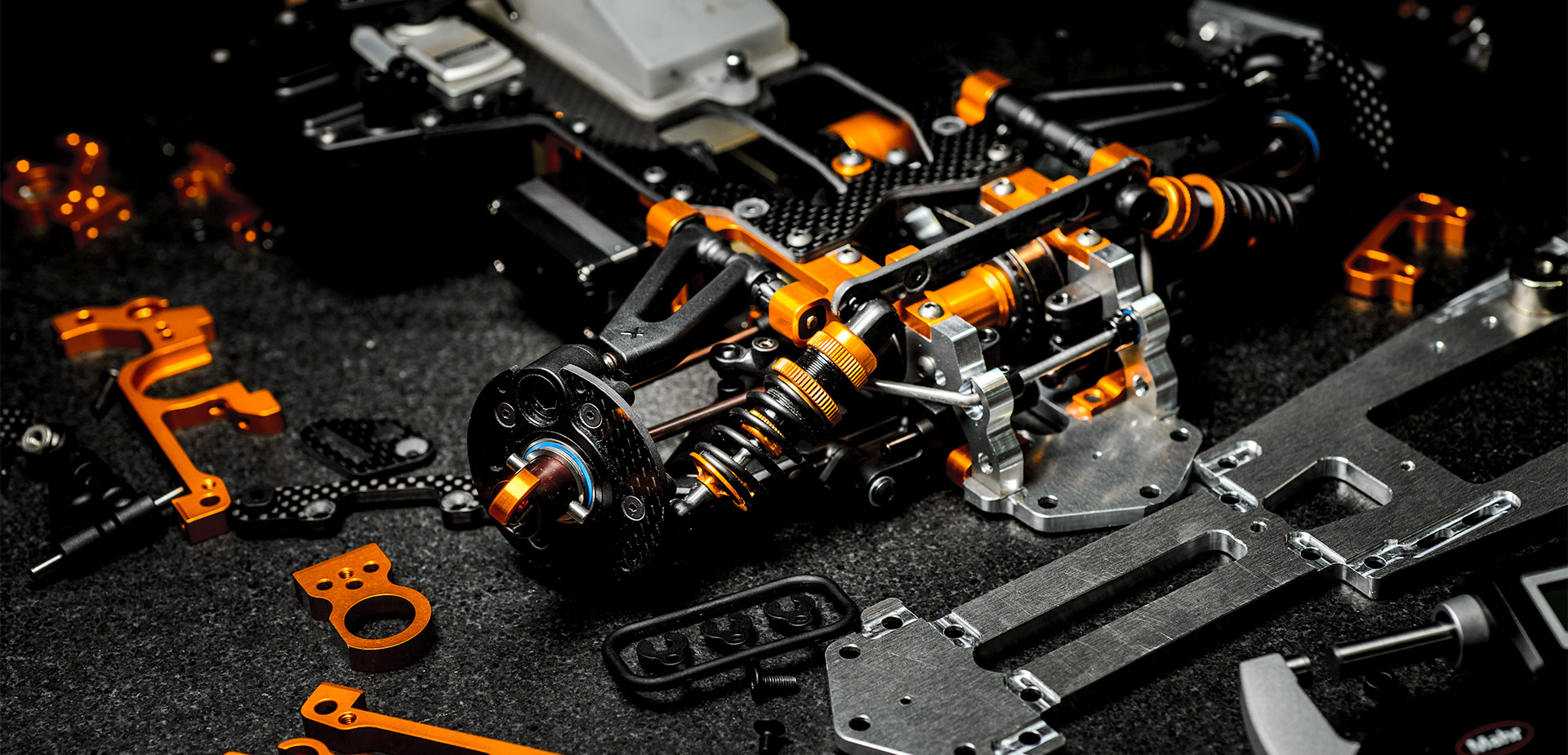

Back in 2014 we were probably the last manufacturer that continued to use composite bulkheads. These were great for soft tires, but now that hard tires had to be used we were forced to completely redesign the entire platform. I thought I could make all the changes fairly quickly, but I ended up in an endless loop of design-prototype-test and back to design again. During the over 1.5 years of development (and seemingly never-ending testing), I ended up with 12 different concepts. Yes, that’s right… 12. Twelve different designs, from which 4 different designs were realized into real prototypes that were tested and analyzed. Does this sound crazy to you? Yes, it is crazy for sure, but once I got fully involved and had a clear goal of no-compromise strategy, there was no turning back.

Most of the work and development was in the following critical areas:

- FLEX: Flex is the most important feature that influences the overall characteristics and handling of the car. All changes to the car were made with the intention to achieve the proper flex, and of course to design the key parts to allow flex adjustment as needed.

- BULKHEADS: The aluminum backbone of the car was a major update to the entire concept of the car, a “must have” when using hard, large tires without additive. With experience from the recent NT1 platform redesign changing to aluminum bulkheads, I already knew the critical things to focus on, and how to incorporate new parts to allow the car to flex properly. I also knew how to re-design the car to make it easier to work on, as well as keeping production efficiency in mind.

- CHASSIS: The chassis was re-designed to work with the new aluminum backbone, and it was modified to accommodate the newly-improved geometry.

- SUSPENSION FLEX: Flex of the suspension is very important to the car’s overall performance and handling characteristics. Besides getting the correct stiffness of the composite suspension arms, the way that the suspension is mounted is also very important. Therefore I focused on this area and tested many different alternatives that helped me to make good progress.

Prototype #1:

After the 2014 season, I started working from scratch using concepts from the new NT1. I started with the design of the alu bulkheads, which were assembled to the RX8 chassis. I tried to use as many existing RX8 parts as possible, but of course there were many complications and thousands of small problems. In the computer, I created several different concepts which had the same results, but every one of them used different parts to achieve that. From these first concepts I chose the one that used the most existing RX8 parts so we could quickly create prototypes for the team to test. It took several weeks to produce the new parts, but after I assembled the first car and checked the flex on the workbench I was very positive and optimistic.

Prototype #2:

Based on Prototype #1, I started to work on further modifications and improvements. The basis of Prototype #1 was very good, so I only needed to work on small details to make the car easy to handle but also easier to work on. There were several parts that required design changes to eliminate weaknesses. For example, I received reports from two different drivers who both broke aluminum bulkheads in exactly same place. As such, I had to completely redesign the front bulkheads to make them stronger and more reliable, while still keeping the same flex. Progress with Prototype #2 was going very well, but time was flying by faster than I realized.

I had to decide whether to:

- a) select one of the 3 concepts and put one of them into production, or

- b) get back to work and make new changes.

If I selected the first option, it would not be a disaster as any of the 3 different cars were still a big improvement over the previous RX8. But still, all of them had room for improvement which I knew about and could not get out of my head.

Should I play it safe and compromise… releasing a car on time for the season? Or should I stand by our “no compromise” commitment to ensure that I put the best-of-the-best into the final design?

Prototype #3:

After making the decision to incorporate the changes, I was almost a permanent fixture behind the computer… trying to put all the changes from the 3 different concepts into one car. This was very tricky & demanding, as I had to throw away a significant amount of the work done beforehand, and even still I was constantly running into conflicts and problems. After a huge amount of time & effort spent on this, I finally finished and was very pleased with the outcome. I uploaded all the manufacturing programs to the production server, and Production started to work on the 20 pieces of the cars for the team.

While working on the team cars, we sadly informed distributors that the RX8 would be delayed for the 2015 season. This was not very welcome news.

All the issues & problems I had not expected served to jumpstart my motivation to a whole new level.

Since I had nothing left to lose, I needed to first solve the existing issues:

- The front bulkheads got a design change, with reinforcement in the area that saw breakage;

- To eliminate the rear suspension holder bending issue, I changed the mounting from 2 screws to 4 screws which made the assembly very solid and impossible to bend anymore;

- To solve the problem with the fuel tank, I have decided to use a completely different fuel tank;

- To get more steering from the front suspension I incorporated the same design I recently (successfully) used on the new NT1. Instead of the front upper arm mounting from the side to the bulkhead, I changed the design so the upper arm holder was mounted in two different points – in front at the bulkhead, and in rear at the radio plate. This design resulted in changes to the flex characteristics which improved steering (especially at high-traction tracks). This new design concept required completely changing the front part of the car – making it more difficult to implement – but the benefits & performance improvements were significant.

Prototype #4:

Despite being convinced that we had the final design, a coincidence changed this. This time the idea came from a completely different source: the new T4’16 that I was working on at the time. While racing on asphalt, to make the car roll better we added a 1mm shim under the top deck. This small change gave the car much less roll resistance through the corners, increased traction, and made the car much easier to drive. With this positive experience on the T4, I really wanted to try this on the RX8 as well.

I hope you have enjoyed this short story that hopefully gives you some insight into my daily life and the challenges I face, but also tells of the joy I get once we successfully finish an important project. Please know that I will be with Team XRAY at all races during the 2016 season, so I welcome you to come see me at any time if you need any help with anything.

‘Till next time!