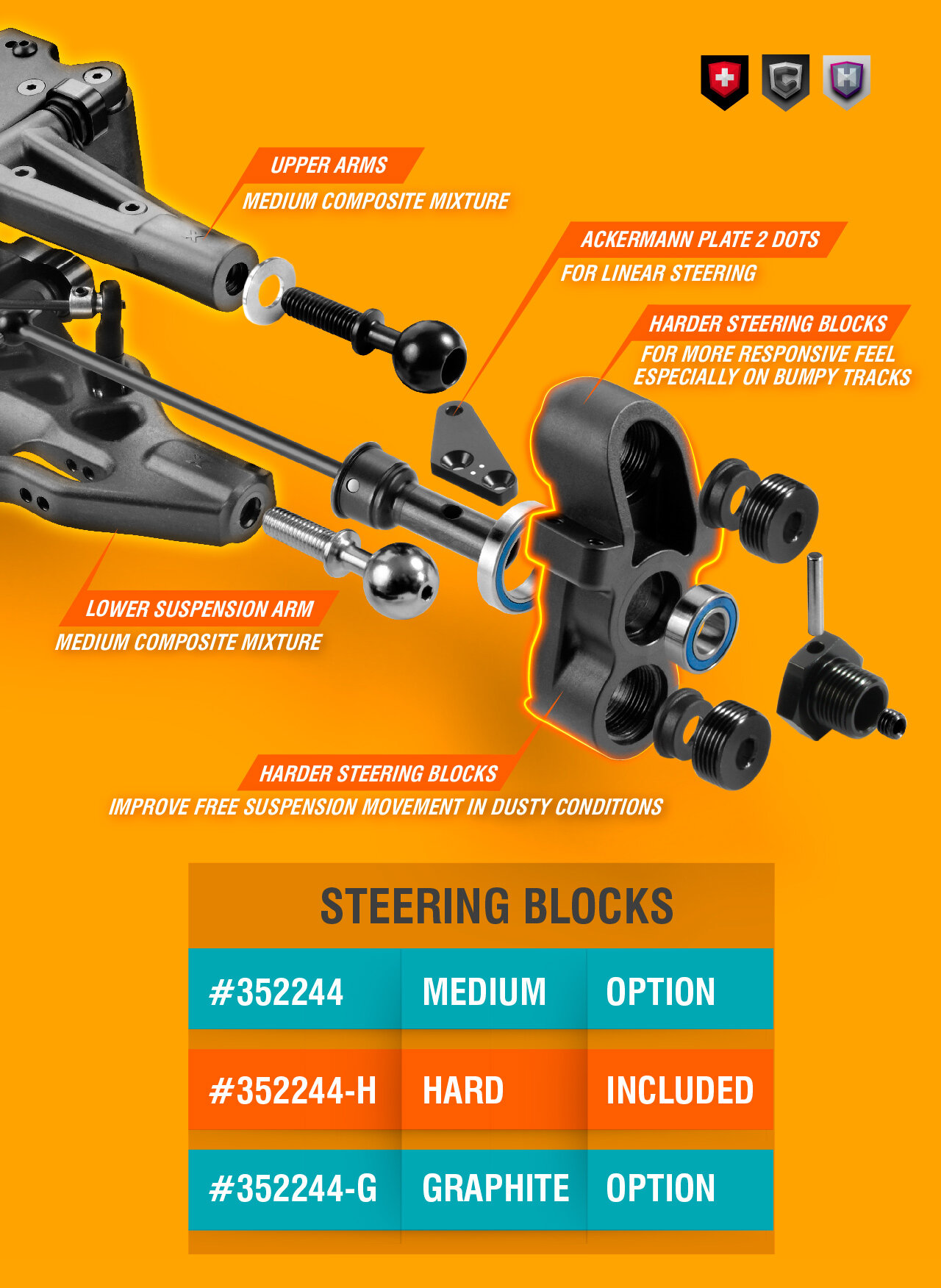

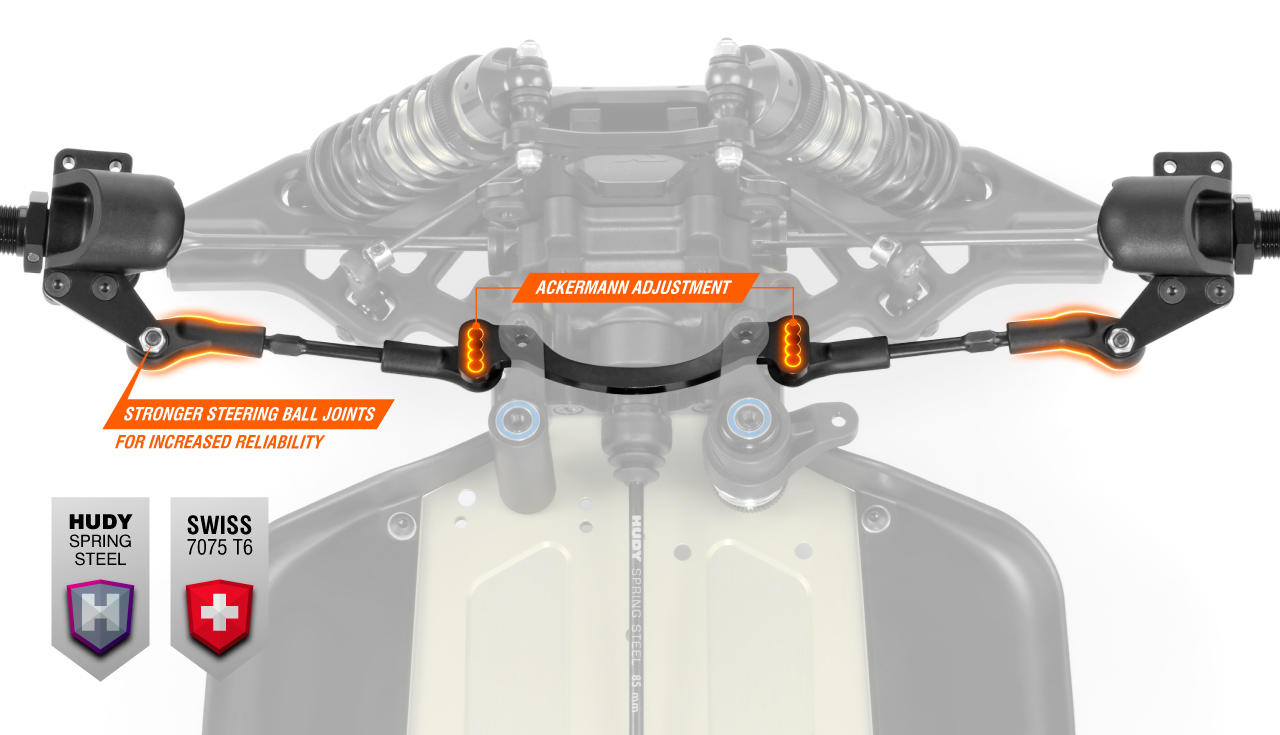

Steering System.

The steering system includes a new Ackermann plate and graphite servo saver component shape to work with the new semi-split bulkhead.

To ensure servo saver reliability, the servo saver parts are moulded from graphite material which is more resistant and efficient in dusty conditions. The dual-arm steering system is simple yet effective, featuring an integrated and easily adjustable servo saver, and a Swiss 7075 T6 aluminum steering plate.

The conical spring is longer and stronger, ensuring more precise steering and improved reliability.

Ackermann is easily adjusted by changing steering link mounting positions on the steering plate. Bump steer is adjusted by inserting shims between the steering plate and steering linkage.

The steering system includes a new Ackermann plate and graphite servo saver component shape to work with the new semi-split bulkhead.

To ensure servo saver reliability, the servo saver parts are moulded from graphite material which is more resistant and efficient in dusty conditions. The dual-arm steering system is simple yet effective, featuring an integrated and easily adjustable servo saver, and a Swiss 7075 T6 aluminum steering plate.

The conical spring is longer and stronger, ensuring more precise steering and improved reliability.

Ackermann is easily adjusted by changing steering link mounting positions on the steering plate. Bump steer is adjusted by inserting shims between the steering plate and steering linkage.

Suspension Holders.

All-new front & rear suspension holders for semi-split bulkheads offer an expanded range of set-up adjustments. The front upper suspension arm holder is also updated for the semi-split bulkhead.

The aluminum suspension holders feature Integrated Suspension Settings™ (I.S.S.) which allows for quick & easy suspension geometry setting.

Using eccentric suspension bushings inserted into aluminum suspension holders – as well as additional suspension shims – the XB8 suspension geometry can be completely adjusted in mere seconds.

Machined from premium Swiss 7075 T6 aluminum and black coated.

All-new front & rear suspension holders for semi-split bulkheads offer an expanded range of set-up adjustments. The front upper suspension arm holder is also updated for the semi-split bulkhead.

The aluminum suspension holders feature Integrated Suspension Settings™ (I.S.S.) which allows for quick & easy suspension geometry setting.

Using eccentric suspension bushings inserted into aluminum suspension holders – as well as additional suspension shims – the XB8 suspension geometry can be completely adjusted in mere seconds.

Machined from premium Swiss 7075 T6 aluminum and black coated.

Wickerbill Wing.

All-new wickerbill rear wing features more downforce that helps increase traction when needed, and has 12 pre-marked air flow hole positions that can be opened to fine tune downforce for any conditions. The wickerbill plate is mounted via 5 screws for easy downforce setup.

Made from a strong special composite mixture, the wing was designed to survive severe abusive and extreme crashes while keeping its shape.

The optional Lexan wing has an adjustable position and consists of two pieces: the main wing and the center fin that adds more stability and increases strength of the wing around the mounting area. The rear section of the wing is pre-bent to reinforce the wing and eliminates the use of additional heavy composite wickers. This makes the back of the wing strong while still allowing for wing flex in a crash. The pre-bent rear section of the wing is an important detail to create the desired downforce. Used by the factory team and suggested for all track conditions.

All-new wickerbill rear wing features more downforce that helps increase traction on wheels and all-new 12 pre-marked holes positions that allow to reduce downforce. The wickerbill plate is mounted via 5 screws for easy downforce setup.

Made from a strong special composite mixture, the wing was designed to survive severe abusive and extreme crashes while keeping its shape.

The optional Lexan wing has an adjustable position and consists of two pieces: the main wing and the center fin that adds more stability and increases strength of the wing around the mounting area. The rear section of the wing is pre-bent to reinforce the wing and eliminates the use of additional heavy composite wickers. This makes the back of the wing strong while still allowing for wing flex in a crash. The pre-bent rear section of the wing is an important detail to create the desired downforce. Used by the factory team and suggested for all track conditions.

All-new wickerbill rear wing features more downforce that helps increase traction when needed, and has 12 pre-marked air flow hole positions that can be opened to fine tune downforce for any conditions. The wickerbill plate is mounted via 5 screws for easy downforce setup.

Made from a strong special composite mixture, the wing was designed to survive severe abusive and extreme crashes while keeping its shape.

The optional Lexan wing has an adjustable position and consists of two pieces: the main wing and the center fin that adds more stability and increases strength of the wing around the mounting area. The rear section of the wing is pre-bent to reinforce the wing and eliminates the use of additional heavy composite wickers. This makes the back of the wing strong while still allowing for wing flex in a crash. The pre-bent rear section of the wing is an important detail to create the desired downforce. Used by the factory team and suggested for all track conditions.

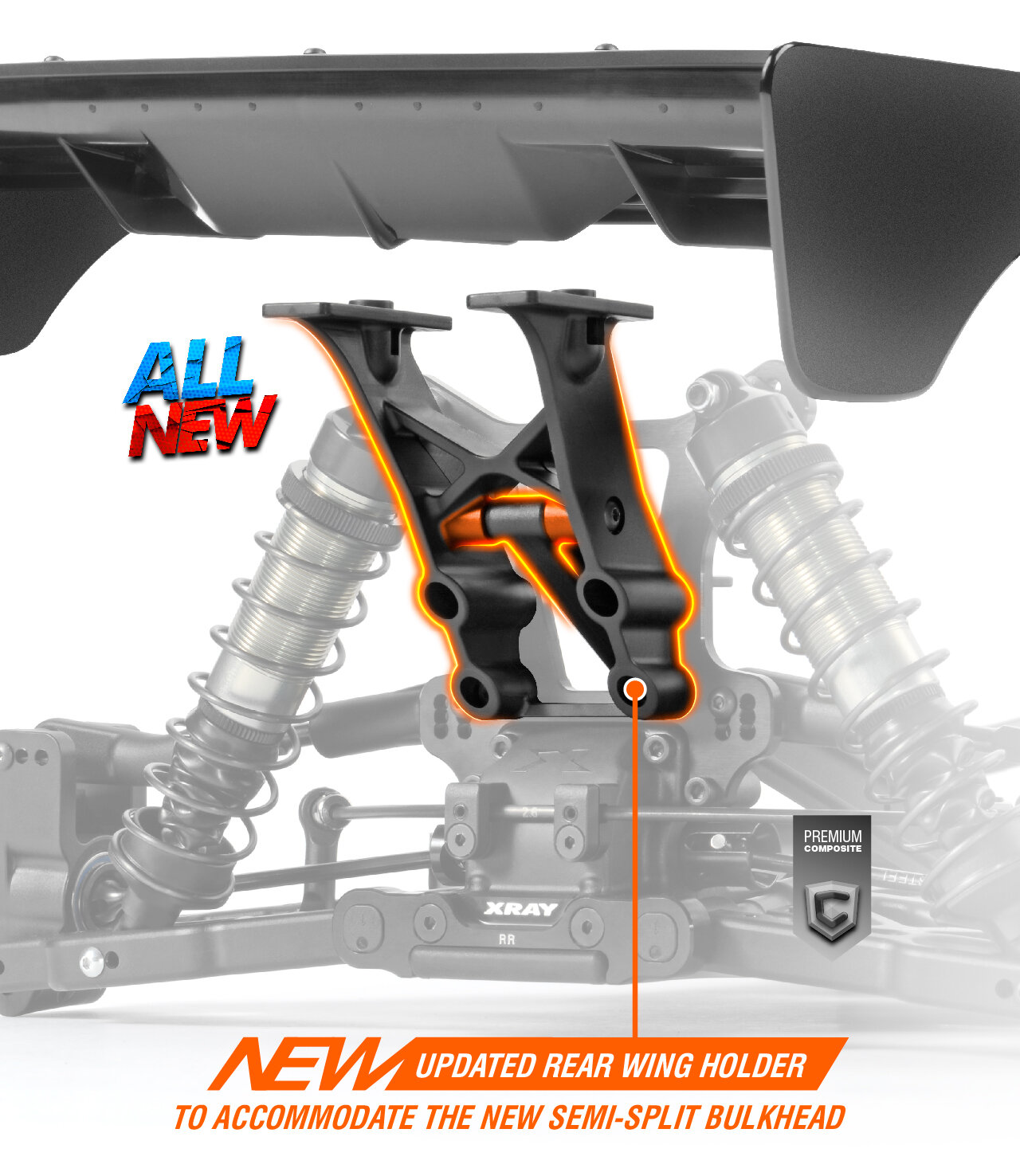

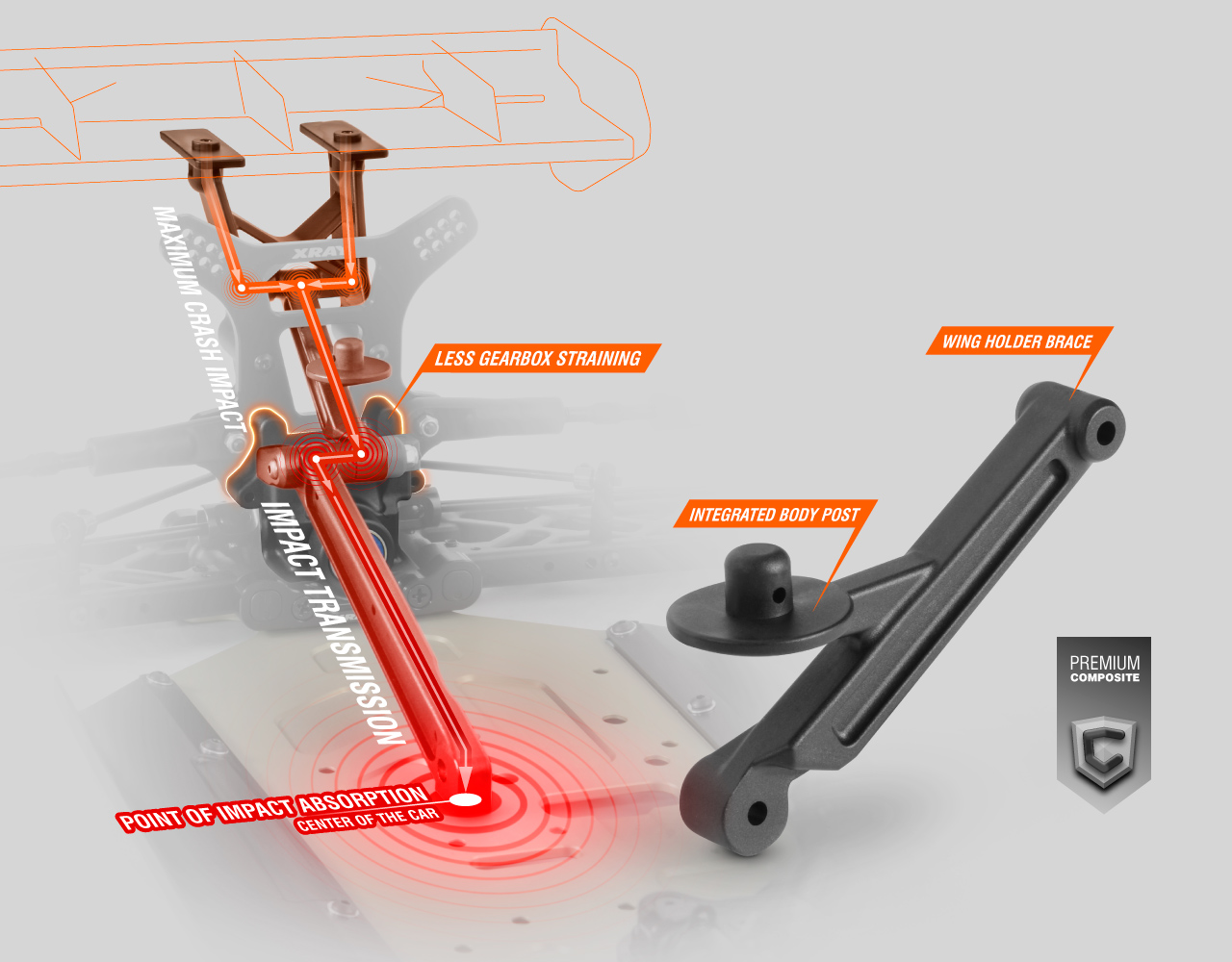

Rear Wing Holder.

Updated rear wing holder fits the new semi-split bullhead. The rear wing holder has a super-slim, 1-piece design that has reduced weight and increased strength. The wing holder has maximum stability while still allowing flex during impacts.

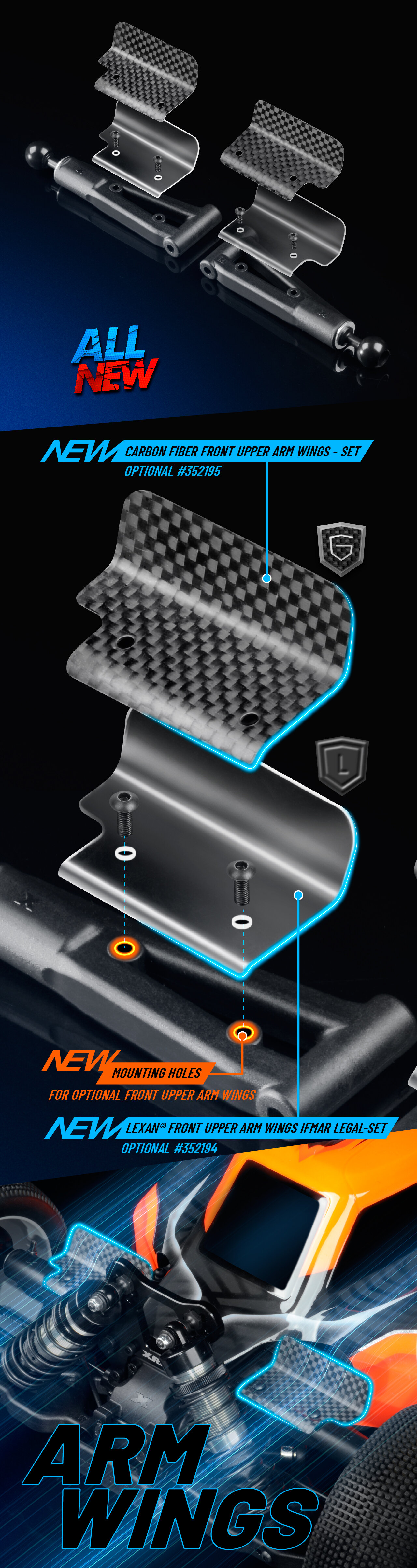

Front Upper Arms.

Front upper arms have additional mounting holes for the optional front upper arm wings. The wings increase downforce on the front suspension for increased traction and helps to keep the buggy nose down.

Optional wings are available in Lexan and Carbon alternatives.

Suspension Arms.

To improve the performance and reliability, the Pivot Ball suspension arms and optional C-hub suspension are molded from special composite mixture. The rear suspension arms are molded from extra-hard composite mixture that makes the car easier to drive. The front lower and upper arms feature a composite mixture change from soft to medium. The optional front lower C-hub suspension arm is molded from a hard composite mixture.

Shocks.

All-new lower shock ball joint features a lock extension that fits into the lower collar, reducing the chances for the retainer to become separated from the spring in a crash.

The XB8 shocks bodies feature composite lower shims for improved shock shaft movement. The shock caps feature 4 bleed holes for easier building and more precise rebound control. The longer shock shafts allow more suspension travel. Multiple shock membrane choices are available to tune the suspension to a wide variety of track conditions.

Oversized big-bore shocks featuring 16.2mm I.D. shock bodies are externally threaded with an adjustable collar for quick & easy spring preload adjustment. The shock bodies are hardcoated in a titanium color and feature a 1-piece alu shock cap.

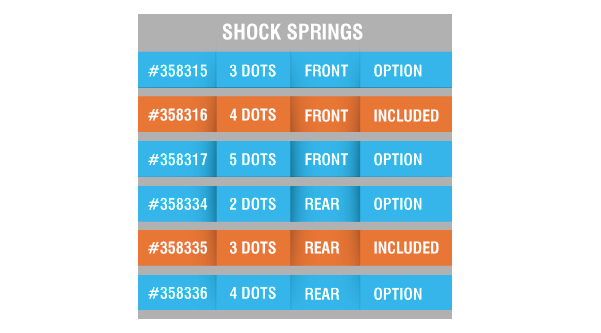

The XB8 now includes the 4 Dot front springs.

All-new lower shock ball joint features a lock extension that fits into the lower collar, reducing the chances for the retainer to become separated from the spring in a crash.

The XB8 shocks bodies feature composite lower shims for improved shock shaft movement. The shock caps feature 4 bleed holes for easier building and more precise rebound control. The longer shock shafts allow more suspension travel. Multiple shock membrane choices are available to tune the suspension to a wide variety of track conditions.

Oversized big-bore shocks featuring 16.2mm I.D. shock bodies are externally threaded with an adjustable collar for quick & easy spring preload adjustment. The shock bodies are hardcoated in a titanium color and feature a 1-piece alu shock cap.

The XB8 now includes the 4 Dot front springs.

Shorter Wing Holder.

The wing mount allows installing the wing further forward to create more downforce on the rear wheels to increase rear traction. The wing holder allows the wing to be positioned 11mm further forwards comparing to previous versions.

The super-slim, 1-piece design of the holder has low weight without sacrificing strength. Made from a special composite mixture to withstand abuse and crashes.

The wing holder shape gives maximum stability while still allowing flex during impacts.

The wing mount allows installing the wing further forward to create more downforce on the rear wheels to increase rear traction. The wing holder allows the wing to be positioned 11mm further forwards comparing to previous versions.

The super-slim, 1-piece design of the holder has low weight without sacrificing strength. Made from a special composite mixture to withstand abuse and crashes.

The wing holder shape gives maximum stability while still allowing flex during impacts.

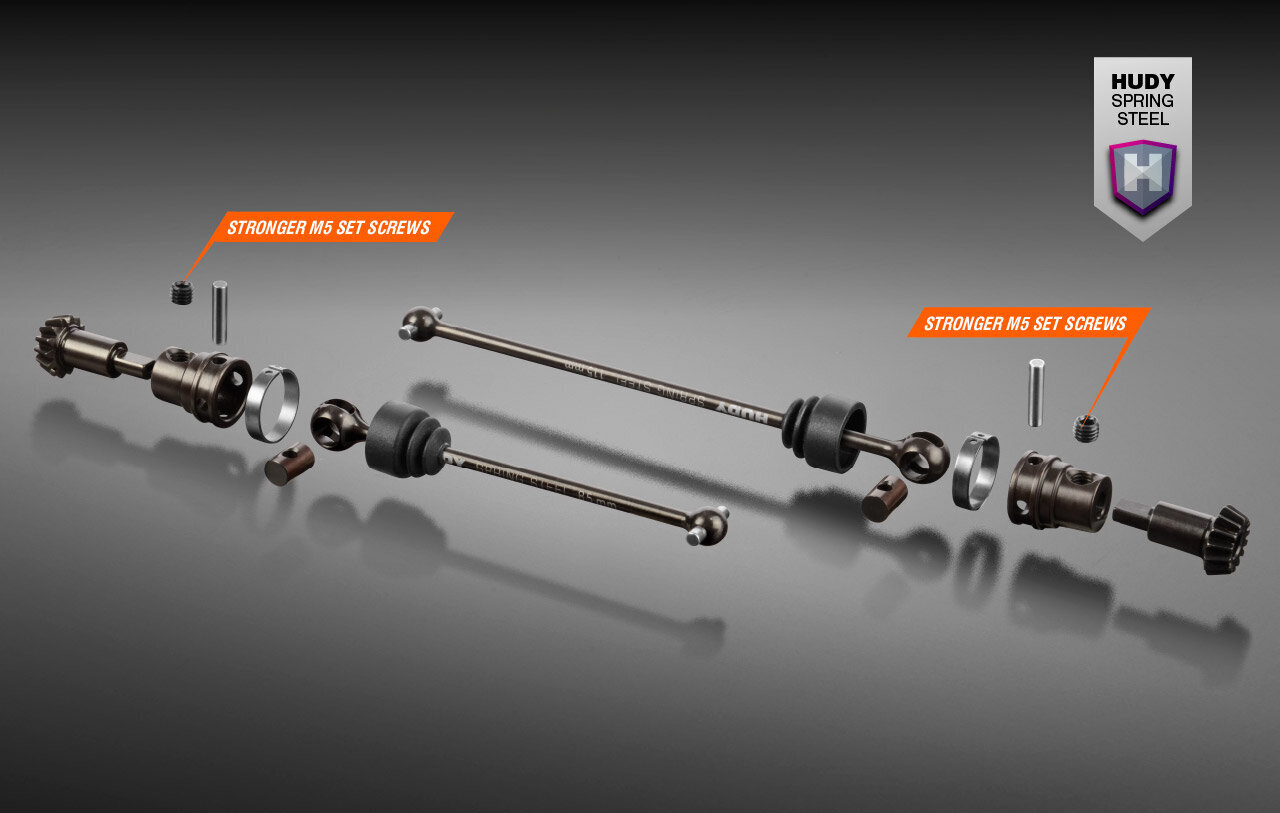

Bevel Drive Pinion Gears.

To increase reliability and strength, the M4 set screws on the central CVD universal joints were replaced by more robust M5 set screws to eliminate stripping the screw during installation or maintenance.

Central CVD shaft universal joints are made from world-renown HUDY Spring Steel. Strategically machined for toughness and reduced weight without compromising strength. Fits front & rear central CVD drive shafts.

Steering Block.

Steering blocks from a harder composite material provide a more responsive feel especially on bumpy tracks and retain free suspension movement in dusty conditions for better consistency. The steering blocks are super lightweight yet extremely strong, featuring a larger outside 8x16x5mm ball-bearings for increased reliability and lifespan.

2-in-1.

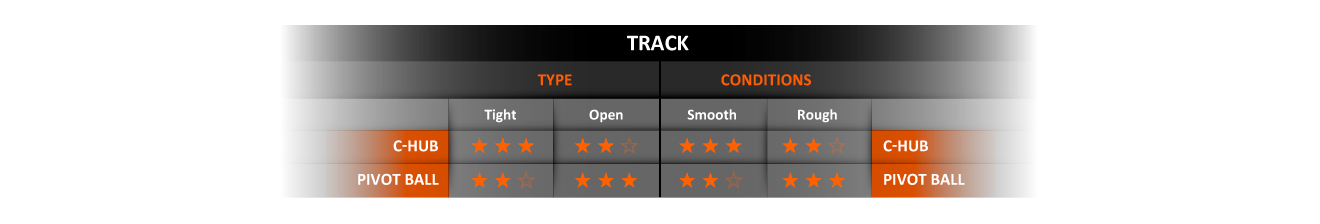

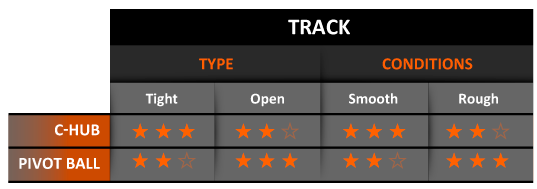

The XB8E design allows to accommodate either the C-hub or Pivot Ball suspension. The included Pivot Ball suspension can be easily exchanged for the optional C-hub suspension to accommodate to the particular track conditions.

C-hub Suspension.

#350910 XB8/XB8E FRONT C-HUB SUSPENSION - SET

The optional C-hub is perfectly suited for smooth and short technical tracks & smooth surface conditions. At these track conditions the C-hub suspension generates increased frontward traction as well increased overall traction with enhanced steering.

The C-hub suspension includes lower suspension arm, steering block with Ackermann plate, C-hub, camber link & Ackermann steering plate.

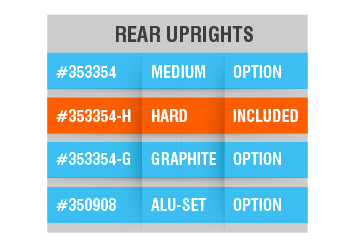

Rear Uprights.

Harder rear uprights maintain stability in all track conditions. The hard material also improves the handling in hotter conditions and better maintains it shape for improved bump absorbing. The uprights are super-strong and feature a larger outside 8x16x5mm ball-bearing for increased reliability and lifespan.

Servo Holder.

To improve the reliability the servo holder has new reinforced design. The servo holder is designed to fit the saddle pack layout.

Battery Holder.

The battery holder features tweak-free split battery holder to mount the saddle packs. This battery holder will accommodate both standard and ‘shorty’ packs, with the shorty packs having the added ability to move front/back for additional weight balance adjustment.

Battery Holder.

The battery holder features tweak-free split battery holder to mount the saddle packs. This battery holder will accommodate both standard and ‘shorty’ packs, with the shorty packs having the added ability to move front/back for additional weight balance adjustment.

Electronics Plate.

The saddle pack battery layout features a moulded electronics mounting plate that is positioned next to the servo. The speed control, receiver and transponder are all installed on this plate for easy removal and maintenance.

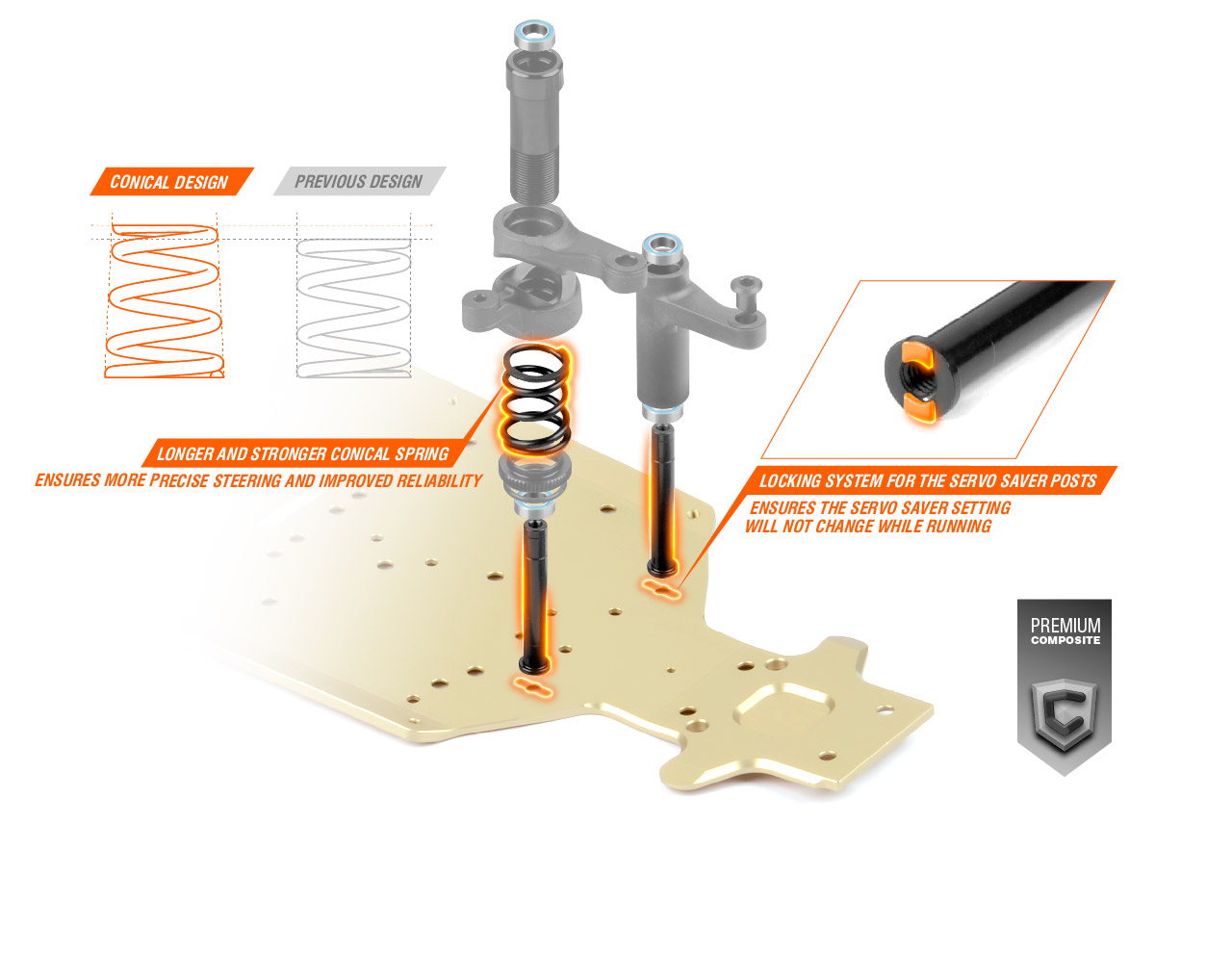

Servo Saver.

The servo saver features a conical spring that is longer and stronger. The spring ensures more precise steering and improved reliability.

The servo saver posts feature the locking system that ensures the servo saver setting will not change while running.

To ensure servo saver reliability (especially in dusty conditions), the servo saver is moulded from graphite material which is more resistant and efficient in dusty conditions. The dual-arm steering system is simple yet effective, featuring an integrated easily-adjustable servo saver and Swiss 7075 T6 aluminum steering plate.

Ackermann is easily adjusted by quickly & easily changing steering link mounting positions on the steering plate. Bump steer is easily adjusted by inserting shims between the steering plate and steering linkage.

Servo Saver Top Deck.

The top deck features holes for the servo saver that ensure the servo saver will not lock when overtighten and will always work freely.

The top deck features an extra hole for the front chassis brace. When built using the single sided battery configuration, the left mounting hole is used to prevent driveshaft collision with the chassis brace.

Fits both XB8 and XB8E.

Chassis.

The chassis features chamfered front edges which prevents dirt pick-up when the chassis contacts the track. The chamfered edges will not “cut” the dirt, but rather the dirt will slide along the chamfered edges and not get stuck at the front of the chassis.

The side guards were moved 4mm rearwards to ensure that under full throttle and full steering lock the inflated tires will not contact the side guards and can operate freely.

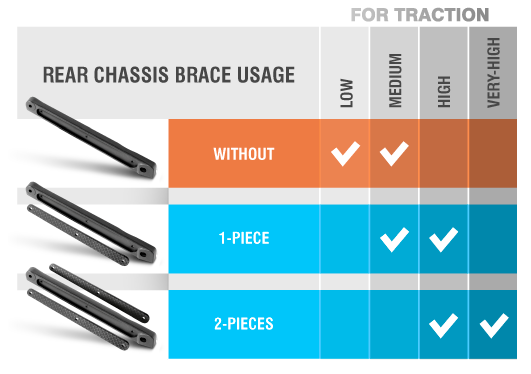

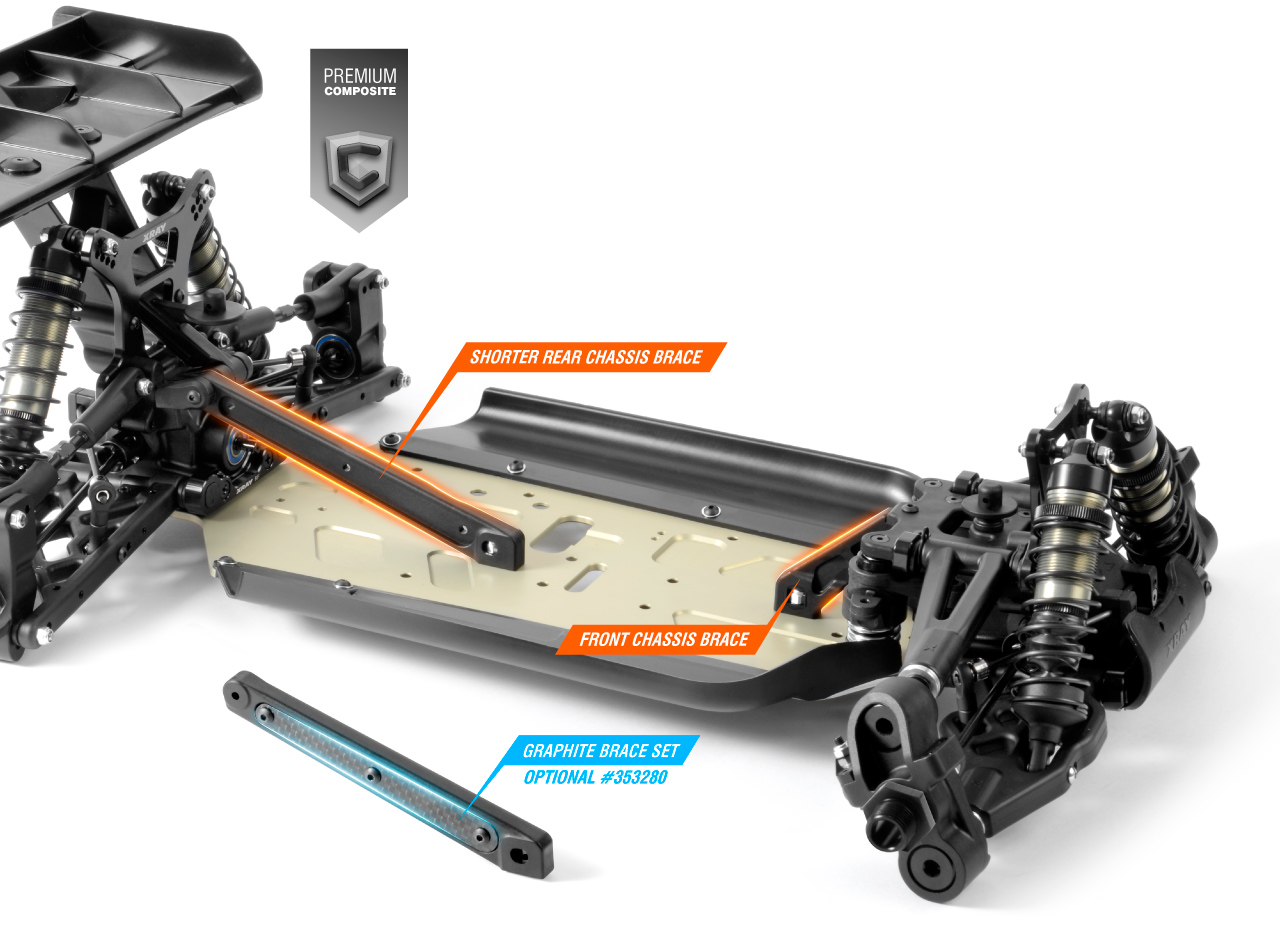

Chassis Braces.

The mounting of the chassis brace to the bulkhead eliminates transfer of energy from the suspension via shock towers to ensure more precise landings and more off-power traction.

The included rear brace is moulded from a medium-stiff composite mixture for improved flex & rigidity, and allows the mounting of optional graphite inserts to reinforce the chassis brace to make it even stiffer for particular track conditions.

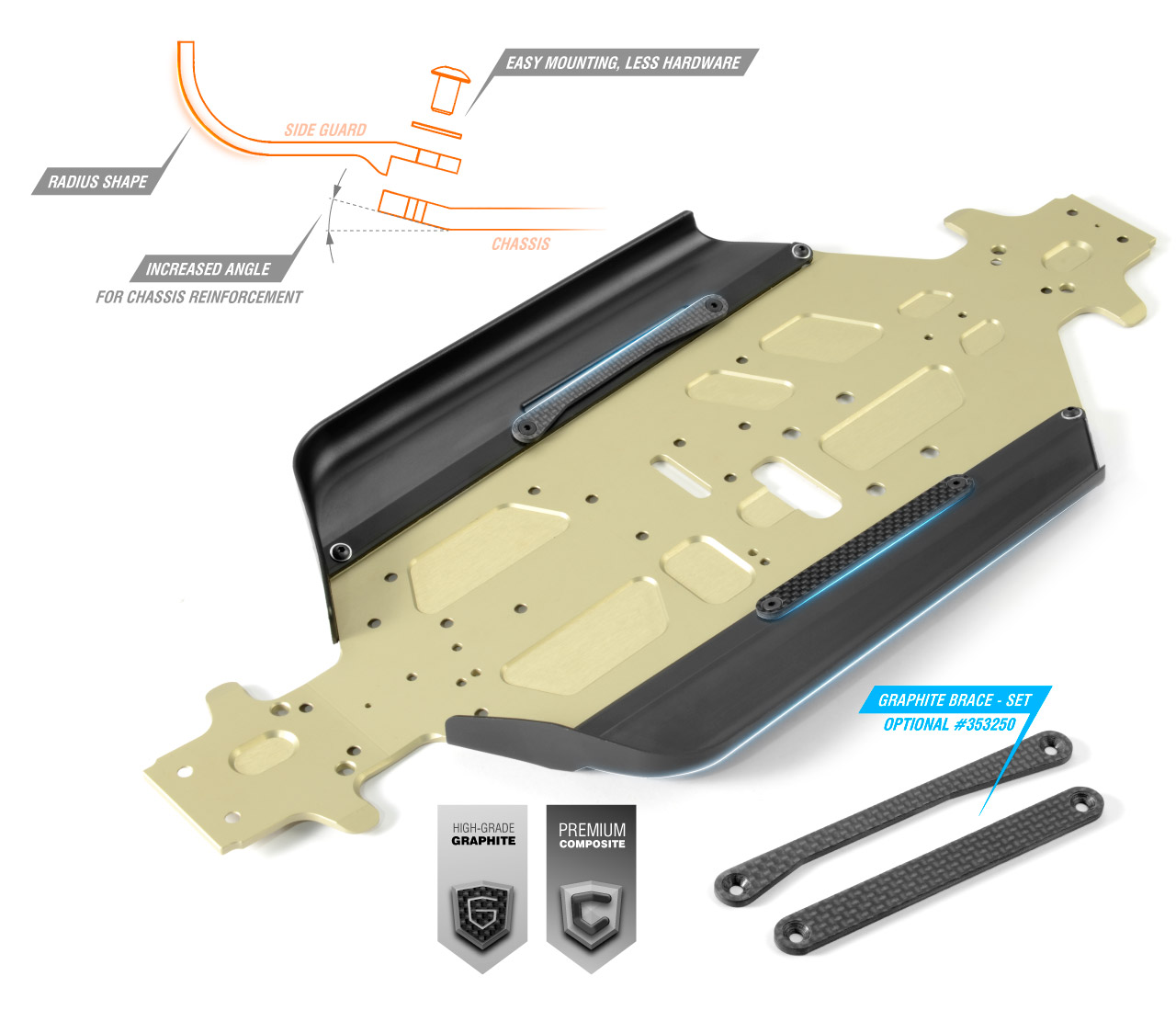

Side Guards.

Side guards feature a larger bottom radius to give better stability on rough tracks. The radius of the side guards increases the car’s longitudinal flex. The side guards are moulded from a special composite mixture for increased flex that helps generate more traction.

The tough composite side guards protect the car, muffler, and fuel tank from side impacts. The side guards perfectly fit the chassis and seal against dirt.

Optional side guard braces allow for very efficient and easy chassis flex adjustment to adjust the handling of the car to different track conditions. By adding the graphite braces, the entire chassis is reinforced and stiffer flex will improve handling in high-traction conditions.

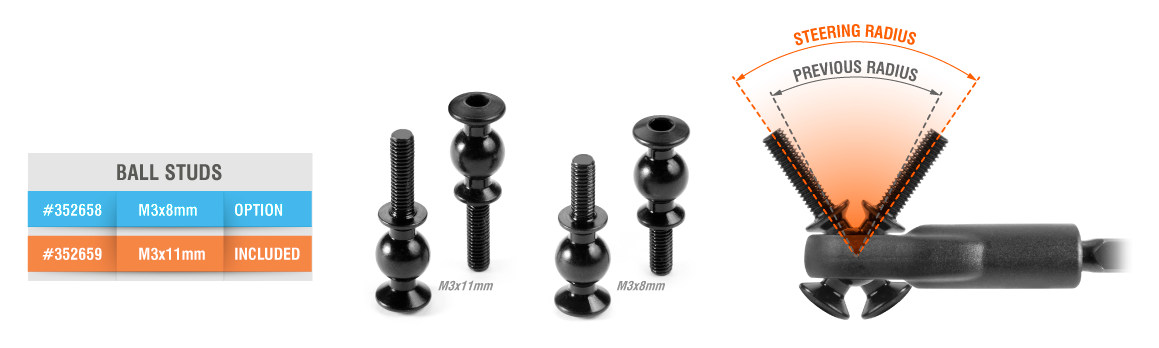

Ackermann.

The specially-designed ball studs eliminate steering lock and allow greater steering radius. The integrated backstops ensure that the pivot balls do not disconnect in crashes.

Ackermann is easily adjusted on the machined Swiss 7075 T6 steering plate to ensure highest reliability and strength.

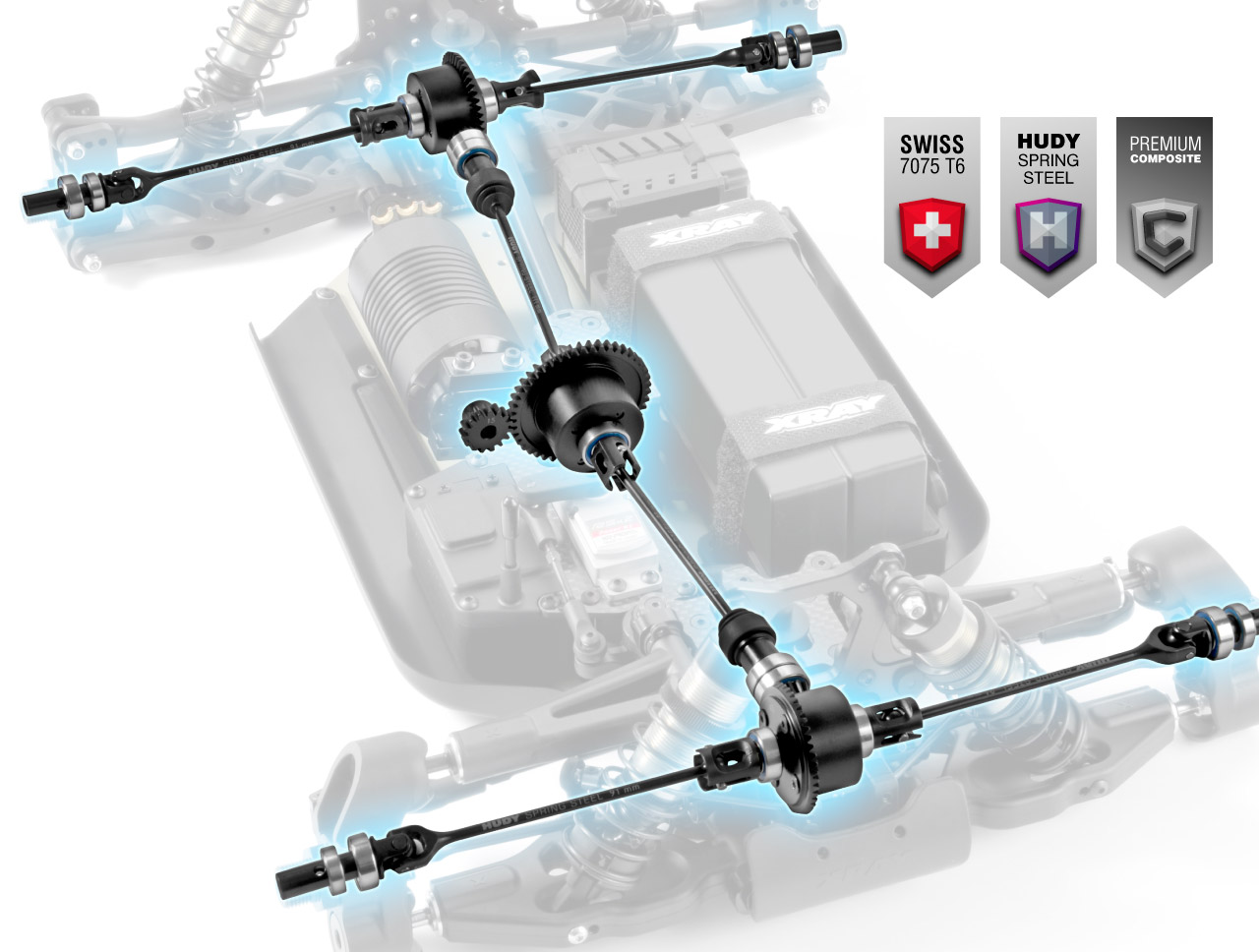

Drive Shafts.

The rear drive shafts are 93mm long and help reduce the chances of bind in the outdrives after extreme jump landings that could cause handling irregularities or damage.

All XB8E drive shafts are manufactured from world-renowned HUDY Spring Steel™, resulting in some of the world‘s thinnest yet most durable drive shafts used in off-road cars. All drive shafts and outdrives are hardened with a proprietary hardening process to provide unsurpassed lifespan & reliability.

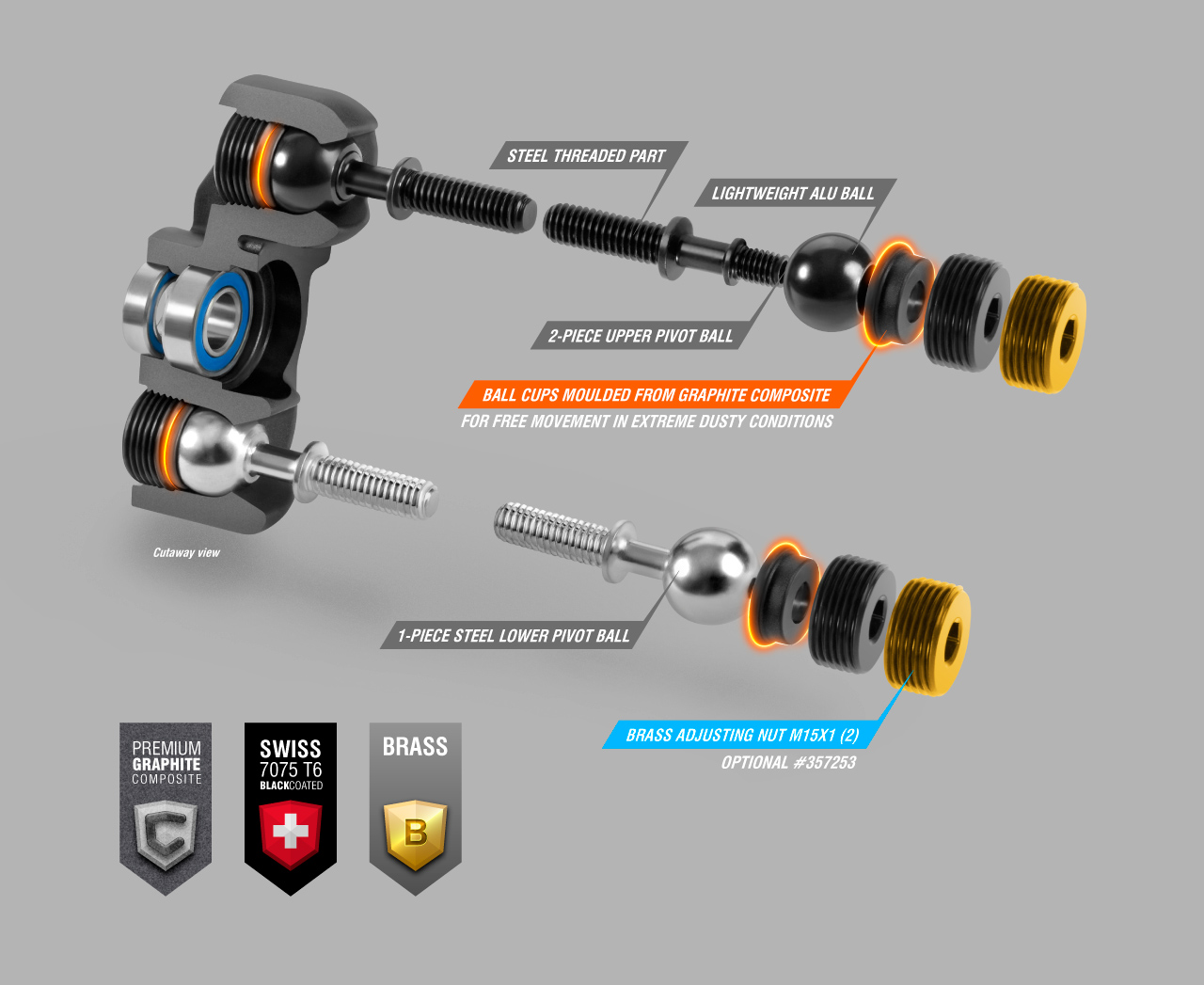

Pivot Balls.

To increase the reliability and free movement of suspension even in the extremely dusty conditions, the pivot ball cups are moulded from a graphite material that ensures more free movement even when dust builds up.

To reduce weight and lower the CG, the front upper pivot balls are combined with a steel threaded part for maximum strength. The aluminum ball is machined from premium Swiss 7075 T6 and additionally hard coated for extended lifespan.

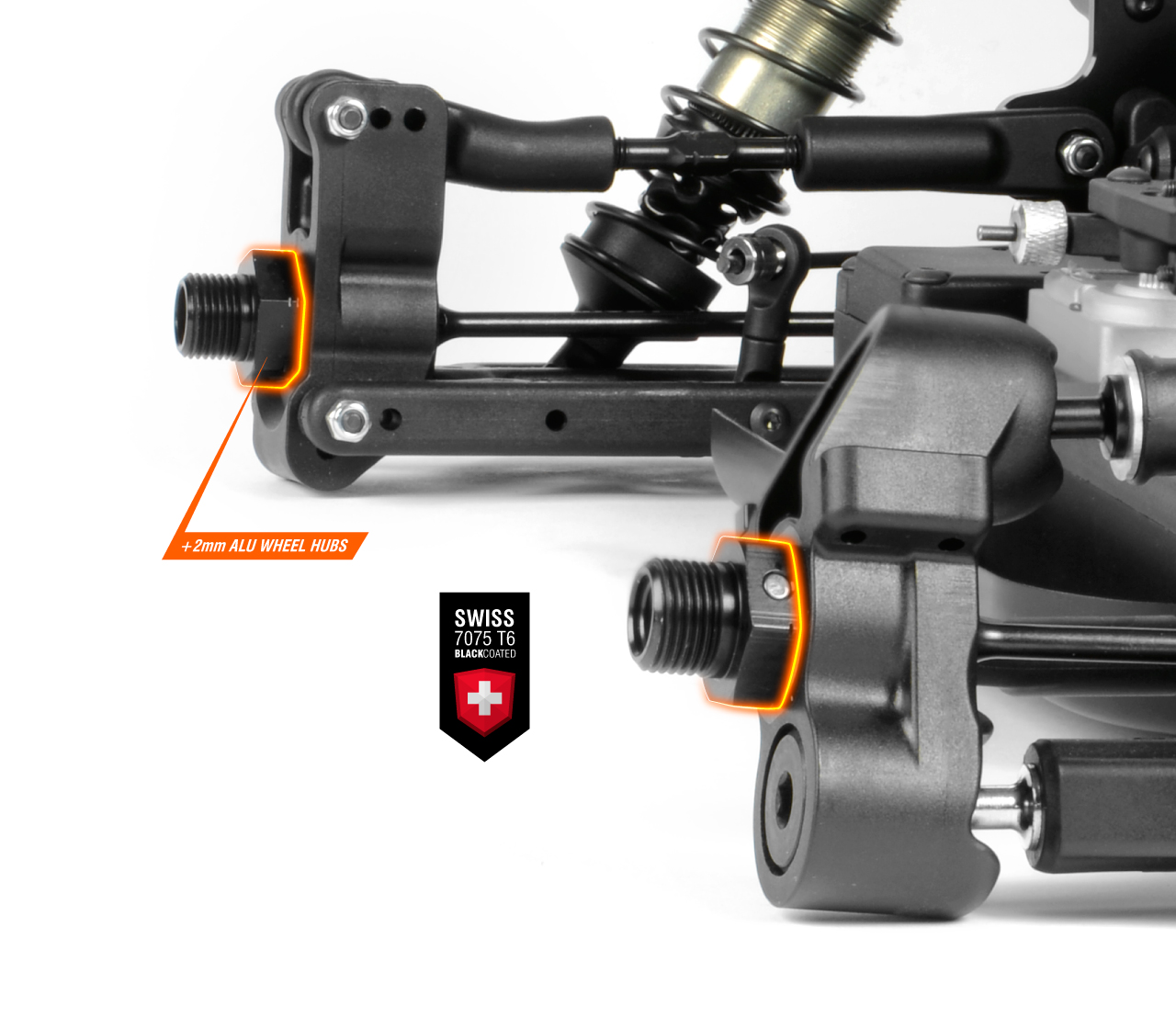

Wheel Hubs.

To accommodate the geometry, the XB8E includes rear wheel hubs with a +2mm off-set while the front features the +1mm off-set wheel hubs.

Ultra-lightweight 17mm wheel hex drive hubs are CNC-machined from Swiss 7075 T6 black-coated aluminum.

The alu hex hubs are specially machined to reduce rotating weight while guaranteeing wobble-free wheel mounting.

Drivetrain.

The XB8E is a conventional shaft-driven 4WD off-road car featuring

- Front & rear gear differentials with adjustable oil viscosity

- Differentials featuring 46T crown gears and 13T pinion gears

- Central differential with adjustable oil viscosity, featuring 46T spur gear

- Front & rear CVD drive shaft, and central CVD drive shaft

Gear Differential.

Both front and rear differentials are identical for easier maintenance and servicing.

The Large Volume diffs feature higher capacity cases, stronger diff pins, and large internal gears with more teeth for improved differential action, consistency and overall reliability. The larger volume of the differential and the shape of the gear teeth help reduce oil overheating.

Central Diff Gear.

The central differential is an extra-large size for increased reliability and performance. The differential is over 5mm larger, with an increased oil capacity to reduce oil overheating in long runs, helping to keep differential performance as consistent as possible.

Internal Diff Gears.

The 20T and 10T internal diff gears are larger to ensure reliability and reduce diff oil overheating. The greater number of teeth ensures more precise fitment and engagement.

Pressed-steel differential bevel and satellite gears are heat-treated and machined for superior precision and smooth operation.

Diff Outdrives.

Updated diff outdrives accommodate the stronger diff pins.

To reduce rotating weight, the super-lightweight diff outdrives are machined from HUDY Spring Steel™ which allows unnecessary material to be removed to further reduce weight without affecting durability. The inner portions of the outdrives are additionally hand-ground for maximum precision and fitment into the diff case.

All outdrives are hardened using HUDY’s own special hardening process for extended lifespan and reliability.

Diff Gears & Drivetrain Ratio.

To improve the acceleration of the XB8E the central spur gears are larger.

Differential main gears are manufactured from HUDY Gear Steel on a precision manual gear machine. This material was specially formulated and developed for use in gears. All gears are hardened to provide the longest possible lifespan.

A wide range of different gears — spur gears and pinion gears — are available for perfect set-up and tailoring to particular racing conditions.

• Pinions are available in sizes of 12T, 13T, 14T, 15T, 16T and 17T

• Spur gears are available in a range of 46T, 47T and 48T

Wing Holder Brace.

To help prevent rear gear box breakage during crash impacts, the rear wing construction features wing holder brace that transfers crash impact energy from the wing and shock tower to the chassis where it is centrally resolved.

The wing holder brace includes an integrated body post as well.

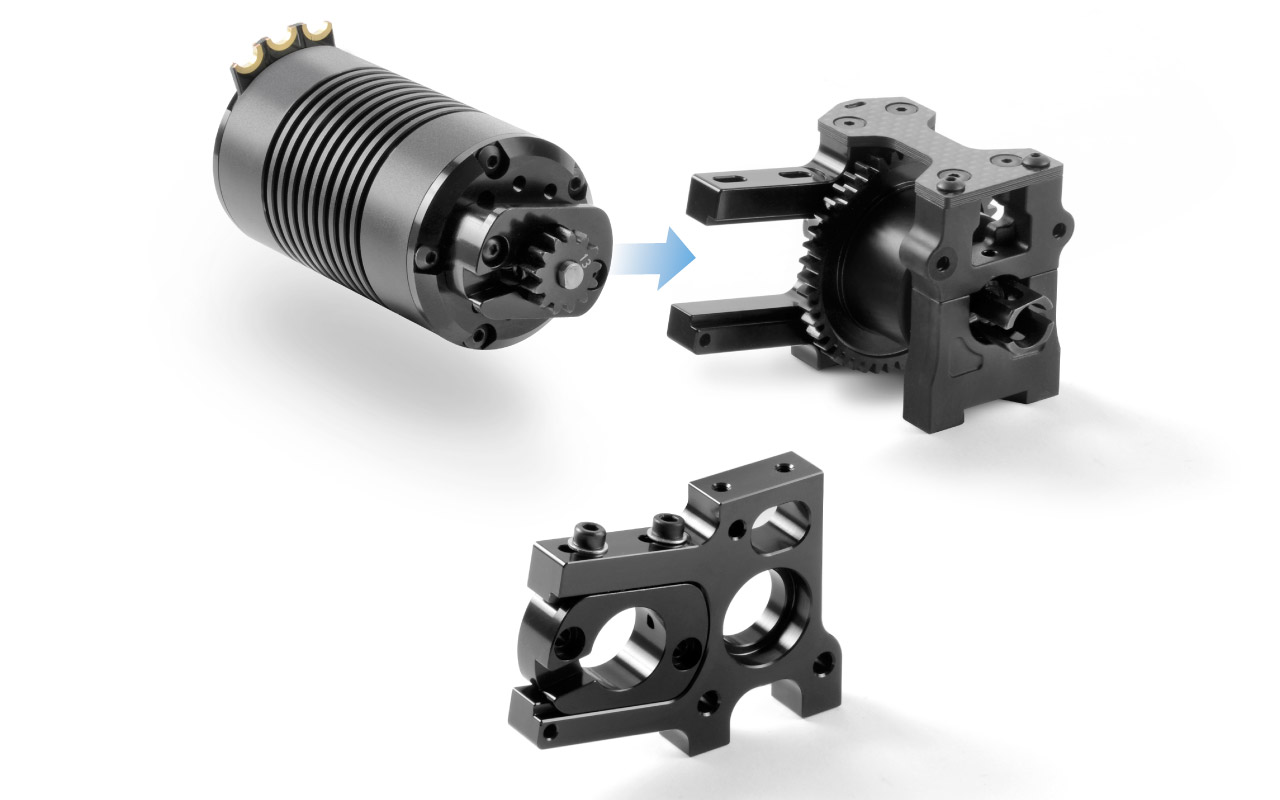

Motor Mount.

The motor is connected to a mounting plate, with the assembly then inserted into an integrated motor holder/drivetrain support. The design of this system allows quick and easy motor rotation to adjust gear mesh, and yet clamp.

The motor mount machined from Swiss 7075 T6 and is 2mm wider compared to older version for improved durability.

Shock Springs.

The XB8E includes the 4-dot front shock springs for stability. XRAY shock springs are manually measured, selected and matched into pairs to guarantee precisely equal length and damping characteristics.

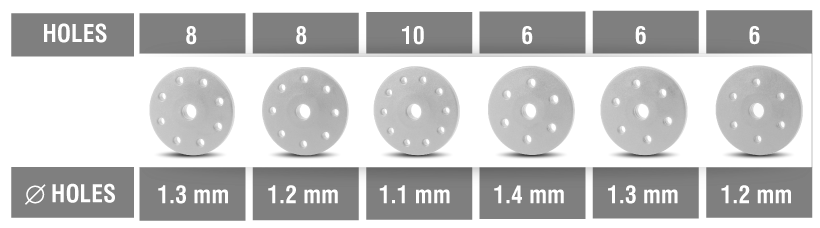

Shock Pistons.

Ultra-precise shock pistons feature 6-, 8- and 10-hole options. The big-bore pistons are molded from tough, well-proven Delrin® material to provide smooth action and durability. The precision molding production process ensures perfect piston roundness after production, so that the pistons move super-smoothly inside the shock bodies for identical perfect action in all four shocks.

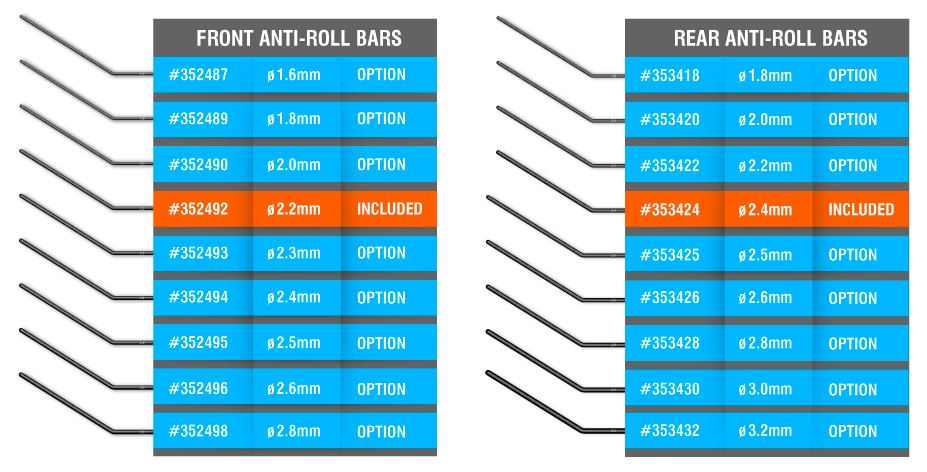

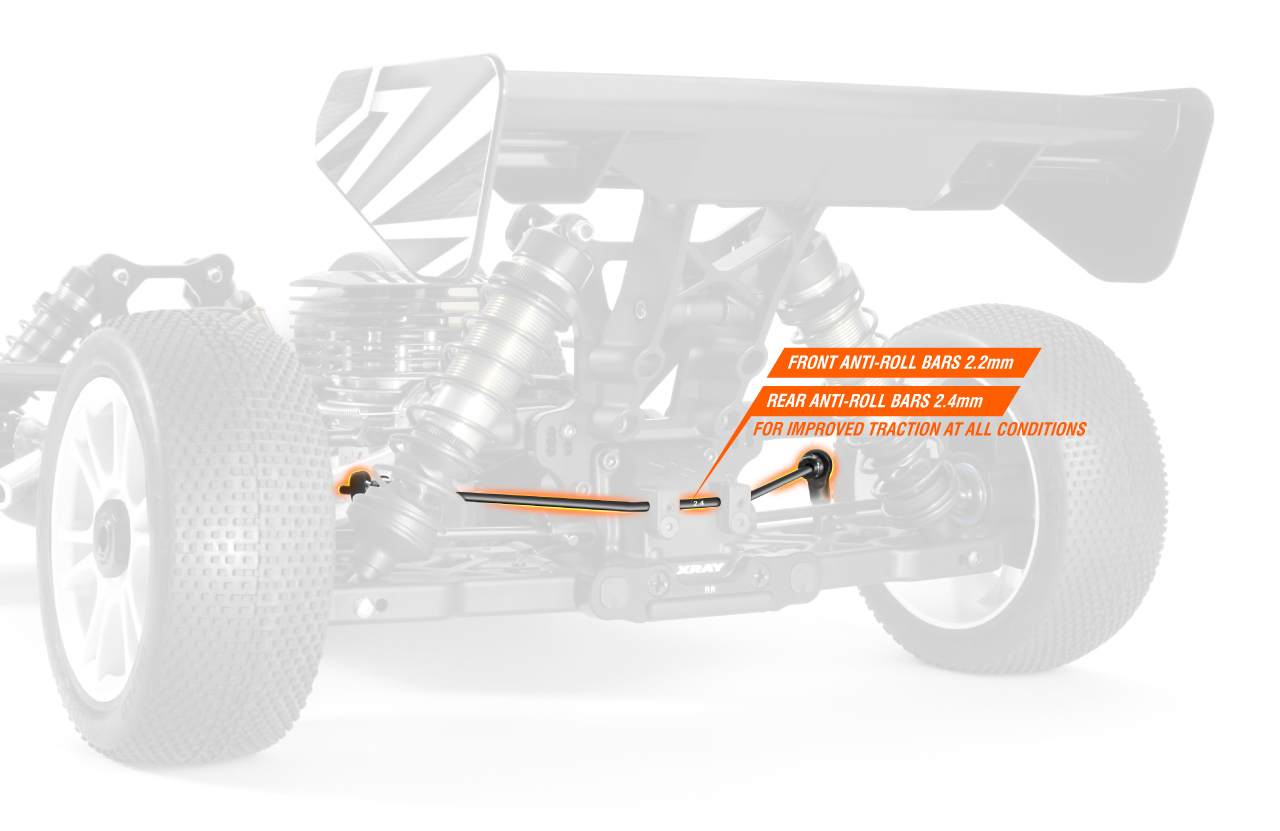

Anti-Roll Bars.

To increase overall traction in all track conditions, the front anti-roll bars used are 2.2mm and the rears to 2.4mm.

Anti-roll bars, manufactured from spring steel material, are easily mounted to front & rear diff cases with easy adjustment using the adjustable linkages.

Anti-roll bar wires of different thicknesses are optionally available for fine-tuning.

Turnbuckles.

To guarantee maximum reliability, all turnbuckles are manufactured from a special blend of HUDY Spring Steel™ which is specifically formulated for turnbuckles. The turnbuckles have a tougher core, making them very well suited for the steering system and rear upright linkages.

Silicone Oils.

HUDY Exclusive Silicone Oils are manufactured in Europe and each batch is laboratory tested and calibrated to ensure the highest possible consistency and quality from batch to batch. Based on the industry-standard cSt rating, the new line of oils will be easy to identify, adjust, and feel.

When following any set-up sheets by XRAY or XRAY team drivers, you can be sure that the oils you will get for your car are exactly same as those used by the factory racing team, thus ensuring very exacting set-ups and handling.

Silicone Oils.

HUDY Exclusive Silicone Oils are manufactured in Europe and each batch is laboratory tested and calibrated to ensure the highest possible consistency and quality from batch to batch. Based on the industry-standard cSt rating, the new line of oils will be easy to identify, adjust, and feel.

When following any set-up sheets by XRAY or XRAY team drivers, you can be sure that the oils you will get for your car are exactly same as those used by the factory racing team, thus ensuring very exacting set-ups and handling.

XB8E “Eazy” Body.

The “Eazy” Body was created after significant time spent testing dozens of different alternatives until the final design was selected. The design of the body improves the handling for all skill levels, from local racers to World Champions. The “Eazy” Body makes the XB8 more stable at speed and more reactive in the corners.

The redesigned sides of the body improve stability at higher speeds. The round front cab and profile make the XB8 easier to drive. Some of the redesigned down force areas increase the speed of the car. The central fin on the roof help control the car more precisely making handling more predictable. Overall, the “Eazy” body is the most significantly improved performance off-road body we have designed.

The front cabin was redesigned with a wider and cab forward design so both left and right sides generate matching downforce even with the cut-out opening for fuel tank.

The body is fully compatible with the XB8 and XB8E platforms.

Socket Head Cup Screws.

To increase lifespan and improve ease of servicing, socket-head cup screws are used instead of regular hex screws. The socket-head cup screws are stronger and more reliable, making it easier to work on the car.

Ball-Bearings.

A full set of 22 high-speed ball-bearings are used throughout the XB8E drivetrain.

Grease lubricated bearings are included for the pinion gears and diffs to increase reliability and lifespan, especially in dusty conditions. The remaining bearings are degreased and oiled with AeroShell® Fluid 12 to reduce drag and maximize driveline efficiency.

Graphite Grease.

The XB8 includes premium HUDY Graphite Grease - a high-performance, advanced-technology semi-fluid lubricant which incorporates both extreme pressure additives and finely-dispersed graphite for load carrying. HUDY Graphite Grease is intended primarily for the lubrication of rotating parts and loaded gears. In addition to providing outstanding load carrying, it is formulated to have excellent adhesion and resistance from "flinging off" under extreme conditions. HUDY Graphite Grease reduces wear and increases parts life.

Click here for more information of the full HUDY Grease range

Adjustment Possibilities.

The XB8E features fully-adjustable front & rear suspension geometry. For quick & easy adjustment, we recommend using set-up tools and accessories from HUDY, the world leader of RC tools.

The extensive and impressive range of adjustment possibilities includes: Caster, Camber, Toe, Kick-up, Anti-dive, Anti-squat, Ride height, Downstops, Track-width, Lower roll center, Upper roll center, Bump steer, Wheelbase, Ackermann, Fully-adjustable shocks, Adjustable front and rear differentials, XRAY Multi-Flex™

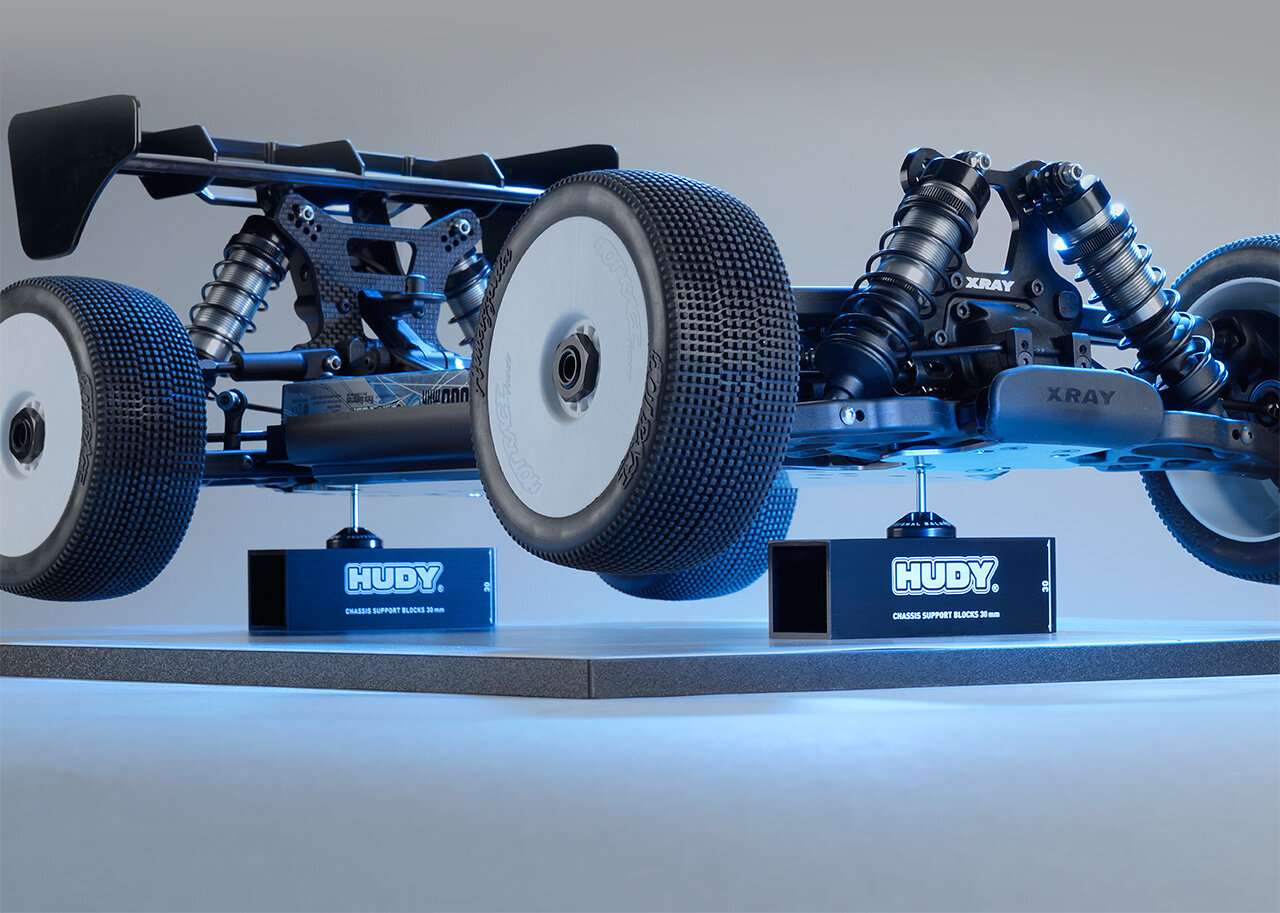

Chassis Balance.

The chassis design focuses on balanced weight distribution and weight transfer. Centerline holes are pre-drilled for easy balancing with the HUDY Chassis Balancing Tool #107880.

XRAY Instruction Manual.

XRAY Instruction Manuals have become the industry standard; they are simply the best manuals you will ever get with an RC model car. Whether you are a first-time builder or an experienced racer, all instructions are straight-forward and easy to understand. The full-color Instruction Manual contains large 3D illustrations that show all assembly details in the easiest and most comprehensive manner.

Instruction manual.

XRAY Instruction Manuals have become the industry standard; they are simply the best manuals you will ever get with an RC model car. Whether you are a first-time builder or an experienced racer, all instructions are straight-forward and easy to understand. The full-color Instruction Manual contains large 3D illustrations that show all assembly details in the easiest and most comprehensive manner.

VIP Customer Treatment.

Owning an XRAY model racing car is an experience unto itself. Not only will you own the most premium luxury model racing car in the world, but you will also become a member of the prestigious family of XRAY owners with direct support and service from the XRAY factory. XRAY brings you the most up-to-date RC website on the Internet, with daily racing news, and the latest product developments. If you have any questions, problems or comments, you can ask the XRAY Support Team or any XRAY Factory Team Driver on the XRAY Support Forum. You can even upload your own set-up sheets or download from the thousands of different set-up sheets available from around the world at the exclusive XRAY Virtual Set-up Sheet Database. And that is only the start of the VIP treatment you get by joining Team XRAY.