2025 All-new Features - Part 1

- All-new one-piece chassis design with more consistent handling in all conditions and improved tweak resistance

- Narrower chassis shape reduces chassis drag during cornering

- Rear POD concept on top of chassis for less drag and improved tweak resistance

- Adjustable POD angle controlled by set screw at the rear of chassis for fine tuning

- Rear spring location improves forward traction with increased adjustability and lower CG

- Rear droop adjustment through rear POD spring tension that sits in a special composite adjuster

- Universal rear spring nut holder works for both conical and linear springs

- 2-piece lower pod plate mounts to the bulkheads, offering droop and pod angle adjustments with support for the side springs

- Ultra-light, lower CG bulkheads are foundation of new POD system

- Left side bulkhead has mounting holes incorporated to mount optional motor cooling fan

- Forward center pivot position for maximum adjustability

- Lowered pivot holder and small diameter pivot ball offer lower roll center positions and greater adjustment range

- Carbon Fiber top plate for center shock and side damper mountings

- New rear carbon side spring brace aligns with new POD geometry

2025 All-new Features - Part 2

- Composite Snap Lock™ bushings press into carbon fiber parts for secure and reliable hardware installation

- All-new spring-free center shock absorber with 1-hole piston provides exceptional bump handling, low maintenance, and helps lower CG.

- New front lower suspension arm is 1mm narrower per side for more initial steering and increased track width adjustability

- Aluminum lower arm pivot balls included in the kit reduce weight by 63%

- Hollow front kingpins improve lubrication of the front suspension

- Aluminum steering blocks with special factory pre-pressed Teflon insert for minimal friction and smoother movement

- New Ackermann positions improve steering characteristics with optional eccentric axle with 1mm less trail for greater adjustability

- 1.6mm side braces with a narrower design save weight and leave more space for electronics

- Narrower side brace mounting holders use M2.5 screws for weight savings

- Aluminum side link holders with 2-pin design for more rigidity and improved tweak resistance

- 2-pin carbon fiber side link plates integrate with aluminum holders for reliable alignment and offer 3 side link front pivot mounting positions for maximum adjustability

- Extra forward battery position and backstop provides more consistent handling with improved cornering speed

- Narrower rear wheel hubs for additional track width adjustability and improved clamping of rear axle

- Shorter solid axle shaft to work with new narrower rear wheel hubs

- Carbon fiber front bumper aligns with new chassis shape

10x European Champion.

“Having been with XRAY since I started racing, I know first-hand the total commitment of the entire XRAY team - R&D, racing team, support team, everyone - when it comes to their ongoing dedication to continually improve their products and bring the absolute best performance, service, and support to the world.

This year XRAY stands at the top in the 1/12 class again, with the well-deserved achievement of being back-to-back 10x European Champions in the modified class.

I thank XRAY for their belief in me, and the support they have given me. I am very proud to bring home these victories for our team.”

Alexander Hagberg

European Champion 2014, 2015, 2016, 2017, 2018, 2019, 2020 & 2023

USA Champion.

Since its debut, winning the ROAR National Championship title, the US team continues on-going development of the US Edition to ensure that the X12 will remain a top competitor on tight, technical, high grip tracks typically found in North America, highlighted by winning the modified class at the 2020 ROAR Carpet Nationals. All of the latest improvements tested by the team are incorporated into the all-new X12 US Edition.

Chassis.

The new one-piece chassis design provides more consistent handling in all track conditions.

The chassis concept integrates with the front Tweak-Free Suspension and the rear Tweak-Free POD System to maximize performance.

The chassis plate’s edges are beveled for less drag on the track surface during cornering to improve handling and efficiency.

Special cut-outs for optimal flex characteristics.

The standard chassis is CNC machined from 2.0mm Swiss 7075 T6 aluminum.

The new one-piece chassis design provides more consistent handling in all track conditions.

The chassis concept integrates with the front Tweak-Free Suspension and the rear Tweak-Free POD System to maximize performance.

The chassis plate’s edges are beveled for less drag on the track surface during cornering to improve handling and efficiency.

Special cut-outs for optimal flex characteristics.

The standard chassis is CNC machined from 2.0mm Swiss 7075 T6 aluminum.

Rear POD.

The 2-piece rear pod concept is positioned above the one-piece chassis plate. As part of the new pod assembly, the pod plate controls the droop setting along with a pod angle adjustment and supports the side springs. The new rear spring location improves forward traction and lowers CG while offering better adjustability.

The new configuration controls the pod droop adjustment using the rear bump spring. The new composite spring adjustment nut is compatible with both linear and conical springs for maximum versatility and adjustment choices.

The pod angle adjustment is a new setting for fine tuning handling; controlled by a set screw at the rear of chassis.

The POD assembly includes aluminum bulkheads and carbon fiber upper and lower pod plates. The pod mounting system improves traction and stability, while also reducing tweak issues after crashes.

The rear carbon fiber upper pod plate uses new super lightweight composite bushings instead of locknuts to save weight, lower CG and improve the clean look of the car. The upper plate mounts to the bulkheads with 4 centering pins and 2 screws to keep the assembly in proper alignment and minimizing the chances of tweak after an impact on the track.

The 2-piece rear pod concept is positioned above the one-piece chassis plate. As part of the new pod assembly, the pod plate controls the droop setting along with a pod angle adjustment and supports the side springs. The new rear spring location improves forward traction and lowers CG while offering better adjustability.

The new configuration controls the pod droop adjustment using the rear bump spring. The new composite spring adjustment nut is compatible with both linear and conical springs for maximum versatility and adjustment choices.

The pod angle adjustment is a new setting for fine tuning handling; controlled by a set screw at the rear of chassis.

The POD assembly includes aluminum bulkheads and carbon fiber upper and lower pod plates. The pod mounting system improves traction and stability, while also reducing tweak issues after crashes.

The rear carbon fiber upper pod plate uses new super lightweight composite bushings instead of locknuts to save weight, lower CG and improve the clean look of the car. The upper plate mounts to the bulkheads with 4 centering pins and 2 screws to keep the assembly in proper alignment and minimizing the chances of tweak after an impact on the track.

Bulkheads.

New lightweight aluminum bulkheads help lower CG as part of the new POD assembly, with the left side bulkhead adding a cooling fan mounting provision.

The bulkheads’ design minimizes weight and lowers CG to improve stability. Centering pins help align the carbon fiber plates with the alum bulkheads to reduce tweak issues in serious crashes for maximum reliability.

The bulkheads use compact eccentric bushings with fine adjustment increments for perfect ride height control while maintaining a low center of gravity. The compact ride height eccentrics allow for compact bulkhead dimensions to reduce weight and a lower CG.

The carbon fiber rear brace is thin and light, continuing with the efforts to maintain the lowest possible CG while controlling pod flex. The rear brace mounts to the bulkheads from the top with a single mounting point to improve tweak resistance.

New lightweight aluminum bulkheads help lower CG as part of the new POD assembly, with the left side bulkhead adding a cooling fan mounting provision.

The bulkheads’ design minimizes weight and lowers CG to improve stability. Centering pins help align the carbon fiber plates with the alum bulkheads to reduce tweak issues in serious crashes for maximum reliability.

The bulkheads use compact eccentric bushings with fine adjustment increments for perfect ride height control while maintaining a low center of gravity. The compact ride height eccentrics allow for compact bulkhead dimensions to reduce weight and a lower CG.

The carbon fiber rear brace is thin and light, continuing with the efforts to maintain the lowest possible CG while controlling pod flex. The rear brace mounts to the bulkheads from the top with a single mounting point to improve tweak resistance.

Rear Assembly.

The new rear carbon fiber side spring brace utilizes composite bushing inserts pressed into the plate at the hardware attachment points for easier assembly and maintenance.

The rear plate location maintains the super low CG focus, improving stability and handling consistency. It also contributes to chassis rigidity and tweak resistance in crashes. The side tubes are top mounted for quick assembly and maintenance.

The rear brace provides mounting locations for the battery backstop.

The side braces are mounted as low as possible, improving stability and consistency on the track.

The new rear carbon fiber side spring brace utilizes composite bushing inserts pressed into the plate at the hardware attachment points for easier assembly and maintenance.

The rear plate location maintains the super low CG focus, improving stability and handling consistency. It also contributes to chassis rigidity and tweak resistance in crashes. The side tubes are top mounted for quick assembly and maintenance.

The rear brace provides mounting locations for the battery backstop.

The side braces are mounted as low as possible, improving stability and consistency on the track.

Center Shock.

All-new center shock provides exceptional bump handling, low maintenance, and helps lower CG. The spring-free design significantly reduces weights and the 1-hole piston configuration ensures consistent handling over bumps.

The center shock features a hard anodized aluminum shock body for great durability.

A silicone shock O-ring seals the dampener for super smooth operation while preventing oil leakage.

The ultra-finely finished shock shaft with the precision-molded composite shock piston creates optimum oil flow and smooth shock absorber action.

All-new center shock provides exceptional bump handling, low maintenance, and helps lower CG. The spring-free design significantly reduces weights and the 1-hole piston configuration ensures consistent handling over bumps.

The center shock features a hard anodized aluminum shock body for great durability.

A silicone shock O-ring seals the dampener for super smooth operation while preventing oil leakage.

The ultra-finely finished shock shaft with the precision-molded composite shock piston creates optimum oil flow and smooth shock absorber action.

Dampening.

All-new rear POD spring replaces the center shock spring. The POD spring improves forward traction, expands adjustment possibilities, and lowers CG.

The spring holder accommodates both conical/progressive and straight/linear springs.

To ensure best handling for most conditions when using the standard solid axle, the included soft rear conical/progressive spring provides a balanced starting set-up out of the box.

All-new rear POD spring replaces the center shock spring. The POD spring improves forward traction, expands adjustment possibilities, and lowers CG.

The spring holder accommodates both conical/progressive and straight/linear springs.

To ensure best handling for most conditions when using the standard solid axle, the included soft rear conical/progressive spring provides a balanced starting set-up out of the box.

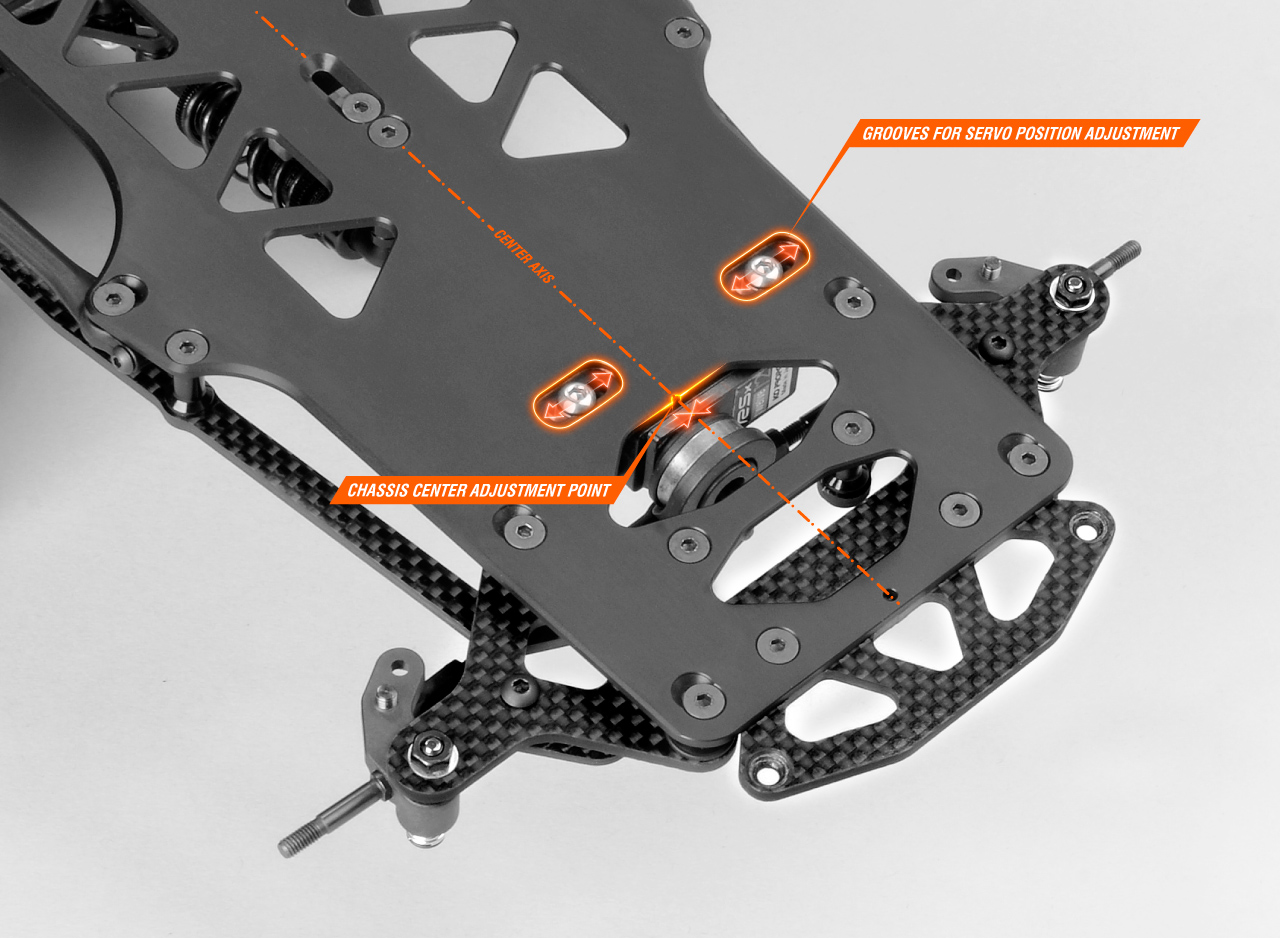

POD Mounting System.

All-new lowered center pivot holder controls POD movement and roll center adjustment. A smaller diameter pivot ball allows for a lower roll center location if desired, with the new forward center pivot position providing maximum adjustability.

The aluminum Tweak-Free Pod Mounting System improves traction and stability and reduces tweak issues after crashes. The system allows for a significantly lowered roll center, lowered center of gravity, and pivot height adjustment using various shims.

Forward – The most forgiving handling; car can be driven more aggressively without fear of losing rear traction.

Middle – Balance between front and rear traction and well suited for most conditions.

Rearward – Improved rotation from the shorter rear pod geometry. Provides more initial steering as well as rotation which is best suited for high traction carpet.

All-new lowered center pivot holder controls POD movement and roll center adjustment. A smaller diameter pivot ball allows for a lower roll center location if desired, with the new forward center pivot position providing maximum adjustability.

The aluminum Tweak-Free Pod Mounting System improves traction and stability and reduces tweak issues after crashes. The system allows for a significantly lowered roll center, lowered center of gravity, and pivot height adjustment using various shims.

Forward – The most forgiving handling; car can be driven more aggressively without fear of losing rear traction.

Middle – Balance between front and rear traction and well suited for most conditions.

Rearward – Improved rotation from the shorter rear pod geometry. Provides more initial steering as well as rotation which is best suited for high traction carpet.

Lower Suspension Arm.

The carbon fiber front lower suspension arm plate is re-designed to match the new chassis plate and improves the front suspension geometry. The arm plate is 1mm narrower per side for improved initial steering and better track width adjustability.

Aluminum lower arm pivot balls are included in the kit for overall weight savings, while importantly removing weight from the nose to shift the weight bias to a more centralized position.

The carbon fiber front lower suspension arm plate is re-designed to match the new chassis plate and improves the front suspension geometry.

The arm plate is 1mm narrower per side for improved initial steering and increased track width adjustability.

Aluminum lower arm pivot balls are included in the kit for overall weight savings, while importantly removing weight from the nose to shift the weight bias to a more centralized position.

Kingpins.

All-new hollow front kingpins improve lubrication of the front suspension while the nickel coating contributes to even smoother and damped suspension movement.

4mm kingpins provide the foundation for the Tweak-Free Front Suspension. The kingpin’s strong design with machined camber angle provides precise geometry and handling.

To match typical track conditions, the kit is delivered with standard 1.0° degree kingpins.

A complete range of 0.5°, 1.0°, 1.5° camber kingpins are available to adjust the camber in fixed steps.

All-new hollow front kingpins improve lubrication of the front suspension while the nickel coating contributes to even smoother and damped suspension movement.

4mm kingpins provide the foundation for the Tweak-Free Front Suspension. The kingpin’s strong design with machined camber angle provides precise geometry and handling.

To match typical track conditions, the kit is delivered with standard 1.0° degree kingpins.

A complete range of 0.5°, 1.0°, 1.5° camber kingpins are available to adjust the camber in fixed steps.

Steering Blocks.

All-new aluminum steering blocks have special factory pre-pressed Teflon inserts for minimal friction and smoother dampening. All-new Ackermann positions improve steering characteristics.

The steering blocks are machined from lightweight Swiss 7075 T6 aluminum material.

Side Braces.

All-new thinner side braces purposely designed to accommodate the new chassis profile for enhanced chassis stiffness. The narrow width saves weight and creates more space for electronics.

Braces use new thinner M2.5 posts and screws for additional weight savings and remove weight from outer perimeter locations for improved rotation.

The thinner side braces increase overall traction, making the car more forgiving on the track. Optional 1mm thick braces are available for improved performance in lower traction conditions.

Multi-flex positions for the side braces allow for extra fine tuning of the chassis flex to improve steering response and cornering speed.

The side brace mounts feature an ultra-low CG design to improve the stability of the car.

Carbon fiber side braces are mounted to the rear link brace and to the chassis via composite posts, offering multi flex adjustments - which is four in total – different flex setting alternatives to alter the chassis stiffness for different track conditions.

All-new thinner side braces purposely designed to accommodate the new chassis profile for enhanced chassis stiffness. The narrow width saves weight and creates more space for electronics.

Braces use new thinner M2.5 posts and screws for additional weight savings and remove weight from outer perimeter locations for improved rotation.

The thinner side braces increase overall traction, making the car more forgiving on the track. Optional 1mm thick braces are available for improved performance in lower traction conditions.

Multi-flex positions for the side braces allow for extra fine tuning of the chassis flex to improve steering response and cornering speed.

The side brace mounts feature an ultra-low CG design to improve the stability of the car.

Carbon fiber side braces are mounted to the rear link brace and to the chassis via composite posts, offering multi flex adjustments - which is four in total – different flex setting alternatives to alter the chassis stiffness for different track conditions.

Side Link Mounting System.

The narrower and lighter side link stand and M2.5 screws reduce the weight. The side link stand features a 2-pin design for more rigidity and increased tweak resistance. The POD linkage angle adjustment provides additional fine set-up tuning.

The carbon fiber side link plates integrate with the aluminum holders‘ 2 locating pins for accurate, reliable alignment. The side link plates feature 3 positions for the side links‘ front pivot for maximum adjustability.

Changing the side link’s front pivot position will quickly alter the handling and feel of the car. The inner mounting position provides the most aggressive handling, with the most mid corner steering. The outer hole will give the most neutral handling. The middle hole, which is in between the two in terms of balance, is the best starting point for most conditions.

The narrower and lighter side link stand and M2.5 screws reduce the weight. The side link stand features a 2-pin design for more rigidity and increased tweak resistance. The POD linkage angle adjustment provides additional fine set-up tuning.

The carbon fiber side link plates integrate with the aluminum holders‘ 2 locating pins for accurate, reliable alignment. The side link plates feature 3 positions for the side links‘ front pivot for maximum adjustability.

Changing the side link’s front pivot position will quickly alter the handling and feel of the car. The inner mounting position provides the most aggressive handling, with the most mid corner steering. The outer hole will give the most neutral handling. The middle hole, which is in between the two in terms of balance, is the best starting point for most conditions.

Snap Lock™ Bushings.

All-new super smart XRAY Snap Lock™ Bushings replace locknuts and aluminum bushings. The 14 super small bushings reduce weight and stay securely held in place after installation for easy chassis assembly and maintenance.

Battery Holder.

All-new forward battery position and backstop provide for more consistent handling and improved cornering speed.

The chassis plate is narrowed in the battery area to make it easier to quickly remove the battery from the car.

The battery mounting system provides simple and reliable battery installation. The front battery stop is mounted to the chassis and can be moved in 2mm steps forward or backwards. The system eliminates the chance of the battery shifting forward in a crash, and it is centered by the shock post to prevent the battery stop from shifting sideways.

The adjustable battery holder system secures the battery in the car in a tweak-free, non-fixed manner to improve traction with more consistency, ultimately making the X12 easier to drive.

The battery holder allows for a wide range of battery placement adjustments with 5 battery mounting positions.

To match the size variations of different battery packs, use a thinner backstop shim to remove extra play, and use a thicker shim if more clearance is needed.

Frontward-placed battery:

- makes the car easier to drive

- reduces wheel lift in corners

- makes the car more predictable over bumps

Rearward-placed battery:

- makes the car more aggressive

- increases cornering speed

- makes the car more difficult to drive

All-new forward battery position and backstop provide for more consistent handling and improved cornering speed.

The chassis plate is narrowed in the battery area to make it easier to quickly remove the battery from the car.

The battery mounting system provides simple and reliable battery installation. The front battery stop is mounted to the chassis and can be moved in 2mm steps forward or backwards. The system eliminates the chance of the battery shifting forward in a crash, and it is centered by the shock post to prevent the battery stop from shifting sideways.

The adjustable battery holder system secures the battery in the car in a tweak-free, non-fixed manner to improve traction with more consistency, ultimately making the X12 easier to drive.

The battery holder allows for a wide range of battery placement adjustments with 5 battery mounting positions.

To match the size variations of different battery packs, use a thinner backstop shim to remove extra play, and use a thicker shim if more clearance is needed.

Frontward-placed battery:

- makes the car easier to drive

- reduces wheel lift in corners

- makes the car more predictable over bumps

Rearward-placed battery:

- makes the car more aggressive

- increases cornering speed

- makes the car more difficult to drive

Bumper Holder.

New carbon fiber front bumper holder aligns with the new chassis shape and provides maximum protection in crashes and perfect body shell support. The IFMAR & EFRA legal size ensures maximum aero efficiency and has a perfect fit with the 3D printed bumper.

The long front bumper support provides sufficient reinforcement for the body shell and maximum aerodynamic efficiency.

The front bumper design and size is designed to meet the latest racing organization rules.

Machined from premium 2.5mm carbon fiber, the brace is flexible yet rigid enough to withstand serious crashes.

New carbon fiber front bumper holder aligns with the new chassis shape and provides maximum protection in crashes and perfect body shell support. The IFMAR & EFRA legal size ensures maximum aero efficiency and has a perfect fit with the 3D printed bumper.

The long front bumper support provides sufficient reinforcement for the body shell and maximum aerodynamic efficiency.

The front bumper design and size is designed to meet the latest racing organization rules.

Machined from premium 2.5mm carbon fiber, the brace is flexible yet rigid enough to withstand serious crashes.

Rear Hubs.

All-new narrower and lightweight rear wheel hubs have significantly reduced rotating weight, provide more secure installation on the rear axle and improve track width adjustability.

Lightweight wheel hubs with M2x5 screws minimize rotating mass and vibrations.

The aluminum rear hubs are machined from lightweight aircraft aluminum and black-coated for a stylish look. The aluminum wheel hubs feature a center-balanced clamping mount system, ensuring secure mounting while eliminating vibration and run out.

All-new narrower and lightweight rear wheel hubs have significantly reduced rotating weight, provide more secure installation on the rear axle and improve track width adjustability.

Lightweight wheel hubs with M2x5 screws minimize rotating mass and vibrations.

The aluminum rear hubs are machined from lightweight aircraft aluminum and black-coated for a stylish look. The aluminum wheel hubs feature a center-balanced clamping mount system, ensuring secure mounting while eliminating vibration and run out.

Rear Axle.

The ultra-lightweight steel solid axle is shorter to accommodate narrower wheel hubs. The solid axle ensures exceptional drivability and throttle response. The hollow solid axle is extremely light and durable, with a steel material that minimizes flex and makes the car more predictable to drive.

The hollow steel construction is extremely light and more durable than a carbon fiber axle. The steel material minimizes flex, making the car more predictable to drive, especially in the Modified class.

Race proven ball differential is still available as a tuning option if needed for low traction situations.

The rear differential features high-grade precision carbide balls in the spur gear, hardened and precision-ground D-steel shims, and premium carbide axial thrust-bearing.

The ultra-lightweight steel solid axle is shorter to accommodate narrower wheel hubs. The solid axle ensures exceptional drivability and throttle response. The hollow solid axle is extremely light and durable, with a steel material that minimizes flex and makes the car more predictable to drive.

The hollow steel construction is extremely light and more durable than a carbon fiber axle. The steel material minimizes flex, making the car more predictable to drive, especially in the Modified class.

Race proven ball differential is still available as a tuning option if needed for low traction situations.

The rear differential features high-grade precision carbide balls in the spur gear, hardened and precision-ground D-steel shims, and premium carbide axial thrust-bearing.

Standard Features.

Some information shown below may include details from previous kits, and it may vary slightly from current kit specifications.

Some information shown below may include details from previous kits, and it may vary slightly from current kit specifications.

3D Printed Bumper.

3D printed bumper – gives better support to the front of the body shell, improving aerodynamic efficiency. The 3D printed material doesn't fold or break, and by allowing more airflow under the body it also helps improve front grip.

3D printed with high quality materials for very light yet very strong properties.

3D printed bumper – gives better support to the front of the body shell, improving aerodynamic efficiency. The 3D printed material doesn't fold or break, and by allowing more airflow under the body it also helps improve front grip.

3D printed bumper – gives better support to the front of the body shell, improving aerodynamic efficiency. The 3D printed material doesn't fold or break, and by allowing more airflow under the body it also helps improve front grip.

3D printed with high quality materials for very light yet very strong properties.

Side Spring Retainers.

The side spring retainers, made from a steel material, feature a precise and consistent side dampening action.

New side spring retainers, made from steel instead of composite, produce more precise and more consistent side dampening action.

The improved side spring fitment made possible by using the steel material is responsible for the improved suspension characteristics, while the metal components also improve durability and aesthetics.

Side Brace Flex Settings.

Soft – no side braces – This option will make the car generate more mechanical grip. Best suited for low to medium grip carpet, as well as asphalt.

Medium – side braces are mounted to the rear graphite brace and to the middle of the chassis – A good compromise between mechanical grip and steering response. A good starting setup for most conditions.

Medium stiff - the side braces are mounted to the rear graphite brace, to the middle of the chassis, and to the middle-front of the chassis – A good compromise between mechanical grip, and steering response. A good adjustment as grip levels approaches high traction.

Stiff – the side braces are mounted to the rear graphite brace, to the middle of the chassis and to the middle-front and front points of the chassis. – The stiffest, and most stable option. Best suited for high grip carpet. This setting allows less roll and will reduce overall grip.

Soft – no side braces – This option will make the car generate more mechanical grip. Best suited for low to medium grip carpet, as well as asphalt.

Medium – side braces are mounted to the rear graphite brace and to the middle of the chassis – A good compromise between mechanical grip and steering response. A good starting setup for most conditions.

Medium stiff - the side braces are mounted to the rear graphite brace, to the middle of the chassis, and to the middle-front of the chassis – A good compromise between mechanical grip, and steering response. A good adjustment as grip levels approaches high traction.

Stiff – the side braces are mounted to the rear graphite brace, to the middle of the chassis and to the middle-front and front points of the chassis. – The stiffest, and most stable option. Best suited for high grip carpet. This setting allows less roll and will reduce overall grip.

Front Suspension Flex Settings.

The Tweak-Free front suspension features a front brace system for a fast steering response and high cornering speed. The design incorporates a flex adjustment system with three different settings for various track conditions.

Soft – the brace is not mounted to the front arm plate – This option makes the car initially less responsive but will provide more mechanical grip. Best suited for low grip carpet conditions and asphalt.

Medium – the brace is mounted to the front arm plate by small posts that raise the brace and make the front suspension stiffer – Gives a good balance between initial response and mechanical grip. Best option for most conditions.

Stiff - the brace is mounted to the front arm plate by small posts that raise the brace and make the front suspension stiffer, and another identical brace is mounted underneath the small posts for added rigidity. Improves steering response compared to the two softer options, without giving away front grip.

The Tweak-Free front suspension features a front brace system for a fast steering response and high cornering speed. The design incorporates a flex adjustment system with three different settings for various track conditions.

Soft – the brace is not mounted to the front arm plate – This option makes the car initially less responsive but will provide more mechanical grip. Best suited for low grip carpet conditions and asphalt.

Medium – the brace is mounted to the front arm plate by small posts that raise the brace and make the front suspension stiffer – Gives a good balance between initial response and mechanical grip. Best option for most conditions.

Stiff - the brace is mounted to the front arm plate by small posts that raise the brace and make the front suspension stiffer, and another identical brace is mounted underneath the small posts for added rigidity. Improves steering response compared to the two softer options, without giving away front grip.

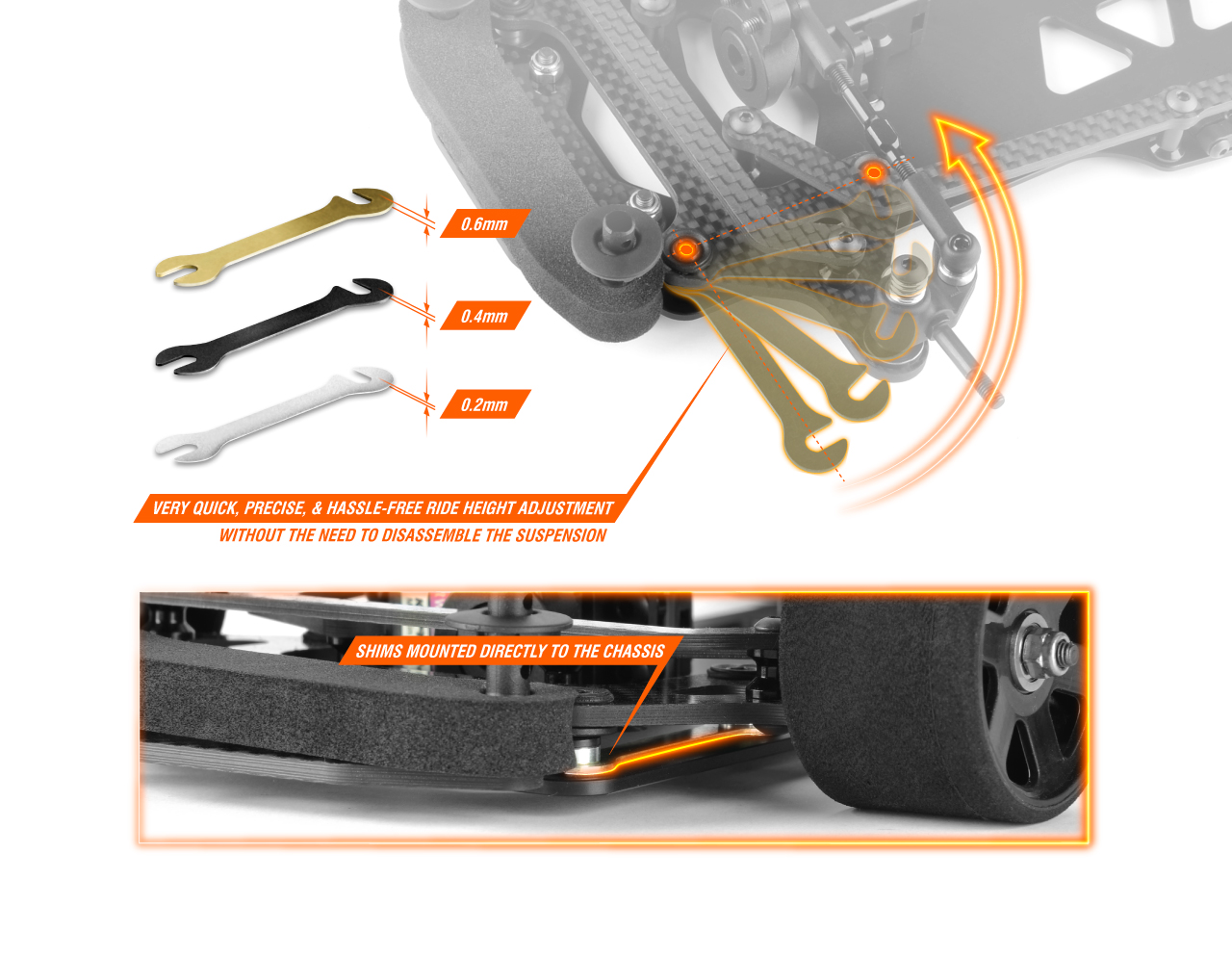

Rear Ride Height.

The alu bulkheads allow for very quick & easy ride height adjustment using eccentric axle holder bushings. The axle height is adjustable in 0.25mm increments over a 2.5mm range for ride height fine tuning.

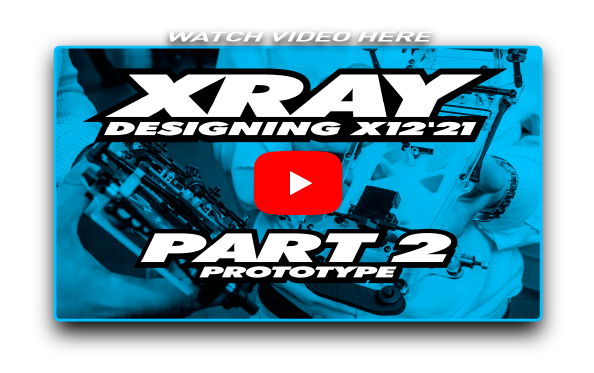

Servo Holders.

The ultra-low CG servo mounting system places the servo directly on the chassis to improve the steering response, and with adjustable grooves in the chassis to place both small and micro size servos into the absolute center of the chassis

The servo holders feature an additional hole to fit micro servos such as Sanwa SRG-HR, HS and PGS-HR, while the standard positions still accommodate the standard 1/12 servo dimensions.

Servo Position.

Unique & innovative fully-adjustable servo mount allows easy adjustment of the servo position. The servo is attached to independent mounts that are mounted using a groove in the chassis. Depending on the size of your servo, you can easily install and adjust the servo and its position to the center of the chassis.

Front Wheelbase.

The X12 chassis features XRAY self-developed front wheelbase adjustment possibility. The chassis has two positions for front suspension mounting; the whole front suspension can be easily moved by 2mm frontwards or rearwards.

The long wheelbase is the same wheelbase as previous X12 cars, and is recommended for larger tracks or tracks with longer sweepers. A long wheelbase works well at low-to-medium traction tracks when more stability is desired. Also better suited to the Open Modified classes to make the car smoother and less twitchy.

The short wheelbase allows the car to rotate better in the middle of the corner to maintain cornering speed. Recommended for tight, technical tracks or tracks with numerous hairpin corners. The short wheelbase works well at medium-to-high traction tracks where a lot of steering is needed. Also better suited to the Stock and blinky classes.

Front Ride Height.

The front suspension uses ride height adjustment shims for very quick, precise, and hassle-free ride height adjustment depending on track conditions. The set of 0.2, 0.4, and 0.6mm ride height adjustment shims are included for fine tuning.

Side Tubes.

Lateral damping side tubes provide ultra-smooth side damping, making the car easier to drive and easier to work on. The outer aluminum tube and inner Delrin® tube operate ultra-smoothly.

Servo Saver.

The XRAY servo saver has become the industry-standard saver and remains unchanged and is included.

Several linkage mounting positions are offered to make the steering linkage adjustment easier. The servo saver consists of 4 springs which makes the servo saver strong enough to provide the precise steering racers demand, while still being flexible enough to prevent servo damage in hard crashes. The servo saver has interchangeable bushings to fit most popular servos.

Spur Gear.

Precision-molded spur gears are made from XRAY's exclusive composite material, ensuring true running, super-quiet operation, and robustness for handling powerful motors. A range of optional spur gears for fine tuning is available.

Differentials.

An ultra-light weight steel solid axle is included in the kit for improved drivability and throttle response.

The hollow steel construction is extremely light and more durable than a graphite axle. The steel material minimizes flex, making the car more predictable to drive, especially in the Modified class.

With the new platform in 2021, the X12 was designed with the use of a solid axle in mind to achieve maximum performance. For 2023, both the EU and US Editions include the new solid axle as this has become the standard for most conditions worldwide.

Our race proven ball differential is still available as a tuning option if needed for low grip situations.

The rear differential features high-grade precision carbide balls in the spur gear, hardened and precision-ground D-steel shims, and premium carbide axial thrust-bearing.

Gear Differential.

The optional XRAY self-designed, revolutionary, super-smooth gear diff is a direct replacement for the ball-differential.

Using the optional gear differential makes the car more stable and easier to drive, especially in high-traction conditions. The gear diff increases on-power steering which is needed on almost all types of tracks. A “must have” for every racer.

The complete gear differential set includes a composite case and cover, precision-molded internal satellite gears made from special XRAY-developed composite material, all ensuring long lifespan and super-smooth efficient operation. A super-strong hollow steel shaft ensures maximum reliability and strength.

The advantage of the gear diff is that it is maintenance-free. When the diff is correctly built, there is no need for maintenance for a very long time, no need for frequent oil changes, and no leakage due to a superior sealing system.

Body Posts.

Robust body posts with fully-adjustable body holders; optional super-fine +1 or +2mm body backstops available optionally for even more super-fine body height adjustment.

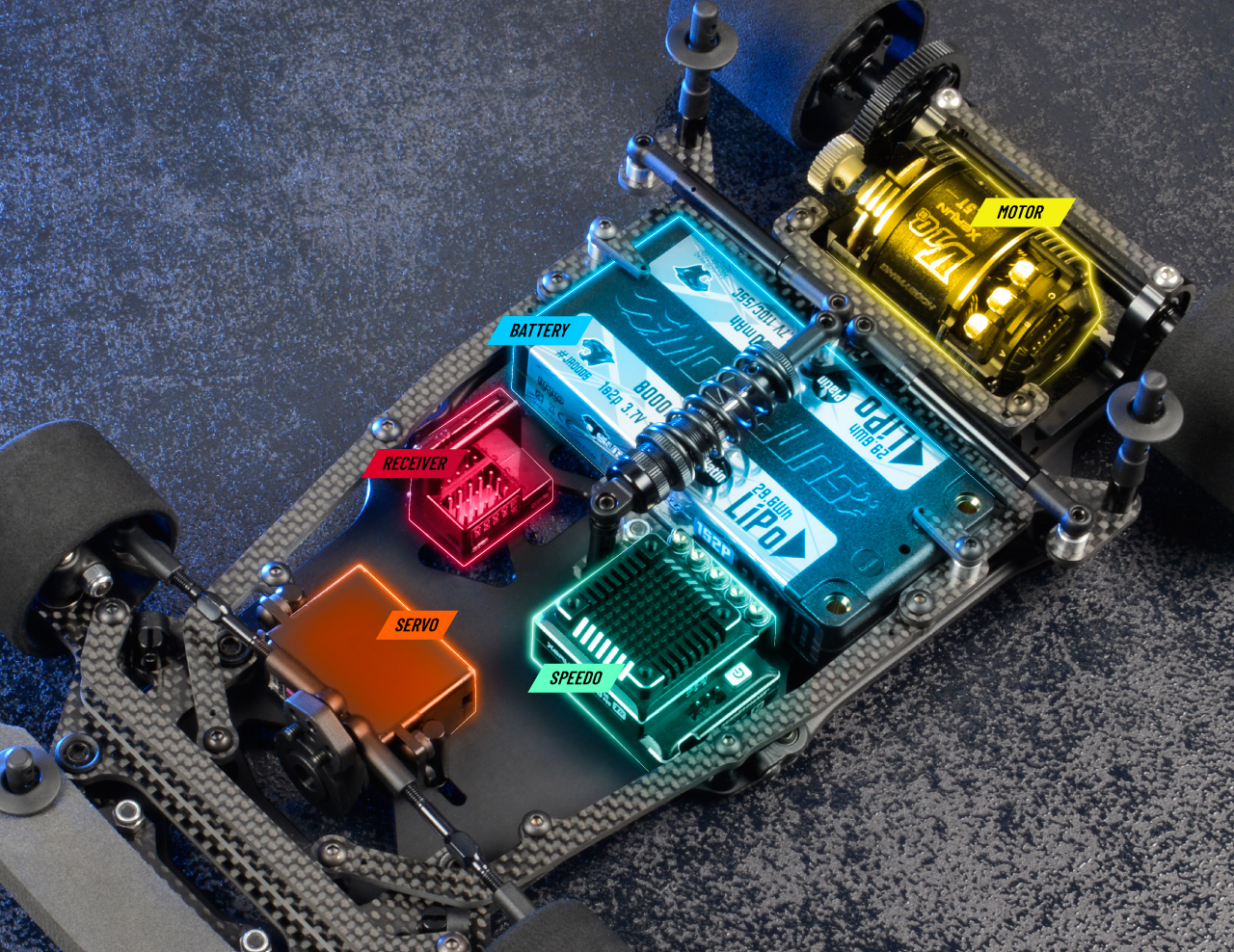

Weight Balance.

The layout of the electronics and position of individual sections of the car were designed with optimum weight distribution and balance in mind.

The steering servo is located in a lay-down position for lowest CG at the chassis center, and the layout of the chassis allows the batteries to be placed either cross or inline.

Depending on battery configuration, the ESC and receiver can be placed in various positions for ideal weight transfer and balance.

Silicone Oils.

HUDY Exclusive Silicone Oils are manufactured in Europe and each batch is laboratory tested and calibrated to ensure the highest possible consistency and quality from batch to batch. Based on the industry-standard cSt rating, the new line of oils will be easy to identify, adjust, and feel.

When following any set-up sheets by XRAY or XRAY team drivers, you can be sure that the oils you will get for your car are exactly same as those used by the factory racing team, thus ensuring very exacting set-ups and handling.

Silicone Oils.

HUDY Exclusive Silicone Oils are manufactured in Europe and each batch is laboratory tested and calibrated to ensure the highest possible consistency and quality from batch to batch. Based on the industry-standard cSt rating, the new line of oils will be easy to identify, adjust, and feel.

When following any set-up sheets by XRAY or XRAY team drivers, you can be sure that the oils you will get for your car are exactly same as those used by the factory racing team, thus ensuring very exacting set-ups and handling.

Pivot Balls.

High-precision, HUDY Spring Steel™ upper pivot balls and composite lower pivot balls ensure smooth & precise movement of the front suspension.

Fully Adjustable.

Fully adjustable front camber, caster, toe, droop, front wheelbase and Ackermann; front offset & rear track-width; bump steer; front & rear ride height; front & rear springs; rear shock damping & spring; pod damping and droop; pod weight balance; battery position; servo position and chassis tweak.

Tech Tip Videos

To get the finest tips & tricks on how to build the X12 or to learn more about each of the set-up options, follow the series of XRAY X12 Tech Tip videos featuring Alexander Hagberg. The videos walk through each section of the building process with suggested assembly techniques, demonstrations, and detailed explanations of the various setup adjustments.

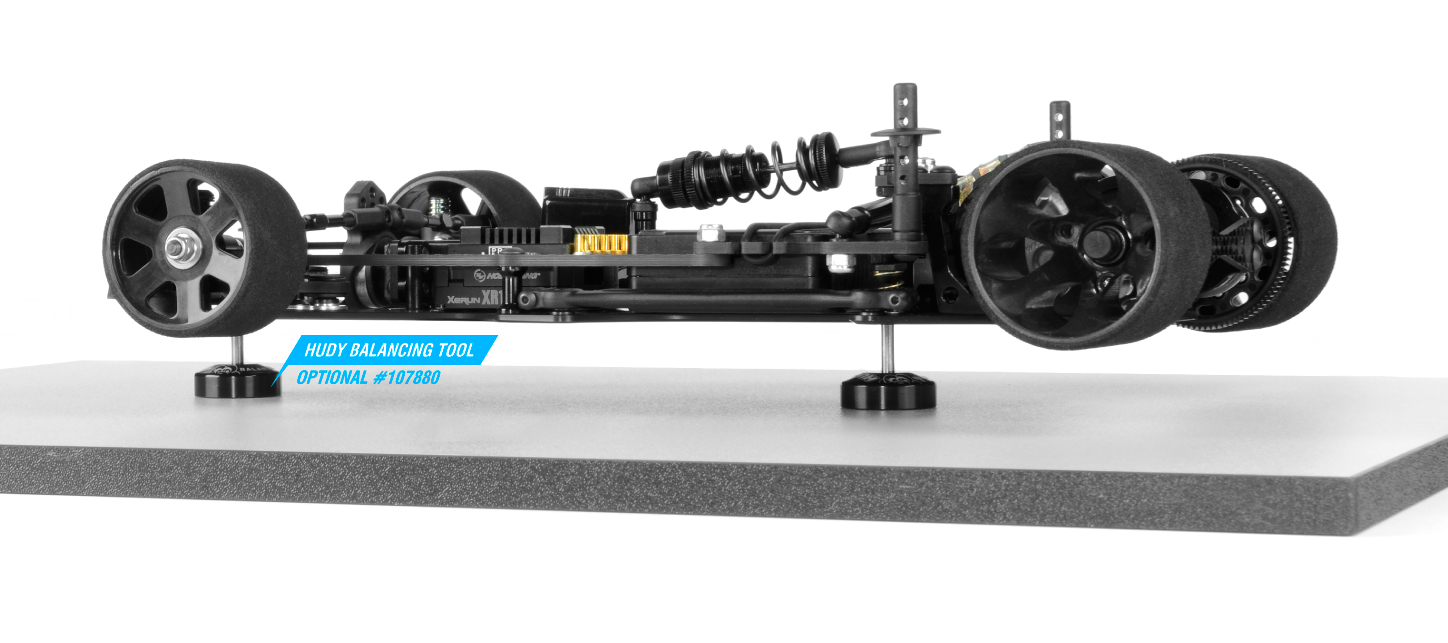

Chassis Weight Balance.

The chassis design focuses on balanced weight distribution and weight transfer. Centerline holes are pre-drilled for easy balancing with the HUDY Chassis Balancing Tool #107880.

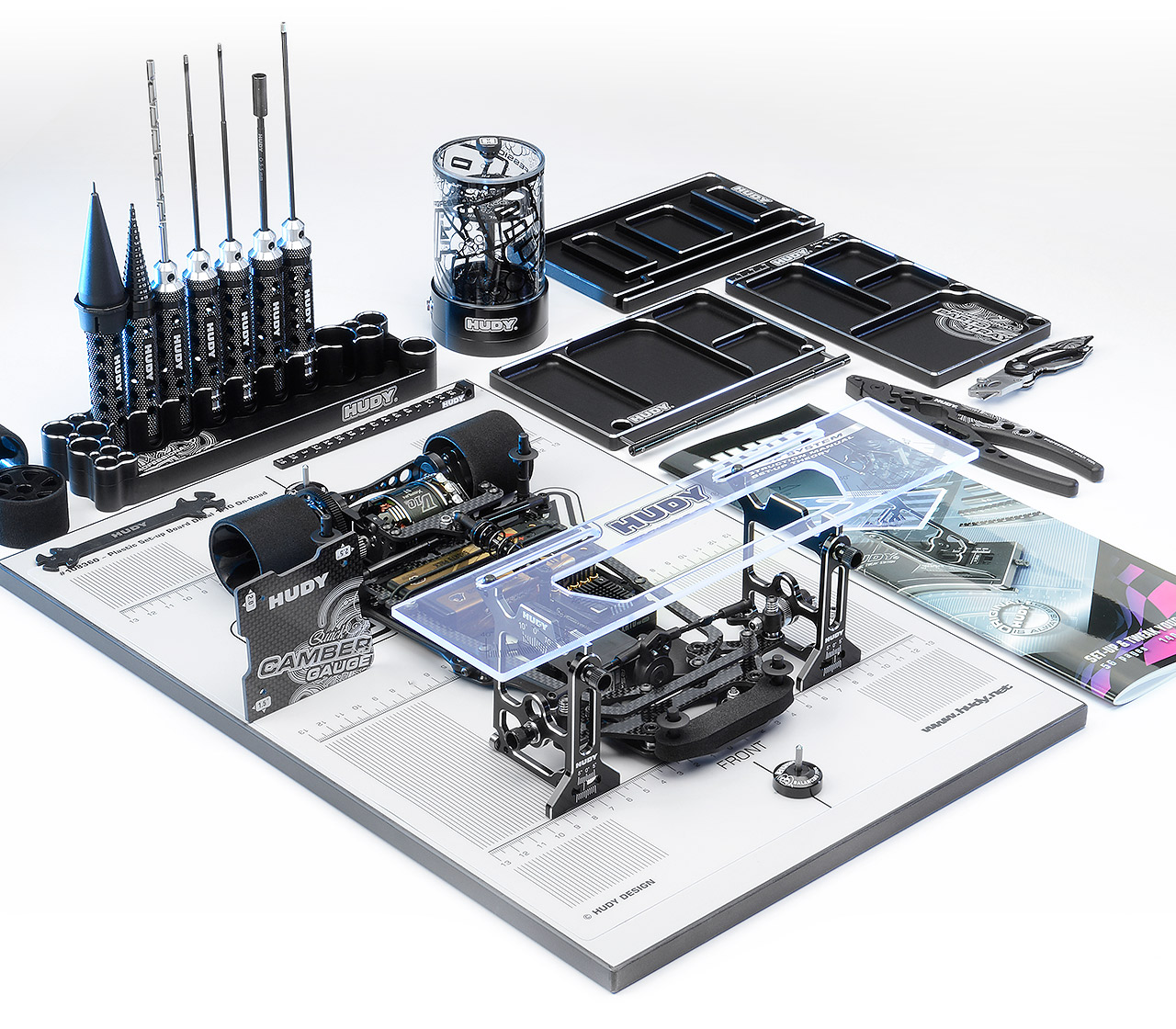

XRAY Instruction Manual.

XRAY Instruction Manuals have become the industry standard; they are simply the best manuals you will ever get with an RC model car. Whether you are a first-time builder or an experienced racer, all instructions are straight-forward and easy to understand. The full-color Instruction Manual contains large 3D illustrations that show all assembly details in the easiest and most comprehensive manner.

XRAY VIP Customer Treatment.

Owning an XRAY model racing car is an experience on its own. Not only will you own the most premium luxury model racing car, but you will also become a member of the prestigious family of XRAY owners with superb support and service from the XRAY factory. The XRAY Web portal features up-to-date racing news and latest product developments. If you have any questions, problems or comments, you can ask the XRAY Support Team or any XRAY Factory Team Driver on the XRAY support forum. You can even upload your own set-up sheets or download from the largest RC set-up database at the exclusive XRAY Virtual Set-up Sheet Database. And that is only the start of the VIP treatment you get by joining Team XRAY.