2019 All-new Features.

- All-new narrower chassis with new rear end geometry improves traction

- All-new lower rear suspension holders shift the rear arms 2.5mm inward for improved geometry

- All-new steel extension plates for the rear suspension arms update the shock mounting geometry to work with the new narrow inner pivot location

- All-new rear shock tower and upper arm holders to work with narrower rear bulkhead positions

- New extended rear steel turnbuckles and upper ball joints to work with new narrow rear end

- New longer rear pivot balls combined with the narrower inner pivot location update the rear suspension geometry for improved traction

- All-new rear solid axle shaft and composite pulley for the new narrow rear end configuration

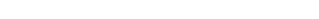

- All-new front and rear bulkheads redesigned to work with new composite anti-roll bar bushings to extend the life of the bulkheads and eliminate unwanted play

- All-new anti-roll bar adapters with less play

- All-new front and rear wire anti-roll bars

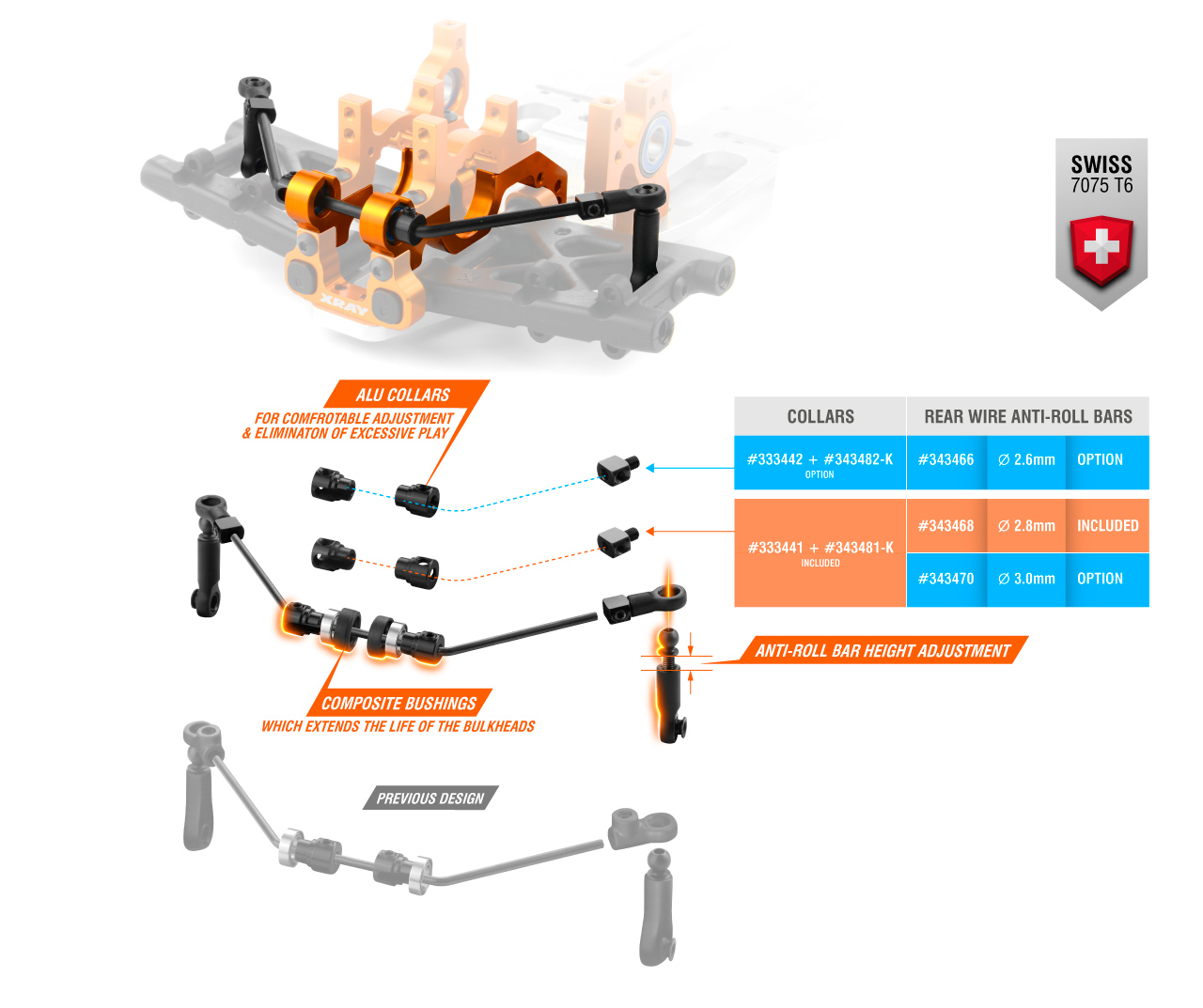

RX8 Platform.

Based on its ultra-successful predecessor, XRAY proudly presents the new RX8E. The new electric kit incorporates the latest improvements and refinements of the RX8 platform developed by the team and race-proven in high-competition races around the world.

Concept.

The RX8E is a typical XRAY: premium, professional, high-competition for the most demanding racers, developed with attention to the smallest details, and backed by premium service & support… a luxury masterpiece.

RX8E Compatibility.

With attention to the smallest details and a mandate to simplify servicing of the car, the all-new RX8E features cross-platform compatibility to ensure you can use the same car platform for both nitro and electric powered version making it either RX8 or RX8E. Most of the parts between RX8 and RX8E are fully compatible.

Chassis.

The new chassis is updated for the narrowed rear suspension configuration. The rear bulkheads are mounted 8.4mm closer together. The rear arm mounts move the inner pivot pins 2.5mm closer together, which combined with the bulkhead placement generates more rear traction and improves the stability of the car.

The chassis also features a unique, innovative front flex adjustment using a removable aluminum brace.

The chassis is narrower to increase chassis flex and generate more traction and steering. The narrower chassis also prevents chassis rub during cornering to help eliminate the feel of the car ‘stopping‘ in mid-corner.

Adjustable weight positions on both sides of the chassis offer quick & easy weight balance adjustment.

Chassis.

The chassis features cut-outs for the bulkheads, arm mounts, radio plate mounts, and front layshaft holder for perfect fitment and to ensure that these parts will always mount into the same precise position.

The outer edges of the chassis have been beveled and screw holes have been countersunk to provide a smooth lower surface with maximum clearance during cornering.

The lightweight chassis is CNC-machined from 5mm premium Swiss 7075 T6 aluminum, strategically machined in low-stress areas to make it as light as possible without affecting strength or rigidity.

Bulkheads.

The aluminum bulkheads provide optimal stiffness & flex for better steering characteristics, even with hard spec tires.

The super-lightweight Swiss 7075 T6 aluminum bulkheads have a very clean and lightweight design to give the lowest weight and CG, and still allow quick access to the driveline components for reduced maintenance downtime.

Rear Bulkheads.

All-new rear bulkheads have been redesigned to fit the new composite bushings for the anti-roll bar bearings that eliminate the wear of the bulkhead. The rear bulkheads are an integral part of the rear suspension Multi-Flex™ system that offers the choice of different flex adjustments.

The rear bulkheads are CNC-machined from premium Swiss 7075 T6 aluminum to provide the lightest & strongest framework for the car.

Front Bulkheads.

All-new front bulkheads have been redesigned to fit the new composite bushings for the anti-roll bar bearings that eliminate the wear of the bulkhead.

The bulkheads are CNC-machined from premium Swiss 7075 T6 aluminum to provide the lightest & strongest framework for the car.

Suspension Mounts.

The all-new rear lower suspension mounts allows the rear lower arms to be moved closer together by 2.5mm for improved traction as well as the stability of the car.

The front & rear suspension holders are fully independent from the bulkheads, mounted directly to the chassis to increase traction and make the car easier to drive.

The suspension mounts are CNC-machined from premium Swiss 7075 T6 aluminum to provide the lightest & strongest framework for the car.

Suspension Extensions.

All-new rear suspension extensions update the shock mounting positions to match the new rear suspension pivot pin and arm locations.

Both front & rear extensions are made from laser-cut steel and additionally black coated for improved durability.

Rear Upper Arm Holders.

All-new graphite upper arm holders feature new positions for the eccentric bushings that position the upper pins 2.5mm narrower to work with the new rear lower arm mount position.

The rear upper arm holders are machined from strong 3.5mm graphite material for optimal flex of the rear suspension. Both front & rear mounts are attached to the rear upper bulkhead clamps.

Shock Towers.

The rear shock tower was redesigned to mount to the new rear narrower bulkheads and to compliment the updated suspension geometry.

Both front & rear shock towers have updated shock mounting positions. The towers are made from thick 3mm graphite material for maximum durability.

Front Wire Anti-roll Bars.

All-new front wire anti-roll bar was redesigned to work with the new adjustable system that allows easier adjustment of the bar as well as remove any excess play from the system.

The RX8E includes both wire & blade-style front anti-roll bars for freedom of choice based on track conditions.

The wire anti-roll bar is used to increase steering response on small, technical tracks. The wire bar is mounted to the bulkheads from the outside to allow quick & easy changes and adjustment. The wire bar turns in ball-bearings for maximum precision and freedom of movement. Anti-roll bar height can be adjusted quickly & easily.

Rear Anti-roll Bars.

All-new rear wire anti-roll bar was redesigned to work with the new adjustable system which allows easier adjustment of the bar and reduces play.

The rear 2.8mm anti-roll bar helps to reduce rear chassis roll. The roll bar turns in ball-bearings for maximum precision and freedom of movement. For fine tuning, optional wires of different thickness are available. Anti-roll bar height is adjustable via a screw… quick & easy.

Axles & Outdrives.

The all-new rear solid axle shaft and lightweight composite pulley were redesigned to fit the new narrow positions of the rear bulkheads. All outdrives are manufactured from HUDY Spring Steel™ and are specially ground for maximum precision. All pulleys have self-cleaning holes to reduce buildup.

The front 1-way and rear solid axle are small and light, ensuring super-low rotating mass and lowest CG. The super-lightweight front 1-way bearing is inserted directly in the axle, and the axle body is machined from Swiss 7075 T6 aluminum.

Pivot Balls.

The all-new rear pivot balls were lengthened to work with the new lower rear arm mounts to still achieve the desired vehicle width.

The RX8E pivot ball suspension contains precision pivot balls that are specially hardened to better withstand harsh crashes and extend their lifespan. A total of eight (8) pivot balls are included and are captured by strong M10 composite nuts to minimize weight and give smooth suspension movement.

Standard pivot balls are made from steel for maximum durability and lifespan. For those who are focused on minimizing unsprung weight, optional lightweight aluminum and titanium pivot balls are available.

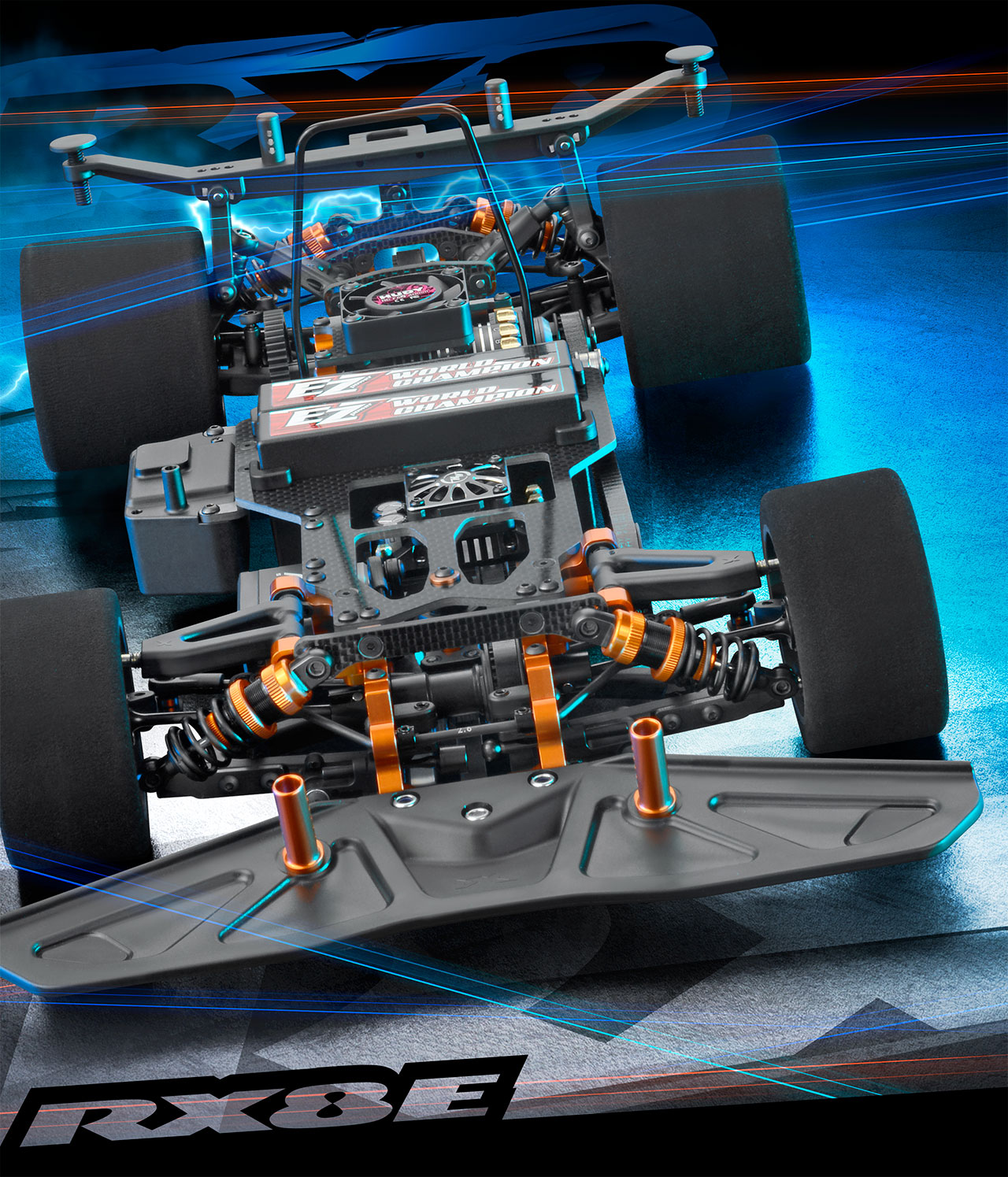

Perfection.

Development at XRAY never stops, nor does our pursuit of perfection. Evolving the RX8 and RX8E to its present state has been a challenge for everyone at XRAY, and this new, re-designed version of the RX8 and RX8E incorporates all the best features and ideas gathered over the past years. Enjoy the new RX8E.

Martin Hudy

XRAY RX8E Platform Designer

High Performance.

The RX8E is based on the RX8 winning platform. With countless a vast number of wins in multiple classes at local, regional, national, and international levels, the XRAY RX8E platform is designed for high-performance competitive racing… ready to win.

Passion & Heritage.

The road to realizing a dream is often filled with challenges, twists & turns, revelations & victories. Such was the literal truth in the pursuit of the ultimate racing machine, fuelled by passion and vision… a dream realized as the new RX8. With a full stable of nearly every imaginable RC car in the XRAY line-up, the center stage held an empty spot for a new flagship to showcase XRAY ideals, philosophy, and commitment to racing perfection.

Martin Hudy

XRAY RX8 Platform Designer

All of the refinements from the last year – based on our own experiences and feedback from drivers all around the world – were incorporated into the new RX8 and RX8E. New ideas and prototypes were long-term tested by the factory team worldwide to ensure that improvements would work well in all track conditions and tracks in Europe, America, and Asia.

Made in Europe.

Designed, developed, and fully manufactured in-house at the XRAY factory in Slovakia, Europe, using the most high-tech German & Swiss machines and premium European materials, crafted with XRAY's legendary attention to detail by our artistic production specialists. The RX8E is truly a masterpiece.

Making of.

Read my exclusive story about the making of the XRAY RX8 here for an insider’s view of our daily work as RC car designers and what we have all done to make the RX8 platform a reality. The RX8E features all the finest details from the RX8 to share the genuine platform.

Martin Hudy

XRAY RX8 Platform Designer

Some information shown below may include details from previous kits or from the nitro version, and it may vary slightly from current kit specifications.

Front Chassis Flex Adjustment.

All-new chassis with unique, innovative front flex adjustment via an insertable aluminum brace. Using the aluminum brace increases steering response & cornering speed; without the aluminum brace, the car is easier to drive and has more forward traction.

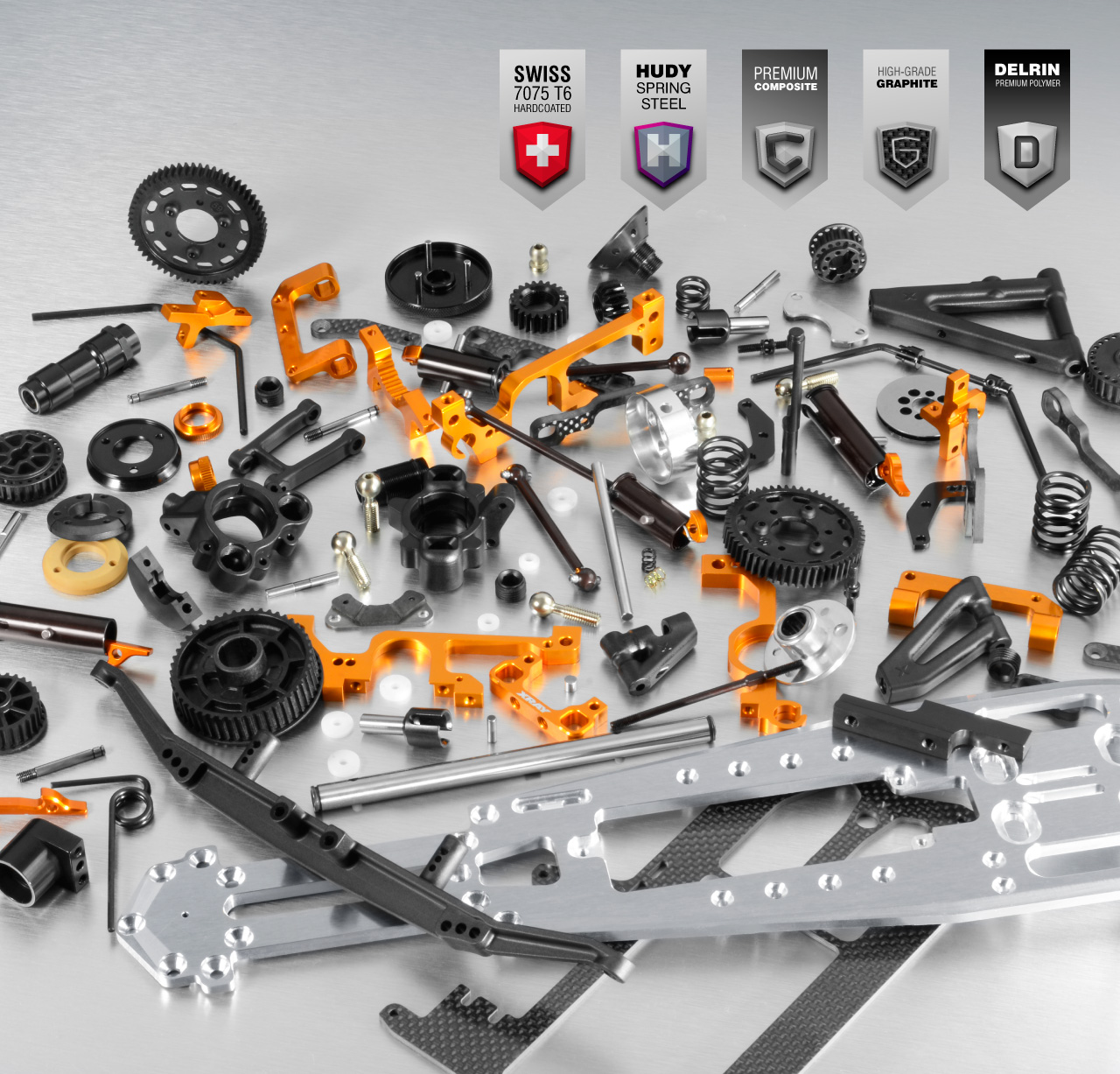

Premium & Exclusive Materials.

The RX8E is luxury model racing car and as such features only the most premium materials: premium woven graphite - exclusive top-secret HUDY Spring Steel™ - high grade Swiss 7075 T6 - high-tensile heat-treated steel and aircraft aluminum - and XRAY's self-developed and formulated composite compounds. All is premium and unique on the RX8E.

Aluminum Backbone.

The most significant change to the latest RX8E platform was the aluminum backbone. The main frame and backbone of the car consist of high-precision aluminum bulkheads and aluminum suspension holders that are mounted to the aluminum chassis.

All bulkhead parts are CNC-machined from premium Swiss 7075 T6 aluminum and have been designed to provide the lightest and strongest possible support framework for the car with maximum flex characteristics for increased traction.

The bulkheads are anodized in a distinctive orange color. XRAY’s legendary attention to detail is noticeable in all the precisely chamfered edges. (Color may vary slightly between products.)

Rear Upper Clamps.

The rear upper clamps – made from Swiss 7075 T6 aluminum – hold the rear shock tower and graphite upper arm holders.

Front Upper Clamps.

The front upper clamps – made from super-lightweight Swiss 7075 T6 aluminum – hold the front shock tower and front upper arm mount, allowing super-easy access to the front 1-way axle.

Front Upper Arm Holders.

Each upper front arm holder is mounted to the front upper clamp via a single screw, and to the radio plate with two screws. This way, the front suspension has optimized flex for improved in-corner steering and better steering response. One of the 2 mounting screws of the radio plate may be removed for even more flex, as part of the Multi-Flex™ system.

Servo Saver.

The centralized servo saver is ball-raced to ensure super-precise, smooth operation, and the adjustable spring preload tension allows for fine tuning. The servo saver also features easily-adjustable Ackermann positions which greatly influence the steering characteristics, allowing the RX8E to be adjusted for driving styles and track conditions.

Pivot Pins & Turnbuckles.

Pivot pins for rear upper & lower and front lower suspension arms are designed to fit aluminum suspension mounts. Rear upper pivot pins feature a machined groove that allows better fixing by set-screw, helping to prevent pins from coming out during operation.

To guarantee maximum reliability, all turnbuckles are manufactured from special HUDY Spring Steel™ material for turnbuckles for maximum core strength.

Shock Absorbers.

Shock bodies are CNC-machined from premium Swiss 7075 T6 aluminum and hardened to ensure maximum lifespan. External fine threading allows for quick & easy ride height adjustment. The shocks feature low-profile membranes for super-smooth, precise damping.

The set of pistons includes 2- and 3-hole pistons with 1.0, 1.1, and 1.2mm diameter holes. The pistons are precision molded from special Delrin™ material to ensure perfect roundness for extra-smooth dampening, while maintaining maximum stiffness and durability.

Shock Springs.

The RX8E comes equipped with C7.5 front springs to provide maximum stability and steering, and C5.6 rear springs to provide maximum traction & cornering speed.

The RX8E springs, like all the other XRAY springs, are manually measured, selected and matched into pairs to guarantee precisely equal length and damping characteristics

Belt Tensioner.

The adjustable side-belt tensioner is captured on a graphite plate, mounted to the side of the radio plate mount. The smart design allows the side-belt tensioner to be easily adjusted, or easily removed for engine removal.

Integrated Belt Tensioning.

Rear upper clamps feature integrated belt-tension adjustment using adjustable bearing eccentric holders, eliminating the need for a separate belt tensioner. All ball-bearings turn in composite hubs to reduce friction and improve drivetrain efficiency.

Drive Shafts.

The tiny drive shafts are manufactured from HUDY Spring Steel™, the most effective drive shaft material by the industry leader HUDY. Self-developed HUDY Spring Steel™ ensures the longest drive shaft life, maximum strength, and lowest weight.

The front of RX8E is driven by CVD driveshafts, while standard dogbones are used in the rear.

Hardened with a proprietary process, the drive shafts provide unbeatable lifetime and reliability.

Pulleys.

PUR® Drive Belts.

The drivetrain is operated by PUR®-reinforced high-efficiency low-friction drive belts, which ensure that all power is properly and efficiently transferred to all drivetrain parts.

Spur Gears.

The small 2-speed allows the use of smaller spur gears from the well-proven NT1, allowing fast acceleration and low rotating mass.

The spur gears are made from graphite material for improved durability. The special graphite material is also very light which helps to decrease the weight of rotating parts for improved acceleration.

The spur gears are molded with a special technique allowing the gears to be absolutely true, thus improving the drivetrain efficiency. Each gear is stamped with a tooth number for easy identification.

Suspension Geometry.

The RX8E features the most advanced, race-engineered suspension geometry for nitro on-road car racing and is designed to provide responsive racing characteristics under all racing conditions.

Over the years XRAY has successfully gained and utilized extensive suspension geometry knowledge and self-developed suspension stiffness technology, which have been used with great success in electric & nitro cars, both on- and off-road. The ultra-lightweight suspension parts are molded from special composite materials that make the parts very light yet very durable to withstand the rigors of high-performance racing.

Integrated Suspension Settings™.

The design of the RX8E features I.S.S. (Integrated Suspension Settings™). All adjustment possibilities are completely integrated, allowing complete set-up changes without changing or replacing any parts. The use of square eccentric bushings in the front bulkheads, as well as in the rear bulkheads for upper & lower suspension, allows for complete geometry adjustment. Roll centers are adjustable in the standard upper & lower positions, as well as in inner and outer positions. High-tensile steel suspension pivot pins are polished for smooth suspension action.

Adjustable Axle Height.

Front steering block and rear uprights feature concentric and eccentric bushings which allow roll center adjustment as well as positive caster adjustment in front. The eccentric bushings in the rear upright also allow independent wheelbase adjustment. The height of front and rear axles can be easily adjusted with eccentric bushings.

Wheelbase & Weight Balance Adjustment.

Wheelbase can be easily adjusted using clips on the front suspension. Moving the arms towards the front or rear can also be used to fine-tune weight balance.

Offset Adjustment.

Wheel offset is easily adjustable by 0.5–2.5mm using included shims. This affects steering adjustment (when adjusted at the front) and also rear traction characteristics (when adjusted at the rear).

FRONT - Less offset at the front gives more in-corner steering and improved steering response. Recommended for small technical tracks.

More offset at the front gives more stability and makes the car easier to drive on large tracks or under high-grip conditions.

REAR - Less offset at the rear gives more in-corner steering, but less rear traction and stability. Therefore it is recommended to use less offset on small technical tracks or under high-traction conditions.

More offset at the rear makes the car more stable and improves cornering speed.

Suspension Arms.

Suspension arms are one of the most important parts of any RC model car, as they directly influence the handling and racing characteristics of the car. The RX8E suspension arms are the result of long-term testing of different designs and layouts. Length, thickness, flexibility, geometry of suspension points, and materials used… all these concepts and details have been thoroughly reviewed to create optimal suspension arms.

The exclusive composite mixture used for suspension arms is a perfect balance between reliability and performance. The suspension arm itself is rigid enough to provide a responsive feel, yet soft enough to provide extreme durability.

Steering Blocks.

The tiny, tough steering blocks are molded from a special composite mixture for maximum strength. Thanks to perfect molding, bearings fit into the steering blocks without any extra play for maximum stability and steering.

The included 0° kingpin steering blocks allow the mounting of optional graphite aerodynamic disks which improve both low & high-speed steering, and improve stability in high-speed corners.

The steering block extension is mounted to the steering block, and features 3 different Ackermann positions. The kit includes 2mm bump steer shims for optimized bump steer characteristics; bump steer can be easily changed by adding or removing shims.

The extensions for steering blocks are made from Swiss 7075 T6 aluminum for increased durability and unmatched lifespan.

Rear Uprights.

The small, compact rear uprights are very strong due to the special composite mixture used. Thanks to perfect molding, bearings fit into the rear uprights without any extra play, giving maximum stability and handling.

The rear uprights allow mounting of optional graphite aerodynamic disks which improve, improve rear traction, and improve stability in high-speed corners.

The rear uprights feature two easily-adjustable upper roll center positions which are used for traction adjustment. The uprights also feature two body mount adjustment positions depending on the type of body used. Also included are shorter and longer pivot ball joints for optimum set-up adjustment.

Body Posts.

Front body posts are machined from premium Swiss 7075 T6 aluminum and are additionally lightened for minimal weight.

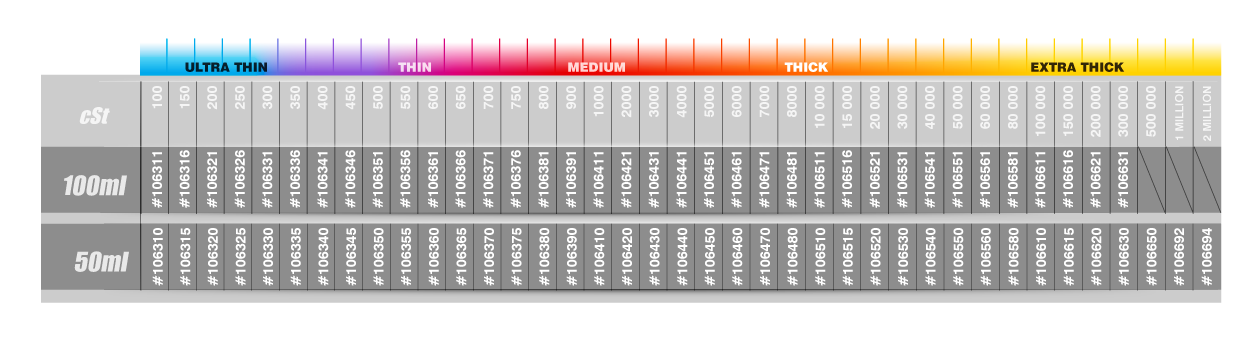

Silicone Oils.

HUDY Exclusive Silicone Oils are manufactured in Europe and each batch is laboratory tested and calibrated to ensure the highest possible consistency and quality from batch to batch. Based on the industry-standard cSt rating, the new line of oils will be easy to identify, adjust, and feel.

When following any set-up sheets by XRAY or XRAY team drivers, you can be sure that the oils you will get for your car are exactly same as those used by the factory racing team, thus ensuring very exacting set-ups and handling.

Ball-Bearings.

The RX8E is fully ball-bearing equipped and features high-speed, blue-sealed ball-bearings throughout the drivetrain for maximum drivetrain efficiency. The high-tolerance, high-performance bearings are degreased and lightly oiled with Aero Shell Fluid 12™ for maximum smoothness and long life. The main ball-bearings are oversized with extra-strong bearing frames to ensure smooth, efficient running even under extreme conditions.

XRAY Instruction Manual.

XRAY Instruction Manuals have become the industry standard, and are simply the best manuals you will ever get with an RC model car. Whether you are a first-time builder or an experienced racer, all instructions are straight-forward and easy to understand. The full-color Instruction Manual contains large 3D illustrations that show all assembly details in the easiest and most comprehensive manner.

VIP Customer Treatment.

Owning an XRAY model racing car is an experience unto itself. Not only will you own the most premium luxury model racing car in the world, but you will also become a member of the prestigious family of XRAY owners with direct support and service from the XRAY factory. XRAY brings you the most up-to-date RC Web site on the Internet, with daily racing news and the latest product developments. If you have any questions, problems or comments, you can ask the XRAY Support Team or any XRAY Factory Team Driver on the XRAY support forum. You can even upload your own set-up sheets or download from the thousands of different set-up sheets available from around the world at the exclusive XRAY Virtual Set-up Sheet Database. And that is only the start of the VIP treatment you get by joining Team XRAY.