2018 All-New:

- All-new X12 Uni-platform™ design with fully interchangeable parts

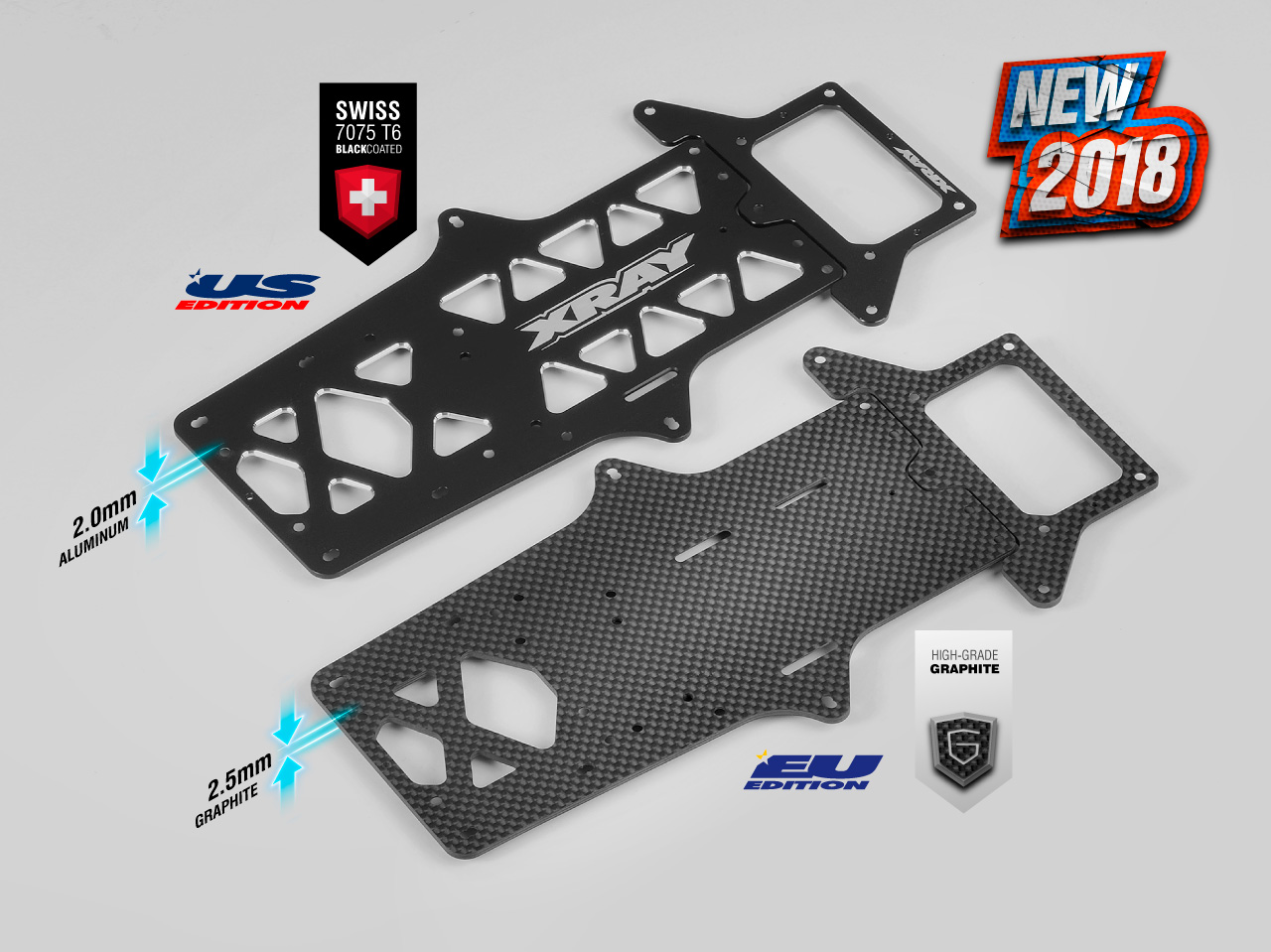

- All-new EU and US Edition both designed & optimized for particular traction conditions

- All-new EU Edition is optimized for low-, medium-, and high-traction conditions

- All-new US Edition is optimized for high- and very-high traction conditions

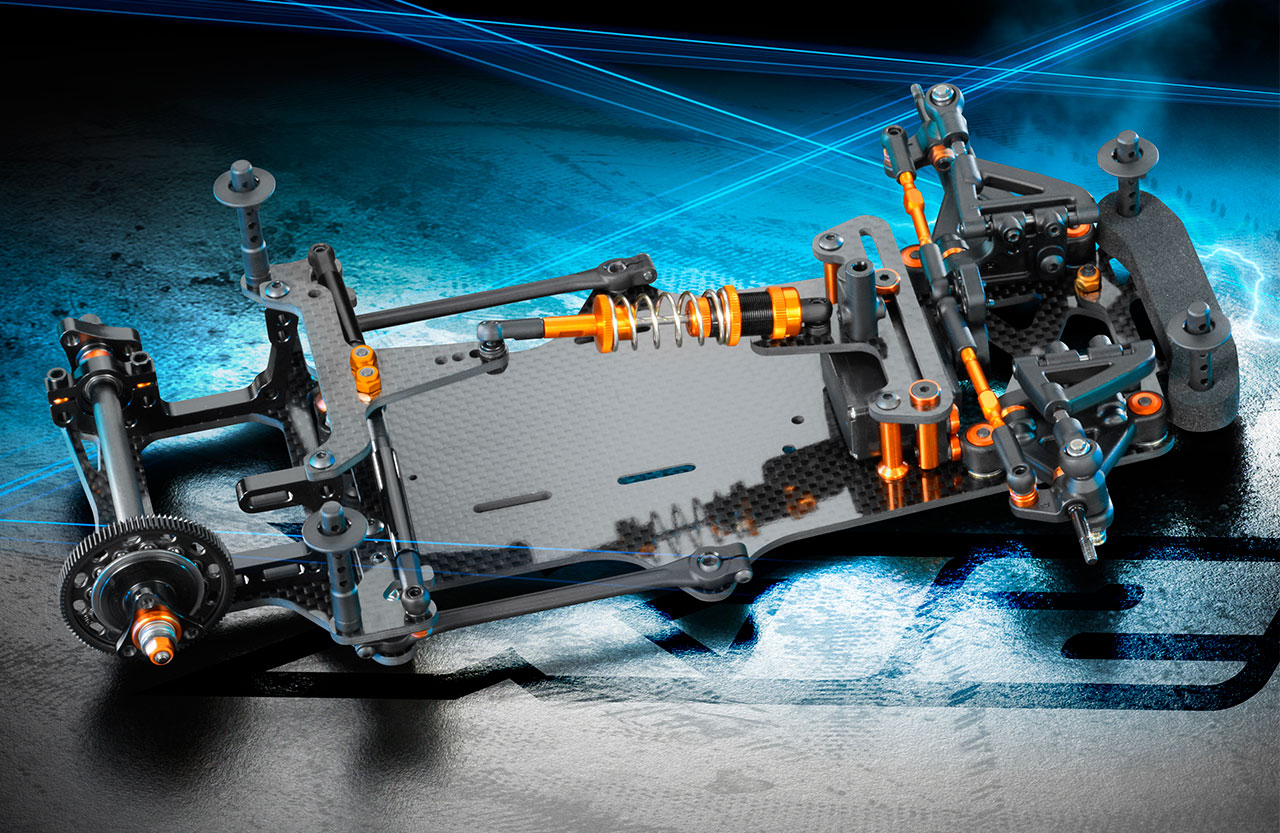

- All-new chassis concept features a split design of a 14mm shorter chassis + elevated bumper holder to eliminate chassis touching the track surface, minimizing front scrub allowing for increased steering and more consistent handling

- All-new 2.5mm graphite chassis for EU Edition

- All-new 2.0mm Swiss 7075 T6 aluminum chassis & rear pod for US Edition

- Front suspension concept has optimized specs for EU Edition and US Edition

- All-new stiffer front graphite suspension for US Edition gives increased cornering speed

- All-new innovative wheelbase adjustment

- All-new front graphite bumper holder

- Foam bumper improves the durability of the car and protects the front in hard collisions

- All-new lower servo mounts with variable mounting depending on battery orientation

- All-new adjustable-position battery backstops

- All-new frontward/rearward shock position adjustment for more set-up options

- All-new track-width adjustment inserts for US Edition

- All-new tweak-free lower pivot brace

- All-new lightweight graphite rear axle to significantly reduce the rotating mass and improve steering

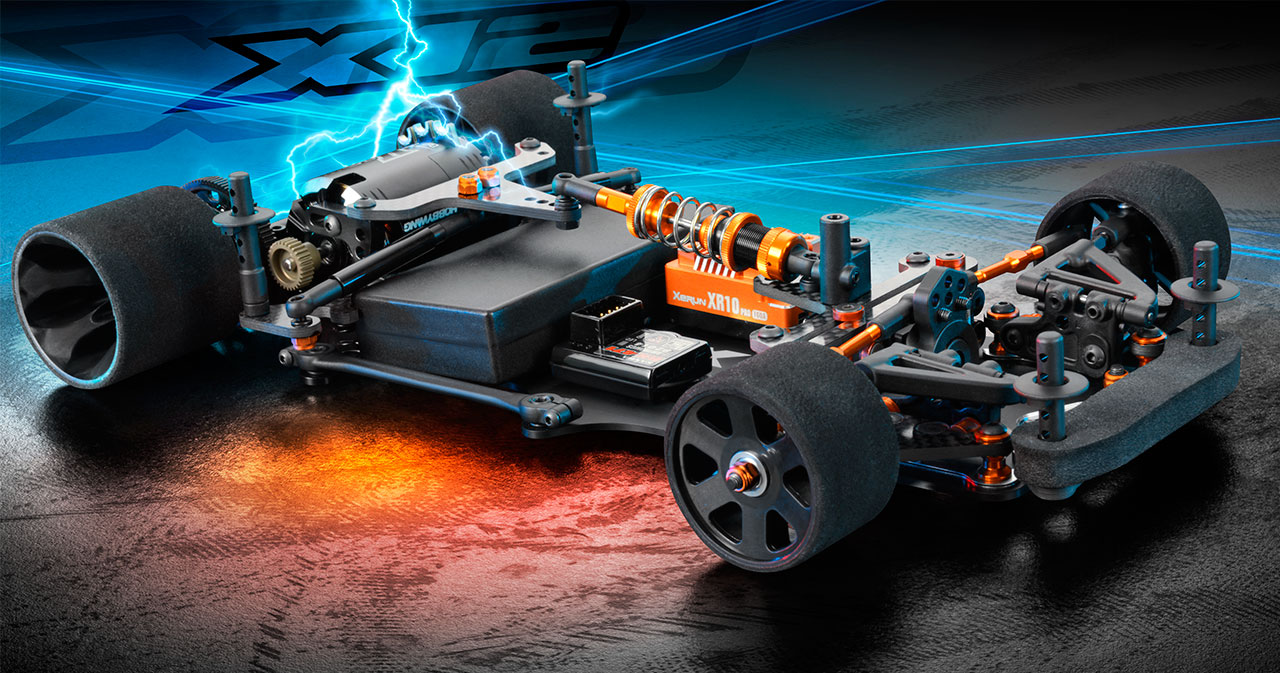

XRAY X12 Platform.

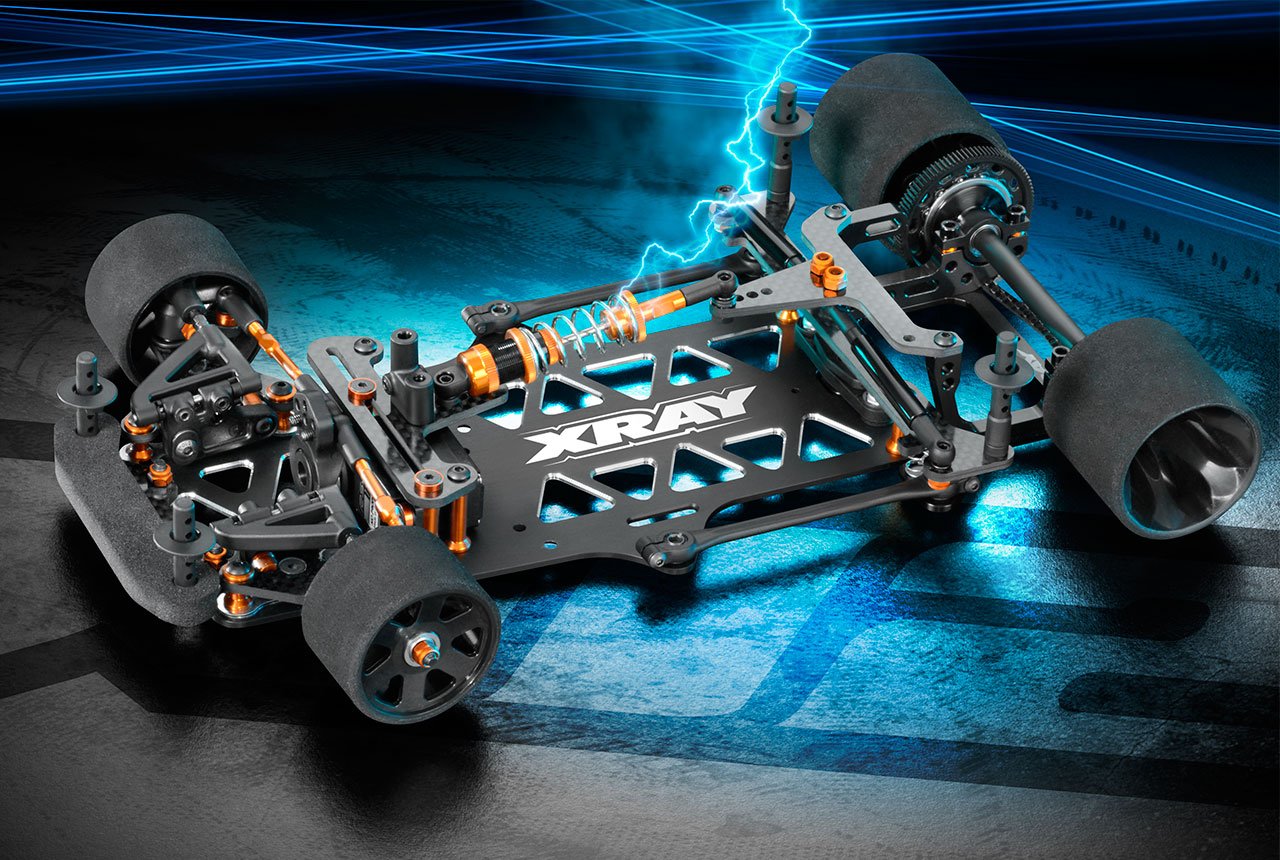

Based on the ultra-successful X12 platform, XRAY proudly presents the 2018-spec X12 which incorporates the latest improvements and refinements gathered by the team, race-proven in high-competition races around the world, and ready out-of-the-box to take you to the Winners’ Circle.

USA Edition.

Eric Anderson has been the main driving force behind designing, testing, and adopting the X12 platform to the very-high traction tracks in USA. His hard work and dedication paid off when he won the 2017 US Championship with an early prototype of the X12 US Edition, which is now in its final production design.

"During testing for the X12 we tested many different front end configurations including lower arms, stand-offs, caster block mounts, and other items. All of these tests were performed on super-high grip CRC FT2 carpet.

The first test was for a new lower arm that could be made lighter, stiffer, and which could remove any slop in the lower pivot ball. There were numerous shapes and designs tested along with different pivot ball heights for roll center. Once we finally decided on a lower arm made of carbon fibre, we started testing different caster block heights and standoff heights for roll centers and upper arm angles.

For the chassis we decided to include the alloy chassis which has been found to be more consistent and produce faster lap times on high-grip black carpet. We also shortened the front overhang of the chassis and included an all-new graphite bumper for the body mounts so it allows the racer to run the chassis at a lower ride height without the front of the chassis touching the carpet. This helped improve corner speed drastically, and also reduces the chance of traction rolling with the lower ride height.

After many days of testing under controlled conditions and evaluating lap times, consistency, and overall runs, we came up with the best possible X12 edition for CRC FT2 carpet used in the USA. This is easily the best 12th scale car I have ever had the pleasure of driving in my racing career. Our goal was to create the ultimate car ready for the black carpet in the US, and we have that in the X12 US Edition."

Eric Anderson

X12 US Edition designer

Made in Europe.

From unique HUDY Spring Steel™, through the world’s strongest Swiss 7075 T6 aluminum, along with XRAY’s own secret composite mixtures, to the premium high grade graphite materials… everything is exclusive and premium on the X12.

Using premium European exclusive materials crafted by XRAY’s engineering artists using the state of the art German, Italian, and Swiss CNC machines, the X12 is a blend of only the world’s finest.

European Champions.

XRAY X12 is currently the best-performing and most winning 1/12 pan-car in Europe. Alexander Hagberg continues his winning streak with back-to-back European Championship in the Modified class making it 4 in a row: 2014, 2015, 2016, and 2017. XRAY factory team driver Hupo Hönigl brings back-to-back European Champion titles in Stock class – 2016 and 2017.

Perfection.

Designed in virtual reality using the world's most sophisticated CAD tools, and manufactured using the world's best machining and molding machinery, the X12 achieves a level of premium perfection in all details that is second to none.

USA Champions.

Within some of the toughest and highest-competition pan-car racing at the USA National Championship, Team XRAY continues to bring home the USA National Champion titles with the X12 platform.

At 2017 USA National Championship, Eric Anderson dominated and won the Stock class with an early prototype of the all-new 2018 X12 US Edition.

Premium.

From unique HUDY Spring Steel™, through the world’s strongest Swiss 7075 T6 aluminum, along with XRAY’s own secret composite mixtures, to the premium high grade graphite materials… everything is exclusive and premium on the X12. Using premium European exclusive materials crafted by XRAY’s engineering artists using the state of the art German, Italian, and Swiss CNC machines, the X12 is a blend of only the world’s finest.

US & EU Edition.

With XRAY’s no-compromise, high-competition focus, the X12 was split into two different platforms, each optimized for specific, different track conditions out of the box with no extras needed.

Whether at medium-traction tracks typical of Europe, or super-high tracks typical of US permanent tracks, there is an X12 edition to choose from: the US or the EU Edition, both built on the same core platform with compatibility and interchangeable parts.

The EU Edition is suitable for low, medium, and high-traction conditions, while the US Edition is designed & suitable for high- and super-high traction conditions.

Chassis Concept.

Whether you are racing at US very-high traction tracks or European medium-traction tracks, whether the track is carpet or asphalt, there is an X12 Edition that is specifically designed and suitable for your particular traction conditions.

The US Edition features a chassis and pod plate CNC-machined from 2.0mm Swiss 7075 T6 aluminum which is more suitable for high- and very-high traction tracks; it makes the car easier to drive, keeps more cornering speed, and prevents the car from traction rolling.

The EU Edition features a chassis and pod plate CNC-machined from custom-manufactured 2.5mm high-grade graphite material with a specially-designed compound for low, medium, and high-traction tracks. The graphite material is softer than an aluminum chassis and therefore generates more traction.

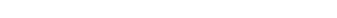

Chassis.

The X12 chassis was completely redesigned and re-engineered. In order to prevent the chassis from touching the track surface at the front, the chassis was split into two pieces: the main chassis and an elevated graphite bumper holder. This new design shortens the chassis by 14mm and elevates the bumper holder above the track surface.

The new split chassis concept minimizes scrub at the front part of the chassis, allowing for increased steering and more consistent handling, particularly in high-traction conditions. The new design results in increased off-power steering.

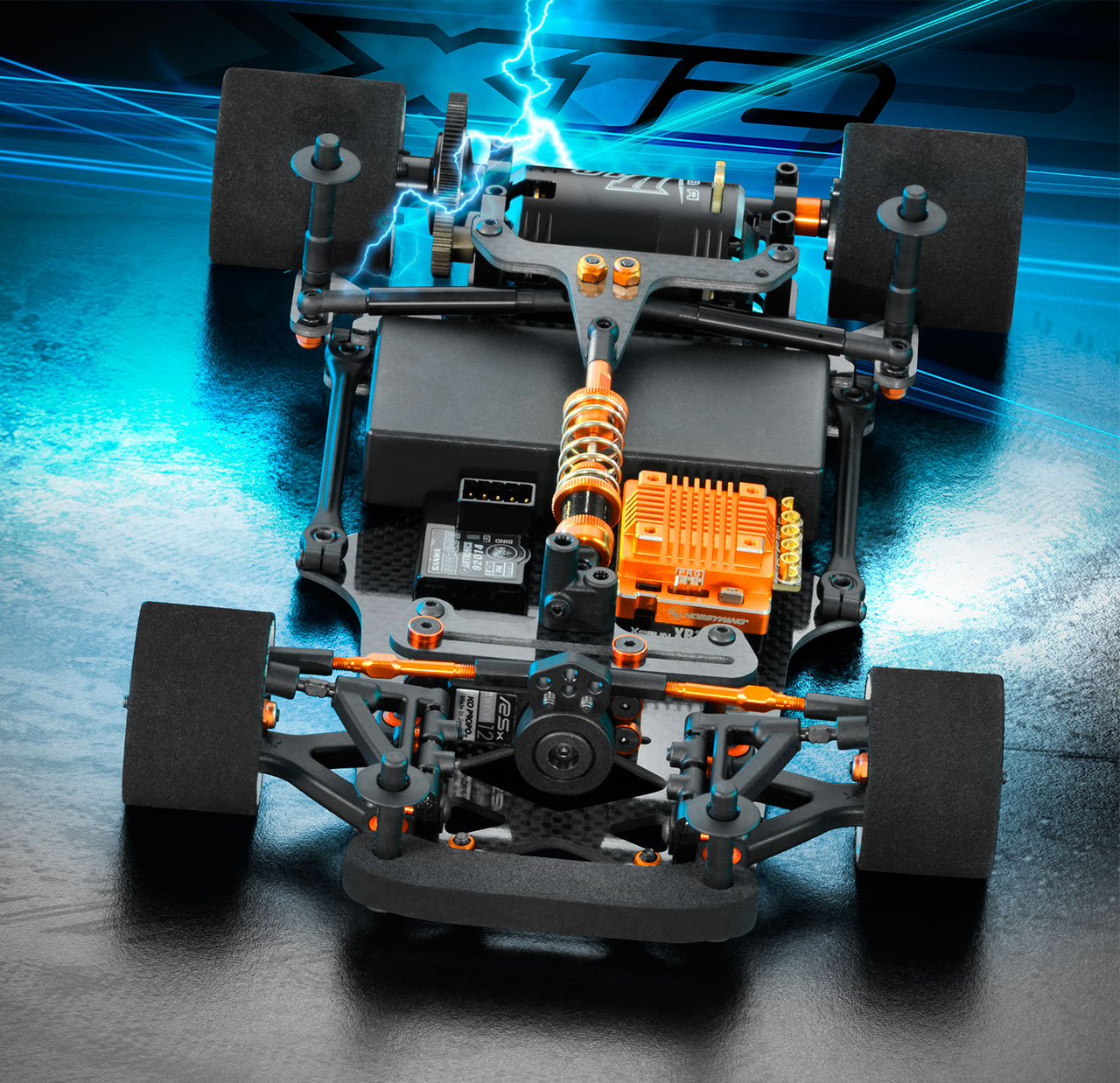

Suspension Concept.

To utilize the performance potential in various traction conditions, there are two different suspension concepts used on the 2018-spec X12.

The EU Edition includes a standard composite suspension that makes the car predictable and generates more traction.

The US Edition features an all-new unique graphite suspension arms that reduces torsional flex of the arms in the corners of very-high traction tracks, making the car more reactive and easier to drive

Suspension.

The all-new XRAY self-designed graphite front suspension was specially designed for high-traction US-style tracks. With the stiffer front, the car has more cornering speed while being easier to drive and more consistent in high-traction conditions.

The graphite arm is mounted on aluminum posts which are mounted to the chassis. The holder for the composite front upper arm mount is mounted on the graphite arm as well.

The graphite front suspension was successfully used by the US team where Eric Anderson won the US National Championship title in Stock class with this new suspension concept.

Wheelbase.

The X12 chassis features a new, innovative front wheelbase adjustment possibility. The chassis has two positions for front suspension mounting; the whole front suspension can be easily moved by 2mm frontwards or rearwards.

The long wheelbase is the same wheelbase as previous X12 cars, and is recommended for larger tracks or tracks with longer sweepers. A long wheelbase works well at low-to-medium traction tracks when more stability is desired. Also better suited to the Open Modified classes to make the car smoother and less twitchy.

The short wheelbase allows the car to rotate better in the middle of the corner to maintain cornering speed. Recommended for tight, technical tracks or tracks with numerous hairpin corners. The short wheelbase works well at medium-to-high traction tracks where a lot of steering is needed. Also better suited to the Stock and blinky classes.

Graphite Bumper Holder.

All-new graphite bumper holder is designed to fit into the new shorter chassis and keep the front body posts at the same position as previous versions, but atop the chassis so it does not touch the racing surface. This improves the steering of the car and prevents front scrubbing.

Machined from premium 2.5mm graphite, the brace is flexible yet rigid enough to withstand serious crashes.

Foam Bumper.

X12 now includes a foam bumper which improves the durability of the car and protects the front in hard collisions. Hand-cut from specially-developed foam material, the bumper is very light, yet very strong.

Servo Mount.

The graphite plate posts and servo mount posts are 3mm shorter to allow the servo to sit lower to decrease the CG of the car.

When the inline chassis battery alignment is used, the included 3mm shims allow the plate posts & servo mounts to be raised so the battery can be placed below the graphite plate.

Battery Backstops.

The chassis features new grooves to allow mounting of the battery backstops and adjustment of battery position when cross-chassis battery alignment is used.

To eliminate battery movement when inline battery alignment is used, the chassis features holes for composite battery backstops.

Shock Position.

The all-new rear link pod upper plate includes extra holes for center shock mounting to allow fine tuning and greater range of shock adjustability.

By using a longer or shorter shock, the damping and steering characteristics can be changed. The new upper plate allow the shock to be moved front & back to alter how the car enters & exits corners.

Long Shock:

• Shock built WITH adaptor (extension)

• Improves drivability over bumps,

improves on-power traction

Short Shock:

• Shock built WITHOUT adaptor

• Improves steering response,

quicker direction changes

Frontward positions:

• Make the car run smoother in very-high tractions conditions with less roll-over

Rearward positions:

• Makes the car more reactive and provides more steering in the middle/exit of the corner

Track-Width.

The lower suspension arms feature smart eccentric aluminum inserts which allow quick & easy track-width changes depending on track conditions. Optional aluminum 0.5mm and 1.0mm eccentrics are used to set the track-width either narrower or wider.

Both EU and US Editions include specific track-width adjustment inserts.

Pivot Brace.

All-new tweak-free lower pivot brace was redesigned for easier mounting of the pod plate on the chassis. Thanks to the nut groove on the brace, nuts that connect chassis with the brace will find the position by themselves, removing the need to reset the position for free movement when mounting the pod plate.

The composite upper & lower pivot braces were redesigned to allow the pivot ball to be lowered by 0.5mm so as to lower the roll center of the car, resulting in more rear traction and improved rear stability.

The pivot ball is smaller and lighter, which is very important for a pan car. The pivot ball has an internal thread so a separate locking nut atop the pivot ball is not needed any more. This saves weight but also allows for greater side movement of the rear pod.

Rear Axle.

To significantly reduce the rotating mass and improve steering, the original steel rear axle was replaced with an all-new, super-lightweight graphite rear axle.

The rear differential features high-grade precision carbide balls in the spur gear, hardened and precision-ground D-steel shims, and premium carbide axial thrust-bearing.

Legend.

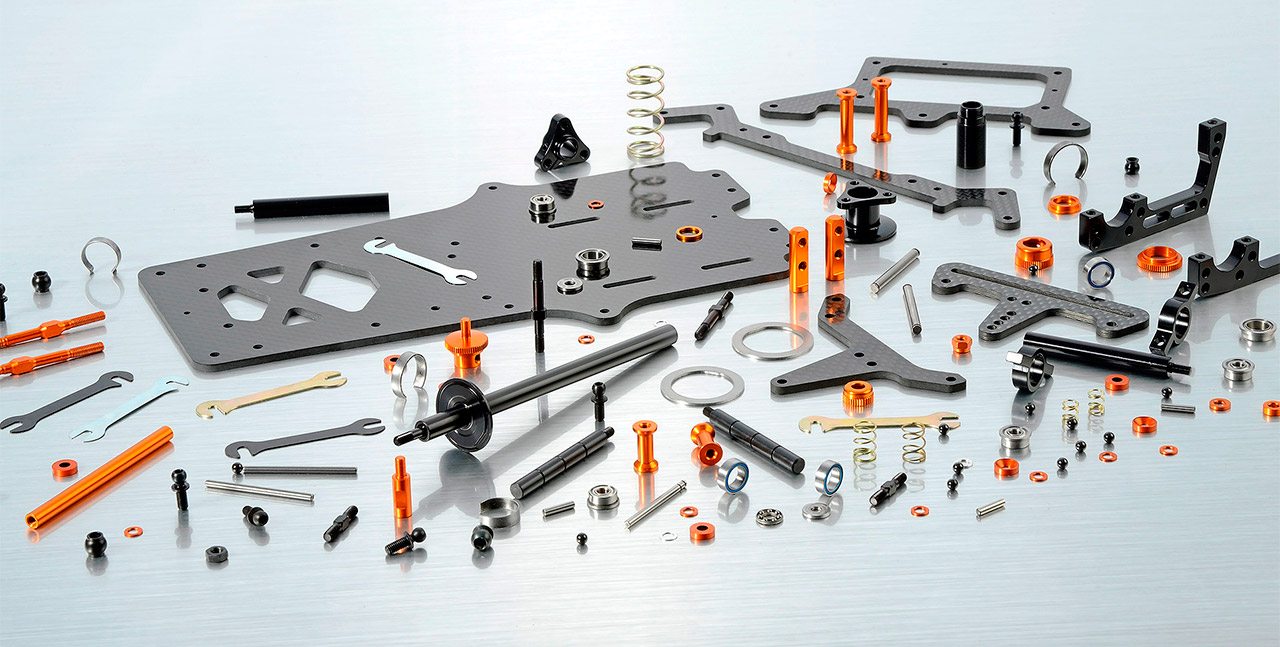

Legendary XRAY premium design, workmanship & material quality and unmatched attention to the finest details result in a state of perfection achieved by well thought-out refinements to create a car that is easy to drive, work on, and adjust.

All of the refinements from the last year – based on our own experiences and feedback from drivers all around the world – were incorporated into the new X12. New ideas and prototypes were long-term tested by the factory team worldwide to ensure the improvements would work well in all track conditions and tracks in Europe, America, and Asia.

Based on the feedback from the team, the X12 platform was for the first time split into a specific EU and US Edition to ensure the X12 would have the highest performance straight out of the box under specific, different track conditions.

Performance.

With countless wins in multiple classes at local, regional, national, and international levels, XRAY X12 is designed for highest competition racing and ready to win. Take your X12 to win your race.

It has been rightfully called “miniature Formula 1” and has proven to be a class at the pinnacle of RC car racing. Fractions of a second separate the world’s best 1/12 pancar drivers. With simpler designs compared to larger touring cars, attention to detail is paramount, and XRAY is second to none in its evolution of a small, agile, and super-fast car that is destined for the Winners Circle.

To the untrained eye, the new XRAY X12 may at first glance seem a simple and traditional design, but it’s upon closer inspect that the details and engineering marvels shine through. With unparalleled experience and innovation in its team, XRAY has achieved a state of pancar perfection with the X12 by focusing on strategically-planned refinements to create a car that is easy to drive, work on, and adjust.

Martin Hudy

XRAY designer

Winning Heritage.

Team XRAY continues its winning streak at major international & national races all around the world! Just recently, Team XRAY added another European Champion and USA Champion titles to the already impressive list of achievements, which includes dozens of national titles from around the world, from the USA National Championship, and multiple wins at other famous races such as IIC, Snowbirds, and many others. Be part of one of the most successful racing teams in the world!

4x European Champion in a row.

Having been with XRAY since I started racing, I know first-hand the total commitment of the entire XRAY team - R&D, racing team, support team, everyone - when it comes to their ongoing dedication to continually improve their products and bring the absolute best performance, service, and support to the world.

I have won many Junior European titles and XRAY has won many European Championships in other classes, but this year XRAY stands at the top in the 1/12 class again, with the well-deserved achievement of being back-to-back 4x European Champions in modified class. I thank XRAY for their belief in me, and the support they have given me. I am very proud to bring home these victories for our team.

Alexander Hagberg

European Champion 2014, 2015, 2016 & 2017

Bulkheads.

The tiny rear bulkheads including the upper bulkhead clamps are significantly lower and lighter than standard pan cars, CNC-machined from premium extra-hard Swiss 7075 T6 aluminum and additionally black-coated for long life and stylish look.

The right bulkhead has motor mount design with multiple motor mounting positions. The upper motor mount position prevents the motor from moving in serious crashes, and it adds another option to easily mount different types of motors.

Rear Brace.

The rear graphite brace replaces the previous aluminum brace. The graphite brace significantly reduces tweak of the rear pod. To keep the lowest possible CG, the brace is positioned in the lowest possible position.

Machined from premium graphite, the brace is flexible yet rigid enough to withstand serious crashes.

Rear Hubs.

The aluminum rear hubs are machined from lightweight aircraft aluminum, specially lightened and black-coated for stylish look. The rear left aluminum wheel hub features a center-balanced clamping mount system, ensuring secure mounting while eliminating vibration and run out.

Rear Link Brace.

The rear link brace features a narrow design that helps to move the weight more into the chassis centerline, and gives lower weight.

The graphite rear link brace holds the side tubes as well as the side springs and body posts, and works as a backstop for the battery pack.

Side Tubes.

Lateral damping side tubes provide ultra-smooth side damping, making the car easier to drive and easier to work on. The outer aluminum tube and inner Delrin® tube operate ultra-smoothly.

Side Shock.

Rear link pod upper plate includes a hole so an optional side shock can be mounted. The advantage of using the side shock is that it provides more traction in low-to-medium traction conditions.

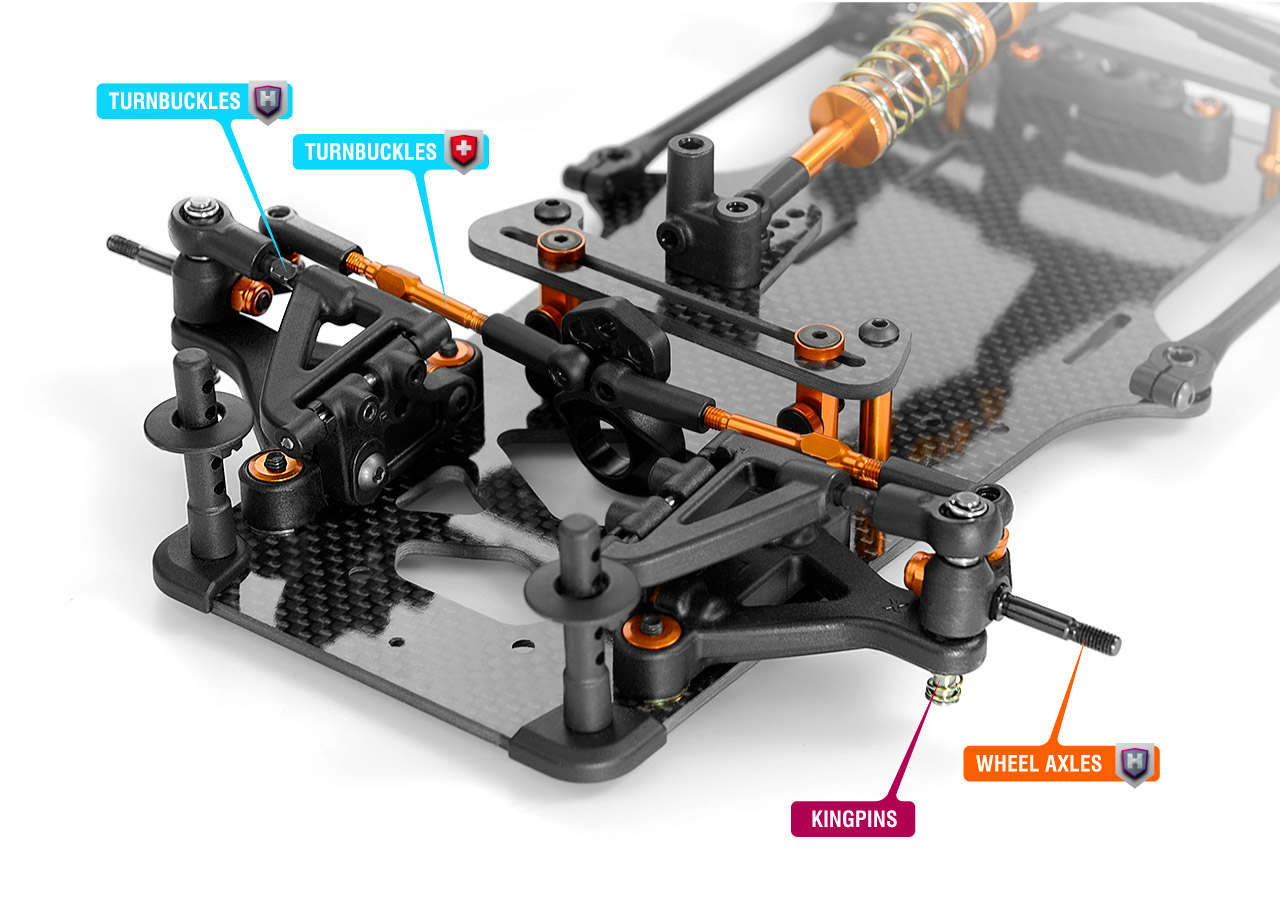

Front Suspension.

Strong, simple, yet refined front suspension made from strong, lightweight, self-developed composite material. Tiny yet strong HUDY Spring Steel™ upper pivot balls ensure smooth, bind-free operation, while composite lower pivot balls allow the front suspension to operate even more smoothly. Fast & easy adjustment of front caster, front wheelbase, track-width, bump steer, roll center and ride height via included shims and clips.

Kingpins.

Super-smooth, hardened steel kingpins provide the foundation for the front suspension.

Wheel Axles.

Ultra-precise wheel axles CNC-machined from premium HUDY Spring Steel™ are additionally hardened and hand ground for precision fitment.

Adjustable Turnbuckles.Front upper 3mm adjustable HUDY Spring Steel™ camber turnbuckles are lightweight yet can withstand hard impacts, with precision threading to ensure fine camber adjustment. The 4mm adjustable steering turnbuckles are manufactured from lightweight aluminum.

Steering Block.

The tiny yet strong steering blocks have excess play removed for precise steering response.

Reactive Caster.

Reactive caster is easily adjustable by using easy-to-change eccentric bushings of 2.5°, 5.0° or 7.5° (included). Reactive caster is used to adjust the amount of caster change when the front end of the car is compressing (diving) or decompressing (rising).

Front Ride Height.

The front suspension uses ride height adjustment shims for very quick, precise, and hassle-free ride height adjustment depending on track conditions. The set of 0.2, 0.4, and 0.6mm ride height adjustment shims are included for fine tuning.

Camber Gain.

The upper arm shims allow for moving the front upper arm mount together with the upper arm more out from the lower arm, thus generating less camber gain and making the car easier to drive. With more shims, less camber gain is generated, reducing initial steering and giving less “twitchiness.”

Bump Steer.

3mm shims are included for the steering block to make the car easier to drive under high-traction conditions.

Servo Position.

Unique & innovative fully-adjustable servo mount allows easy adjustment of the servo position. The servo is attached to independent mounts that are inserted in a groove on the front upper plate. Depending on the size of your servo, you can easily install and adjust the servo and its position to the center of the chassis. By changing the orientation of the servo, you can adjust the weight balance of the car.

The floating servo does not touch the chassis, so it eliminates unwanted tweak and also allows you to adjust any servo to the centerline of the chassis. Smart and easy.

The optimal position of the servo depends on the weight of the electronics. If the car is heavier on the right side, a left-side servo position is used… and vice versa.

Premium Composite Parts.

All composite parts are manufactured by XRAY using premium self-developed composite mixtures which guarantee sufficient flex of the suspension parts, while being hard enough to withstand hard impacts.

Pivot Balls.

High-precision, HUDY Spring Steel™ upper pivot balls and composite lower pivot balls ensure smooth & precise movement of the front suspension.

Ackermann.

The quick adjustable Ackermann positions can be adjusted by adding/removing shims between the servo and servo mounting posts. The composite shims included in the kit come in three different sizes: 3x6x1, 3x6x2, 3x6x3. Ackermann influences the steering of the car, and therefore it is important to make it an adjustable feature.

Servo Saver.

Tiny yet robust servo saver protects the servo from impact damage. Easy Ackermann adjustment is made via shims mounted below steering block pivot balls.

Shock Absorber.

The fully-adjustable shock features an aluminum shock body that is hard-anodized for ultra durability. The fine-threaded shock body allows for quick and easy shock spring preload adjustment.

Tiny, thin shock membrane gives smooth dampening characteristics, and a super-soft silicone shock O-ring gives super-smooth operation while preventing oil leakage.

The ultra-finely finished shock shaft with precise-molded composite shock piston ensures optimum shock oil flow and smooth shock absorber action.

The shock adaptor allows for quick & easy changes to the shock position. Using the adaptor allows for forward shock mounting position, and when the adaptor is removed the standard rearward position is used.

Weight Balance.

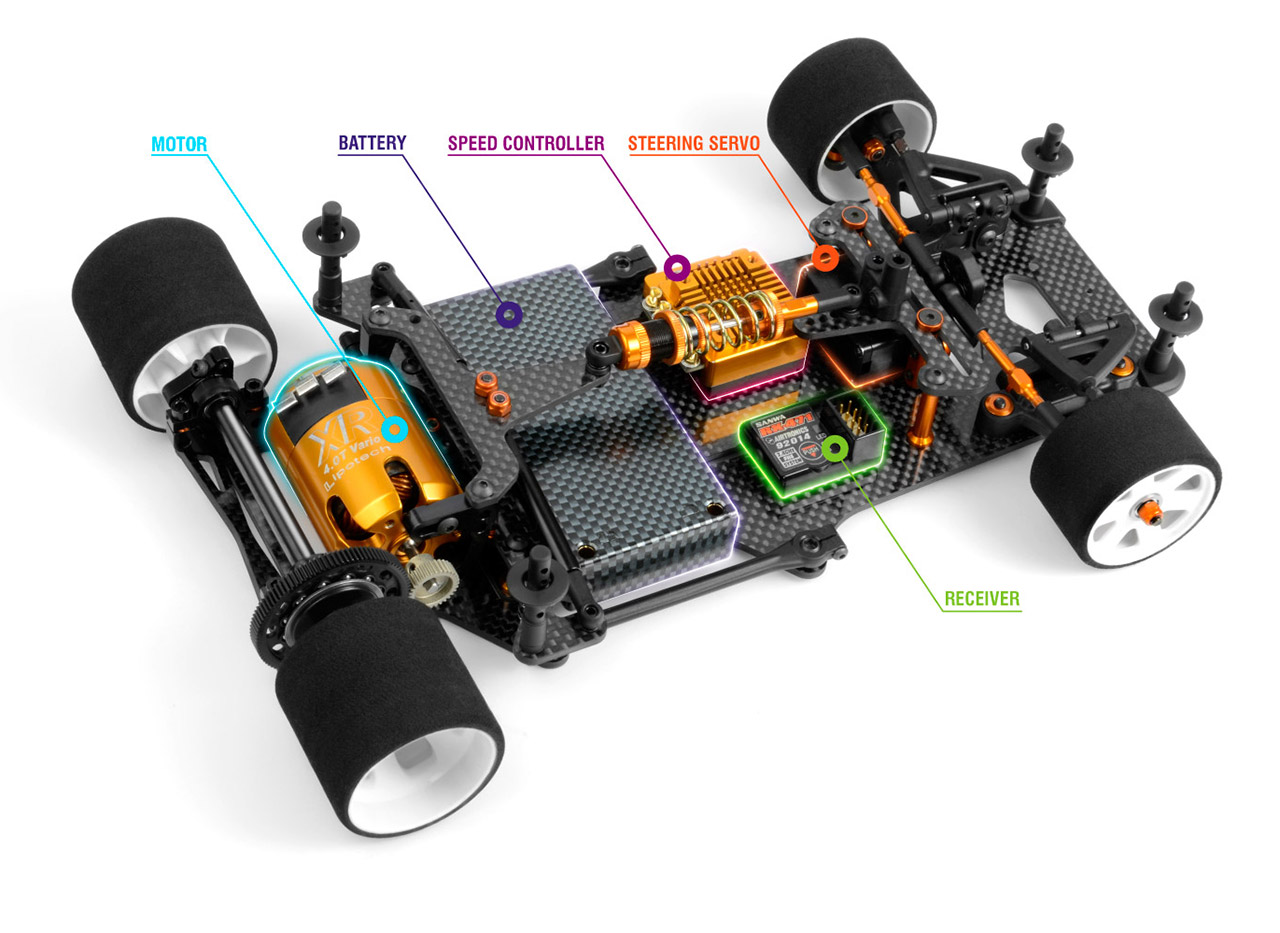

The layout of the electronics and position of individual sections of the car were designed with optimum weight distribution and balance in mind.

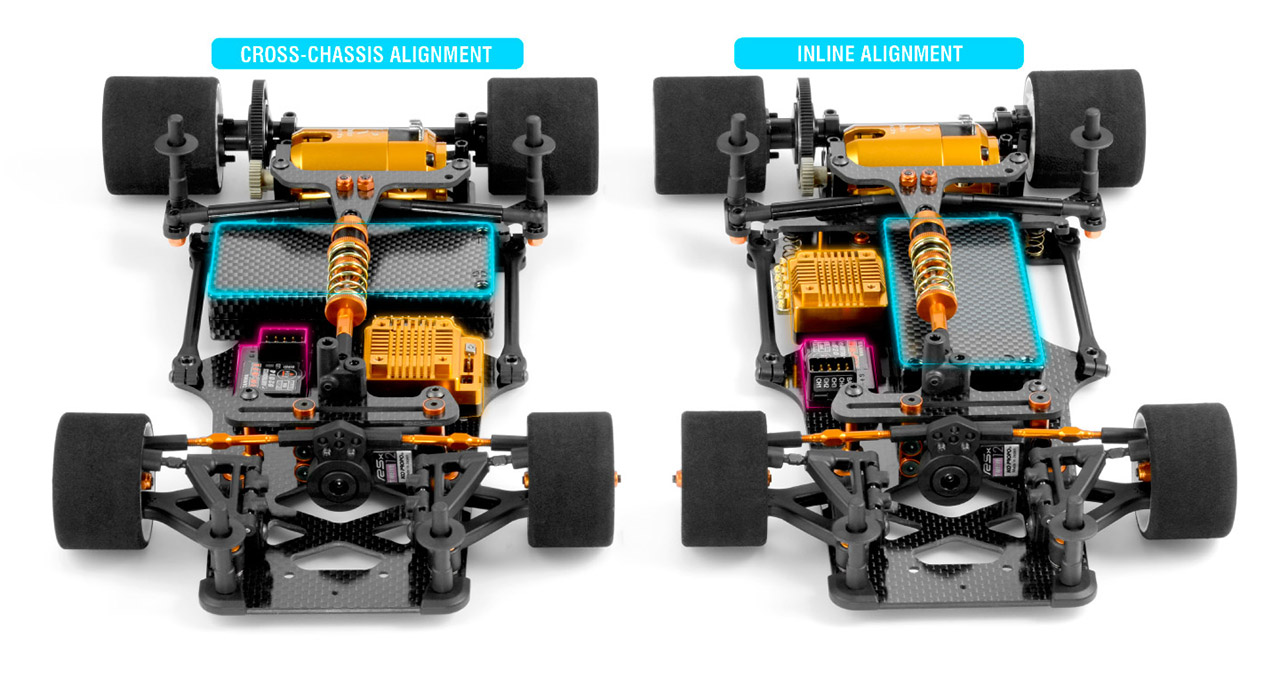

The steering servo is located in a lay-down position for lowest CG at the chassis center, and the layout of the chassis allows the batteries to be placed either cross or inline.

Depending on battery configuration, the ESC and receiver can be placed in various positions for ideal weight transfer and balance.

Battery Placement.

The position of the battery placement in the chassis has a significant influence on weight balance adjustment. To offer instant and comfortable weight balance adjustment - depending on various track conditions - the battery placement can be quickly changed from inline to cross-chassis. Smart and handy - an all-new unique feature and system.

Rear Ride Height.

The alu bulkheads allow for very quick & easy ride height adjustment. No more hassle to dismount the car to change the rear ride height! The included ride height shims are inserted between the bulkhead and upper bulkhead clamp to alter the ride height. Smart & easy.

The new method for ride height adjustment allows ultra-fine adjustment by 0.25mm increments, in comparison to the previous 0.5mm increments using eccentric bushings.

Side Springs.

Side springs are placed directly on the chassis for smooth and precise movement.

Spur Gear.

Precision-molded spur gears are made from XRAY's exclusive composite material, ensuring true running, super-quiet operation, and robustness for handling powerful motors. A range of optional spur gears for fine tuning is available.

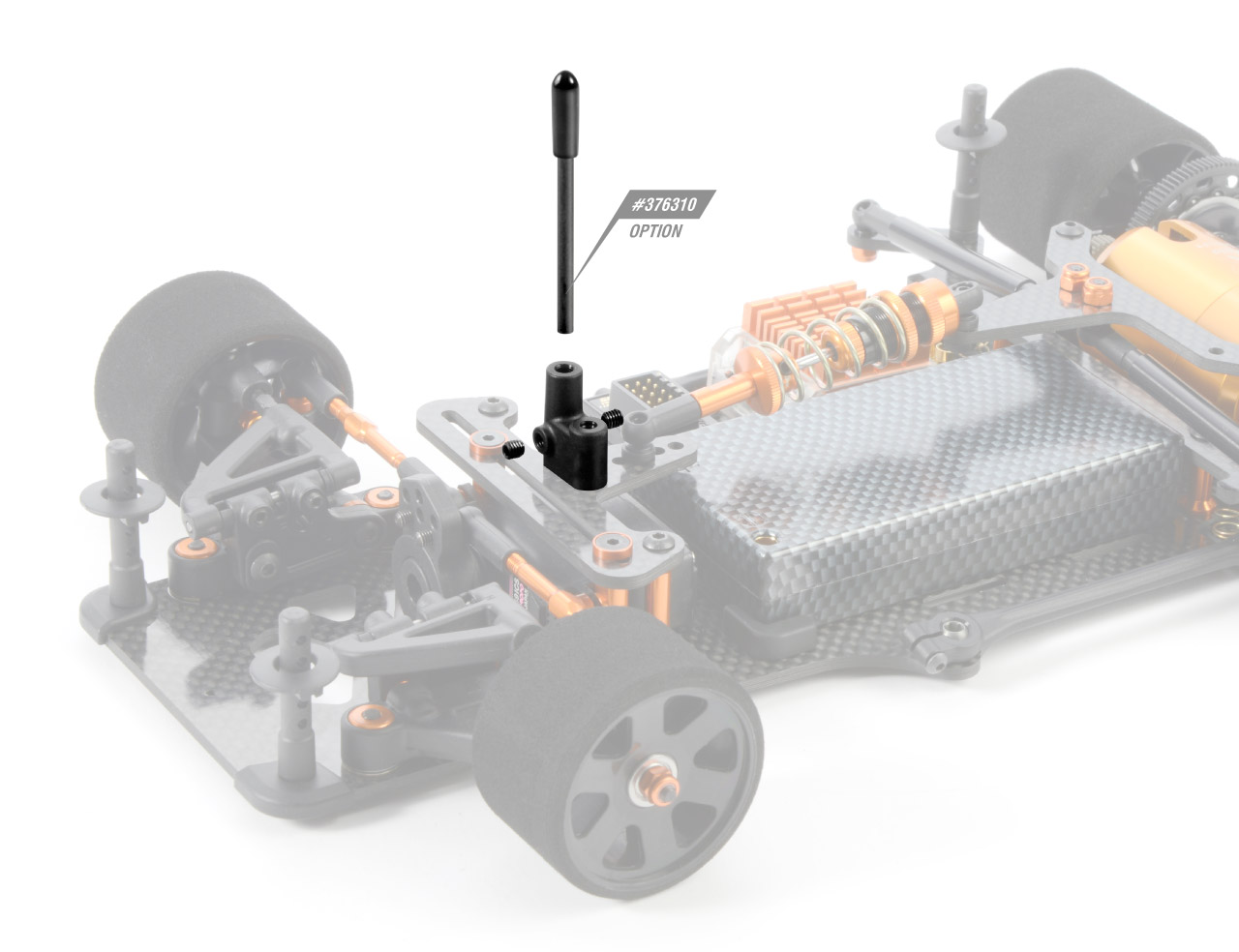

Antenna Mount.

A tiny lightweight antenna mount secures the lightweight yet strong molded fiberglass rollover antenna which is available as an option #376310.

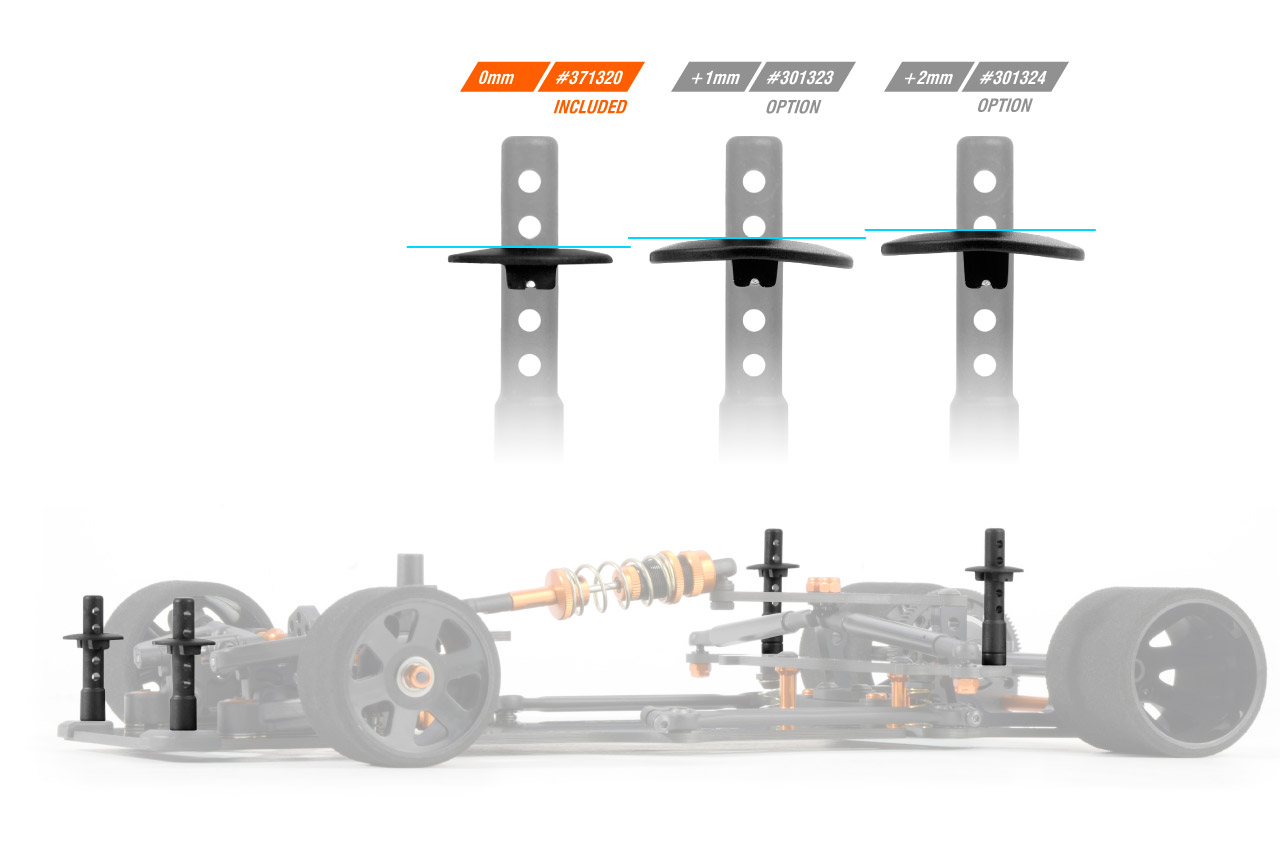

Body Posts.

Robust body posts with fully-adjustable body holders; optional super-fine +1 or +2mm body backstops available optionally for even more super-fine body height adjustment.

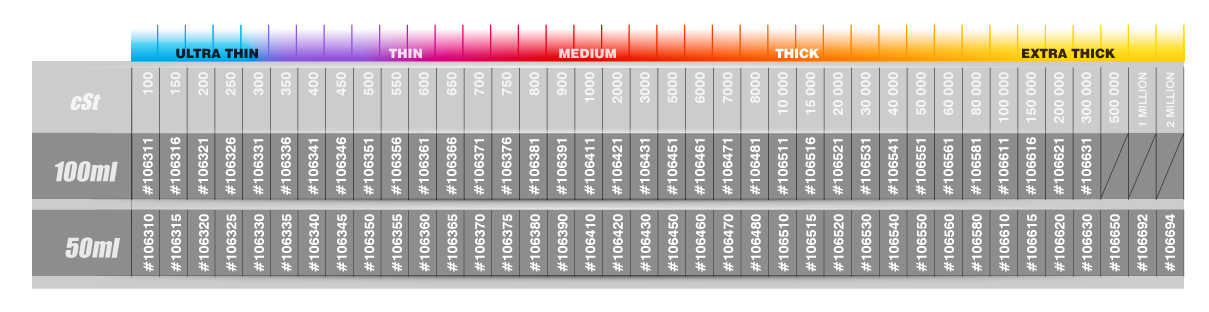

Silicone Oils.

HUDY Exclusive Silicone Oils are manufactured in Europe and each batch is laboratory tested and calibrated to ensure the highest possible consistency and quality from batch to batch. Based on the industry-standard cSt rating, the new line of oils will be easy to identify, adjust, and feel.

When following any set-up sheets by XRAY or XRAY team drivers, you can be sure that the oils you will get for your car are exactly same as those used by the factory racing team, thus ensuring very exacting set-ups and handling.

Ball-Bearings.

A full set of 10 high-speed, blue-sealed and steel ball-bearings are used throughout the drivetrain to ensure maximum efficiency. All of the bearings are degreased and oiled with Aero Shell® Fluid 12 for maximum smoothness and long life.

Premium & Exclusive Materials.

The X12 is luxury model racing car and as such features only the finest, most premium materials: premium woven graphite - exclusive top-secret HUDY Spring Steel™ - high grade Swiss 7075 T6 - high-tensile heat-treated steel and aircraft aluminum - and XRAY's self-developed and formulated composite compounds. All is premium and unique on the X12.

Fully Adjustable.

Fully adjustable front camber, camber rise, caster, reactive caster, toe, and Ackermann; front & rear track-width; bump steer; front & rear ride height; front & rear springs; rear shock damping & spring; pod damping; pod weight balance; battery position; servo position and chassis tweak.

Chassis Weight Balance Adjustment.

The chassis design focuses on balanced weight distribution and weight transfer. Centerline holes are pre-drilled for easy balancing with the HUDY Chassis Balancing Tool #107880.

XRAY Instruction Manual.

XRAY Instruction Manuals have become the industry standard, and are simply the best manuals you will ever get with an RC model car. Whether you are a first-time builder or an experienced racer, all the instructions are straight-forward and easy to understand. The full-color instruction manual contains large 3D illustrations for easy comprehension.

XRAY VIP Customer Treatment.

Owning an XRAY model racing car is an experience on its own. Not only will you own the most premium luxury model racing car, but you will also become a member of the prestigious family of XRAY owners with superb support and service from the XRAY factory. The XRAY Web portal features up-to-date racing news and latest product developments. If you have any questions, problems or comments, you can ask the XRAY Support Team or any XRAY Factory Team Driver on the XRAY support forum. You can even upload your own set-up sheets or download from the largest RC set-up database at the exclusive XRAY Virtual Set-up Sheet Database. And that is only the start of the VIP treatment you get by joining Team XRAY.